Crankshaft Position Sensor Pinout . The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. When it fails, your engine’s computer won't know the crankshaft's phase. The crankshaft position sensor (cps) is a vital sensor. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. Here’s how to fix the cps. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire.

from mungfali.com

Here’s how to fix the cps. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. When it fails, your engine’s computer won't know the crankshaft's phase. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. The crankshaft position sensor (cps) is a vital sensor. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel.

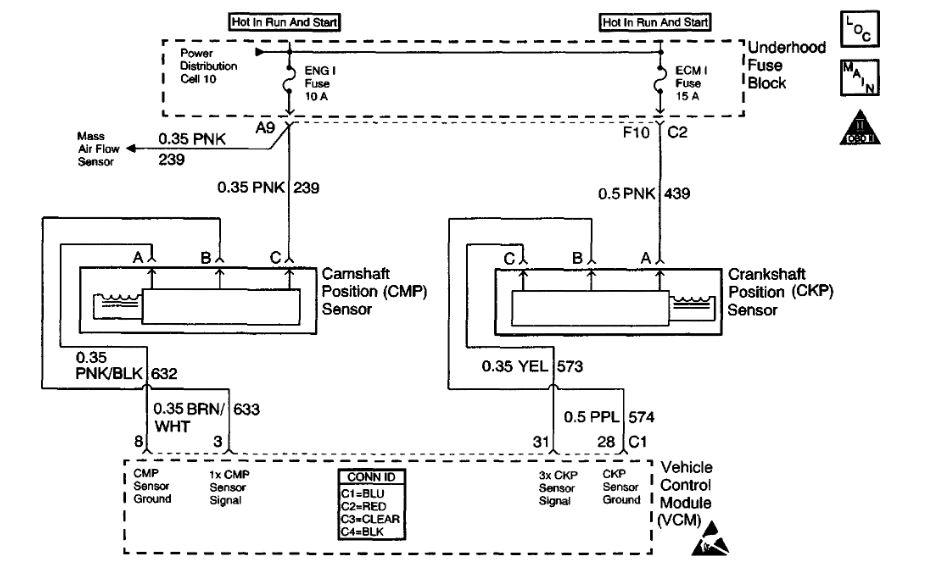

Crankshaft Position Sensor Wiring

Crankshaft Position Sensor Pinout When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. When it fails, your engine’s computer won't know the crankshaft's phase. The crankshaft position sensor (cps) is a vital sensor. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. Here’s how to fix the cps.

From wiring.hpricorpcom.com

Crank Sensor Wiring Diagram Wiring Diagram and Schematic Crankshaft Position Sensor Pinout We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also. Crankshaft Position Sensor Pinout.

From www.8thcivic.com

crankshaft position sensor pinout 8th Generation Honda Civic Forum Crankshaft Position Sensor Pinout The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. The crankshaft position sensor (cps) is a vital sensor. When it fails, your engine’s computer won't know the crankshaft's phase. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to. Crankshaft Position Sensor Pinout.

From www.2carpros.com

Crankshaft Position Sensor Wire Colors Diagram Needed? Crankshaft Position Sensor Pinout The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. When it fails, your engine’s computer won't know the crankshaft's phase. It consists of a sensor, often a hall effect or magnetic. Crankshaft Position Sensor Pinout.

From www.youtube.com

Crankshaft Position Sensor Install YouTube Crankshaft Position Sensor Pinout We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. Here’s how to fix the cps. The crankshaft position. Crankshaft Position Sensor Pinout.

From manualmanualwannemaker.z19.web.core.windows.net

2 Wire Crank Sensor Wiring Diagram Crankshaft Position Sensor Pinout The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. In short, 2 wire crank sensors operate using the signal and. Crankshaft Position Sensor Pinout.

From www.autozone.com

Repair Guides Electronic Engine Controls Crankshaft Position (ckp Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. When it fails, your engine’s computer won't know the crankshaft's phase. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger. Crankshaft Position Sensor Pinout.

