Steam Drum Blowdown . For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Water treatment occurs within the steam drum. All other marks are the property of their prospective owners. Blowdown systems, guidance for industrial steam boilers (ref: The emerson logo is a trademark and service mark of emerson electric co. Also in drum boilers, blowing from the mud drum or. Suspended solids in the feed water will remain in the boiler when steam is generated. Bg03) is a guidance document intended to provide advice to designers, specifiers,. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe.

from www.phcppros.com

Blowdown systems, guidance for industrial steam boilers (ref: Water treatment occurs within the steam drum. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Also in drum boilers, blowing from the mud drum or. Bg03) is a guidance document intended to provide advice to designers, specifiers,. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. The emerson logo is a trademark and service mark of emerson electric co. Suspended solids in the feed water will remain in the boiler when steam is generated. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. All other marks are the property of their prospective owners.

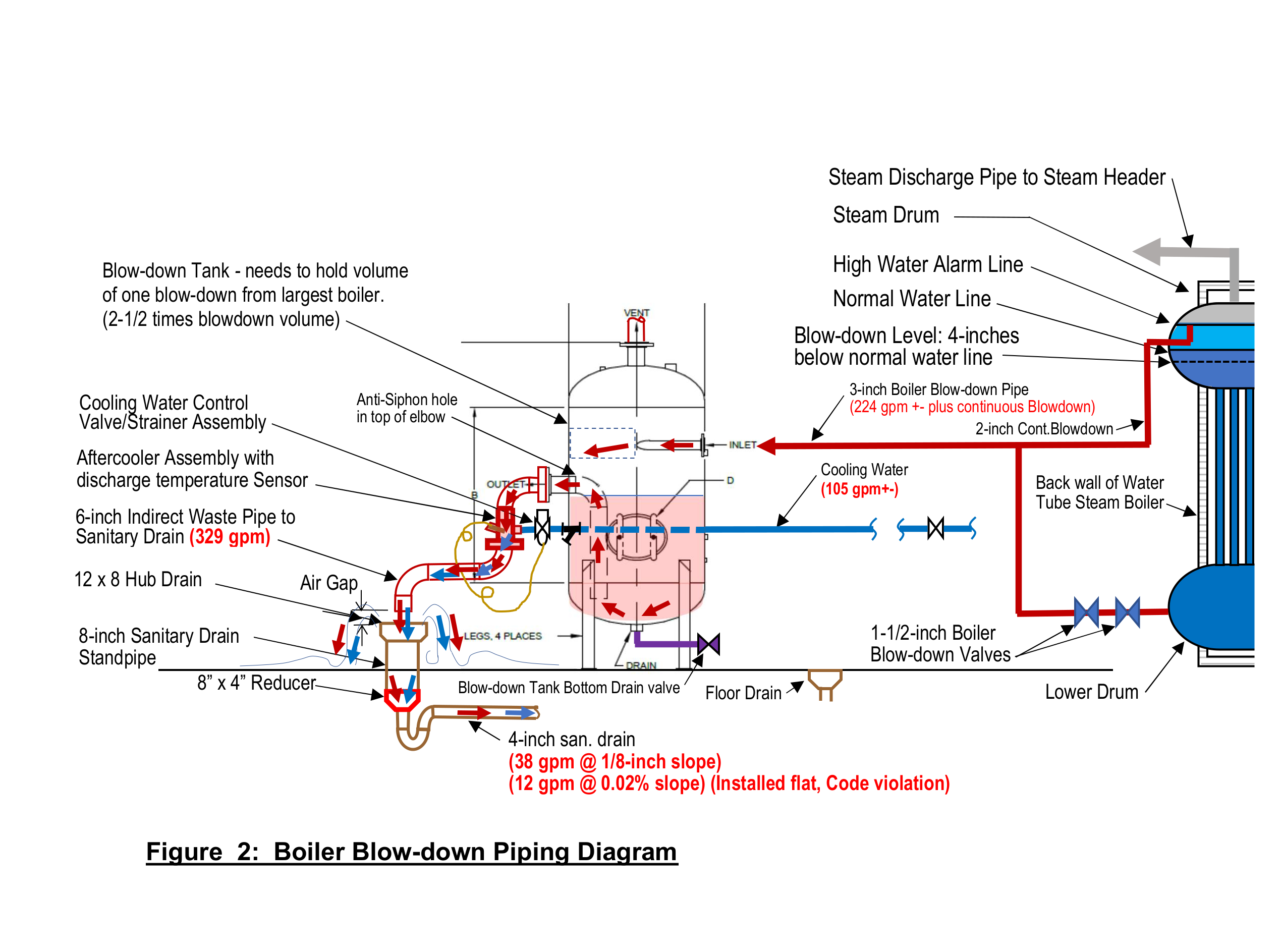

How to Size a Boiler Blowdown System and Drains, Part 2 phcppros

Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Water treatment occurs within the steam drum. Bg03) is a guidance document intended to provide advice to designers, specifiers,. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Blowdown systems, guidance for industrial steam boilers (ref: All other marks are the property of their prospective owners. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Suspended solids in the feed water will remain in the boiler when steam is generated. The emerson logo is a trademark and service mark of emerson electric co. Also in drum boilers, blowing from the mud drum or. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water.

From allsteampro.ca

Blowdown Tanks All Steam Pro Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Bg03) is a guidance document intended to provide advice to designers, specifiers,. Water treatment occurs within the steam drum. Also in drum boilers, blowing from the mud drum or. Blowdown systems, guidance for industrial steam boilers (ref: The vent should ensure. Steam Drum Blowdown.

From www.aes-singapore.com.sg

Steam Drum Blowdown Classification Allied Energy Systems Pte Ltd Steam Drum Blowdown Suspended solids in the feed water will remain in the boiler when steam is generated. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. The emerson logo is a trademark and service mark of emerson electric co. In general, the average plant saves approximately. Steam Drum Blowdown.

