How To Select Rack And Pinion Gear . When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. The tolerances, especially with helical teeth, are very important!. Maintain a controlled gap between the rack and pinion gear teeth to. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. When implementing a rack and pinion component for your application, you must account for many factors before making your selection. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). As long as these three specifications are the same, your gears will fit. Examples include size, quality number, materials used,. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'.

from www.youtube.com

In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. When implementing a rack and pinion component for your application, you must account for many factors before making your selection. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Examples include size, quality number, materials used,. As long as these three specifications are the same, your gears will fit. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). Maintain a controlled gap between the rack and pinion gear teeth to. The tolerances, especially with helical teeth, are very important!. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting.

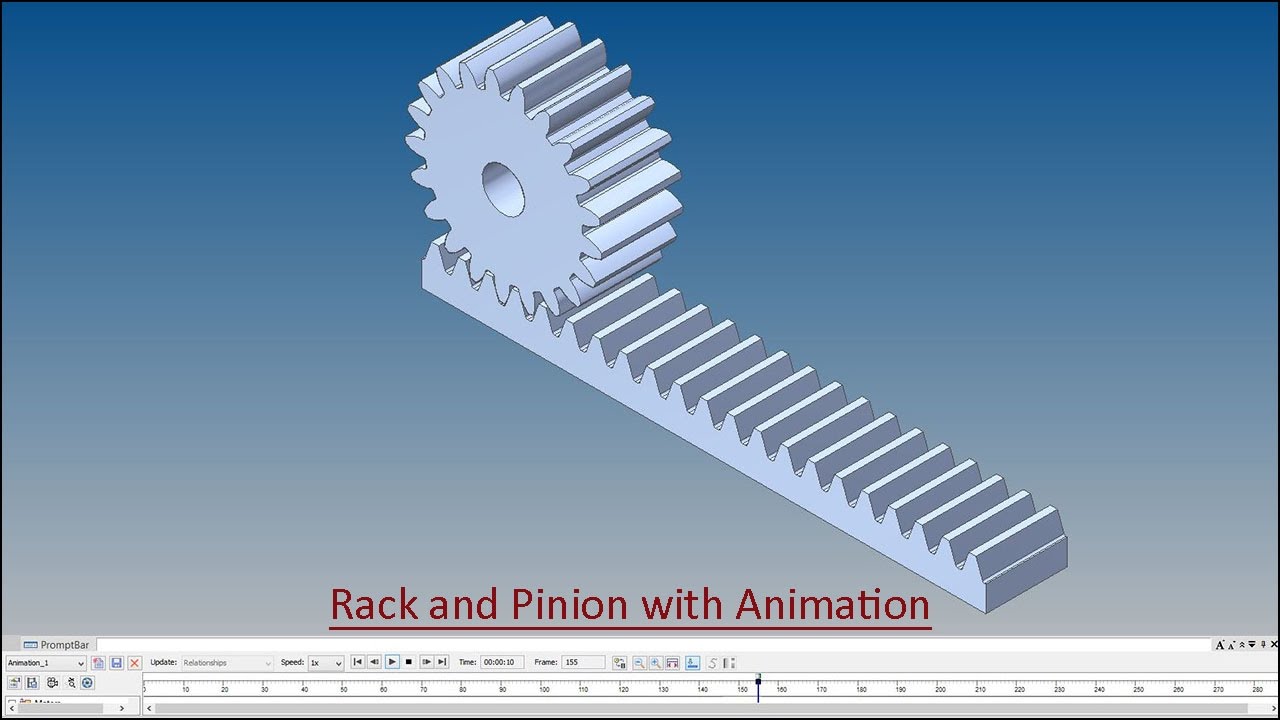

Rack and Pinion with Animation (Solid Edge Tutorial) YouTube

How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. When implementing a rack and pinion component for your application, you must account for many factors before making your selection. The tolerances, especially with helical teeth, are very important!. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. Examples include size, quality number, materials used,. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). Maintain a controlled gap between the rack and pinion gear teeth to. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. As long as these three specifications are the same, your gears will fit. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'.