From www.ls2.com

LS2 Crank Sensor wiring Crankshaft Position Sensor Pinout Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. Here’s how to fix the cps. We’ll dive into the specifics of. Crankshaft Position Sensor Pinout.

From www.2carpros.com

Crankshaft Position Sensor Pigtail Wire Diagram Needed Crankshaft Position Sensor Pinout When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. Here’s how to fix the cps. The crankshaft position sensor (cps) is a vital sensor. We’ll dive into the specifics of how each one functions and detail. Crankshaft Position Sensor Pinout.

From partdiagrambozzettaew.z21.web.core.windows.net

How To Test Crankshaft Sensor Wiring Crankshaft Position Sensor Pinout Here’s how to fix the cps. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. It consists of a sensor,. Crankshaft Position Sensor Pinout.

From diy-electronicsprojects.blogspot.com

3 wire crank sensor wiring diagram Crankshaft position sensor Crankshaft Position Sensor Pinout Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. The crankshaft position sensor (cps) is a vital sensor. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3. Crankshaft Position Sensor Pinout.

From userwiringencrinites.z19.web.core.windows.net

How To Wire A Crankshaft Position Sensor Crankshaft Position Sensor Pinout Here’s how to fix the cps. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. The. Crankshaft Position Sensor Pinout.

From wiring.hpricorpcom.com

Crank Sensor Wiring Diagram Wiring Diagram and Schematic Crankshaft Position Sensor Pinout It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. When it fails, your engine’s computer won't know the crankshaft's phase. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank. Crankshaft Position Sensor Pinout.

From www.pinterest.co.uk

the wiring diagram for an engine control system is shown in this manual Crankshaft Position Sensor Pinout Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. Here’s how to fix the cps. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. The crankshaft position sensor (cps) is a vital. Crankshaft Position Sensor Pinout.

From mavink.com

Ls1 Crank Sensor Pinout Crankshaft Position Sensor Pinout The crankshaft position sensor (cps) is a vital sensor. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. In short, 2 wire crank sensors operate. Crankshaft Position Sensor Pinout.

From www.2carpros.com

Crankshaft Position Sensor Location Where Is the Crankshaft Crankshaft Position Sensor Pinout We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. The crankshaft position sensor (cps) is a vital sensor. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. It consists of a sensor, often. Crankshaft Position Sensor Pinout.

From www.autozone.com

Repair Guides Electronic Engine Controls Crankshaft Position Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. We’ll dive into the specifics of how each one functions. Crankshaft Position Sensor Pinout.

From mungfali.com

Crankshaft Position Sensor Wiring Crankshaft Position Sensor Pinout The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. We usually recommend fitting a sensor. Crankshaft Position Sensor Pinout.

From www.youtube.com

Crankshaft Position Sensor Wiring Diagram Functions Working Crankshaft Position Sensor Pinout The crankshaft position sensor (cps) is a vital sensor. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors. Crankshaft Position Sensor Pinout.

From diagramweb.net

Delphi Crankshaft And Camshaft Position Sensor Wiring Diagram Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. Here’s how to fix the cps. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. When it fails, your. Crankshaft Position Sensor Pinout.

From www.pelicanparts.com

Pelican Parts Technical Article BMWX3 M54 Engine Crankshaft Sensor Crankshaft Position Sensor Pinout Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. The crankshaft. Crankshaft Position Sensor Pinout.

From carfromjapan.com

How To Test Camshaft And Crankshaft Position Sensors Crankshaft Position Sensor Pinout When it fails, your engine’s computer won't know the crankshaft's phase. Here’s how to fix the cps. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. The crankshaft position sensor. Crankshaft Position Sensor Pinout.

From www.justanswer.com

Cadillac Seville STS Wiring Upper Crankshaft Position Q&A Crankshaft Position Sensor Pinout The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing. Crankshaft Position Sensor Pinout.

