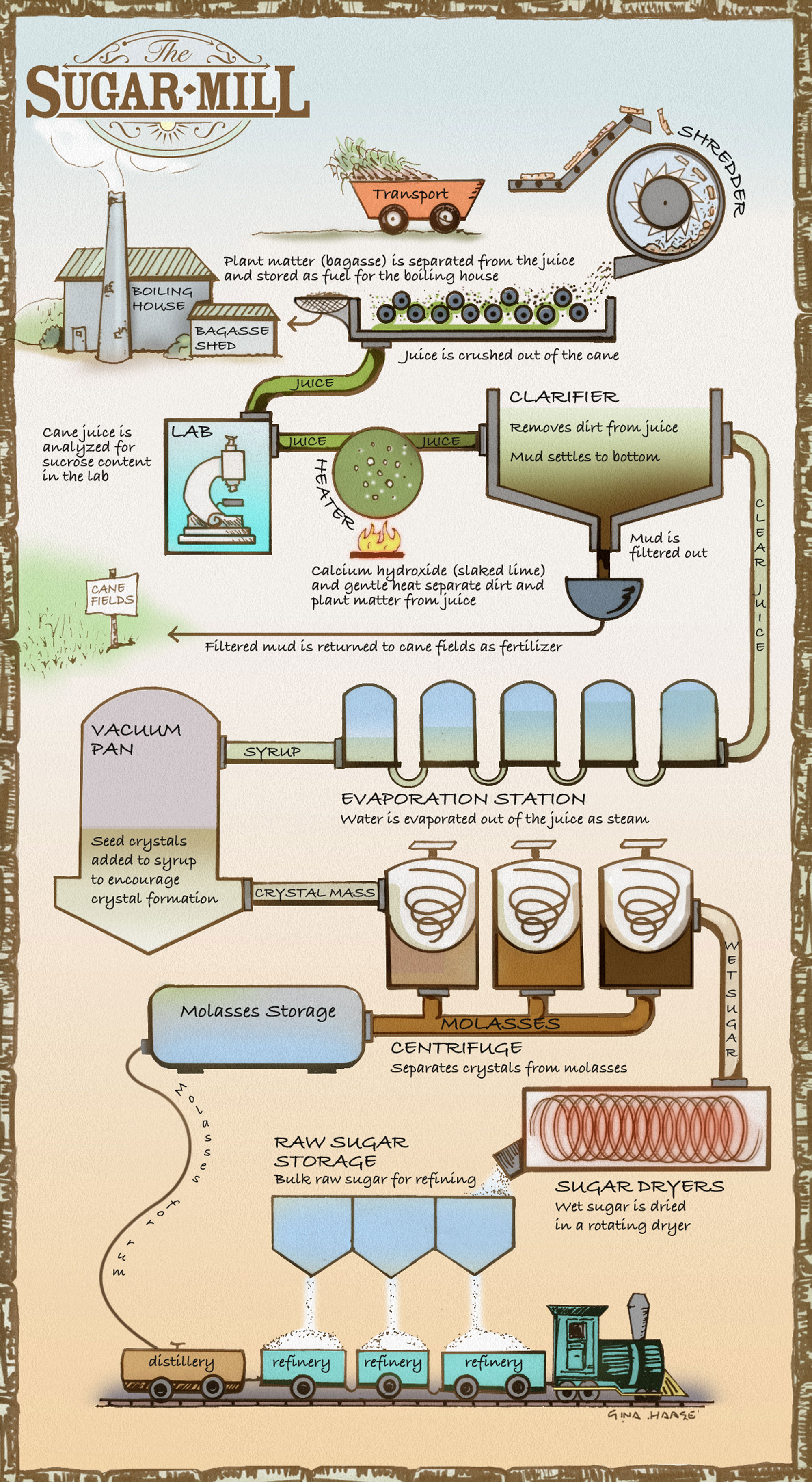

Sugar Plant Manufacturing Process . Juices of sugarcane (saccharum officinarum). In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. Sugar cane and sugar beets. This processing column describes the process by which sugar is harvested and processed. At the refinery, cane sugar is further refined to remove the final impurities (1). In the sap of some plants, the sugar mixtures are condensed into syrup. More than 60% of the. The manufacturing process planting and harvesting 1 sugarcane. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. “sugar is derived from two main plant sources:

from www.rumreader.com

The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. Juices of sugarcane (saccharum officinarum). This processing column describes the process by which sugar is harvested and processed. Sugar cane and sugar beets. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. “sugar is derived from two main plant sources: More than 60% of the. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. The manufacturing process planting and harvesting 1 sugarcane. In the sap of some plants, the sugar mixtures are condensed into syrup.

