Cast Mold Temperature . The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die.

from www.zhycasting.com

The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature.

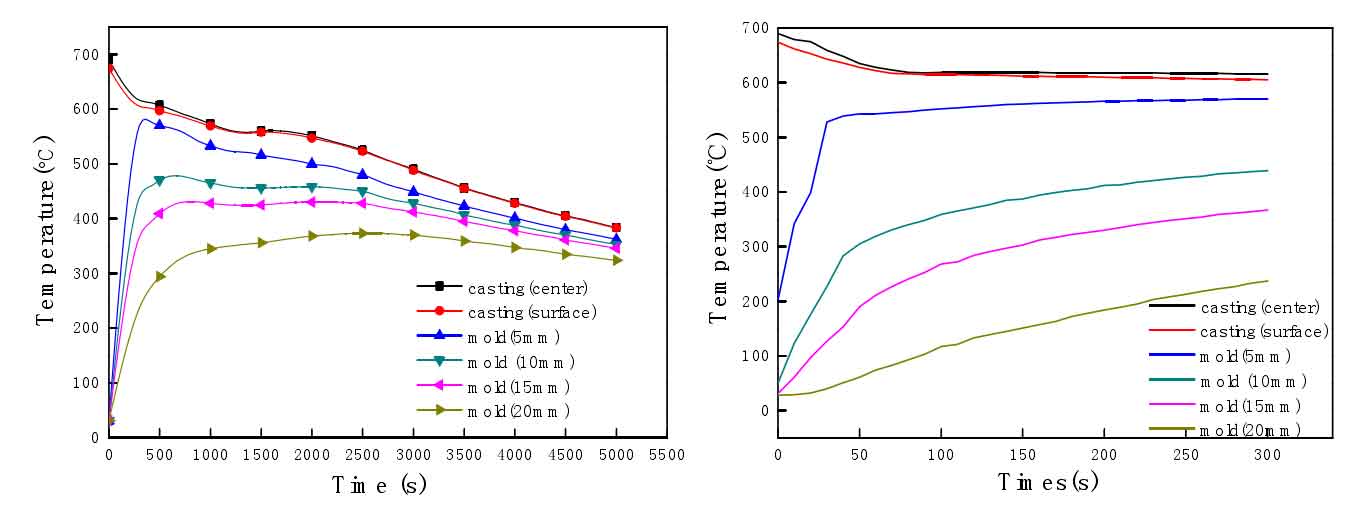

Measurement of sand casting and mold temperature ZHY Casting

Cast Mold Temperature The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy.

From www.researchgate.net

Dimensions and shape of casting mold, used in current investigation Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The rate of heat transfer from the cast to the mold is very high as it releases larger. Cast Mold Temperature.

From www.easycomposites.co.uk

TC160 Tool Cast High Temp Epoxy Casting Resin Easy Composites Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The rate of heat transfer from. Cast Mold Temperature.

From www.wikihow.com

How to Build a Metal Melting Furnace for Casting 15 Steps Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting. Cast Mold Temperature.

From www.youtube.com

Aluminum Alloy Diecasting Temperature Control System (Die Casting Mold Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The mold temperature greatly affects the mechanical properties,. Cast Mold Temperature.

From www.aeromarineproducts.com

The MustTry Method for Pewter Casting with High Temp Silicone Mold Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The mould temperature is not. Cast Mold Temperature.

From ldsmachinery.en.made-in-china.com

300c DualLoop Die Casting Mold Temperature Controller China Casting Cast Mold Temperature The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The air gap plays a significant role in varying ihtc with various factors influencing solidification.. Cast Mold Temperature.

From www.zhycasting.com

Effect of pouring temperature on the quality of sand castings ZHY Casting Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. This article investigates the heat transfer. Cast Mold Temperature.

From vietnamcastiron.com

Optimal Aluminum Casting Temperature Melting and Pouring Conditions Cast Mold Temperature The air gap plays a significant role in varying ihtc with various factors influencing solidification. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The rate. Cast Mold Temperature.

From www.zhycasting.com

Inverse calculation of temperature data of mold No. 1 unit in sand Cast Mold Temperature The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. Mold. Cast Mold Temperature.

From www.researchgate.net

(PDF) TEMPERATURES IN A DIE CAST MOLD Cast Mold Temperature The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The mould temperature is not the same thing as the cooling water temperature, it is the. Cast Mold Temperature.

From www.mdpi.com

Metals Free FullText Temperature Field Evolution of Seeding during Cast Mold Temperature This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus. Cast Mold Temperature.

From whatiscasting.com

What is the reason for the high temperature of the diecasting mold Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The rate of heat transfer from the cast to the mold is very high as it releases. Cast Mold Temperature.