From diy-electronicsprojects.blogspot.com

3 wire crank sensor wiring diagram Crankshaft position sensor Crankshaft Position Sensor Pinout Here’s how to fix the cps. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. In short, 2 wire crank sensors operate using the signal. Crankshaft Position Sensor Pinout.

From www.2carpros.com

Engine Cranks but Does Not Stay Started, Camshaft Position Sensor Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. Here’s how to fix the cps. When it fails, your engine’s computer won't know the. Crankshaft Position Sensor Pinout.

From diagramweb.net

Delphi Crankshaft And Camshaft Position Sensor Wiring Diagram Crankshaft Position Sensor Pinout The crankshaft position sensor (cps) is a vital sensor. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground. Crankshaft Position Sensor Pinout.

From www.denso-am.eu

How camshaft & crankshaft sensors work DENSO Crankshaft Position Sensor Pinout Here’s how to fix the cps. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3. Crankshaft Position Sensor Pinout.

From lymanbriana.blogspot.com

9+ camshaft position sensor wiring diagram LymanBriana Crankshaft Position Sensor Pinout The crankshaft position sensor (cps) is a vital sensor. Here’s how to fix the cps. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. When it fails, your engine’s computer won't know the crankshaft's phase. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors. Crankshaft Position Sensor Pinout.

From www.justanswer.com

Q&A Nissan Crankshaft Position Sensor Wiring Diagram JustAnswer Crankshaft Position Sensor Pinout We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. The crankshaft position sensor (cps) is a vital sensor. It consists of a sensor, often. Crankshaft Position Sensor Pinout.

From www.denso-am.eu

How camshaft & crankshaft sensors work DENSO Crankshaft Position Sensor Pinout We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. Here’s how to fix the cps. In short, 2 wire crank sensors operate using the signal and ground. Crankshaft Position Sensor Pinout.

From guidelibraryfurst.z19.web.core.windows.net

3wire Crank Sensor Wiring Diagram Crankshaft Position Sensor Pinout Here’s how to fix the cps. In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. When it fails, your engine’s computer won't know the crankshaft's phase. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. The crankshaft position sensor. Crankshaft Position Sensor Pinout.

From toolsweek.com

3 Wire Crank Position Sensor Wiring Diagram Crankshaft Position Sensor Pinout The crankshaft position sensor (cps) is a vital sensor. We’ll dive into the specifics of how each one functions and detail the wiring in diagrams below. When it fails, your engine’s computer won't know the crankshaft's phase. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth. Crankshaft Position Sensor Pinout.

From lymanbriana.blogspot.com

9+ camshaft position sensor wiring diagram LymanBriana Crankshaft Position Sensor Pinout Learn how to test 3 wire crank sensor with multimeter, as well as how to test a 2 wire crank sensor with a digital multimeter. The crankshaft position sensor diagram typically shows the sensor’s location in relation to the crankshaft, as well as its wiring connections. We usually recommend fitting a sensor without any inbuilt filtering as these may cause. Crankshaft Position Sensor Pinout.

From natureced.blogspot.com

Crankshaft Position Sensor Wiring Diagram Natureced Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. We usually recommend fitting a sensor without any inbuilt filtering as these may cause havoc when you’re trying to detect a missing tooth on a crank trigger wheel. The crankshaft position sensor (cps) is a vital sensor. It. Crankshaft Position Sensor Pinout.

From www.autozone.com

Repair Guides Electronic Engine Controls Crankshaft Position (ckp Crankshaft Position Sensor Pinout In short, 2 wire crank sensors operate using the signal and ground wires, while 3 wire sensors also have a power wire. It consists of a sensor, often a hall effect or magnetic sensor, and a toothed wheel or reluctor ring mounted on the crankshaft. We’ll dive into the specifics of how each one functions and detail the wiring in. Crankshaft Position Sensor Pinout.