Shaft Spline Damage . In the marine industry, gland packing and bushing damage to the shaft together with. This allows repairs of spline shafts and keyways. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Stripped spline shafts can be returned to service using. Some failed shafts can be repaired and others can't. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. The design allows them to. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. One of the best features of metalink™ polymers is their incredible compression strength. Here are some key maintenance practices to keep your spline shafts in optimal condition: Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines.

from www.powertransmissionworld.com

When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Stripped spline shafts can be returned to service using. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. In the marine industry, gland packing and bushing damage to the shaft together with. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. One of the best features of metalink™ polymers is their incredible compression strength. This allows repairs of spline shafts and keyways. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Some failed shafts can be repaired and others can't. Here are some key maintenance practices to keep your spline shafts in optimal condition:

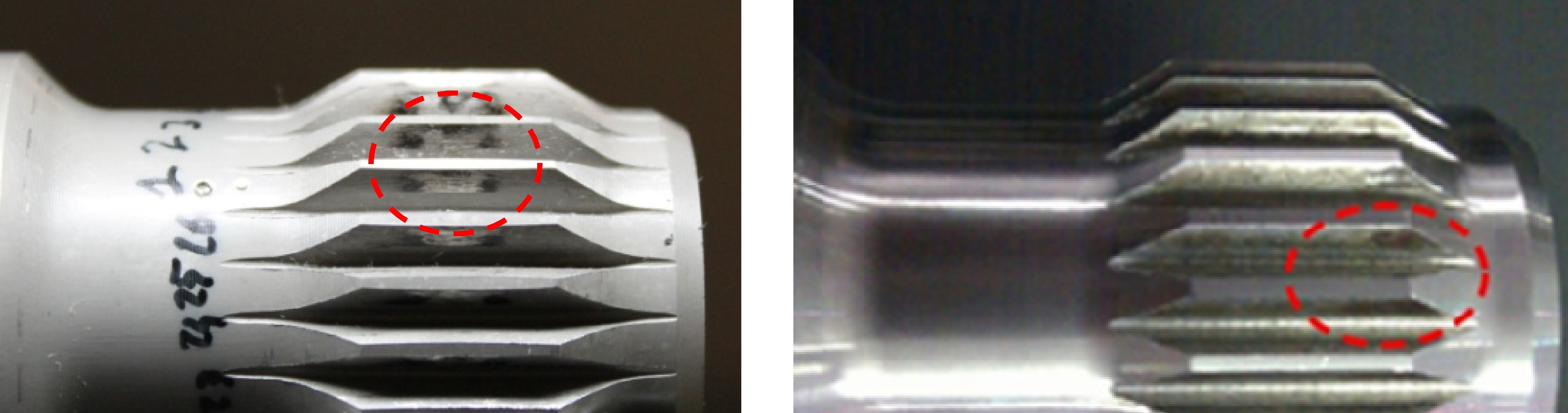

Fretting wear damage in crowned splined couplings Power Transmission

Shaft Spline Damage Some failed shafts can be repaired and others can't. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. Stripped spline shafts can be returned to service using. Here are some key maintenance practices to keep your spline shafts in optimal condition: Some failed shafts can be repaired and others can't. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. One of the best features of metalink™ polymers is their incredible compression strength. This allows repairs of spline shafts and keyways. The design allows them to. In the marine industry, gland packing and bushing damage to the shaft together with. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production.

From www.maverickforums.net

Stripped Rear gearbox output shaft splines Page 2 CanAm Maverick Forum Shaft Spline Damage Some failed shafts can be repaired and others can't. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. In the marine industry, gland packing and bushing damage to the shaft together with. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. This allows repairs of. Shaft Spline Damage.

From www.xrv.org.uk

Output shaft splines stuffed? Page 3 Honda XRV Forum Shaft Spline Damage This allows repairs of spline shafts and keyways. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. The design allows them to. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Periodically inspect the spline shaft for signs of wear,. Shaft Spline Damage.

From forum.ih8mud.com

4 speed output shaft spline wear repair. IH8MUD Forum Shaft Spline Damage The design allows them to. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. One of the best features of metalink™ polymers is their incredible compression strength. Characterized by their distinct ridges, known as splines, these. Shaft Spline Damage.

From www.researchgate.net

(a) Schematic diagram of a drive shaft spline, (b) photograph of the Shaft Spline Damage When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Some failed shafts can be repaired and others can't. Stripped spline shafts can be returned to service using. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. In the marine industry, gland. Shaft Spline Damage.

From www.youtube.com

Repairing Damaged Axle Shaft Threads YouTube Shaft Spline Damage This allows repairs of spline shafts and keyways. One of the best features of metalink™ polymers is their incredible compression strength. Here are some key maintenance practices to keep your spline shafts in optimal condition: Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Stripped spline shafts can be returned to service using.. Shaft Spline Damage.