From dca20921d44ca7b7.en.made-in-china.com

DieCasting Industrial Mold Temperature Controller China DieCasting Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life. Cast Mold Temperature.

From njsingde.en.made-in-china.com

120kw Mold Temperature Controller for Die Casting China Mold Cast Mold Temperature The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The. Cast Mold Temperature.

From jmxiecheng.en.made-in-china.com

6kw Water Type DieCasting Mold Temperature Controller DieCasting Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life. Cast Mold Temperature.

From www.researchgate.net

Scheme of temperature distribution in the mold and hardened casting Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The rate of heat transfer from the cast to the mold is very high as it releases. Cast Mold Temperature.

From www.zhycasting.com

Variation of interfacial heat transfer coefficient with temperature in Cast Mold Temperature The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. This article investigates the heat transfer properties at the interface between two types of. Cast Mold Temperature.

From www.researchgate.net

Comparison of mold temperature between molds designed with and without Cast Mold Temperature The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. Mold temperature can be managed using. Cast Mold Temperature.

From www.steel-foundry.com

General Information of Heat Treatment for Steel Castings Investment Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a. Cast Mold Temperature.

From www.zhycasting.com

Measurement of sand casting and mold temperature ZHY Casting Cast Mold Temperature Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold. Cast Mold Temperature.

From scrolller.com

Mold Chart for Temperature and Humidity Monitors Scrolller Cast Mold Temperature Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The key. Cast Mold Temperature.

From www.zhycasting.com

Influence of different mold temperature on the quality of squeeze Cast Mold Temperature The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator,. Cast Mold Temperature.

From artnsyn.com

How slip casting and plaster molds work artnsyn Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. This article investigates the heat transfer properties at. Cast Mold Temperature.

From startup-buzz.com

The Beginner’s Guide to Permanent Mold Casting Startup Buzz Cast Mold Temperature The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the. Cast Mold Temperature.

From tiansrun.com

Basic Parameters Of Die Casting Process Tiansrun Company Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mould temperature is not the same thing as the cooling water temperature, it is the temperature. Cast Mold Temperature.

From www.aliexpress.com

Mould Temperature Controller Die Casting Mold Automatic Thermostat Cast Mold Temperature The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. The air gap plays a significant role in varying ihtc with various factors influencing solidification. The mold temperature greatly affects the. Cast Mold Temperature.

From cncmachining.wiki

What is the reason for the high temperature of the diecasting mold Cast Mold Temperature This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The air gap plays a. Cast Mold Temperature.

From www.researchgate.net

Variation of fluidity with mold temperature at different melt Cast Mold Temperature The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The mould temperature. Cast Mold Temperature.

From www.researchgate.net

Schematic of continuous casting process Download Scientific Diagram Cast Mold Temperature This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The mould temperature is not the same thing as the cooling water temperature, it is. Cast Mold Temperature.

From www.alibaba.com

300 Degree High Temp Diecasting Mold Temperature Controller Buy Die Cast Mold Temperature The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. The mold temperature greatly affects the mechanical properties, dimensional accuracy. Cast Mold Temperature.

From www.researchgate.net

Temperature distribution inside sand mold after heating. Download Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The air gap plays a significant role in varying ihtc with various factors influencing solidification. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air. Cast Mold Temperature.

From www.jmxiecheng.com

Mold Temperature Controller Mould Temperature Controller Xiecheng Cast Mold Temperature The rate of heat transfer from the cast to the mold is very high as it releases larger quantity of latent heat to the mold and the cast temperature gradually reaches a solidus (t s) temperature of the alloy. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mold. Cast Mold Temperature.

From fabacademy.org

10. Molding and casting Remy Ducros Cast Mold Temperature The mold temperature greatly affects the mechanical properties, dimensional accuracy and the life of the die casting die. The air gap plays a significant role in varying ihtc with various factors influencing solidification. Mold temperature can be managed using thermal management tools such as inserts, water coolant and forced air lines, mold. The mold temperature generally refers to the surface. Cast Mold Temperature.

From mold.wiki

The importance and control principle of die casting mold temperature Cast Mold Temperature The key variables in the casting process include the mold temperature, the thermal insulation properties of the mold, the cycle time and the method of the operator, etc. The mold temperature generally refers to the surface temperature of the mold, and its standard measurement should be about 1/3 of the alloy liquid pouring temperature. The mold temperature greatly affects the. Cast Mold Temperature.

From www.degruyter.com

Heat transfer behavior in ultrahighspeed continuous casting mold Cast Mold Temperature The mould temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mould cavity after it. This article investigates the heat transfer properties at the interface between two types of steel used for die casting molds (steel a) and additively manufactured cooling inserts. The rate of heat transfer from the cast to. Cast Mold Temperature.