Hopper Extruder . One end of the barrel is attached to the feed throat while the. 2.1) consists of a screw in a metal cylinder or barrel. The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. It is used to hold and feed plastic material into the extruder (see. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding.

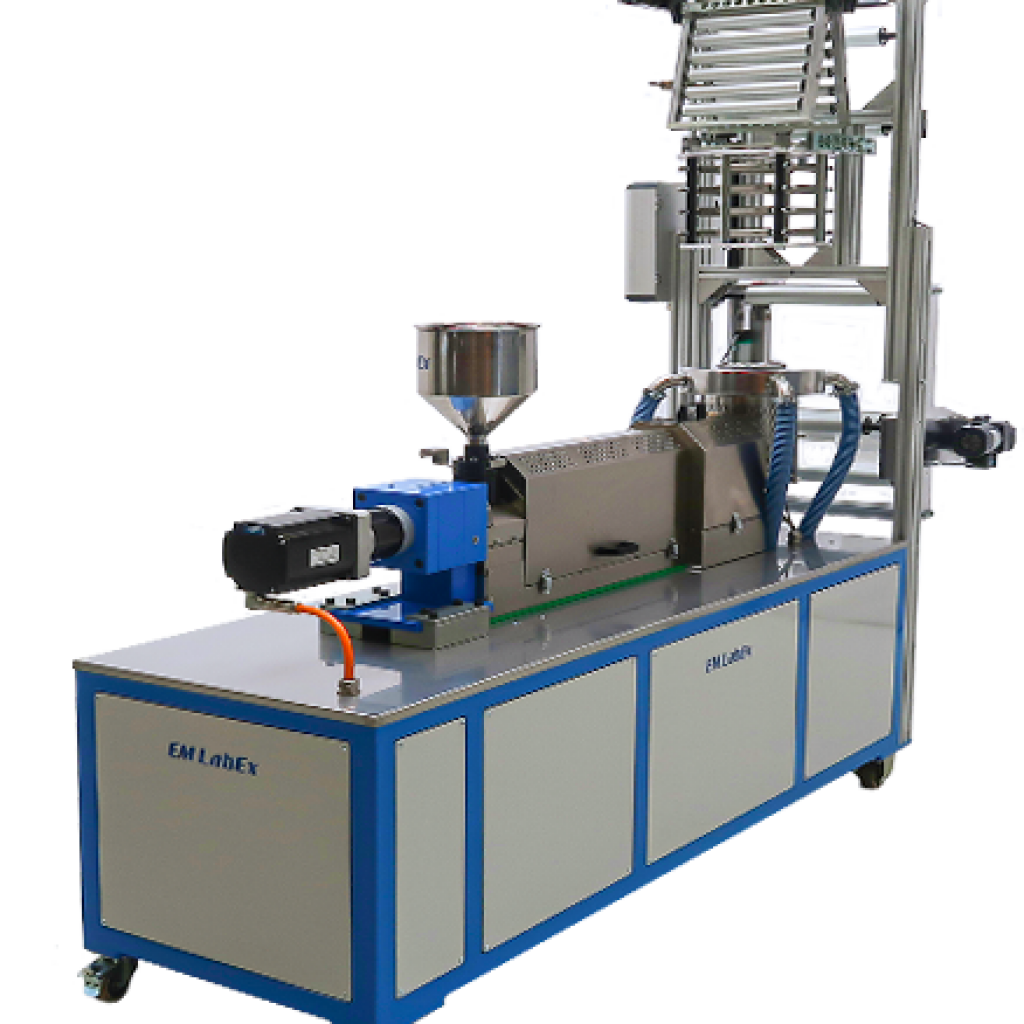

from www.em-labex.com

The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. It is used to hold and feed plastic material into the extruder (see. 2.1) consists of a screw in a metal cylinder or barrel. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. One end of the barrel is attached to the feed throat while the.

Hoppers for material Lab extruder for testing film

Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. One end of the barrel is attached to the feed throat while the. The material is gradually melted. 2.1) consists of a screw in a metal cylinder or barrel. It is used to hold and feed plastic material into the extruder (see. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder.

From avonlakesheetmetal.com

Extruder Feed Hopper Project Avon Lake Sheet Metal Hopper Extruder The material is gradually melted. 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached to the barrel at the. Hopper Extruder.

