Surface Finish For Sealing Face . the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. these microscopic features of any surface are particularly important to sealing performance. The design charts in the sections below indicate a surface roughness value not to exceed. The surface finish is important because it should not only. a flange face’s surface roughness value defines its surface finish. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. surface finish is the most important consideration when designing the groove to ensure a good seal. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure.

from www.youtube.com

The design charts in the sections below indicate a surface roughness value not to exceed. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. surface finish is the most important consideration when designing the groove to ensure a good seal. the right surface finish. The surface finish is important because it should not only. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. these microscopic features of any surface are particularly important to sealing performance. a flange face’s surface roughness value defines its surface finish.

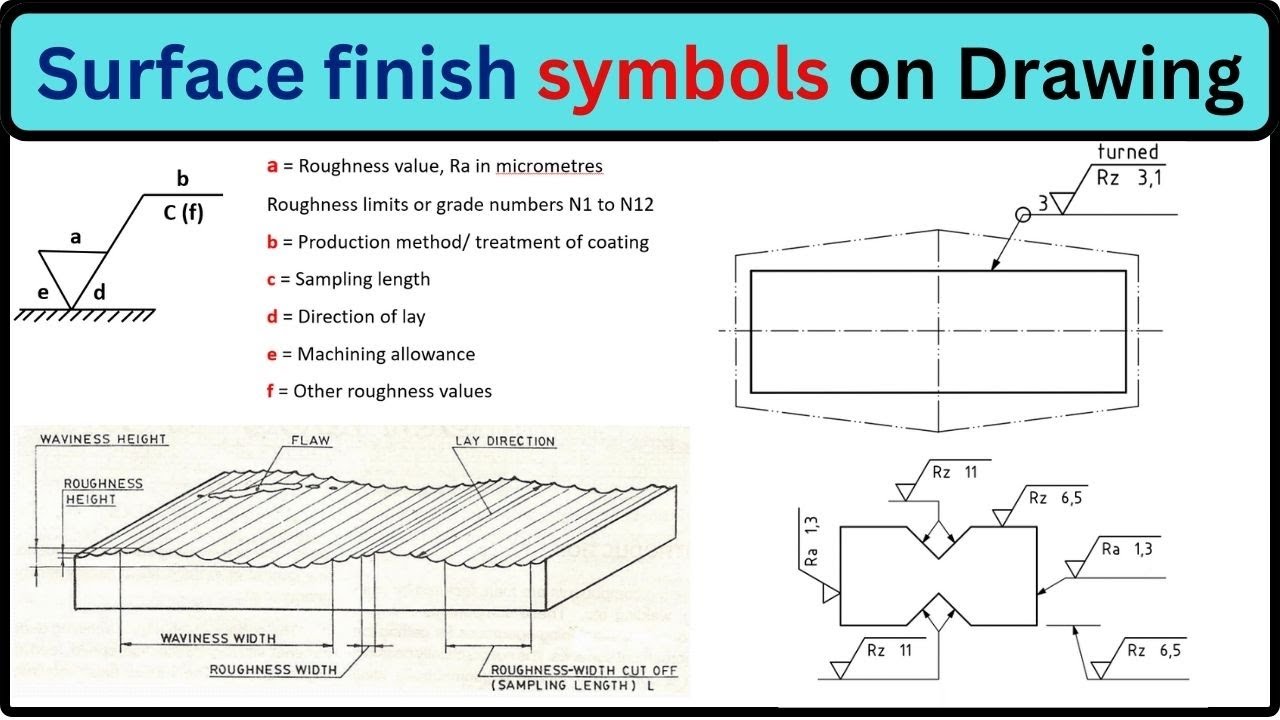

Different surface finish symbol on drawing and Surface finish of

Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. surface finish is the most important consideration when designing the groove to ensure a good seal. these microscopic features of any surface are particularly important to sealing performance. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. the right surface finish. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. The surface finish is important because it should not only. The design charts in the sections below indicate a surface roughness value not to exceed. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. a flange face’s surface roughness value defines its surface finish.

From dichvuhoicuoi.com

Download DOWNLOAD Surface Finish For Sealing Face In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. surface finish is the most important consideration when designing the groove to ensure a good seal. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. the right surface finish. in. Surface Finish For Sealing Face.

From www.ats-italia.it

Surface finish Surface Finish For Sealing Face the right surface finish. these microscopic features of any surface are particularly important to sealing performance. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. surface finish is the most important consideration when designing the groove to ensure a good seal. in fact, an optimal surface finish. Surface Finish For Sealing Face.

