Gear Pump Mechanical Efficiency . Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. The gear meshing friction is found. Determining a pump's mechanical/hydraulic efficiency. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated.

from chemicalengineeringworld.com

In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. Determining a pump's mechanical/hydraulic efficiency. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. The gear meshing friction is found. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures.

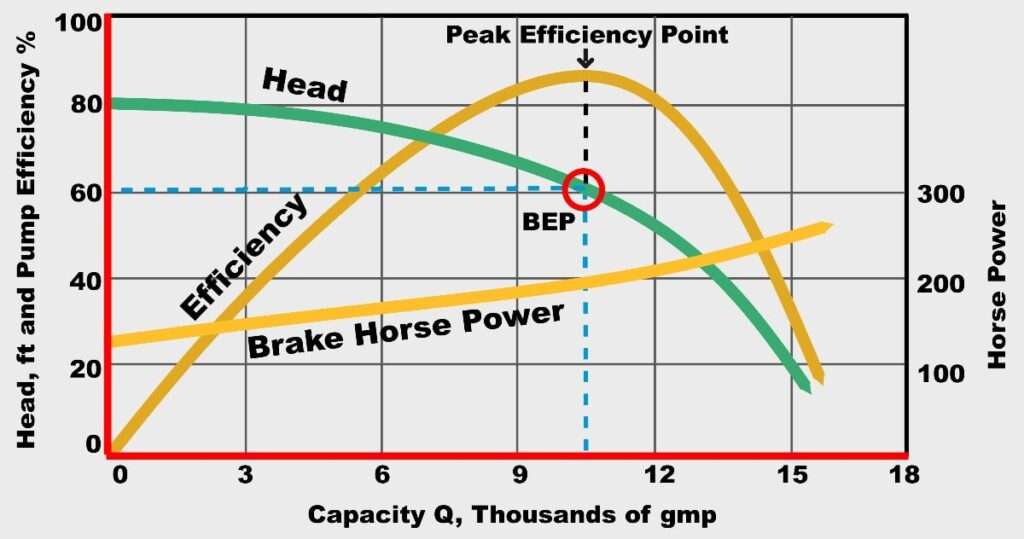

Pump Performance Curve Chemical Engineering World

Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. The gear meshing friction is found. Determining a pump's mechanical/hydraulic efficiency.

From www.sepump.net

How to Read a Pump Curve Southeast Pump Specialist Repair and Service Gear Pump Mechanical Efficiency A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. Determining a pump's mechanical/hydraulic efficiency. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. A. Gear Pump Mechanical Efficiency.

From www.yishgpump.com

Working principle of hydraulic gear pump Guangdong YiHe Hydraulic Gear Pump Mechanical Efficiency A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Determining a pump's mechanical/hydraulic efficiency. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive. Gear Pump Mechanical Efficiency.

From www.researchgate.net

Example pump performance and efficiency curves. Download Scientific Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. The gear meshing friction is found. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Determining a pump's mechanical/hydraulic efficiency. In this work, the volumetric efficiency dependence on the operating. Gear Pump Mechanical Efficiency.

From www.pumpsandsystems.com

Gear Pumps for Demanding Applications Pumps & Systems Gear Pump Mechanical Efficiency In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. The gear meshing friction is found. A. Gear Pump Mechanical Efficiency.

From mollaengineering.blogspot.com

What are the types of the gear pumps? With neat sketch discuss Gear Pump Mechanical Efficiency The gear meshing friction is found. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Determining. Gear Pump Mechanical Efficiency.

From savree.com

Gear Pump (What Are Gear Pumps?) Explained saVRee saVRee Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. The gear meshing friction is found. A new method has been developed that formulates the volumetric. Gear Pump Mechanical Efficiency.

From webmotor.org

How To Calculate Overall Efficiency Of Pump And Motor Gear Pump Mechanical Efficiency A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. This paper presents. Gear Pump Mechanical Efficiency.

From engineerexcel.com

Pump Efficiency Explained EngineerExcel Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. The gear meshing friction is found. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that. Gear Pump Mechanical Efficiency.

From www.linquip.com

7 Parts of Gear Pump and Function + Diagram & Applications Linquip Gear Pump Mechanical Efficiency Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. The gear meshing friction is found. Determining a pump's mechanical/hydraulic efficiency. A new method has been developed that formulates the volumetric efficiency as a function of. Gear Pump Mechanical Efficiency.

From blog.chesterton.com

Using the Pump Performance Curve to Increase Pump Efficiency & Save Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A mechanical/hydraulic efficiency of 100% would mean. Gear Pump Mechanical Efficiency.

From blog.thepipingmart.com

13 Different Types Of Pumps and Their Uses Gear Pump Mechanical Efficiency The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would.. Gear Pump Mechanical Efficiency.

From learnmech.com

Mechanical Drives Belt, Chain, Gear Advantages and Disadvantages Gear Pump Mechanical Efficiency Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. Determining a pump's mechanical/hydraulic efficiency. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck. Gear Pump Mechanical Efficiency.

From mollaengineering.blogspot.com

Explain the working principle of external gear pump with sketch. Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. The gear meshing friction is found. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered.. Gear Pump Mechanical Efficiency.

From learnchannel-tv.com

Hydraulic Pumps Gear Pump Mechanical Efficiency In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. A new method has been developed that formulates the volumetric efficiency as a function of a single. Gear Pump Mechanical Efficiency.

