Wire Rope Sheave Inspection . If the groove shows signs of rope imprints. As shown in figure 1, the gauge should contact the groove for about 150° of arc. How often should ropes be inspected? The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Also examine the rope near the end connections. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. How do you calculate wire rope strength? The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. To check the sheave size, contour and amount of wear, a groove gauge is used.

from enginemechanics.tpub.com

To check the sheave size, contour and amount of wear, a groove gauge is used. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. How do you calculate wire rope strength? As shown in figure 1, the gauge should contact the groove for about 150° of arc. How often should ropes be inspected? Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. If the groove shows signs of rope imprints. Also examine the rope near the end connections. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance.

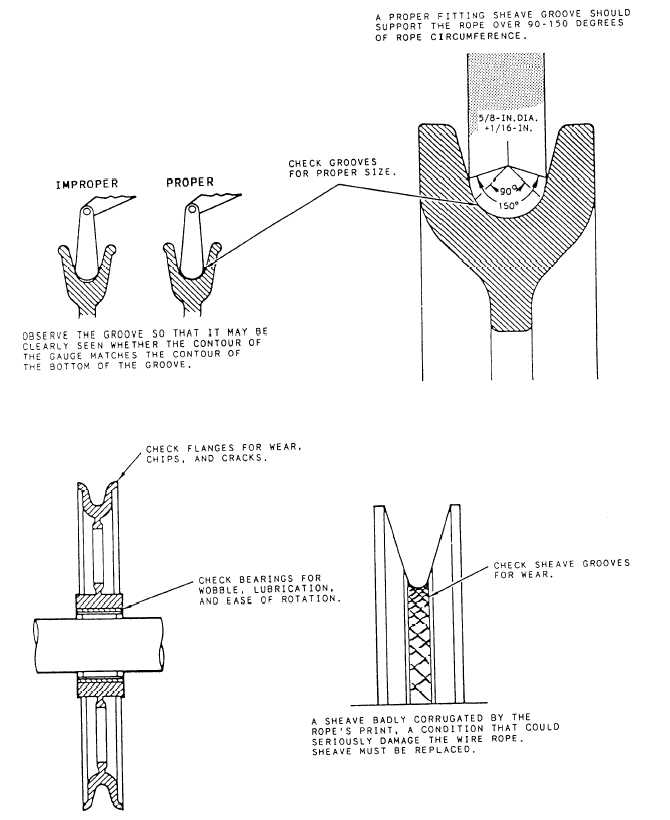

Figure 1239.Sheave (pulley) inspection.

Wire Rope Sheave Inspection The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. As shown in figure 1, the gauge should contact the groove for about 150° of arc. How often should ropes be inspected? The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. If the groove shows signs of rope imprints. To check the sheave size, contour and amount of wear, a groove gauge is used. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. How do you calculate wire rope strength? Also examine the rope near the end connections.

From www.techknowserv.com

Wire Rope Testing A Review of Different Nondestructive Testing Methods Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. How often should ropes be inspected? In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. The. Wire Rope Sheave Inspection.

From www.linkedin.com

Wire Rope Inspection Wire Rope Sheave Inspection As shown in figure 1, the gauge should contact the groove for about 150° of arc. To check the sheave size, contour and amount of wear, a groove gauge is used. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. How often should ropes be inspected? The. Wire Rope Sheave Inspection.

From www.alatas.com

Crane Wire Rope Inspections Alatas Crane Services Wire Rope Sheave Inspection The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. How often should ropes be inspected? How do you calculate wire rope strength? The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Check as the rope runs. Wire Rope Sheave Inspection.

From blog.demagcranes.com

Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Wire Rope Sheave Inspection The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment. Wire Rope Sheave Inspection.

From mepsystems.com.sg

MORDEC WIRE ROPE SHEAVE GAUGE MEP Deck Solutions Wire Rope Sheave Inspection How do you calculate wire rope strength? Also examine the rope near the end connections. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. How often should ropes be inspected? If the groove shows signs of rope imprints. The primary rule to follow in conducting a wire. Wire Rope Sheave Inspection.

