Tapped Hole Lead In Chamfer . I do the math to figure out. The number varies with the pitch of the thread and by the machinability of the material. Grailo is talking about clearance holes, not a threaded hole. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The tool sequence must be changed if a. Noboby cares, just make it a 90 and it goes in just fine. The specs call for a 120 degree chamfer in the hole. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. Clearance holes get chamfers to provide clearance for the.

from brazilmetalparts.com

The number varies with the pitch of the thread and by the machinability of the material. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. Noboby cares, just make it a 90 and it goes in just fine. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Grailo is talking about clearance holes, not a threaded hole. The tool sequence must be changed if a. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Clearance holes get chamfers to provide clearance for the. The specs call for a 120 degree chamfer in the hole. I do the math to figure out.

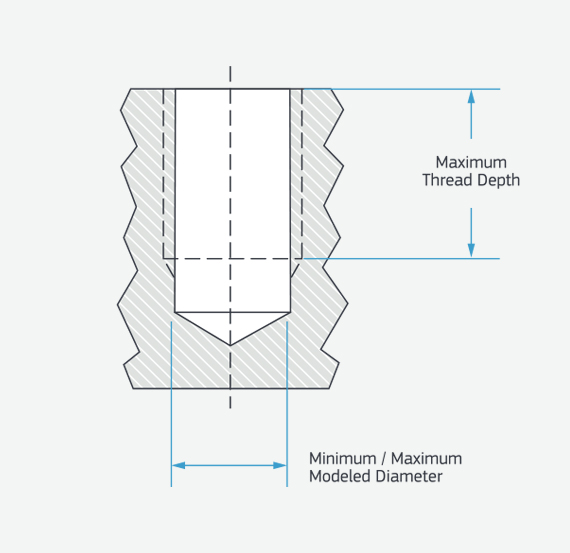

Threading Standard Holes

Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. The number varies with the pitch of the thread and by the machinability of the material. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. Clearance holes get chamfers to provide clearance for the. Grailo is talking about clearance holes, not a threaded hole. The tool sequence must be changed if a. I do the math to figure out. The specs call for a 120 degree chamfer in the hole. Noboby cares, just make it a 90 and it goes in just fine.

From www.wonkeedonkeetools.co.uk

What is a tapped hole? Wonkee Donkee Tools Tapped Hole Lead In Chamfer Clearance holes get chamfers to provide clearance for the. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Applying a 90° spot drill prior to drilling with a 140°. Tapped Hole Lead In Chamfer.

From www.xometry.com

What Are Blind Holes in Engineering and Machining? Xometry Tapped Hole Lead In Chamfer Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. I do the math to figure out. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The number varies with the pitch of. Tapped Hole Lead In Chamfer.

From forums.autodesk.com

Solved Drill, chamfer, tap Autodesk Community Tapped Hole Lead In Chamfer Noboby cares, just make it a 90 and it goes in just fine. Clearance holes get chamfers to provide clearance for the. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. How much bigger depends on the size of the tapped hole, i. Tapped Hole Lead In Chamfer.

From www.kemalmfg.com

How to Make Difference Between Threaded Holes and Tapped Holes for CNC Tapped Hole Lead In Chamfer Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The specs call for a 120 degree chamfer in the hole. The number varies with the pitch of the thread and by the machinability of the material. The tool sequence must be changed if. Tapped Hole Lead In Chamfer.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Grailo is talking about clearance holes, not a threaded hole. Applying a 90° spot drill prior to drilling with. Tapped Hole Lead In Chamfer.

From www.instructables.com

How to Tap a Hole 3 Steps Instructables Tapped Hole Lead In Chamfer On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Clearance holes get chamfers to provide clearance for the. The tool sequence must be changed if a. The number varies with the pitch of the thread and by the machinability of the material. I do. Tapped Hole Lead In Chamfer.

From www.slideserve.com

PPT Module 1 TAPPING PowerPoint Presentation, free download ID2222265 Tapped Hole Lead In Chamfer I do the math to figure out. The tool sequence must be changed if a. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The specs call for a 120 degree chamfer in the hole. Noboby cares, just make it a 90 and it goes in just fine. Applying. Tapped Hole Lead In Chamfer.