From blog.enerpac.com

Choosing the Right Flange Surface Finish. an Overview of ASME, ESF and Surface Finish For Sealing Face In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. a flange face’s surface roughness value defines its surface finish. The design charts in the sections below indicate a surface roughness value not to exceed. surface finish is the most important consideration when designing the groove to ensure a good. Surface Finish For Sealing Face.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Surface Finish For Sealing Face The surface finish is important because it should not only. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity. Surface Finish For Sealing Face.

From concretecoloursystems.com.au

Sealing and maintaining your concrete surface Concrete Colour Systems Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. these microscopic features of any surface are particularly important to sealing performance. The surface finish is important because it should not only. the right surface. Surface Finish For Sealing Face.

From ftl.technology

Mechanical Face Seals FTL Bespoke Sealing Solutions Surface Finish For Sealing Face the right surface finish. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. The surface finish is important because it should not only. surface finish is the most important consideration when designing. Surface Finish For Sealing Face.

From www.youtube.com

Piping Flange Types, Faces, and Surfaces Explained! YouTube Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. surface finish is the most important consideration when designing the groove to ensure a good seal. a flange face’s surface roughness value defines its surface finish. in fact, an optimal surface finish can deliver a competitive advantage. Surface Finish For Sealing Face.

From www.vrogue.co

Pipe Flange Flange Face Surface Finish vrogue.co Surface Finish For Sealing Face in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. these microscopic features of any surface are particularly important to sealing performance. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. a flange face’s surface roughness value defines its surface finish. . Surface Finish For Sealing Face.

From china-maching.com

Surface Finishing Symbols Understanding Surface Roughness ETCN Surface Finish For Sealing Face “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. surface finish is the most important consideration when designing the groove to ensure a good seal. the right surface finish. The surface finish is. Surface Finish For Sealing Face.

From www.vrogue.co

Flange Face Finish vrogue.co Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. The surface finish is important because it should not only. surface finish is the most important consideration when designing the groove to ensure a good seal. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. “what. Surface Finish For Sealing Face.

From informacionpublica.svet.gob.gt

The Basics Of Surface Finish GD&T Basics Surface Finish For Sealing Face surface finish is the most important consideration when designing the groove to ensure a good seal. the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. The surface finish is important because it should not only. in fact, an optimal surface finish can deliver a. Surface Finish For Sealing Face.

From hallite.com

Surface Roughness & Finish for Bearings and Seals Hallite Surface Finish For Sealing Face a flange face’s surface roughness value defines its surface finish. The surface finish is important because it should not only. these microscopic features of any surface are particularly important to sealing performance. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In contrast, aggressive seal wear from a poor finish. Surface Finish For Sealing Face.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish For Sealing Face The surface finish is important because it should not only. surface finish is the most important consideration when designing the groove to ensure a good seal. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. these microscopic features of any surface are particularly important to sealing performance. in. Surface Finish For Sealing Face.

From apiint.com

Guide to Flange Face Finish Types Surface Finish For Sealing Face surface finish is the most important consideration when designing the groove to ensure a good seal. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. “what is the ‘right’ surface roughness for the. Surface Finish For Sealing Face.

From savree.com

Flange Face Surfaces Explained (Serrated and Smooth) saVRee Surface Finish For Sealing Face the right surface finish. a flange face’s surface roughness value defines its surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. The design charts in the sections below indicate. Surface Finish For Sealing Face.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish For Sealing Face surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. these microscopic features of any surface are particularly important to sealing performance. The surface finish is important because it should not only. surface finish is the most important consideration when designing the groove to ensure a good seal. in. Surface Finish For Sealing Face.

From www.gtweed.com

The Right Surface Finish for Seal Mating Hardware Greene Tweed Surface Finish For Sealing Face these microscopic features of any surface are particularly important to sealing performance. The surface finish is important because it should not only. The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. surface finish is the most important consideration when designing the groove to ensure a good seal.. Surface Finish For Sealing Face.

From ahpseals.com

Seal design Viton seal American High Performance Seals Surface Finish For Sealing Face the right surface finish. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. The surface finish is important because it should not only. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. In contrast, aggressive seal wear from a poor finish on. Surface Finish For Sealing Face.

From www.gtweed.com

The Right Surface Finish for Seal Mating Hardware Greene Tweed Surface Finish For Sealing Face these microscopic features of any surface are particularly important to sealing performance. the right surface finish. a flange face’s surface roughness value defines its surface finish. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In contrast, aggressive seal wear from a poor finish on the mating surface can. Surface Finish For Sealing Face.