Sugar A Practical Guide The Rum Reader

Sugar Plant Manufacturing Process In the sap of some plants, the sugar mixtures are condensed into syrup. Juices of sugarcane (saccharum officinarum). In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. In the sap of some plants, the sugar mixtures are condensed into syrup. The manufacturing process planting and harvesting 1 sugarcane. Sugar cane and sugar beets. This processing column describes the process by which sugar is harvested and processed. More than 60% of the. At the refinery, cane sugar is further refined to remove the final impurities (1). “sugar is derived from two main plant sources:

From www.isgec.com

Sugar Plant and Machinery Sugar Factory Supplier Diffusers Turnkey Sugar Plant Manufacturing Process More than 60% of the. This processing column describes the process by which sugar is harvested and processed. Sugar cane and sugar beets. In the sap of some plants, the sugar mixtures are condensed into syrup. In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. Juices of sugarcane (saccharum officinarum). “sugar. Sugar Plant Manufacturing Process.

From processflowsheets.blogspot.com

Process flow sheets Sugar from sugar cane Production process with Sugar Plant Manufacturing Process As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. At the refinery, cane sugar is further refined to remove the final impurities (1). Juices of sugarcane (saccharum officinarum). The manufacturing process planting and harvesting 1 sugarcane. More than 60% of the. The sugar industry processes sugar cane and sugar beets to manufacture edible. Sugar Plant Manufacturing Process.

From www.johnkingchains.com

Typical Layout in Sugar Beet Diffuser Process John King Chains Sugar Plant Manufacturing Process Sugar cane and sugar beets. Juices of sugarcane (saccharum officinarum). As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. This processing column describes the process by which sugar is harvested and processed. In the sap of some plants, the sugar mixtures are condensed into syrup. More than 60% of the. The manufacturing process. Sugar Plant Manufacturing Process.

From www.sulzer.com

Sulzer pumps improve wastewater treatment in a sugar and bioethanol Sugar Plant Manufacturing Process Sugar cane and sugar beets. “sugar is derived from two main plant sources: The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. This processing column describes the process by which sugar is. Sugar Plant Manufacturing Process.

From netsolwater.com

How does Waste Water Treatment Plant benefit the sugar industry Sugar Plant Manufacturing Process In the sap of some plants, the sugar mixtures are condensed into syrup. More than 60% of the. Juices of sugarcane (saccharum officinarum). As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a. Sugar Plant Manufacturing Process.

From www.vrogue.co

Block Diagram Sugar Manufacturing Process Flow Chart vrogue.co Sugar Plant Manufacturing Process Juices of sugarcane (saccharum officinarum). Sugar cane and sugar beets. At the refinery, cane sugar is further refined to remove the final impurities (1). This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. “sugar is. Sugar Plant Manufacturing Process.

From www.vectorstock.com

A sugar production diagram Royalty Free Vector Image Sugar Plant Manufacturing Process The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. The manufacturing process planting and harvesting 1 sugarcane. This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery. Sugar Plant Manufacturing Process.

From www.sugarcane.org

Infographics SugarCane Sugar Plant Manufacturing Process Sugar cane and sugar beets. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. More than 60% of the. At the refinery, cane sugar is further refined to remove the final impurities (1). In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. This processing. Sugar Plant Manufacturing Process.

From www.rumreader.com

Sugar A Practical Guide The Rum Reader Sugar Plant Manufacturing Process This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. Juices of sugarcane (saccharum officinarum). The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. Sugar cane and sugar beets. At the refinery,. Sugar Plant Manufacturing Process.

From grade9sugar.weebly.com

Manufacturing Process Sugar Sugar Plant Manufacturing Process “sugar is derived from two main plant sources: As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. The manufacturing process planting and harvesting 1 sugarcane. This processing column describes the process by which sugar is harvested and processed. In the hot and sunny climate of coastal queensland and northern new south wales with. Sugar Plant Manufacturing Process.

From www.dreamstime.com

Concept of Industrial Plant for Sugar Cane Processing and Sugar Sugar Plant Manufacturing Process Juices of sugarcane (saccharum officinarum). In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. The manufacturing process planting and harvesting 1 sugarcane. “sugar is derived from two main plant sources: As one of the oldest commodities in the. Sugar Plant Manufacturing Process.

