What Is Intermediate Gear . There is a disadvantage with this. However, internal gears are more difficult to produce. General applications include rotation / power transmission of bevel gears. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. Planetary gear reducers alone are. Bevel gears with gear ratio of. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Gears involving two axis crossing at a point are called intersecting axis gears; Gears are used for transmitting power from one part of a machine to another.

from cncreplacementparts.com

Gears involving two axis crossing at a point are called intersecting axis gears; There is a disadvantage with this. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: However, internal gears are more difficult to produce. General applications include rotation / power transmission of bevel gears. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears are used for transmitting power from one part of a machine to another. Bevel gears with gear ratio of. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel.

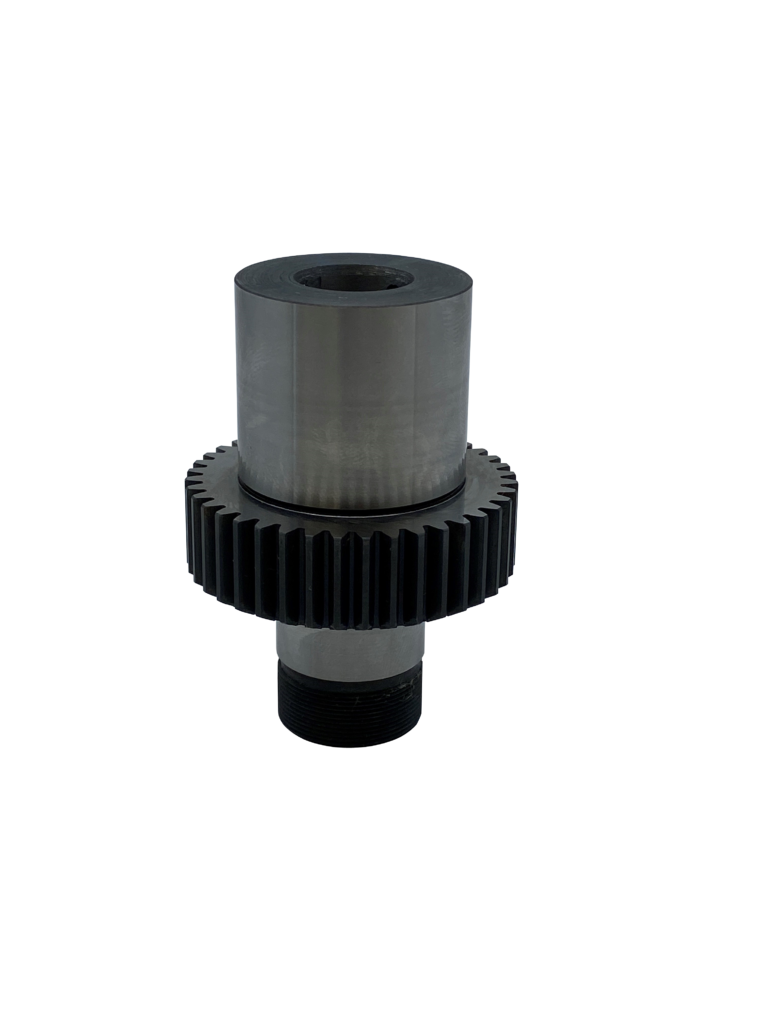

40 Tooth Intermediate Gear Threaded CNC Replacement Parts

What Is Intermediate Gear The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: However, internal gears are more difficult to produce. There is a disadvantage with this. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Gears are used for transmitting power from one part of a machine to another. General applications include rotation / power transmission of bevel gears. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears involving two axis crossing at a point are called intersecting axis gears; Planetary gear reducers alone are. Bevel gears with gear ratio of.

From woodgears.ca

Gear ratios and compound gear ratios What Is Intermediate Gear General applications include rotation / power transmission of bevel gears. However, internal gears are more difficult to produce. Gears involving two axis crossing at a point are called intersecting axis gears; Planetary gear reducers alone are. There is a disadvantage with this. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages,. What Is Intermediate Gear.

From bitfab.io

All you need to know about gears. Types and parts Bitfab What Is Intermediate Gear Gears involving two axis crossing at a point are called intersecting axis gears; There is a disadvantage with this. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other. What Is Intermediate Gear.

From www.rgmnorton.co.uk

INTERMEDIATE GEAR What Is Intermediate Gear In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: Planetary gear reducers alone are. General applications include rotation / power. What Is Intermediate Gear.

From www.researchgate.net

Schematic diagram of an intermediate gearbox. At the high rotational What Is Intermediate Gear In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. However, internal gears are more difficult to produce. General applications include rotation / power transmission of bevel gears. Gears involving two axis crossing at a point are called intersecting axis gears; Bevel gears with gear ratio of.. What Is Intermediate Gear.