From www.ptonline.com

Extrusion How Hopper Crammers Can Help Feeding Plastics Technology Hopper Extruder 2.1) consists of a screw in a metal cylinder or barrel. The hopper is the material holding unit attached to the barrel at the feed port. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The material is. Hopper Extruder.

From www.kreyenborg.com

Extruder feeding system. Special feed hopper. Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. 2.1) consists of a screw in a metal cylinder or barrel. The hopper is the material holding unit attached to the barrel at the feed port. It is used to hold and feed plastic. Hopper Extruder.

From www.italgi.it

P250DV Double hopper pasta machine (Pasta extruder) Hopper Extruder The material is gradually melted. The hopper is the material holding unit attached to the barrel at the feed port. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a. Hopper Extruder.

From yyguotai.en.made-in-china.com

Hopper Dryer for Plastic Extruder Hopper Dryer Price and Plastic Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or. Hopper Extruder.

From www.researchgate.net

Isometric view of the extruder.AHopper, BFeeding Conveyor, CExtruder Hopper Extruder The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached to the barrel at the feed port. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the. Hopper Extruder.

From www.alibaba.com

Industrial Plastic Hopper For Extruder/plastic Drying Machine Buy Hopper Extruder The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. It is used to hold and feed plastic material into the extruder (see. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into. Hopper Extruder.

From www.youtube.com

Boyu Extruder Feeding Hopper YouTube Hopper Extruder The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached to the barrel at the feed port. It is used to hold and feed plastic material into the extruder (see. 2.1). Hopper Extruder.

From www.filabot.com

EX6 Extruder Hopper Filabot Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The material is gradually melted. One end of the barrel is attached to the feed throat while the. It is used to hold and feed plastic material into the extruder (see. 2.1) consists of. Hopper Extruder.

From www.plastic-recyclingequipment.com

Iron Body 1.5kw Extruder Hopper , 900mm Storage Height Screw Feeder Hopper Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. One end of the barrel is attached to the feed throat while the. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. 2.1) consists of a screw in. Hopper Extruder.

From www.adtechextrusionmachinery.com

SPIRAL HOPPER LOADER Adtech Extrusion Machinery Llp Ahmedabad Hopper Extruder This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. One end of the barrel is attached to the feed throat while the.. Hopper Extruder.

From www.alibaba.com

Feeding Masterbatch Pellets Plastic Extruder Hopper Automatic Screw Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is. Hopper Extruder.

From lvextrusion.ru

Loading hopper LVExtrusion Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. It is used to hold and feed plastic material into the extruder (see. The material is gradually melted. One end of the barrel is. Hopper Extruder.

From hsextruder.en.made-in-china.com

Automatic Screw Feeder Feeding Hopper in Extrusion Line China Feeder Hopper Extruder It is used to hold and feed plastic material into the extruder (see. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through. Hopper Extruder.

From www.arlingtonmachinery.com

60" Diameter S/S Extruder Hopper, Plastic Machinery Used Plastic Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. One end of the barrel is attached to the feed throat while the. The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic. Hopper Extruder.

From www.arlingtonmachinery.com

Used 36" x 36" Davis Standard Stainless Steel Hopper For 6" Extruder Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. It is used to hold and feed plastic material into the extruder (see. The feeding method of a large. Hopper Extruder.

From www.haisiextrusion.com

Small Output Twin Screw Extruder for PET Recycle with Big Hopper Hopper Extruder 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel. Hopper Extruder.

From www.doteco.com

Extrumate Gravimetric hopper and extrusion control Doteco Hopper Extruder The material is gradually melted. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The hopper is the material holding unit attached to the barrel at the feed port. 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or. Hopper Extruder.

From www.autoinjectionmoldingmachine.com

Fully Automatic Injection Molding Hopper , Vacuum Hopper Loaders For Hopper Extruder One end of the barrel is attached to the feed throat while the. It is used to hold and feed plastic material into the extruder (see. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is. Hopper Extruder.

From www.alibaba.com

Plastic Vacuum Hopper Auto Loader For Extruder Hopper Auto Loader Hopper Extruder It is used to hold and feed plastic material into the extruder (see. The material is gradually melted. One end of the barrel is attached to the feed throat while the. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The feeding method of a large extruder or. Hopper Extruder.

