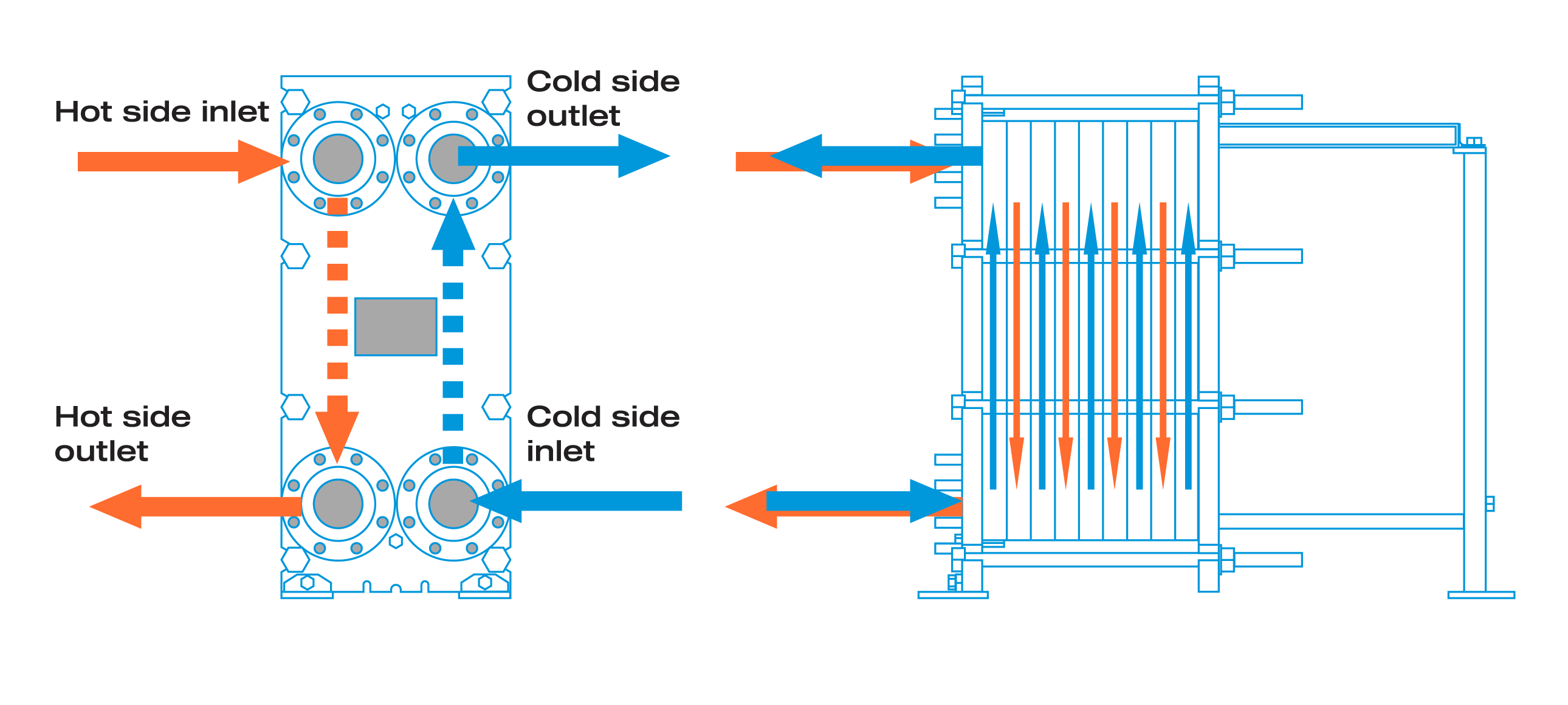

Plate Heat Exchanger Flow . Plate heat exchanger calculation procedure : For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Why use plate heat exchangers? Counter flow is sometimes known as. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower.

from www.arsopi-thermal.pt

Counter flow is sometimes known as. The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. Plate heat exchanger calculation procedure : Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Why use plate heat exchangers? The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower.