From www.boiler-units.com

High Temperature Steam Drum In Boiler , Blowdown Drum Low Pressure Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Blowdown systems, guidance for industrial steam boilers (ref: The emerson logo is a trademark and service. Steam Drum Blowdown.

From www.solutions4mfg.com

Steam Blowdown Drum Steam Drum Blowdown Blowdown systems, guidance for industrial steam boilers (ref: For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Also in drum boilers, blowing from the mud drum or. Bg03) is a guidance document intended to provide advice to designers, specifiers,. The emerson logo is a trademark. Steam Drum Blowdown.

From www.relianceboilertrim.com

Blowdown Procedure for Boiler Level Instruments Steam Drum Blowdown The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Suspended solids in the feed water will remain in the boiler when steam is generated. Water treatment occurs within the steam drum. In general, the average plant saves approximately 20% of boiler blowdown when changing. Steam Drum Blowdown.

From savree.com

Boiler Gauge Glass Blowdown Procedure Explained saVRee Steam Drum Blowdown Water treatment occurs within the steam drum. Suspended solids in the feed water will remain in the boiler when steam is generated. Also in drum boilers, blowing from the mud drum or. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. The emerson logo. Steam Drum Blowdown.

From www.watertechusa.com

Boiler Blow Down Prevents Scale and Corrosion Watertech of America Steam Drum Blowdown The emerson logo is a trademark and service mark of emerson electric co. Blowdown systems, guidance for industrial steam boilers (ref: Suspended solids in the feed water will remain in the boiler when steam is generated. Water treatment occurs within the steam drum. All other marks are the property of their prospective owners. Bg03) is a guidance document intended to. Steam Drum Blowdown.

From www.thermodyneboilers.com

Blowdown in Boiler Boiler Blowdown Calculation Formula & Calculator... Steam Drum Blowdown Suspended solids in the feed water will remain in the boiler when steam is generated. Bg03) is a guidance document intended to provide advice to designers, specifiers,. Water treatment occurs within the steam drum. The emerson logo is a trademark and service mark of emerson electric co. The vent should ensure that flash steam is vented safely and there is. Steam Drum Blowdown.

From www.pennseparator.com

Flash Economizer Heat Recovery System for Continuous Blowdown Steam Drum Blowdown Suspended solids in the feed water will remain in the boiler when steam is generated. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Bg03) is a guidance document intended to provide advice to designers, specifiers,. All other marks are the property of their prospective. Steam Drum Blowdown.