From www.indiamart.com

Massey Ferguson Tractors Gears Intermediate Gear 36/46 Teeth, Sliding What Is Intermediate Gear Planetary gear reducers alone are. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. However, internal gears are more difficult to produce. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Bevel gears with. What Is Intermediate Gear.

From www.indiamart.com

Intermediate Gear Job Works in Faridabad ID 3839235248 What Is Intermediate Gear Gears involving two axis crossing at a point are called intersecting axis gears; However, internal gears are more difficult to produce. Planetary gear reducers alone are. There is a disadvantage with this. General applications include rotation / power transmission of bevel gears. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other. What Is Intermediate Gear.

From maktrans.net

Differential intermediate gear HF35 eCVT DG9P7H348CA What Is Intermediate Gear Planetary gear reducers alone are. Gears are used for transmitting power from one part of a machine to another. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Gears involving two axis crossing at a point are called intersecting axis gears; There is a disadvantage with. What Is Intermediate Gear.

From www.total911.com

Technology explained Intermediate shaft Total 911 What Is Intermediate Gear Gears are used for transmitting power from one part of a machine to another. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth. What Is Intermediate Gear.

From maktrans.net

Intermediate shaft with differential drive gear 23 teeth intermediate What Is Intermediate Gear In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Gears are used for transmitting power from one part of a machine to another. General applications include rotation / power transmission of bevel gears. Bevel gears with gear ratio of. Planetary gear reducers alone are. There is. What Is Intermediate Gear.

From www.reddit.com

Types of Gears r/coolguides What Is Intermediate Gear Gears involving two axis crossing at a point are called intersecting axis gears; Planetary gear reducers alone are. Bevel gears with gear ratio of. General applications include rotation / power transmission of bevel gears. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. In the previous. What Is Intermediate Gear.

From www.engineersgallery.com

TYPES OF GEARS Gear and Its types Mechanical Gears What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. There is a disadvantage with this. However, internal gears are more difficult to produce. Gears involving two axis crossing at a point are called intersecting axis gears; Planetary gear reducers alone are. Gears are used for transmitting power from. What Is Intermediate Gear.

From www.fvd.net

Intermediate Shaft Gear Size 1 What Is Intermediate Gear However, internal gears are more difficult to produce. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Bevel gears with gear ratio of. Gears are used for transmitting power from one part of a machine to another. The most common use of internal gears is in planetary (epicyclical). What Is Intermediate Gear.

From www.researchgate.net

Tesla Model S transmission. Gear 1 is the output ring gear and gear 2 What Is Intermediate Gear The most common use of internal gears is in planetary (epicyclical) gear reducer applications. There is a disadvantage with this. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears are used for transmitting power from one part of a machine to another. However, internal gears are more. What Is Intermediate Gear.

From www.aceindustries.com

Intermediate Gear (2657) 403J6 What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears are used for transmitting power from one part of a machine to another. Bevel gears with gear ratio of. Gears involving two axis crossing at a point are called intersecting axis gears; The most common use of internal. What Is Intermediate Gear.

From expedition-imports.com

intermediategear.html What Is Intermediate Gear There is a disadvantage with this. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. However, internal gears are more difficult to produce. Bevel gears with gear ratio of. Gears involving two axis crossing at a point are called intersecting axis gears; In a bicycle, for example, it's. What Is Intermediate Gear.

From www.hitachi-feeder.com

INTERMEDIATE GEAR 0730C0025 What Is Intermediate Gear The most common use of internal gears is in planetary (epicyclical) gear reducer applications. Bevel gears with gear ratio of. Planetary gear reducers alone are. However, internal gears are more difficult to produce. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. General applications include rotation / power. What Is Intermediate Gear.

From cottagecraftworks.com

White Mountain Intermediate Gear and Pinion Rod What Is Intermediate Gear In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Planetary gear reducers alone are. However, internal gears are more difficult to produce. Gears involving two axis crossing at a point are called intersecting axis gears; There is a disadvantage with this. The most common use of. What Is Intermediate Gear.

From www.carid.com

Crown® 83505451 5th Intermediate Gear What Is Intermediate Gear Gears are used for transmitting power from one part of a machine to another. Gears involving two axis crossing at a point are called intersecting axis gears; Bevel gears with gear ratio of. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Planetary gear reducers alone. What Is Intermediate Gear.

