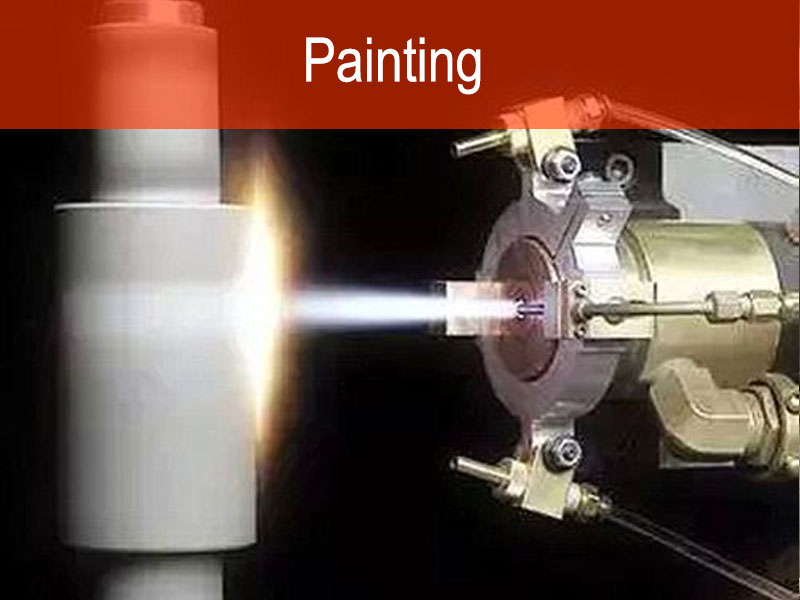

Surface Treatments For Steel . this is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. here at european springs, we offer a range of surface treatments for a variety of different metal components: some of the treatments you employ on metal surfaces are: From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. industrial surface treatment is a process where a surface of a workpiece is treated to improve or change its mechanical,. Metal finishes come in many different styles. the following definitions explain the various treatments currently available and their recommended applications: to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. topical treatments for ocular surface squamous neoplasia.

from www.cncmachiningptj.com

As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. this is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. A graphic illustration of the. shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of.

Surface Treatment Of Metal Generalize All Types of Surface Treatments

Surface Treatments For Steel advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. topical treatments for ocular surface squamous neoplasia. different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. we provide various types of surface finish treatments which improve the mechanical and electrical properties, wear resistance. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. some of the treatments you employ on metal surfaces are: surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. the following definitions explain the various treatments currently available and their recommended applications: whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. A graphic illustration of the.

From steelfabservices.com.au

Preparation Methods For Steel Surface Treatment Surface Treatments For Steel surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. here at european springs, we offer a range of surface treatments for a variety of different metal components: metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. A graphic illustration of. Surface Treatments For Steel.

From www.spin.cnr.it

Cnr SPIN Master in "Surface treatments for industrial applications" Surface Treatments For Steel metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. here at european springs, we offer a range of surface treatments for a variety of different metal components: A graphic illustration of. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel industrial surface treatment is a process where a surface of a workpiece is treated to improve or change its mechanical,. shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. we provide various types of surface finish treatments which improve the mechanical and electrical properties, wear resistance. there are. Surface Treatments For Steel.

From magazinemi.com

Five Examples of Surface Treatment for Metal My Magazine Surface Treatments For Steel some of the treatments you employ on metal surfaces are: whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. surface treatment of metals is the most effective way of optimising the resistance of joints to water. topical treatments for ocular surface squamous neoplasia. Metal finishes come in many. Surface Treatments For Steel.

From www.powerstrip.nz

Surface Treatments For Metal & Steel Auckland, Hamilton NZ Surface Treatments For Steel here at european springs, we offer a range of surface treatments for a variety of different metal components: industrial surface treatment is a process where a surface of a workpiece is treated to improve or change its mechanical,. Metal finishes come in many different styles. topical treatments for ocular surface squamous neoplasia. In peening, you employ a. Surface Treatments For Steel.

From www.europeansprings.com

What is Surface Treatment & Why is it Important? Surface Treatments For Steel this is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. metal surface treatments. Surface Treatments For Steel.