From saesipjoskejc.blogspot.com

画像をダウンロード oring groove design face seal 308010Oring groove design Surface Finish For Sealing Face surface finish is the most important consideration when designing the groove to ensure a good seal. The design charts in the sections below indicate a surface roughness value not to exceed. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. a flange face’s surface roughness value defines its surface finish.. Surface Finish For Sealing Face.

From blog.enerpac.com

Guide to Flange Face Finish Types Enerpac Blog Surface Finish For Sealing Face the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. The design charts in the sections below indicate a surface roughness value not to exceed. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. surface finish is the. Surface Finish For Sealing Face.

From www.youtube.com

Different surface finish symbol on drawing and Surface finish of Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. these microscopic features of any surface are particularly important to sealing performance. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. The surface finish is important because it should not only.. Surface Finish For Sealing Face.

From www.serco-tools.com

Reconditioning of sealing surfaces Surface Finish For Sealing Face in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. The surface finish is important. Surface Finish For Sealing Face.

From get-it-made.co.uk

Surface Finish Symbols Get It Made Surface Finish For Sealing Face the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. a flange face’s surface roughness value defines its surface finish. these microscopic features of any surface are particularly important to sealing performance. In contrast, aggressive seal wear from a poor finish on the mating surface. Surface Finish For Sealing Face.

From blog.thepipingmart.com

Overview of Stainless Steel Surface Finishes ThePipingMart Blog Surface Finish For Sealing Face In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. a flange face’s surface roughness value defines its surface finish. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. surface finish is the most important consideration when designing the groove to ensure. Surface Finish For Sealing Face.

From www.newequipment.com

Do You Know the Right Surface Finish for Your Seal’s Mating Hardware Surface Finish For Sealing Face in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. surface finish is the most important consideration when designing the groove to ensure a good seal. a flange face’s surface roughness value defines its surface finish. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that. Surface Finish For Sealing Face.

From www.ekkeagle.com

Surface Textured Mechanical Seal Eagle Industry Co., Ltd. Surface Finish For Sealing Face surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. surface finish is the most important consideration when designing the groove to ensure a good seal. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. The surface finish is important because it. Surface Finish For Sealing Face.

From mungfali.com

Surface Finish Symbols Printable Surface Finish For Sealing Face The surface finish is important because it should not only. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. the right surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. In contrast, aggressive seal wear from a poor finish on. Surface Finish For Sealing Face.

From www.want.net

The Ultimate Guide to Metal Surface Finishes » Surface Finish For Sealing Face The design charts in the sections below indicate a surface roughness value not to exceed. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. In contrast, aggressive seal wear from a poor finish on. Surface Finish For Sealing Face.

From www.iqsdirectory.com

Hydraulic Seals Construction, Types, Applications, and Benefits Surface Finish For Sealing Face a flange face’s surface roughness value defines its surface finish. surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. In contrast, aggressive seal wear from a poor finish on the. Surface Finish For Sealing Face.

From saesipjoskejc.blogspot.com

画像をダウンロード oring groove design face seal 308010Oring groove design Surface Finish For Sealing Face In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. the right surface finish. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. The design charts in the sections below indicate a surface roughness value not to exceed. a flange face’s surface. Surface Finish For Sealing Face.

From www.gallagherseals.com

How Surface Finish Affects Sealing Performance Surface Finish For Sealing Face In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. a flange face’s surface roughness value defines its surface finish. The design charts in the sections below indicate a surface roughness value not to exceed. The surface finish is important because it should not only. surface finish carries profound functional. Surface Finish For Sealing Face.

From jiga.io

Surface Finish Standards, Techniques, Applications, and More Surface Finish For Sealing Face a flange face’s surface roughness value defines its surface finish. in fact, an optimal surface finish can deliver a competitive advantage in seal longevity and performance. The design charts in the sections below indicate a surface roughness value not to exceed. the right surface finish. surface finish is the most important consideration when designing the groove. Surface Finish For Sealing Face.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Surface Finish For Sealing Face surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. these microscopic features of any surface are particularly important to sealing performance. In contrast, aggressive seal wear from a poor finish on the mating surface can lead to seal failure. the right surface finish. “what is the ‘right’ surface roughness. Surface Finish For Sealing Face.

From savree.com

Flange Faces Explained (Flat, Raised, etc) saVRee Surface Finish For Sealing Face surface finish carries profound functional importance in a multitude of product aspects, directly influencing friction, wear/chemical erosion. The surface finish is important because it should not only. “what is the ‘right’ surface roughness for the optimum sealing connection” is a question that arises time. The design charts in the sections below indicate a surface roughness value not to exceed.. Surface Finish For Sealing Face.