From ar.inspiredpencil.com

Standard Countersink Hole Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. Clearance holes get chamfers to provide clearance for the. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Noboby cares, just make it a 90 and it goes in just fine. Typically on. Tapped Hole Lead In Chamfer.

From www.wonkeedonkeetools.co.uk

What is a tapped hole? Wonkee Donkee Tools Tapped Hole Lead In Chamfer Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. The tool sequence must be changed if a. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. Grailo is talking about clearance. Tapped Hole Lead In Chamfer.

From madeinusatools.com

CMM Fixture Tapped Hole Location Gage, UNC Kit Made in USA Tools Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. Grailo is talking about clearance holes, not a threaded hole. The tool sequence must be changed if a. On tapped holes the issue. Tapped Hole Lead In Chamfer.

From www.pdfprof.com

Threads for the aerospace industry Yamawa Tapped Hole Lead In Chamfer Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. Grailo is talking about clearance holes, not a threaded hole. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The number varies with. Tapped Hole Lead In Chamfer.

From brazilmetalparts.com

Threading Standard Holes Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. Clearance holes get chamfers to provide clearance for the. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead. Tapped Hole Lead In Chamfer.

From www.fictiv.com

9 Engineering Drawing Tips to Save Time and Money Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The tool sequence must be changed if a. I do the math to figure out. Typically on a 60 degree thread a 45. Tapped Hole Lead In Chamfer.

From www.yamawa.eu

Cored holes Direct tapping with no tool breakage Yamawa Tapped Hole Lead In Chamfer I do the math to figure out. The tool sequence must be changed if a. The number varies with the pitch of the thread and by the machinability of the material. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Typically on a 60. Tapped Hole Lead In Chamfer.

From www.slideserve.com

PPT Holes PowerPoint Presentation ID2107959 Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The tool sequence must be changed if a. The number varies with the pitch of the thread and by the machinability of the material.. Tapped Hole Lead In Chamfer.

From www.eng-tips.com

GD&T for Threaded holes Drafting Standards, GD&T & Tolerance Analysis Tapped Hole Lead In Chamfer How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Grailo is talking about clearance holes, not a threaded hole. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The tool sequence must be. Tapped Hole Lead In Chamfer.

From www.aliexpress.com

LHX High speed steel Multifunctional Composite Screw Tap Titanium faced Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. The tool sequence must be changed if a. Noboby cares, just make it a 90 and it goes in just fine. Clearance holes get chamfers to provide clearance for the. Grailo is talking about clearance holes, not a threaded hole. On tapped holes the. Tapped Hole Lead In Chamfer.

From www.xometry.com

Tapped Holes vs Threaded Holes Differences and Comparison Tapped Hole Lead In Chamfer On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Clearance holes get chamfers to provide clearance for the. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. Applying a 90° spot drill prior. Tapped Hole Lead In Chamfer.

From campolden.org

Roll Form Tap Drill Chart Templates Sample Printables Tapped Hole Lead In Chamfer I do the math to figure out. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The specs call for a 120 degree chamfer in the hole. The number varies with the pitch of the thread and by the machinability of the material. Applying. Tapped Hole Lead In Chamfer.

From www.youtube.com

Tapping & Chamfering 3/4" Waterjet Holes Offline (From Hand Tapping to Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. Noboby cares, just make it a 90 and it goes in just fine. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The specs call for a 120 degree chamfer in the hole.. Tapped Hole Lead In Chamfer.

From forums.autodesk.com

Drill, CBore, and Chamfer Autodesk Community Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. Grailo is talking about clearance holes, not a threaded hole. The number varies with the pitch of the thread and by the machinability of the material. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the. Tapped Hole Lead In Chamfer.

From waykenrm.com

Make Threaded Holes Considerations For Tapped A Hole WayKen Tapped Hole Lead In Chamfer Clearance holes get chamfers to provide clearance for the. Grailo is talking about clearance holes, not a threaded hole. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. Noboby cares, just make it a 90 and it goes in just fine. The. Tapped Hole Lead In Chamfer.