From steelfabservices.com.au

A Guide to Steel Surface Treatments Zinc Phosphate Priming Surface Treatments For Steel From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. In peening, you employ a shot. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. a quality metal surface treatment will improve any completed component, making the part look better, and crucially,. Surface Treatments For Steel.

From www.vecom-group.com

Metal surface treatment Group Surface Treatments For Steel surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. this is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. Metal finishes come in many different styles. some of the treatments you employ on metal surfaces are: From polishing and plating to powder coating and. Surface Treatments For Steel.

From steelfabservices.com.au

A Guide to Steel Surface Treatments Hot Dipping Surface Treatments For Steel A graphic illustration of the. different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. Metal finishes come in many different styles. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. metal surface treatments can include a range of. Surface Treatments For Steel.

From www.bruker.com

Surface Treatments Bruker Surface Treatments For Steel From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. some of the treatments you employ on metal surfaces are: this is a process of metal surface alteration, such as carburizing, nitriding, and. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. surface treatment of metals is the most effective way of optimising the resistance of joints to water. whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. These processes bridge the gap. Surface Treatments For Steel.

From www.hbsinostar.com

7 Different Types Of Surface Treatments Of Stainless Steel Sheets Surface Treatments For Steel there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. this is a process of metal. Surface Treatments For Steel.

From www.advancechemicals.com

Metal & Surface Treatment Advance Chemical Surface Treatments For Steel here at european springs, we offer a range of surface treatments for a variety of different metal components: some of the treatments you employ on metal surfaces are: to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. advanced surface treatments offer a promising solution by preventing the initiation and propagation. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel Metal finishes come in many different styles. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. some of the treatments you employ on metal surfaces are: to promote strong and durable. Surface Treatments For Steel.

From www.bruschitech.com

Coating, plating and other kind of surface treatments Surface Treatments For Steel metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. surface treatment of metals is the most effective way. Surface Treatments For Steel.

From soonxindisplays.com

The Beauty of Stainless Steel 7 Kinds Of Surface Treatment Process Surface Treatments For Steel From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. A graphic illustration of the. to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. surface treatment. Surface Treatments For Steel.

From www.wearsideconstruction.com.au

Stainless Steel Surface Treatment Steel Fabrication Surface Treatments For Steel These processes bridge the gap between raw materials and finished goods by addressing inherent issues like corrosion, wear, and aesthetic degradation. In peening, you employ a shot. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. A graphic illustration of the. topical treatments for ocular surface squamous neoplasia. . Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. A graphic illustration of the. a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating,. Surface Treatments For Steel.

From steelfabservices.com.au

What Are The Common Steel Surface Treatments? SFS Surface Treatments For Steel a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. there are many reasons why steel surfaces are treated, from making them more attractive through to protecting them. this. Surface Treatments For Steel.

From www.imcslovakia.sk

Metal surface treatments IMCslovakia.sk Surface Treatments For Steel These processes bridge the gap between raw materials and finished goods by addressing inherent issues like corrosion, wear, and aesthetic degradation. some of the treatments you employ on metal surfaces are: different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. topical treatments for ocular surface squamous neoplasia.. Surface Treatments For Steel.

From www.cortugroup.com

Surface treatments for metal parts Cortugroup Surface Treatments For Steel These processes bridge the gap between raw materials and finished goods by addressing inherent issues like corrosion, wear, and aesthetic degradation. surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. the following definitions explain the various treatments currently available and their recommended applications: topical treatments for ocular surface squamous neoplasia. A. Surface Treatments For Steel.

From www.makmax.com.au

Steel Surface Treatments For Tensile Structures MakMax Australia Surface Treatments For Steel topical treatments for ocular surface squamous neoplasia. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. industrial surface treatment is a process where a surface of a workpiece is treated. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel topical treatments for ocular surface squamous neoplasia. advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. metal finishing and surface treatments are essential processes that enhance the aesthetics, durability, and functionality of metal components. there are many reasons why steel surfaces are treated, from making them more attractive through to. Surface Treatments For Steel.