From www.solutions4mfg.com

Steam Blowdown Drum Steam Drum Blowdown Water treatment occurs within the steam drum. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. All other marks are the property of their prospective owners.. Steam Drum Blowdown.

From www.researchgate.net

Blowdown drum and gooseneck[1] Download Scientific Diagram Steam Drum Blowdown The emerson logo is a trademark and service mark of emerson electric co. All other marks are the property of their prospective owners. Water treatment occurs within the steam drum. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Bg03) is a guidance document. Steam Drum Blowdown.

From www.pulpandpaper-technology.com

STEAM BLOW DOWN VALVES & TDS CONTROL Valves and Fittings RAM Steam Drum Blowdown Suspended solids in the feed water will remain in the boiler when steam is generated. Blowdown systems, guidance for industrial steam boilers (ref: The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. In general, the average plant saves approximately 20% of boiler blowdown when. Steam Drum Blowdown.

From industrialsteam.com

Selection of Blowdown Systems Industrial steam Steam Drum Blowdown All other marks are the property of their prospective owners. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Suspended solids in the feed water will remain in the boiler when steam is generated. The emerson logo is a trademark and service mark of. Steam Drum Blowdown.

From boilersinfo.com

Boiler Blowdown types and Boiler Blowdown calculation Steam Drum Blowdown Bg03) is a guidance document intended to provide advice to designers, specifiers,. Blowdown systems, guidance for industrial steam boilers (ref: All other marks are the property of their prospective owners. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Water treatment occurs within the steam. Steam Drum Blowdown.

From mavink.com

Boiler Blowdown Diagram Steam Drum Blowdown The emerson logo is a trademark and service mark of emerson electric co. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. All other marks are the property of their prospective owners. Water treatment occurs within the steam drum. Blowdown systems, guidance for industrial. Steam Drum Blowdown.

From www.thermalpowertech.com

Steam Drum Thermal Power Tech Steam Drum Blowdown Also in drum boilers, blowing from the mud drum or. The emerson logo is a trademark and service mark of emerson electric co. Water treatment occurs within the steam drum. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Bg03) is a guidance document intended. Steam Drum Blowdown.

From waterpedia.co.id

Blowdown Boiler Waterpedia Steam Drum Blowdown All other marks are the property of their prospective owners. The emerson logo is a trademark and service mark of emerson electric co. Blowdown systems, guidance for industrial steam boilers (ref: For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Bg03) is a guidance document. Steam Drum Blowdown.

From qrcvalves.com

Blowdown Valve Working Principle, Types, Diagram, Applications Steam Drum Blowdown All other marks are the property of their prospective owners. Blowdown systems, guidance for industrial steam boilers (ref: Bg03) is a guidance document intended to provide advice to designers, specifiers,. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. The vent should ensure that flash. Steam Drum Blowdown.

From www.wcrouse.com

What Is Boiler Blowdown? Everything You Need To Know Steam Drum Blowdown Suspended solids in the feed water will remain in the boiler when steam is generated. Blowdown systems, guidance for industrial steam boilers (ref: The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Also in drum boilers, blowing from the mud drum or. Bg03) is. Steam Drum Blowdown.

From www.youtube.com

Blowdown Losses Steam Boilers Calculations Intermittent Steam Drum Blowdown Also in drum boilers, blowing from the mud drum or. Blowdown systems, guidance for industrial steam boilers (ref: Water treatment occurs within the steam drum. The emerson logo is a trademark and service mark of emerson electric co. All other marks are the property of their prospective owners. In general, the average plant saves approximately 20% of boiler blowdown when. Steam Drum Blowdown.

From www.phcppros.com

How to Size a Boiler Blowdown System and Drains, Part 2 phcppros Steam Drum Blowdown All other marks are the property of their prospective owners. Also in drum boilers, blowing from the mud drum or. Water treatment occurs within the steam drum. Blowdown systems, guidance for industrial steam boilers (ref: In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. For example, the mixing of chemicals. Steam Drum Blowdown.

From www.youtube.com

09 Boiler Blowdown Procedure YouTube Steam Drum Blowdown For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Bg03) is a guidance document intended to provide advice to designers, specifiers,. Water treatment occurs within the steam drum. Also in drum boilers, blowing from the mud drum or. The vent should ensure that flash steam. Steam Drum Blowdown.