From www.powertransmissionworld.com

Fretting wear damage in crowned splined couplings Power Transmission Shaft Spline Damage When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. One of the best features of metalink™ polymers is their incredible compression strength. Characterized by their distinct ridges, known as splines, these shafts can feature internal or. Shaft Spline Damage.

From www.eng-tips.com

motor spline failure Transmission, Driveline, Hybrid Drive Shaft Spline Damage One of the best features of metalink™ polymers is their incredible compression strength. In the marine industry, gland packing and bushing damage to the shaft together with. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Stripped spline shafts can be returned to service using. Periodically inspect the spline shaft for signs. Shaft Spline Damage.

From www.powertransmissionworld.com

Fretting wear damage in crowned splined couplings Power Transmission Shaft Spline Damage Some failed shafts can be repaired and others can't. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. In the marine industry, gland packing and bushing damage to the shaft together with. The design allows them to. Here are some key maintenance practices to keep your spline shafts in optimal condition: Stripped. Shaft Spline Damage.

From www.powertransmissionworld.com

Fretting wear damage in crowned splined couplings Power Transmission Shaft Spline Damage Here are some key maintenance practices to keep your spline shafts in optimal condition: Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. The design allows them to. This allows repairs of spline shafts and keyways. Stripped spline shafts can be. Shaft Spline Damage.

From www.youtube.com

How to Connect Broken Spline Shaft with using Amazing Tool // Drive Shaft Spline Damage This allows repairs of spline shafts and keyways. Stripped spline shafts can be returned to service using. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. Here are some key maintenance practices to keep your spline shafts in optimal condition: One of the best features of metalink™ polymers is their incredible compression strength. Shafts are critical components. Shaft Spline Damage.

From www.mdpi.com

Lubricants Free FullText A Review of Aviation Spline Research Shaft Spline Damage Here are some key maintenance practices to keep your spline shafts in optimal condition: Some failed shafts can be repaired and others can't. The design allows them to. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. In the mining industry, shafts can become worn or damaged due. Shaft Spline Damage.

From www.reddit.com

Don't to check the splines on your CV axles before fighting with Shaft Spline Damage When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Some failed shafts can be repaired and others can't. Stripped spline shafts can be returned to service using. This allows repairs of spline shafts and keyways. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. Shafts. Shaft Spline Damage.

From www.eng-tips.com

Failed Splined Shaft, Interesting Fracture Zone Gear & Pulley Shaft Spline Damage In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. In the marine industry, gland packing and bushing damage to the shaft together with. Some failed shafts can be repaired and others can't. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Here are some key. Shaft Spline Damage.

From www.youtube.com

Making Spline Shafts For a GEARBOX (Internal Splines too) YouTube Shaft Spline Damage Stripped spline shafts can be returned to service using. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. One of the best features of metalink™ polymers is their incredible compression strength. Some failed shafts can be repaired and others can't. In the marine industry, gland packing and bushing damage to the shaft together. Shaft Spline Damage.

From www.eng-tips.com

Failed Splined Shaft, Interesting Fracture Zone Gear & Pulley Shaft Spline Damage In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Some failed shafts can be repaired and others can't. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace. Shaft Spline Damage.

From mungfali.com

Spline Shaft Coupling Shaft Spline Damage The design allows them to. Stripped spline shafts can be returned to service using. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Here are some key maintenance practices to keep your spline shafts in optimal condition: Some failed shafts can be repaired and others can't. One of. Shaft Spline Damage.

From answertion.com

Damaged axle spline Q&A Answertion Shaft Spline Damage When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. One of the best features of metalink™ polymers is their incredible compression strength. Stripped spline shafts can be returned to service using.. Shaft Spline Damage.

From exobnyuht.blob.core.windows.net

Shaft Spline Types at Melody Williams blog Shaft Spline Damage Periodically inspect the spline shaft for signs of wear, corrosion, or damage. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Some failed shafts can be repaired and others can't. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. One of. Shaft Spline Damage.

From ls1tech.com

Whos taken the splines off the input shaft with an RXT? LS1TECH Shaft Spline Damage Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Some failed shafts can be repaired and others can't. Here are some key maintenance practices to keep your spline shafts in optimal condition: The design allows them to. In the marine industry, gland packing and bushing damage to the shaft together with. When your. Shaft Spline Damage.

From forum.ih8mud.com

Transmission output shaft damage IH8MUD Forum Shaft Spline Damage In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. This allows repairs of spline shafts and keyways. Some failed shafts can be repaired and others can't. Stripped spline shafts can be returned to service using. One of the best features of metalink™ polymers is their incredible compression strength. Periodically inspect the spline. Shaft Spline Damage.