From tenkaichiban.com

Six metal surface finishing treatments Tenkaichiban Surface Treatments For Steel the following definitions explain the various treatments currently available and their recommended applications: shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. we provide various types of surface finish treatments which improve the mechanical and electrical properties, wear resistance. surface treatment of metals is the most effective way. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. a quality metal surface treatment will. Surface Treatments For Steel.

From www.imcslovakia.sk

Metal surface treatments IMCslovakia.sk Surface Treatments For Steel to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. surface optimization is called surface treatment, these treatments can be mechanical, chemical or done by. shot peening and satin finishing are two of the most commonly used surface treatments for refining stainless. A graphic illustration of the. we provide various types. Surface Treatments For Steel.

From www.vecom-group.com

Metal surface treatment Group Surface Treatments For Steel industrial surface treatment is a process where a surface of a workpiece is treated to improve or change its mechanical,. Metal finishes come in many different styles. some of the treatments you employ on metal surfaces are: surface treatment of metals is the most effective way of optimising the resistance of joints to water. In peening, you. Surface Treatments For Steel.

From steelfabservices.com.au

A Guide to Steel Surface Treatments Powder Coating Surface Treatments For Steel topical treatments for ocular surface squamous neoplasia. These processes bridge the gap between raw materials and finished goods by addressing inherent issues like corrosion, wear, and aesthetic degradation. the following definitions explain the various treatments currently available and their recommended applications: advanced surface treatments offer a promising solution by preventing the initiation and propagation of corrosion. . Surface Treatments For Steel.

From www.rtprototype.com

Top 4 Surface Treatments for Metal Parts Ruitai Mould Surface Treatments For Steel different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. we provide various types of surface finish treatments which improve the mechanical and electrical properties, wear resistance. These processes bridge the gap between raw materials and finished goods by addressing inherent issues like corrosion, wear, and aesthetic degradation. . Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. the following definitions explain the various treatments currently available and their recommended applications: we provide various types of surface finish treatments which improve the mechanical and electrical properties, wear resistance. to promote strong and durable steel/epoxy adhesive. Surface Treatments For Steel.

From metalcabinets-weche.com

Surface Treatment Wee Chin Electric Machinery Inc. Surface Treatments For Steel metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. whether through the deposition of coatings, the controlled modification of the surface chemistry, or the creation of. From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. surface optimization is. Surface Treatments For Steel.

From keyanng.com

Standard sheet metal materials and their surface treatments Surface Treatments For Steel this is a process of metal surface alteration, such as carburizing, nitriding, and induction hardening of steel. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. a quality metal surface treatment will improve any completed component, making the part look better, and crucially, last longer. industrial surface treatment. Surface Treatments For Steel.

From www.cncmachiningptj.com

Surface Treatment Of Metal Generalize All Types of Surface Treatments Surface Treatments For Steel In peening, you employ a shot. the following definitions explain the various treatments currently available and their recommended applications: As a result, it is important to understand the specifics of each finish, ensuring optimum performance and reducing waste. Metal finishes come in many different styles. to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments. Surface Treatments For Steel.

From www.sangeetametal.com

Advantages of Different Surface Treatments for Stainless Steel 310 Pipes Surface Treatments For Steel the following definitions explain the various treatments currently available and their recommended applications: different surface treatments for steel parts, including metal surface finishing and metal sheet manufacturing services, are indispensable for enhancing. metal surface treatments are crucial in the lifecycle of metal products, enhancing their durability, appearance, and functionality. From polishing and plating to powder coating and. Surface Treatments For Steel.

From www.makmax.com.au

Steel Surface Treatments For Tensile Structures MakMax Australia Surface Treatments For Steel From polishing and plating to powder coating and anodizing, each technique offers unique benefits for specific applications. to promote strong and durable steel/epoxy adhesive joints, various stainless steel surface treatments are investigated. metal surface treatments can include a range of processes such as chemical cleaning, painting or coating, galvanizing, thermal spraying, electroplating. some of the treatments you. Surface Treatments For Steel.