From www.mr-cfd.com

Internal Gear Pump CFD Simulation, ANSYS Fluent Training MR CFD Gear Pump Mechanical Efficiency The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the. Gear Pump Mechanical Efficiency.

From mollaengineering.blogspot.com

What are the types of the gear pumps? With neat sketch discuss Gear Pump Mechanical Efficiency A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined. Gear Pump Mechanical Efficiency.

From www.slideserve.com

PPT Water Pumps PowerPoint Presentation, free download ID5243000 Gear Pump Mechanical Efficiency In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Determining. Gear Pump Mechanical Efficiency.

From www.slideserve.com

PPT Fluid Mechanics Lab Positive Displacement Pumps PowerPoint Gear Pump Mechanical Efficiency The gear meshing friction is found. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing. Gear Pump Mechanical Efficiency.

From www.pumpsandsystems.com

How to Define & Measure Centrifugal Pump Efficiency Part 1 Pumps Gear Pump Mechanical Efficiency A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. Determining a pump's mechanical/hydraulic efficiency. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow. Gear Pump Mechanical Efficiency.

From www.growmechanical.com

Centrifugal pump characteristic curves Grow Mechanical Gear Pump Mechanical Efficiency Determining a pump's mechanical/hydraulic efficiency. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. This. Gear Pump Mechanical Efficiency.

From www.saivs-industrial.com

Internal Gear Pumps A Complete OverviewBLOGSAIVS Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. The gear meshing friction is found. Determining a pump's mechanical/hydraulic efficiency. A pump's mechanical/hydraulic efficiency is determined by dividing. Gear Pump Mechanical Efficiency.

From www.animalia-life.club

Hydraulic Gear Pump Diagram Gear Pump Mechanical Efficiency In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Determining a pump's mechanical/hydraulic efficiency. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A new method has been developed that formulates the volumetric efficiency as a function of a. Gear Pump Mechanical Efficiency.

From www.youtube.com

Gear Pump Working Principle How does gear pump work? Gear Pump Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. The gear meshing friction is found. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. A new method has been developed that formulates the volumetric. Gear Pump Mechanical Efficiency.

From www.researchgate.net

Pump efficiency map (contour lines in percentage). Download Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces. Gear Pump Mechanical Efficiency.

From www.youtube.com

Fluid Mechanics Topic 7.3.3 Definition of pump efficiency & turbine Gear Pump Mechanical Efficiency The gear meshing friction is found. Determining a pump's mechanical/hydraulic efficiency. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. In this work, the volumetric efficiency dependence on the operating speed and. Gear Pump Mechanical Efficiency.

From www.researchgate.net

Exploded view of an external gear pump (a) components of a pump Gear Pump Mechanical Efficiency The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. A. Gear Pump Mechanical Efficiency.

From www.animalia-life.club

Hydraulic Gear Pump Diagram Gear Pump Mechanical Efficiency Determining a pump's mechanical/hydraulic efficiency. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. In this work, the volumetric efficiency dependence on the operating speed and. Gear Pump Mechanical Efficiency.

From www.slideserve.com

PPT Pumps Lectures 1 PowerPoint Presentation, free download ID Gear Pump Mechanical Efficiency The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. Determining a pump's mechanical/hydraulic efficiency. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. A new method has been developed that formulates the volumetric efficiency as. Gear Pump Mechanical Efficiency.

From www.youtube.com

Mechanisms of Hydraulic External Gear Pump Mechanical Principles Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. In this work, the volumetric efficiency dependence on the operating speed and delivery pressure of external gear pumps is investigated. Friction. Gear Pump Mechanical Efficiency.

From mechanicalxx.blogspot.com

Gear Pump Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque. Gear Pump Mechanical Efficiency.

From www.mdpi.com

Energies Free FullText The Influence of Radial and Axial Gaps on Gear Pump Mechanical Efficiency A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. The gear meshing friction is found. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. This paper presents an experimental study of external gear pump efficiency based upon. Gear Pump Mechanical Efficiency.

From www.engineeringchoice.com

What is a Pump? Working, Types, and Application Engineering Choice Gear Pump Mechanical Efficiency The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. Determining a pump's mechanical/hydraulic efficiency. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive. Gear Pump Mechanical Efficiency.

From chemicalengineeringworld.com

Pump Performance Curve Chemical Engineering World Gear Pump Mechanical Efficiency This paper presents an experimental study of external gear pump efficiency based upon an analysis of the stribeck values. A mechanical/hydraulic efficiency of 100% would mean if the pump was delivering flow at zero pressure, no force or torque would. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures.. Gear Pump Mechanical Efficiency.

From www.slideserve.com

PPT Internal External Gear Pump PowerPoint Presentation, free Gear Pump Mechanical Efficiency A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. The gear meshing friction is found. Friction at the gears’ tooth tips, lateral surfaces, shafts and meshing interfaces is considered. A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required. Gear Pump Mechanical Efficiency.

From www.pinterest.ca

Pumps are mechanical devices used to move fluids, gases, or slurries Gear Pump Mechanical Efficiency A pump's mechanical/hydraulic efficiency is determined by dividing the theoretical torque required to drive it by the actual torque required to drive it. A new method has been developed that formulates the volumetric efficiency as a function of a single parameter that captures. Determining a pump's mechanical/hydraulic efficiency. This paper presents an experimental study of external gear pump efficiency based. Gear Pump Mechanical Efficiency.