Gasket Plate Heat Exchangers ArsopiThermal

Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. Counter flow is sometimes known as. Why use plate heat exchangers? Plate heat exchanger calculation procedure : Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer.

From www.stollpche.com

A Guide on How to install heat exchanger plate correctly? Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Counter flow is sometimes known as. Why use plate heat exchangers? Plate heat exchanger calculation procedure : The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head. Plate Heat Exchanger Flow.

From www.evomart.co.uk

Vol.15 Brazed Plate Heat Exchanger (BPHE) as an evaporator Evomart Plate Heat Exchanger Flow Counter flow is sometimes known as. Plate heat exchanger calculation procedure : Why use plate heat exchangers? For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers usually use counter flow as this is the most. Plate Heat Exchanger Flow.

From www.researchgate.net

(a) Schematic representation of crossflow platefin heat exchanger Plate Heat Exchanger Flow The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers. Plate Heat Exchanger Flow.

From www.csidesigns.com

How Do Heat Exchangers Work A 101 Guide Plate Heat Exchanger Flow Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchangers usually use counter flow as this is. Plate Heat Exchanger Flow.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Counter flow is sometimes known as. The plate and frame. Plate Heat Exchanger Flow.

From www.alfalaval.my

How plate heat exchanger work Alfa Laval Plate Heat Exchanger Flow Plate heat exchanger calculation procedure : Counter flow is sometimes known as. Why use plate heat exchangers? Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. The purpose of a. Plate Heat Exchanger Flow.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Flow Counter flow is sometimes known as. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. The plate and frame heat exchanger (see figure 1) consists of a frame in. Plate Heat Exchanger Flow.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Flow For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. The purpose of. Plate Heat Exchanger Flow.

From www.rasmech.com

Plate Heat Exchanger (For Dummies) Rasmussen Mechanical Plate Heat Exchanger Flow The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. For example, in building services, you might want to transfer heat from a primary. Plate Heat Exchanger Flow.

From mungfali.com

Plate Heat Exchanger Flow Diagram Plate Heat Exchanger Flow Plate heat exchanger calculation procedure : Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. Plate heat exchangers usually use counter flow as this is. Plate Heat Exchanger Flow.

From www.linquip.com

Working Principle of Plate Heat Exchanger Linquip Plate Heat Exchanger Flow For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Counter flow is sometimes known as. Plate heat exchanger. Plate Heat Exchanger Flow.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Flow Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchanger calculation procedure : Why use plate. Plate Heat Exchanger Flow.

From www.researchgate.net

Schematic diagram of a plate heat exchanger Download Scientific Diagram Plate Heat Exchanger Flow Counter flow is sometimes known as. Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Why use plate heat exchangers? Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. The purpose of a plate heat exchanger is to transfer. Plate Heat Exchanger Flow.

From academy.paulmueller.com

Which Heat Exchanger Is Best? The Three Main Types Explained... Plate Heat Exchanger Flow The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. Plate heat exchanger calculation procedure : The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchangers usually use counter flow as. Plate Heat Exchanger Flow.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Flow Counter flow is sometimes known as. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchanger calculation procedure : Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. The plate and frame heat exchanger (see figure 1). Plate Heat Exchanger Flow.

From www.onda-it.com

Plate Heat Exchangers Working Principle Onda S.p.A Plate Heat Exchanger Flow The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of. Plate Heat Exchanger Flow.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Flow The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. Counter flow is sometimes known as. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchanger. Plate Heat Exchanger Flow.

From www.iqsdirectory.com

Plate Heat Exchangers Components, Types, Applications and Advantages Plate Heat Exchanger Flow The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Why use plate heat exchangers? Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Plate heat exchanger sizing the procedure below aims at. Plate Heat Exchanger Flow.

From wcruk.com

Plate Heat Exchangers Functions & Principles Explained Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. Plate heat exchanger calculation procedure : For example, in building services, you might want to transfer heat. Plate Heat Exchanger Flow.