From www.iqsdirectory.com

Plastic Extrusion What Is It? How Does It Work? Process Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such. Hopper Extruder.

From www.alibaba.com

Professional Hot Air Extruder Hopper Dryer With High Quality Buy Hot Hopper Extruder It is used to hold and feed plastic material into the extruder (see. One end of the barrel is attached to the feed throat while the. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. In single screw extruders, a screw mixer melts the entering plastic materials, pushes. Hopper Extruder.

From auxiliaryequipment.process-control.com

HGSeries 2 GRAVITROL® Weigh Hoppers On Process Control Corp. Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. It is used to hold and feed plastic material into the extruder (see. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. This. Hopper Extruder.

From tairongmachinery.en.made-in-china.com

China Plastic Hopper Dryer / Hopper Drier / Extruder Hopper Dyier Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. One end of the barrel is attached to the feed throat while the. The hopper is the material holding unit attached to the barrel at the feed port. The feeding method of a large. Hopper Extruder.

From www.em-labex.com

Hoppers for material Lab extruder for testing film Hopper Extruder One end of the barrel is attached to the feed throat while the. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring. Hopper Extruder.

From theaiminstitute.com

Better check what’s going into your feed hopper AIM Institute Hopper Extruder 2.1) consists of a screw in a metal cylinder or barrel. It is used to hold and feed plastic material into the extruder (see. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. This process starts by feeding plastic material (pellets, granules, flakes. Hopper Extruder.

From www.alibaba.com

Feeding Machine Screw Extruder Hopper Plastic Loader Buy Plastic Hopper Extruder This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached. Hopper Extruder.

From www.haisiextrusion.com

Small Output Twin Screw Extruder for PET Recycle with Big Hopper Hopper Extruder This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. It is used to hold and feed plastic material into the extruder (see. The hopper is the material holding unit attached to the barrel at the feed port. One end of the barrel is attached to the feed throat. Hopper Extruder.

From www.kreyenborg.com

Extruder feeding system. Special feed hopper. Hopper Extruder One end of the barrel is attached to the feed throat while the. The material is gradually melted. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. 2.1) consists of a screw in a metal cylinder or barrel. In single screw extruders, a screw mixer melts the entering. Hopper Extruder.

From www.arlingtonmachinery.com

60" Diameter S/S Extruder Hopper, Plastic Machinery Used Plastic Hopper Extruder 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel. Hopper Extruder.

From www.youtube.com

UsedCincinnati Milacron Extruder Crammer Feeder Hopper stock Hopper Extruder The hopper is the material holding unit attached to the barrel at the feed port. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the. Hopper Extruder.

From noztek.com

Extended Vertical Hopper Noztek Extrusion Systems Hopper Extruder In single screw extruders, a screw mixer melts the entering plastic materials, pushes the material through the extruder, and forms the plastic into the desired shape. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The hopper is the material holding unit attached to the barrel at the. Hopper Extruder.

From www.arlingtonmachinery.com

60" Diameter S/S Extruder Hopper, Plastic Machinery Used Plastic Hopper Extruder It is used to hold and feed plastic material into the extruder (see. The material is gradually melted. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. 2.1) consists of a screw in a metal cylinder or barrel. The feeding method of a large extruder or a parallel. Hopper Extruder.

From www.filabot.com

EX6 Extruder Hopper Filabot Hopper Extruder The feeding method of a large extruder or a parallel production hopper with multiple extruders can adopt methods such as spring feeding, vacuum feeding, and compressed air pipeline transportation for feeding. The hopper is the material holding unit attached to the barrel at the feed port. 2.1) consists of a screw in a metal cylinder or barrel. This process starts. Hopper Extruder.

From ahkaifeng.en.made-in-china.com

Hopper Dryer and Hopper for Extruder Auxiliary Equipment China Used Hopper Extruder It is used to hold and feed plastic material into the extruder (see. 2.1) consists of a screw in a metal cylinder or barrel. This process starts by feeding plastic material (pellets, granules, flakes or powders) from a hopper into the barrel of the extruder. The material is gradually melted. The hopper is the material holding unit attached to the. Hopper Extruder.