From www.youtube.com

How Cane Sugar is processed Manufacturing Project of Sugar Mill Sugar Plant Manufacturing Process As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. Juices of sugarcane (saccharum officinarum). Sugar cane and sugar beets. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. “sugar is derived from two main plant sources: At the refinery, cane sugar. Sugar Plant Manufacturing Process.

From www.temp.sugarcane.org

SugarCane Sugar Plant Manufacturing Process The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. This processing column describes the process by which sugar is harvested and processed. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. Sugar cane and sugar beets. More than 60% of the. “sugar is derived from two main plant sources:. Sugar Plant Manufacturing Process.

From www.separatech.com

Batch centrifugal and continuous centrifugal machine Sugar Plant Manufacturing Process Juices of sugarcane (saccharum officinarum). The manufacturing process planting and harvesting 1 sugarcane. At the refinery, cane sugar is further refined to remove the final impurities (1). The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. This processing column describes the process by which sugar is harvested and. Sugar Plant Manufacturing Process.

From snipe.fm

😍 Manufacturing process of sugar industry. Sugar Industry in India Sugar Plant Manufacturing Process The manufacturing process planting and harvesting 1 sugarcane. Juices of sugarcane (saccharum officinarum). The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. At the refinery, cane sugar is further refined to remove the final impurities (1). The sugar industry processes sugar cane and sugar beets to manufacture edible. Sugar Plant Manufacturing Process.

From cbpengineering.com

sugar processing plant Sugar Plant Manufacturing Process In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. “sugar is derived from two main plant sources: The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. At the refinery, cane sugar is further refined to remove the final impurities. Sugar Plant Manufacturing Process.

From www.pinterest.com

Sugar Industry _A Process Process Control Overview Sugar industry Sugar Plant Manufacturing Process In the sap of some plants, the sugar mixtures are condensed into syrup. This processing column describes the process by which sugar is harvested and processed. Juices of sugarcane (saccharum officinarum). Sugar cane and sugar beets. “sugar is derived from two main plant sources: As one of the oldest commodities in the world, it was first domesticated around 8000 b.c.. Sugar Plant Manufacturing Process.

From mavink.com

Sugar Cane Process Flow Diagram Sugar Plant Manufacturing Process Sugar cane and sugar beets. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. At the refinery, cane sugar is further refined to remove the final impurities (1). In the sap of some plants, the sugar mixtures are condensed into syrup. The sugar industry processes sugar cane and. Sugar Plant Manufacturing Process.

From www.researchgate.net

Process flow diagram of a typical Sugar Mill Cogeneration system [100 Sugar Plant Manufacturing Process The manufacturing process planting and harvesting 1 sugarcane. At the refinery, cane sugar is further refined to remove the final impurities (1). The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. In the sap of some plants, the sugar mixtures are condensed into syrup. This processing column describes the process by which sugar is harvested and. Sugar Plant Manufacturing Process.

From www.researchgate.net

Mass balance of sugar production block in the designed process plant Sugar Plant Manufacturing Process This processing column describes the process by which sugar is harvested and processed. Juices of sugarcane (saccharum officinarum). The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. In the sap of some plants, the sugar mixtures are condensed into syrup. As one of the oldest commodities in the. Sugar Plant Manufacturing Process.

From www.mdpi.com

Processes Free FullText Enabling Total Process Digital Twin in Sugar Plant Manufacturing Process As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. “sugar is derived from two main plant sources: The manufacturing process planting and harvesting 1 sugarcane. This processing column describes the process by. Sugar Plant Manufacturing Process.

From pubs.rsc.org

An integrated biorefinery concept for conversion of sugar beet pulp Sugar Plant Manufacturing Process The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. This processing column describes the process by which sugar is harvested and processed. In the sap of some plants, the sugar mixtures are condensed into syrup. “sugar is derived from two main plant sources: Sugar cane and sugar beets.. Sugar Plant Manufacturing Process.

From www.pinterest.com

Manufacturing Process for Making Sugar from Sugar Cane Task 1 Process Sugar Plant Manufacturing Process The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. More than 60% of the. In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. “sugar is derived from two main plant sources: This processing column describes the process by which sugar is harvested and processed. Sugar cane and. Sugar Plant Manufacturing Process.