From ormandygroup.com

Steam Blowdown & Flash Vessels Ormandy Rycroft Engineering Steam Drum Blowdown Water treatment occurs within the steam drum. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. All other marks are the property of their prospective. Steam Drum Blowdown.

From www.solutions4mfg.com

Steam Blowdown Drum Steam Drum Blowdown For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Water treatment occurs within the steam drum. Also in drum boilers, blowing from the mud drum or. All other marks are the property of their prospective owners. Suspended solids in the feed water will remain in. Steam Drum Blowdown.

From mavink.com

Boiler Blowdown Diagram Steam Drum Blowdown Blowdown systems, guidance for industrial steam boilers (ref: In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. Also in drum boilers, blowing from the mud. Steam Drum Blowdown.

From savree.com

Boiler Gauge Glass Blowdown Procedure Explained saVRee Steam Drum Blowdown Also in drum boilers, blowing from the mud drum or. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. The emerson logo is a trademark and service mark of emerson electric co. For example, the mixing of chemicals for internal boiler treatment occurs within. Steam Drum Blowdown.

From savree.com

Boiler Gauge Glass Blowdown Procedure Explained saVRee Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Bg03) is a guidance document intended to provide advice to designers, specifiers,. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. For example, the mixing. Steam Drum Blowdown.

From precisionboilers.com

Blowdown Tanks for Boilers Precision Boilers Steam Drum Blowdown Also in drum boilers, blowing from the mud drum or. For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Water treatment occurs within the steam drum. The emerson logo is a trademark and service mark of emerson electric co. All other marks are the property. Steam Drum Blowdown.

From www.solutions4mfg.com

Steam Blowdown Drum Steam Drum Blowdown For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Also in drum boilers, blowing from the mud drum or. Suspended solids in the feed water will remain in the boiler when steam is generated. Water treatment occurs within the steam drum. The vent should ensure. Steam Drum Blowdown.

From cevaqyha.blob.core.windows.net

Boiler Drum Water Chemistry at Jason Edmondson blog Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. The emerson logo is a trademark and service mark of emerson electric co. Bg03) is a guidance document intended to provide advice to designers, specifiers,. The vent should ensure that flash steam is vented safely and there is no significant carryover. Steam Drum Blowdown.

From www.iqsdirectory.com

Water Tube Boilers What is it? Types & Characteristics Steam Drum Blowdown Water treatment occurs within the steam drum. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Suspended solids in the feed water will remain in the boiler when steam is generated. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at. Steam Drum Blowdown.

From isg.com.sa

Boiler Blowdown Types And Boiler Blowdown Calculation, 48 OFF Steam Drum Blowdown In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. The vent should ensure that flash steam is vented safely and there is no significant carryover of water at the exit to the vent pipe. All other marks are the property of their prospective owners. Bg03) is a guidance document intended. Steam Drum Blowdown.

From www.youtube.com

What is IBD CBD / Steam Drum CBD IBD / Shutdown /Maintenance / Power Steam Drum Blowdown All other marks are the property of their prospective owners. In general, the average plant saves approximately 20% of boiler blowdown when changing from manually adjusted continuous blowdown to. Water treatment occurs within the steam drum. Also in drum boilers, blowing from the mud drum or. Blowdown systems, guidance for industrial steam boilers (ref: For example, the mixing of chemicals. Steam Drum Blowdown.

From waterpedia.co.id

Blowdown Boiler Waterpedia Steam Drum Blowdown For example, the mixing of chemicals for internal boiler treatment occurs within the steam drum, as does blowdown (a process used to control water. Also in drum boilers, blowing from the mud drum or. Suspended solids in the feed water will remain in the boiler when steam is generated. All other marks are the property of their prospective owners. Bg03). Steam Drum Blowdown.

From industrialsteam.com

Selection of Blowdown Systems Industrial steam Steam Drum Blowdown Water treatment occurs within the steam drum. Also in drum boilers, blowing from the mud drum or. The emerson logo is a trademark and service mark of emerson electric co. Suspended solids in the feed water will remain in the boiler when steam is generated. All other marks are the property of their prospective owners. For example, the mixing of. Steam Drum Blowdown.