Filler Wire Manufacturing Process . The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning.

from www.alphanickel.com

Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup.

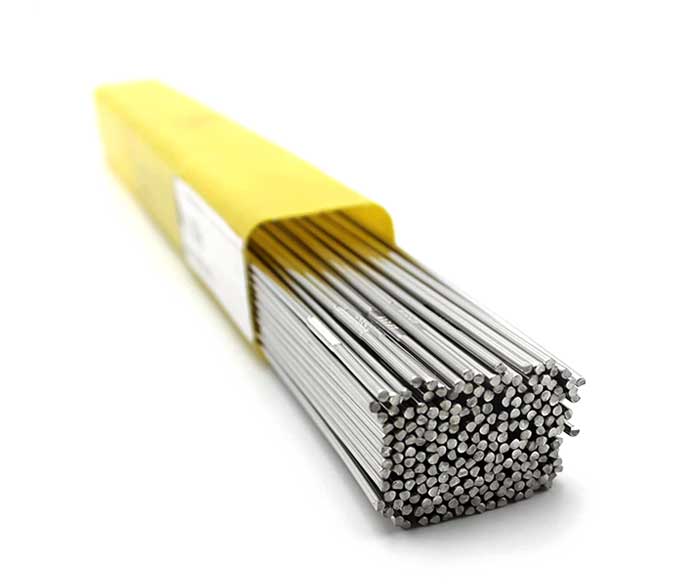

Duplex Steel 2205, S31803 Filler Wire Manufacturers & Suppliers

Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts.

From www.tradeindia.com

Filler Wire, Filler Wire Manufacturers & Suppliers, Dealers Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 304L Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From www.goodluckmetal.com

Advantages of Using SS Filler Wire in Medical Equipment Manufacturing Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.youtube.com

Visualization of 3 kW Laser welding with filler wire YouTube Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From weldnotes.com

What is Flux Cored Arc Welding (FCAW)? Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From www.metalyardindia.com

Filler Wire Supplier Manufacturer in Mumbai Metal Yard India Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the. Filler Wire Manufacturing Process.

From www.thefabricator.com

Getting to Know Fluxcored Wires The Fabricator Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 347 / 347H Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.indiamart.com

Stainless Steel ER310 Filler Wire, For Construction, Thickness 4 mm Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 316, 316L Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From blog.thepipingmart.com

ERCOCRB Filler Wire Composition, Properties, and Uses Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.goodluckmetal.com

Advantages of Using 316 Filler Wire in Marine Engineering Applications Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From pearlitesteel.com

Stainless Steel Pipe and Tube Manufacturing Process Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the. Filler Wire Manufacturing Process.

From www.indiamart.com

SUPERON ER304L Stainless Steel Welding Filler Wire, Thickness 1.6MM Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the. Filler Wire Manufacturing Process.

From www.findlight.net

Metal Manufacturing Processes Brief Guide Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.threewatertrade.com

Flux Cored Wire Production Line Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.alphanickel.com

Duplex Steel 2205, S31803 Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.researchgate.net

e Schematic diagram of underwater filler wire laser welding process at Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the. Filler Wire Manufacturing Process.

From www.alphanickel.com

Duplex Steel 2205, S31803 Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the. Filler Wire Manufacturing Process.

From eureka.patsnap.com

Thick plate narrow gap doublebeam laser filler wire efficient welding Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 321 / 321H Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 310, 310S Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From dlx-alloy.en.made-in-china.com

Inconel 601 ASTM B166 Inconel Metalizing Thermal Spray Wire Incoloy Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.bhansalioverseas.com

Wire, Stainless Steel Wire Bobbin, SS Filler Wire, Carbon Steel Wire Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 316, 316L Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process. Filler Wire Manufacturing Process.

From www.entrepreneurindia.co

MIG Welding Wire Manufacturing Business Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.medicaldesignandoutsourcing.com

PlasticsOne illustrates the making of a perfect cable Medical Design Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.iqsdirectory.com

Wire Cloth What Is It? How Is It Used? Materials, Types Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.alphanickel.com

Cupro Nickel Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the. Filler Wire Manufacturing Process.

From www.slideserve.com

PPT Semiconductor Manufacturing Technology Semiconductor Filler Wire Manufacturing Process Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.tradeindia.com

Smo 254 Filler Wire Application Hardware Parts at Best Price in Mumbai Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.indiamart.com

Round 174 Ph Filler Wire, for Construction at best price in Mumbai Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.ganpatind.com

Filler Wires Suppliers, Manufacturers in India Filler Wire Manufacturing Process It belongs to the direct energy deposition (ded) family of additive manufacturing. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Both laser welding with and without filler wire are investigated, along with. Filler Wire Manufacturing Process.

From www.alphanickel.com

SS 316Ti Filler Wire Manufacturers & Suppliers Filler Wire Manufacturing Process Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. It belongs to the direct energy deposition (ded) family of additive manufacturing. The wire arc additive manufacturing process parameters influence the macro morphology. Filler Wire Manufacturing Process.

From www.metcoresteel.com

The Benefits Of Using 316 Filler Wire Filler Wire Manufacturing Process The wire arc additive manufacturing process parameters influence the macro morphology by determining the heat input and thermal buildup. Wire arc additive manufacturing (waam) is a production process used to 3d print or repair metal parts. Both laser welding with and without filler wire are investigated, along with the potential advantages of using a wobbling scanning. It belongs to the. Filler Wire Manufacturing Process.