From www.mazzellacompanies.com

How to Inspect Wire Rope Slings According to ASME B30.9 Standards Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. To check the sheave size, contour and amount of wear, a groove gauge is used.. Wire Rope Sheave Inspection.

From blog.demagcranes.com

Understanding Wire Rope Lay for Your Next Wire Rope Hoist Repair or Wire Rope Sheave Inspection The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. If the groove shows signs of rope imprints. As shown in figure 1, the gauge. Wire Rope Sheave Inspection.

From www.youtube.com

WIRE ROPE INSPECTION WITH RECOILING YouTube Wire Rope Sheave Inspection As shown in figure 1, the gauge should contact the groove for about 150° of arc. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. How often should. Wire Rope Sheave Inspection.

From www.samselsupply.com

HOWTO Order Wire Rope Sheaves Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. How do you calculate wire rope strength? Also examine the rope near the end connections. If the groove shows signs of rope imprints. In this article we will be describing ways to perform a wire rope inspection and. Wire Rope Sheave Inspection.

From www.offshoremarineservices.co.uk

Wire Rope Inspection OMS Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. As shown in figure 1, the gauge should contact the groove for about 150° of arc. In this article we will be describing. Wire Rope Sheave Inspection.

From ccoschool.us

What to Expect at a Crane & Rigging Inspection Crane Operator School Wire Rope Sheave Inspection In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. How often should ropes be inspected? As shown in figure 1, the gauge should contact the groove for about. Wire Rope Sheave Inspection.

From inspectiongc.com

Wire Rope Inspection Inspection GC Wire Rope Sheave Inspection In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. To check the sheave size, contour and amount of wear, a groove gauge is used. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire.. Wire Rope Sheave Inspection.

From www.lift-it.com

Wire Rope Sling Inspection Criteria LiftIt® Manufacturing Wire Rope Sheave Inspection As shown in figure 1, the gauge should contact the groove for about 150° of arc. Also examine the rope near the end connections. How often should ropes be inspected? To check the sheave size, contour and amount of wear, a groove gauge is used. The primary rule to follow in conducting a wire rope inspection on any typical machine. Wire Rope Sheave Inspection.

From enginemechanics.tpub.com

Wire Rope Inspection Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. To check the sheave size, contour and amount of wear, a groove gauge is used. Also examine the rope near the end connections. How do you calculate wire rope strength? If the groove shows signs of rope imprints.. Wire Rope Sheave Inspection.

From www.slideserve.com

PPT OSHA 29 CFR Part 1926 Crane & Derricks In Construction PowerPoint Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. How do you calculate wire rope strength? In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance.. Wire Rope Sheave Inspection.

From www.youtube.com

Wire Rope Sling Explained with SWL Loading capacity formula Wirerope Wire Rope Sheave Inspection The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. Also examine the rope near the end connections. How often should ropes be inspected? As shown in figure 1,. Wire Rope Sheave Inspection.

From www.mazzellacompanies.com

Wire Rope Inspection and Removal from Service Criteria Wire Rope Sheave Inspection The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Also examine the rope near the end connections. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. If the groove shows signs of rope imprints. How do. Wire Rope Sheave Inspection.

From www.slideserve.com

PPT Wire Rope Inspection PowerPoint Presentation, free download ID Wire Rope Sheave Inspection The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. Also examine the rope near the end connections. To check the sheave size, contour and amount of wear, a groove gauge is used. If the groove shows signs of rope imprints. In this article we will be. Wire Rope Sheave Inspection.

From enginemechanics.tpub.com

Figure 1239.Sheave (pulley) inspection. Wire Rope Sheave Inspection How often should ropes be inspected? If the groove shows signs of rope imprints. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. To check the sheave. Wire Rope Sheave Inspection.

From www.mdpi.com

Materials Free FullText Sliding Friction and Wear Characteristics Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. How often should ropes be inspected? How do you calculate wire rope strength? Also examine. Wire Rope Sheave Inspection.

From www.alatas.com

Annual Wire Rope Inspections Alatas Wire Rope Sheave Inspection The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. How do you calculate wire rope strength? How often should ropes be inspected? Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. Also examine the rope near the. Wire Rope Sheave Inspection.

