Punch Tool Limitations . The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. In real practice, the process of hole punching differs depending on the materials, thickness, and the. The other option is to. Punch and die act together. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment.

from www.mechstudies.com

The other option is to. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: The american standard known as the tsm standard and the. Punch and die act together. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged.

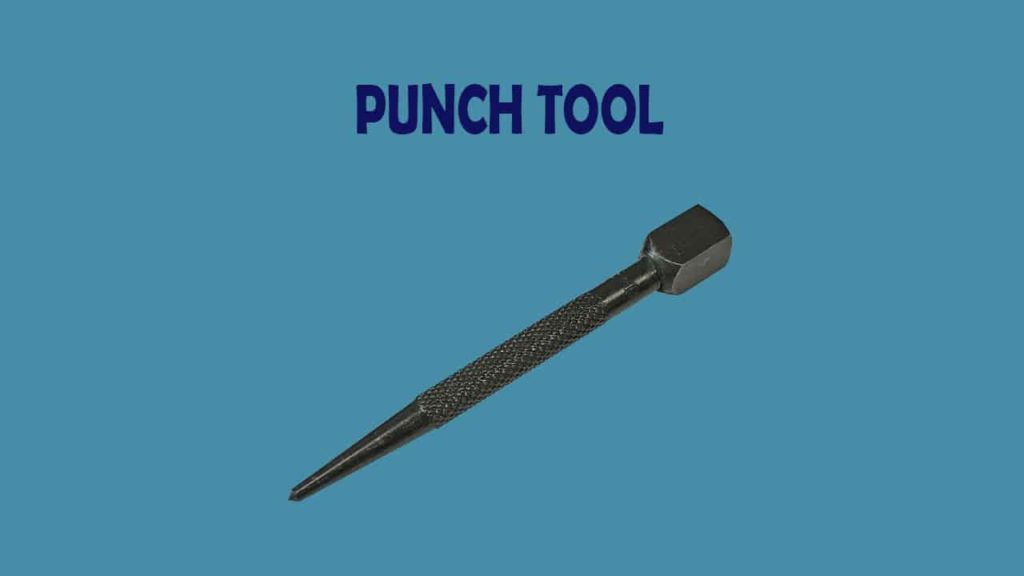

What is Punch Tool? Types of Punch Tools

Punch Tool Limitations Punch and die act together. Sheet metal hole punching is a common method to create a hole in a metal sheet. Punch and die act together. The american standard known as the tsm standard and the. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. The other option is to. In real practice, the process of hole punching differs depending on the materials, thickness, and the.

From monroeengineering.com

What Is a Punch Tool? Blog Posts OneMonroe Punch Tool Limitations Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. In real practice, the process of hole punching. Punch Tool Limitations.

From www.engineeringchoice.com

What Is Punch Tool? Definition, Types and Their Uses Engineering Choice Punch Tool Limitations Punch and die act together. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. Sheet metal hole punching is a common method to create a hole in a metal sheet. Natoli accommodates both standards of “b”. Punch Tool Limitations.

From www.canadianmetalworking.com

Improve punch tool organization for higher productivity Punch Tool Limitations Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. Sheet metal hole punching is a common method to create a hole in a metal sheet. The american standard known as the tsm standard and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: The other. Punch Tool Limitations.

From www.theengineerspost.com

The Engineers Post Punch Tool Limitations In real practice, the process of hole punching differs depending on the materials, thickness, and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. The other option is to. This is the main component of. Punch Tool Limitations.

From www.canadianmetalworking.com

Time for a punch tooling Punch Tool Limitations The other option is to. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches which. Punch Tool Limitations.

From www.reddit.com

Types of Punch Tools r/coolguides Punch Tool Limitations Sheet metal hole punching is a common method to create a hole in a metal sheet. The american standard known as the tsm standard and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Successful. Punch Tool Limitations.

From www.thefabricator.com

Heavyduty sheet metal punching with the modern mechanical punch press Punch Tool Limitations There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: The american standard known as the tsm standard and the. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Cluster. Punch Tool Limitations.

From www.desertcart.in

15 Ton Hydraulic Punch Driver Kit Manual Hole Knockout Puncher Punch Tool Limitations The other option is to. Punch and die act together. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches which have its application in drilling, drawing circles, punching. Punch Tool Limitations.

From store.pipeman.com

Punch Tool ¯5mm Punch Tool Limitations Punch and die act together. The american standard known as the tsm standard and the. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Successful punching relies on features designed into the tooling. Punch Tool Limitations.

From acadsystems.com

Inventor Sheet Metal Create Custom Punch Tool Acad Systems Punch Tool Limitations This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. The other option is to. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Punch and die act together. Successful punching relies on features designed into the tooling to mitigate the effects. Punch Tool Limitations.

From aste.com.sg

Punch Tool Set Aste Global Pte Ltd Punch Tool Limitations The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. The other option is to. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Successful punching relies on features designed into the tooling to mitigate the effects of. Punch Tool Limitations.

From misterpatchbay.com

ADC Punch Tool Punch Tool Limitations Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Sheet metal hole punching is a common method to create a hole in a metal sheet. Punch and die act together. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. In real practice, the process of. Punch Tool Limitations.

From craftstoredirect.com

How To Using The Silhouette Punch Tool Graphtec GB Craft Store Punch Tool Limitations Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Natoli accommodates both standards of “b” and “d” tooling configurations. Punch Tool Limitations.

From www.engineeringchoice.com

What Is Punch Tool? Definition, Types and Their Uses Engineering Choice Punch Tool Limitations The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: There are various. Punch Tool Limitations.