From www.researchgate.net

1 Existing sugar process flow diagram Download Scientific Diagram Sugar Plant Manufacturing Process “sugar is derived from two main plant sources: In the sap of some plants, the sugar mixtures are condensed into syrup. This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. In the hot and sunny. Sugar Plant Manufacturing Process.

From www.chinimandi.com

Sugar Factories Announce High Procurement Prices ChiniMandi Sugar Plant Manufacturing Process The manufacturing process planting and harvesting 1 sugarcane. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. “sugar is derived from two main plant sources: At the refinery, cane sugar is further refined to remove the final impurities (1). In the sap of some plants, the sugar mixtures. Sugar Plant Manufacturing Process.

From mavink.com

Sugar Cane Process Flow Diagram Sugar Plant Manufacturing Process At the refinery, cane sugar is further refined to remove the final impurities (1). Juices of sugarcane (saccharum officinarum). “sugar is derived from two main plant sources: More than 60% of the. Sugar cane and sugar beets. In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. The raw sugar is then. Sugar Plant Manufacturing Process.

From zorays.com

How is Sugar Cane Used to Generate Electricity? (Bagasse Power Plant in Sugar Plant Manufacturing Process The manufacturing process planting and harvesting 1 sugarcane. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. Juices of sugarcane (saccharum officinarum). As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. Sugar cane and sugar beets. “sugar is derived from two. Sugar Plant Manufacturing Process.

From www.youtube.com

How Sugar Is Made from Sugarcane Amazing Sugar Factory Process YouTube Sugar Plant Manufacturing Process Juices of sugarcane (saccharum officinarum). More than 60% of the. The manufacturing process planting and harvesting 1 sugarcane. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. In the hot and sunny. Sugar Plant Manufacturing Process.

From www.sucropower.co.za

Tech SucroPower Sugar Plant Manufacturing Process This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. Sugar cane and sugar beets. Juices of sugarcane. Sugar Plant Manufacturing Process.

From www.nandantechnicals.com

Different stages involved in the production for sugar industry. Sugar Plant Manufacturing Process At the refinery, cane sugar is further refined to remove the final impurities (1). In the sap of some plants, the sugar mixtures are condensed into syrup. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. More than 60% of the. Juices of sugarcane (saccharum officinarum). “sugar is derived from two main plant sources: In the. Sugar Plant Manufacturing Process.

From writing9.com

The diagram below shows the manufacturing process for making sugar from Sugar Plant Manufacturing Process This processing column describes the process by which sugar is harvested and processed. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. In the sap of some plants, the sugar mixtures are condensed into syrup.. Sugar Plant Manufacturing Process.

From www.alibaba.com

Sugar Manufacturing Plant Buy Sugar Manufacturing Plant,Sugar Plant Sugar Plant Manufacturing Process In the sap of some plants, the sugar mixtures are condensed into syrup. At the refinery, cane sugar is further refined to remove the final impurities (1). The manufacturing process planting and harvesting 1 sugarcane. “sugar is derived from two main plant sources: As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. The. Sugar Plant Manufacturing Process.

From www.sugarprocesstech.com

what is refined sugar and Refined sugar making process Sugar Plant Manufacturing Process More than 60% of the. Sugar cane and sugar beets. Juices of sugarcane (saccharum officinarum). In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. The manufacturing process planting and harvesting 1 sugarcane. “sugar is derived from two main plant sources: As one of the oldest commodities in the world, it was. Sugar Plant Manufacturing Process.

From www.vrogue.co

The Diagram Below Shows The Manufacturing Process For vrogue.co Sugar Plant Manufacturing Process As one of the oldest commodities in the world, it was first domesticated around 8000 b.c. The raw sugar is then transported to a sugar refinery (usually via a dry bulk ship) where it is further purified. Sugar cane and sugar beets. Juices of sugarcane (saccharum officinarum). In the sap of some plants, the sugar mixtures are condensed into syrup.. Sugar Plant Manufacturing Process.

From www.forbesmarshall.com

Sugar Plant Sugar Plant Manufacturing Process More than 60% of the. The sugar industry processes sugar cane and sugar beets to manufacture edible sugar. In the sap of some plants, the sugar mixtures are condensed into syrup. In the hot and sunny climate of coastal queensland and northern new south wales with plenty of rain. “sugar is derived from two main plant sources: Sugar cane and. Sugar Plant Manufacturing Process.