From www.youtube.com

24. Gear Terminology Terms used in gears YouTube What Is Intermediate Gear General applications include rotation / power transmission of bevel gears. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. There is a disadvantage with this. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In a bicycle, for example, it's gears (with the. What Is Intermediate Gear.

From cncreplacementparts.com

40 Tooth Intermediate Gear Threaded CNC Replacement Parts What Is Intermediate Gear Planetary gear reducers alone are. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gears are used for transmitting power from one part of a machine to another. There is a disadvantage with this.. What Is Intermediate Gear.

From smallfordspares.co.uk

100E7103/4 intermediate gear with shaft sleeve Gearbox and Clutch What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting. What Is Intermediate Gear.

From www.raildev.com

74 Tooth, Intermediate Gear, 5F/5H Rail Development Group What Is Intermediate Gear There is a disadvantage with this. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears. What Is Intermediate Gear.

From maktrans.net

Differential intermediate gear HF35 eCVT DG9P7H348CA What Is Intermediate Gear However, internal gears are more difficult to produce. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: General applications include rotation / power transmission of bevel gears. Gears involving two axis crossing at a point are called intersecting axis gears; There is a. What Is Intermediate Gear.

From www.exportersindia.com

Round Polished Stainless Steel OT289 Intermediate Gear, for What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. However, internal gears are more difficult to produce. Gears are used for transmitting power from one part of a machine to another. In a bicycle, for example, it's gears (with the help of a chain) that take power from. What Is Intermediate Gear.

From www.marine-deals.co.nz

Buy Winch Intermediate Gear online at MarineDeals.co.nz What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. Gears are used for transmitting power from one part of a machine to another. Gears involving two axis crossing at a point are called intersecting. What Is Intermediate Gear.

From www.flashgroup.in

GEARS & TRANSMISSIONS What Is Intermediate Gear There is a disadvantage with this. General applications include rotation / power transmission of bevel gears. Bevel gears with gear ratio of. Planetary gear reducers alone are. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: Gears are used for transmitting power from. What Is Intermediate Gear.

From www.dreamstime.com

Third Gear of the Intermediate Stock Photo Image of mechanism What Is Intermediate Gear Gears involving two axis crossing at a point are called intersecting axis gears; In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. There is a. What Is Intermediate Gear.

From somarmotor.com

Intermediate Gear Somar 4X4 The House of Jeep What Is Intermediate Gear The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: There is a disadvantage with this. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. The most common use of. What Is Intermediate Gear.

From smallfordspares.co.uk

100E7103/4 intermediate gear with shaft sleeve Gearbox and Clutch What Is Intermediate Gear The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. There is a disadvantage with this. Bevel gears with gear ratio of. The simplest form of an intermdiate gear is simply a single gear (the. What Is Intermediate Gear.

From maktrans.net

Differential intermediate gear HF35 eCVT DG9P7H348CA What Is Intermediate Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: General applications include rotation / power transmission of bevel gears. In a bicycle,. What Is Intermediate Gear.

From www.theengineerspost.com

12 Different Types of Gears and Their Applications [PDF] What Is Intermediate Gear There is a disadvantage with this. The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals. What Is Intermediate Gear.

From cobratransmission.com

ATC35L Intermediate Gear What Is Intermediate Gear The most common use of internal gears is in planetary (epicyclical) gear reducer applications. Bevel gears with gear ratio of. Gears involving two axis crossing at a point are called intersecting axis gears; However, internal gears are more difficult to produce. There is a disadvantage with this. In a bicycle, for example, it's gears (with the help of a chain). What Is Intermediate Gear.

From www.steinertractor.com

Allis Chalmers WD45 PTO Intermediate Drive Gear 227323 ACS008 What Is Intermediate Gear In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. The simplest form of an intermdiate gear is simply a single gear (the intermediate gear) connecting two other gears like shown in the example diagram below: The most common use of internal gears is in planetary (epicyclical). What Is Intermediate Gear.

From www.dreamstime.com

Third Gear of the Intermediate Stock Photo Image of concept, metallic What Is Intermediate Gear Planetary gear reducers alone are. In a bicycle, for example, it's gears (with the help of a chain) that take power from the pedals to the back wheel. Bevel gears with gear ratio of. There is a disadvantage with this. General applications include rotation / power transmission of bevel gears. Gears are used for transmitting power from one part of. What Is Intermediate Gear.

From www.multinationalparts.com

Starter Gear Intermediate Gear, 30T, UTV, Odes, 800cc Multi What Is Intermediate Gear Gears are used for transmitting power from one part of a machine to another. Gears involving two axis crossing at a point are called intersecting axis gears; The most common use of internal gears is in planetary (epicyclical) gear reducer applications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. What Is Intermediate Gear.