From www.canadianmetalworking.com

Improve punch tool organization for higher productivity Punch Tool Limitations Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: The american standard known as the tsm standard and. Punch Tool Limitations.

From www.mechstudies.com

What is Punch Tool? Types of Punch Tools Punch Tool Limitations This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Punch and die act together. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Natoli accommodates. Punch Tool Limitations.

From engineeringlearn.com

14 Types of Punches (Tool) Applications, Precautions, Working Punch Tool Limitations Punch and die act together. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the. Punch Tool Limitations.

From www.thefabricator.com

Quickchange thickturret punching system uses toolless design Punch Tool Limitations There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: This is the main component of die assembly, which is directly. Punch Tool Limitations.

From www.wikihow.com

How to Use a Punch Down Tool 9 Steps (with Pictures) wikiHow Punch Tool Limitations Punch and die act together. The other option is to. Sheet metal hole punching is a common method to create a hole in a metal sheet. The american standard known as the tsm standard and the. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: This is the main component of die assembly, which. Punch Tool Limitations.

From www.canadianmetalworking.com

Improve punch tool organization for higher productivity Punch Tool Limitations Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Punch and die act together. In real practice, the process of hole punching differs depending on the materials, thickness, and the. The other option is to. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable. Punch Tool Limitations.

From www.youtube.com

How to Use Punch Down Tool? (Only 8 Steps)Detailed InstructionStep by Punch Tool Limitations The other option is to. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. There are various types. Punch Tool Limitations.

From shlejia.en.made-in-china.com

Punch Tooling, Special Forming Tool, Louver Punch Tooling for CNC Punch Tool Limitations There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional. Punch Tool Limitations.

From www.ladedanlar.com

Southwire 57177701 10 Gauge Stainless Steel MAX PUNCH® Pro Knockout Punch Tool Limitations Punch and die act together. Sheet metal hole punching is a common method to create a hole in a metal sheet. The american standard known as the tsm standard and the. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. In real practice, the process of hole punching differs depending. Punch Tool Limitations.

From studentlesson.com

Most common types of punch tools and their uses student lesson Punch Tool Limitations Sheet metal hole punching is a common method to create a hole in a metal sheet. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Natoli accommodates both standards of “b” and “d” tooling. Punch Tool Limitations.

From www.eunasa.com

11892 Swaging Punch Tool Kit (5 UNITS) Flaring Tool Punch Tool Limitations Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. The american standard known as the tsm standard and the. Sheet metal hole punching is a common method to create a hole in a metal sheet. Successful. Punch Tool Limitations.

From www.themachinedesign.com

Sheet Metal Operations Definition and Types The Machine Design Punch Tool Limitations Sheet metal hole punching is a common method to create a hole in a metal sheet. In real practice, the process of hole punching differs depending on the materials, thickness, and the. The other option is to. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Successful punching relies on features designed into the. Punch Tool Limitations.

From pedersontoolanddesign.com

Punch Tool Services Pederson Tool & Design, Inc. Punch Tool Limitations Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. The american standard known as the tsm standard and the. In real practice, the process of hole punching differs depending on the materials, thickness, and the. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling. Punch Tool Limitations.

From www.youtube.com

Types of Punch ( tool ) & Full Information YouTube Punch Tool Limitations The other option is to. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Punch and die act together. Sheet metal hole punching is a common method to create a hole in. Punch Tool Limitations.

From www.aliexpress.com

ProfessionalInterchangeableLargeHollowHolePunchToolSet10Piece Punch Tool Limitations This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Sheet metal hole punching is a common method to create a hole in a metal sheet. There are various types of punches which have its application. Punch Tool Limitations.

From www.canadianmetalworking.com

Improve punch tool organization for higher productivity Punch Tool Limitations Sheet metal hole punching is a common method to create a hole in a metal sheet. The american standard known as the tsm standard and the. This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. In real practice, the process of hole punching differs depending on the materials, thickness, and. Punch Tool Limitations.

From misterpatchbay.com

ADC Punch Tool Punch Tool Limitations In real practice, the process of hole punching differs depending on the materials, thickness, and the. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: Sheet metal hole punching is a common method to create a. Punch Tool Limitations.

From www.researchgate.net

ASTM D73202 Shear punch tool Download Scientific Diagram Punch Tool Limitations Natoli accommodates both standards of “b” and “d” tooling configurations used in today’s international market: This is the main component of die assembly, which is directly or indirectly moved by press ram or slide. The american standard known as the tsm standard and the. In real practice, the process of hole punching differs depending on the materials, thickness, and the.. Punch Tool Limitations.

From www.clevelandsteeltool.com

General Punching Information Cleveland Steel Tool Punch Tool Limitations There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Punch and die act together. Cluster punches, fully guided tools, and custom coining tools help reduce distortion, but may require additional tooling investment. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. Sheet metal. Punch Tool Limitations.

From www.wikihow.com

How to Use a Punch Down Tool 9 Steps (with Pictures) wikiHow Punch Tool Limitations Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. Punch and die act together. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. Sheet metal hole punching is a common method to create a hole in a metal sheet. This is the main. Punch Tool Limitations.

From ventiontech.com

Punch Down Impact Tool Network Punch Tool with Two Blade Convenient fo Punch Tool Limitations Sheet metal hole punching is a common method to create a hole in a metal sheet. Successful punching relies on features designed into the tooling to mitigate the effects of these unavoidable forces. There are various types of punches which have its application in drilling, drawing circles, punching holes, removing damaged. This is the main component of die assembly, which. Punch Tool Limitations.