From www.youtube.com

How to Inspect a Wire Rope Lifting Sling to OSHA and ASME Standards L Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. As shown in figure 1, the gauge should contact the groove for about 150° of arc. The very first item to be. Wire Rope Sheave Inspection.

From www.slideserve.com

PPT Wire Rope Inspection PowerPoint Presentation, free download ID Wire Rope Sheave Inspection Also examine the rope near the end connections. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. The very first item to be checked. Wire Rope Sheave Inspection.

From v9306.1blu.de

Inspection Of Wire Rope Sheaves And Drums v9306.1blu.de Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. How often should ropes be inspected? Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier. Wire Rope Sheave Inspection.

From suncorstainless.com

Stainless Steel Sheaves Selection and Use Suncor Stainless Wire Rope Sheave Inspection How often should ropes be inspected? The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. If the groove shows signs of rope imprints. How do you calculate wire rope strength? To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1,. Wire Rope Sheave Inspection.

From www.youtube.com

Inspection of Wire rope Discard Criteria of Wire Ropes Crushing Bird Wire Rope Sheave Inspection How do you calculate wire rope strength? The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. If the groove shows signs of rope imprints. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see.. Wire Rope Sheave Inspection.

From www.wireropegauges.com

Wire Rope and Sheave Gauges API RP 9B Complete Range Sets Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. How often should ropes be inspected? If the groove shows signs of rope imprints. The primary. Wire Rope Sheave Inspection.

From www.wireropegauges.com

Wire Rope and Sheave Gauges API RP 9B Complete Range Sets Wire Rope Sheave Inspection In this article we will be describing ways to perform a wire rope inspection and we will provide solutions for meticulous maintenance. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. How do you calculate wire rope strength? If the groove shows signs of rope imprints. To check the sheave. Wire Rope Sheave Inspection.

From www.mazzellacompanies.com

inspection of wire rope sheaves Resources Mazzella Companies Wire Rope Sheave Inspection If the groove shows signs of rope imprints. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. To check the sheave size, contour and amount of wear, a groove gauge is used. How do you calculate wire rope strength? How often should ropes be inspected? In this. Wire Rope Sheave Inspection.

From www.slideserve.com

PPT Wire Rope Inspection PowerPoint Presentation, free download ID Wire Rope Sheave Inspection To check the sheave size, contour and amount of wear, a groove gauge is used. As shown in figure 1, the gauge should contact the groove for about 150° of arc. If the groove shows signs of rope imprints. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to. Wire Rope Sheave Inspection.

From www.yumpu.com

14 Wire Rope Inspection WorkSafeNB Wire Rope Sheave Inspection Also examine the rope near the end connections. As shown in figure 1, the gauge should contact the groove for about 150° of arc. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. How do you calculate wire rope strength? The very first item to be checked. Wire Rope Sheave Inspection.

From www.pinterest.co.uk

an article about wire rope inspection guidelines Wire Rope Sheave Inspection If the groove shows signs of rope imprints. To check the sheave size, contour and amount of wear, a groove gauge is used. Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. As shown in figure 1, the gauge should contact the groove for about 150° of. Wire Rope Sheave Inspection.

From www.secure-tools.com

Rope and Sheave Gauges Secure Tools Wire Rope Sheave Inspection The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. How often should ropes be inspected? Also examine the rope near the end connections. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. In this article we. Wire Rope Sheave Inspection.

From www.certex.dk

Wire Rope Sheave, type SR CERTEX Denmark Wire Rope Sheave Inspection The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. The very first item to be checked when examining sheaves and drums is the condition of the grooves (figs. Also examine the rope near the end connections. How often should ropes be inspected? Check as the rope. Wire Rope Sheave Inspection.

From www.youtube.com

Safety inar Wire Rope Inspection and Maintenance for Your Underhung Wire Rope Sheave Inspection Check as the rope runs at a slow speed over the sheaves, where crown (surface) wire breaks may be easier to see. Also examine the rope near the end connections. The primary rule to follow in conducting a wire rope inspection on any typical machine or piece of equipment is that each wire. As shown in figure 1, the gauge. Wire Rope Sheave Inspection.