From www.onda-it.com

Plate Heat Exchangers Working Principle Onda S.p.A Plate Heat Exchanger Flow Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchangers are used to transfer heat from one. Plate Heat Exchanger Flow.

From www.youtube.com

Plate Heat Exchanger, How it works working principle hvac industrial Plate Heat Exchanger Flow Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers are used. Plate Heat Exchanger Flow.

From www.researchgate.net

(a) Simplified flow schematic of platefin heat exchanger and example Plate Heat Exchanger Flow Counter flow is sometimes known as. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating. Plate Heat Exchanger Flow.

From www.zwirnerequipment.com

What is a Plate Heat Exchanger? Zwirner Equipment Company Plate Heat Exchanger Flow The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchanger calculation procedure : Counter flow is sometimes known as. Why use plate heat exchangers? Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs. Plate Heat Exchanger Flow.

From mungfali.com

Plate Heat Exchanger Schematic Plate Heat Exchanger Flow Why use plate heat exchangers? Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Counter flow is sometimes known as. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The plate and frame heat. Plate Heat Exchanger Flow.

From www.arsopi-thermal.pt

Gasket Plate Heat Exchangers ArsopiThermal Plate Heat Exchanger Flow Plate heat exchanger calculation procedure : Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Counter flow is sometimes. Plate Heat Exchanger Flow.

From www.onda-it.com

Plate Heat Exchangers Working Principle Onda S.p.A Plate Heat Exchanger Flow Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Why use plate heat exchangers? Plate heat exchanger calculation procedure : Plate heat exchangers usually use. Plate Heat Exchanger Flow.

From www.thomasnet.com

Understanding Heat Exchangers Plate Heat Exchanger Flow Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. Why use plate heat exchangers? Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. The plate and frame heat exchanger (see figure 1) consists of. Plate Heat Exchanger Flow.

From savree.com

Plate Heat Exchanger (PHE) Explained saVRee saVRee Plate Heat Exchanger Flow For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Why use plate heat exchangers? Plate heat exchanger calculation procedure : Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the. Plate Heat Exchanger Flow.

From www.linquip.com

Working Principle of Plate Heat Exchanger Linquip Plate Heat Exchanger Flow Counter flow is sometimes known as. Why use plate heat exchangers? For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to. Plate Heat Exchanger Flow.

From www.separationequipment.com

M3 Plate Heat Exchanger Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchanger sizing the procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat. For example, in building services, you might want to transfer heat from a primary loop connected to. Plate Heat Exchanger Flow.

From www.csidesigns.com

Understanding Types of Heat Exchangers Plate, Shell & Tube, and More Plate Heat Exchanger Flow Why use plate heat exchangers? Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. Plate heat exchanger calculation procedure : Plate heat exchanger sizing. Plate Heat Exchanger Flow.

From mepacademy.com

How Plate Heat Exchangers Work MEP Academy Plate Heat Exchanger Flow The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head and follower. For example, in building services, you might want to transfer heat from a primary. Plate Heat Exchanger Flow.

From www.researchgate.net

An exploded view of plate heat exchanger (Courtesy of Alfa Laval Plate Heat Exchanger Flow Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to. Plate Heat Exchanger Flow.

From www.danfoss.com

SONDEX® Free Flow plate heat exchangers Danfoss Plate Heat Exchanger Flow Plate heat exchangers are used to transfer heat from one fluid to another when cross contamination needs to be avoided. The purpose of a plate heat exchanger is to transfer thermal energy between two fluids, without the fluids mixing together. Plate heat exchangers usually use counter flow as this is the most efficient type of flow for heat transfer. The. Plate Heat Exchanger Flow.

From guidedehartsicklewort.z21.web.core.windows.net

Plate Heat Exchanger Diagram Plate Heat Exchanger Flow Why use plate heat exchangers? For example, in building services, you might want to transfer heat from a primary loop connected to a boiler over to a separate secondary loop, maybe in a district heating network. The plate and frame heat exchanger (see figure 1) consists of a frame in which closely spaced metal plates are clamped between a head. Plate Heat Exchanger Flow.