From eziil.com

Chamfering 101 Types, Dimensions & Callout Tapped Hole Lead In Chamfer I do the math to figure out. Noboby cares, just make it a 90 and it goes in just fine. Clearance holes get chamfers to provide clearance for the. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. The number varies with the pitch of the thread and by. Tapped Hole Lead In Chamfer.

From cad.onshape.com

Hole/Thread Callout Tapped Hole Lead In Chamfer Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Grailo is talking about clearance holes, not a threaded. Tapped Hole Lead In Chamfer.

From www.wonkeedonkeetools.co.uk

What is a tapped hole? Wonkee Donkee Tools Tapped Hole Lead In Chamfer On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The tool sequence must be changed if a. The number varies with the pitch of the thread and by the machinability of the material. The specs call for a 120 degree chamfer in the hole.. Tapped Hole Lead In Chamfer.

From madeinusatools.com

CMM Fixture Tapped Hole Location Gage, UNF 1032 Made in USA Tools Tapped Hole Lead In Chamfer Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. I do the math to figure out. Noboby cares, just make it a 90. Tapped Hole Lead In Chamfer.

From nine9.jic-tools.com.tw

Combined Spotting and Chamfering 145 + 90 degree, dia 10, 16 and 25mm Tapped Hole Lead In Chamfer How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. The tool sequence must be changed if a. The specs call for a 120 degree chamfer in the hole. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter. Tapped Hole Lead In Chamfer.

From www.yorkshireprofiles.co.uk

Stainless Steel Laser Cutting Yorkshire Profiles Tapped Hole Lead In Chamfer On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The specs call for a 120 degree chamfer in. Tapped Hole Lead In Chamfer.

From www.kemalmfg.com

How to Make Difference Between Threaded Holes and Tapped Holes for CNC Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. Clearance holes get chamfers to provide clearance for the. How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. I do the math to figure out. The tool sequence must be changed if a.. Tapped Hole Lead In Chamfer.

From www.cutwel.ie

How to select the correct tap for your job Tapped Hole Lead In Chamfer How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Clearance holes get chamfers to provide clearance for the. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. Grailo is talking about clearance. Tapped Hole Lead In Chamfer.

From sendcutsend.com

Tapping Laser Cut Holes Video Tutorial and Guide SendCutSend Tapped Hole Lead In Chamfer On tapped holes the issue is that without a chamfered hole there is a possibility of a burr that will extend above the bearing surface. The number varies with the pitch of the thread and by the machinability of the material. I do the math to figure out. Applying a 90° spot drill prior to drilling with a 140° carbide. Tapped Hole Lead In Chamfer.

From www.youtube.com

53Pah İşleme Operasyonu YouTube Tapped Hole Lead In Chamfer How much bigger depends on the size of the tapped hole, i usually go around.01 for most holes we do. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The tool sequence must be changed if a. The specs call for a 120. Tapped Hole Lead In Chamfer.

From www.cnclathing.com

Tapped Holes vs. Threaded Holes Process, Cost, Size, Material, Speed Tapped Hole Lead In Chamfer Noboby cares, just make it a 90 and it goes in just fine. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The specs call for a 120 degree chamfer in the hole. On tapped holes the issue is that without a chamfered. Tapped Hole Lead In Chamfer.

From www.nord-lock.com

The Experts How much thread engagement is needed in a tapped hole Tapped Hole Lead In Chamfer The specs call for a 120 degree chamfer in the hole. Applying a 90° spot drill prior to drilling with a 140° carbide drill will lead to chipped corners on the latter drill and premature tool failure. The number varies with the pitch of the thread and by the machinability of the material. I do the math to figure out.. Tapped Hole Lead In Chamfer.

From www.kemalmfg.com

How to Make Difference Between Threaded Holes and Tapped Holes for CNC Tapped Hole Lead In Chamfer The number varies with the pitch of the thread and by the machinability of the material. Grailo is talking about clearance holes, not a threaded hole. The specs call for a 120 degree chamfer in the hole. Typically on a 60 degree thread a 45 degree chamfer will be cut just beyond the major or minor diameter. Noboby cares, just. Tapped Hole Lead In Chamfer.