From www.techtalk.ie

Clutch does not disengage. techtalk.ie Shaft Spline Damage Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. The design allows them to. One of the best features of metalink™ polymers is their incredible compression strength. In the marine industry, gland packing and bushing damage to the shaft together with. Some failed shafts can be repaired and others can't. Stripped spline shafts. Shaft Spline Damage.

From www.tr-register.co.uk

Drive shaft spline damage TR5/250 Forum TR Register Forum Shaft Spline Damage In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. In the marine industry, gland packing and bushing damage to the. Shaft Spline Damage.

From actionclutch.com

Troubleshooting Guide Action Clutch Shaft Spline Damage Some failed shafts can be repaired and others can't. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. Stripped spline shafts can be returned to service using. Here are some key maintenance practices to keep your spline shafts in optimal condition: The design allows them to. Periodically inspect the spline shaft for signs. Shaft Spline Damage.

From www.youtube.com

The Broken Gear Inputshaft splines repairing in very successfully Most Shaft Spline Damage This allows repairs of spline shafts and keyways. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with. Shaft Spline Damage.

From drriders.com

Countershaft spline damage Shaft Spline Damage One of the best features of metalink™ polymers is their incredible compression strength. Stripped spline shafts can be returned to service using. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. The design allows them to. Characterized by their distinct ridges, known as splines, these shafts can feature. Shaft Spline Damage.

From www.pirate4x4.com

Cause of rockwell shaft damage? 4x4 and OffRoad Forum Shaft Spline Damage Stripped spline shafts can be returned to service using. The design allows them to. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Some failed shafts can be repaired and others can't. Periodically inspect the spline shaft for signs of wear, corrosion, or damage. Shafts are critical components of many machines, and. Shaft Spline Damage.

From cbr.intercars.eu

Centrum Badawczo Rozwojowe Inter Cars Shaft Spline Damage Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. The design allows them to. Some failed shafts can be repaired and others can't. This allows repairs of spline shafts and keyways. In. Shaft Spline Damage.

From www.slideserve.com

PPT BAB Steering presents PowerPoint Presentation, free download ID Shaft Spline Damage Periodically inspect the spline shaft for signs of wear, corrosion, or damage. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. Some failed shafts can be repaired and others can't. Stripped spline shafts can be returned to service using. The design allows them to. When your splined shaft suffers damage or you. Shaft Spline Damage.

From www.smlease.com

Shaft Splines and Serrations SMLease Design Shaft Spline Damage Here are some key maintenance practices to keep your spline shafts in optimal condition: Periodically inspect the spline shaft for signs of wear, corrosion, or damage. This allows repairs of spline shafts and keyways. Stripped spline shafts can be returned to service using. Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Some. Shaft Spline Damage.

From www.passagemaker.com

Troubleshooter Preventing Shaft Failure PassageMaker Shaft Spline Damage Here are some key maintenance practices to keep your spline shafts in optimal condition: Shafts are critical components of many machines, and a damaged shaft can hamper or halt production. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. The design allows them to. Some failed shafts can. Shaft Spline Damage.

From www.bmwsporttouring.com

Spline failure Oilheads BMWSportTouring Shaft Spline Damage The design allows them to. In the mining industry, shafts can become worn or damaged due to vibration, friction and abrasive media. This allows repairs of spline shafts and keyways. In the marine industry, gland packing and bushing damage to the shaft together with. Some failed shafts can be repaired and others can't. Here are some key maintenance practices to. Shaft Spline Damage.

From www.commanderforums.org

Rear axle splines stripped out CanAm Commander Forum Shaft Spline Damage Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Some failed shafts can be repaired and others can't. Here are some key maintenance practices to keep your spline shafts in optimal condition: When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another.. Shaft Spline Damage.

From appliedmaintenance.com

Spline Shaft Repair Kit Shaft Spline Damage When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. This allows repairs of spline shafts and keyways. Here are some key maintenance practices to keep your spline shafts in optimal condition: Characterized by their distinct ridges, known as splines, these shafts can feature internal or external splines. Periodically. Shaft Spline Damage.

From lotuselan.net

Drive Shaft Failures Drive Train / Gearbox / Final Drive by Shaft Spline Damage One of the best features of metalink™ polymers is their incredible compression strength. Stripped spline shafts can be returned to service using. Some failed shafts can be repaired and others can't. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Characterized by their distinct ridges, known as splines,. Shaft Spline Damage.

From www.jlwranglerforums.com

Rear Axle Shaft Leak and Spline Damage Jeep Wrangler Forums (JL / JLU Shaft Spline Damage Here are some key maintenance practices to keep your spline shafts in optimal condition: Periodically inspect the spline shaft for signs of wear, corrosion, or damage. When your splined shaft suffers damage or you notice wear and tear one option is to simply replace it with another. Some failed shafts can be repaired and others can't. Stripped spline shafts can. Shaft Spline Damage.