From www.youtube.com

Mechanism 19 2 racks & pinion gear SolidWorks Tutorial YouTube How To Select Rack And Pinion Gear When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The tolerances, especially with helical teeth, are very important!. As long as these three specifications are the same, your gears will fit. Maintain a controlled gap between the rack and pinion gear teeth to. In rack and pinion. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion, Bevel Gears Assembly in SolidWorks YouTube How To Select Rack And Pinion Gear When implementing a rack and pinion component for your application, you must account for many factors before making your selection. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. As long as these three specifications are the same, your gears will fit. In the previous pages, we introduced the basics of gears, including 'module', 'pressure. How To Select Rack And Pinion Gear.

From www.researchgate.net

Sideways motion of the rack and pinion gear Download Scientific Diagram How To Select Rack And Pinion Gear As long as these three specifications are the same, your gears will fit. The tolerances, especially with helical teeth, are very important!. Maintain a controlled gap between the rack and pinion gear teeth to. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. Examples include size, quality number, materials. How To Select Rack And Pinion Gear.

From classicautoadvisors.com

Steering System Basics Rack & Pinion vs Recirculating Ball How To Select Rack And Pinion Gear When implementing a rack and pinion component for your application, you must account for many factors before making your selection. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. As long as these three specifications are the same, your gears will fit. The tolerances, especially with helical. How To Select Rack And Pinion Gear.

From www.mopardiy.com

How to Select the Optimal Ring and Pinion Gears for a Dana Rear How To Select Rack And Pinion Gear When implementing a rack and pinion component for your application, you must account for many factors before making your selection. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The engineering360 specsearch database. How To Select Rack And Pinion Gear.

From steeringly.com

All About Rack and Pinion Gears How To Select Rack And Pinion Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. As long as these three specifications are the same, your gears will fit. When implementing a rack and pinion component for your application, you must account for many factors before making your selection. Maintain a controlled gap between. How To Select Rack And Pinion Gear.

From cewivzig.blob.core.windows.net

How To Make Rack And Pinion Gear at William Tillman blog How To Select Rack And Pinion Gear When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. As long as these three specifications are the same, your gears will fit. When implementing a. How To Select Rack And Pinion Gear.

From www.pinterest.com

Steering Gear Box vs Rack And Pinion Vehicle steering wheel covers How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. When selecting gears and gear racks, you'll. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion Design involute spur gear and rack with motion in How To Select Rack And Pinion Gear Examples include size, quality number, materials used,. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'.. How To Select Rack And Pinion Gear.

From www.onallcylinders.com

Rack and Pinion Revisited A Basic Guide to Rack and Pinion Steering How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The tolerances, especially with helical teeth, are very important!. Examples include size, quality number, materials used,. In rack and pinion gear design, ensuring appropriate clearances is. How To Select Rack And Pinion Gear.

From www.hemiperformance.com.au

Manual Rack & Pinion Steering Conversion Kit Hemi Performance How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Maintain a controlled gap between the rack and pinion. How To Select Rack And Pinion Gear.

From engineering.stackexchange.com

gears How to determine optimal distance of rack and pinion How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. When properly selected, a rack and pinion drive can have a near infinite life, assuming. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion gear in fusion 360 Tutorial Power Stroke YouTube How To Select Rack And Pinion Gear When implementing a rack and pinion component for your application, you must account for many factors before making your selection. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The tolerances, especially with helical teeth, are very important!. In rack and pinion gear design, ensuring appropriate clearances. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion Steering Gearbox Mechanism Working Explained with How To Select Rack And Pinion Gear Examples include size, quality number, materials used,. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. As long as these three specifications are the same, your gears. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and pinion gear in Creo Parametric YouTube How To Select Rack And Pinion Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The tolerances, especially with helical teeth, are very important!. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. In rack and pinion gear design, ensuring. How To Select Rack And Pinion Gear.

From design.udlvirtual.edu.pe

How Does Rack And Pinion Steering Work On A Boat Design Talk How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. Maintain a controlled gap between the rack and pinion gear teeth to. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. How To Select Rack And Pinion Gear.

From www.youtube.com

Tutorial for beginnerRack and Pinion Gear MateAnimationInventor How To Select Rack And Pinion Gear Examples include size, quality number, materials used,. As long as these three specifications are the same, your gears will fit. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion with Animation (Solid Edge Tutorial) YouTube How To Select Rack And Pinion Gear As long as these three specifications are the same, your gears will fit. Maintain a controlled gap between the rack and pinion gear teeth to. The tolerances, especially with helical teeth, are very important!. Examples include size, quality number, materials used,. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for. How To Select Rack And Pinion Gear.

From www.researchgate.net

Rack and pinion gears [4]. Download Scientific Diagram How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. The tolerances, especially with helical teeth,. How To Select Rack And Pinion Gear.

From fixenginebrushings.z13.web.core.windows.net

Rack And Pinion Steering System Diagram How To Select Rack And Pinion Gear As long as these three specifications are the same, your gears will fit. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. Maintain a controlled gap between the rack and pinion gear teeth to. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number. How To Select Rack And Pinion Gear.

From www.youtube.com

solidworks tutorial rack and pinion gears design and assembly YouTube How To Select Rack And Pinion Gear As long as these three specifications are the same, your gears will fit. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of. How To Select Rack And Pinion Gear.

From www.youtube.com

SolidWorks tutorial Rack And Pinion YouTube How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. In rack and pinion gear design, ensuring appropriate clearances. How To Select Rack And Pinion Gear.

From absolutenessnews.blogspot.com

How To Make A Rack And Pinion Gear In Inventor absolutenessnews How To Select Rack And Pinion Gear When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Examples include size, quality number, materials used,.. How To Select Rack And Pinion Gear.

From www.youtube.com

Design Rack and pinion gear drive Autodesk Inventor YouTube How To Select Rack And Pinion Gear The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and. How To Select Rack And Pinion Gear.

From www.youtube.com

ME05 rack & pinion gears YouTube How To Select Rack And Pinion Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). As long as these three specifications are the same, your gears will fit. The tolerances, especially. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion Mechanism Steering Ratio Size of Pinion Gear Easy How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. As long as these three specifications are the same, your gears will fit. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. Examples include size, quality number, materials used,. In rack and pinion gear design, ensuring appropriate clearances. How To Select Rack And Pinion Gear.

From www.slideserve.com

PPT Gears PowerPoint Presentation ID6198008 How To Select Rack And Pinion Gear In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. Examples include size, quality number, materials used,. When implementing a rack and pinion component for your. How To Select Rack And Pinion Gear.

From www.thomasnet.com

All About Rack and Pinion Gears What They Are and How They Work How To Select Rack And Pinion Gear The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. When selecting gears and. How To Select Rack And Pinion Gear.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth. How To Select Rack And Pinion Gear.

From www.linearmotiontips.com

How to size a rackandpinion system for a precision motion axis How To Select Rack And Pinion Gear The tolerances, especially with helical teeth, are very important!. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. As long as these three specifications are the same, your gears will fit. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. Maintain a. How To Select Rack And Pinion Gear.

From mechanicaljungle.com

What Is a Rack and Pinion Steering? How Rack and Pinion Steering How To Select Rack And Pinion Gear Examples include size, quality number, materials used,. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. When implementing a rack and pinion component for your application, you must account for many factors before. How To Select Rack And Pinion Gear.

From www.youtube.com

design and assembly of rack and pinion gear in SOLIDWORKS using toolbox How To Select Rack And Pinion Gear When implementing a rack and pinion component for your application, you must account for many factors before making your selection. Maintain a controlled gap between the rack and pinion gear teeth to. In rack and pinion gear design, ensuring appropriate clearances is crucial for smooth operation. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by. How To Select Rack And Pinion Gear.

From www.youtube.com

Rack and Pinion Gears YouTube How To Select Rack And Pinion Gear When properly selected, a rack and pinion drive can have a near infinite life, assuming it has adequate lubrication and proper mounting. Maintain a controlled gap between the rack and pinion gear teeth to. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and thickness'. When implementing a rack. How To Select Rack And Pinion Gear.

From www.engineeringchoice.com

What is Rack and Pinion? Definition and Application Engineering Choice How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. The engineering360 specsearch database allows industrial buyers to select rack and pinion gears by gear type, configuration, and performance specifications. Examples include size, quality number, materials used,. The tolerances, especially with helical teeth, are very important!. When implementing a rack and pinion component for your application, you must. How To Select Rack And Pinion Gear.

From engineering.stackexchange.com

gears How to determine optimal distance of rack and pinion How To Select Rack And Pinion Gear Maintain a controlled gap between the rack and pinion gear teeth to. The tolerances, especially with helical teeth, are very important!. As long as these three specifications are the same, your gears will fit. When selecting gears and gear racks, you'll need to know the gear type, pressure angle, and pitch (or for metric gears, module). The engineering360 specsearch database. How To Select Rack And Pinion Gear.