Turning Tools For Rubber . You must achieve a minimum depth of. Looking for the best full size carbide turning tool, but not sure where to start? High speed steel, ground to a spoon shape, lots of positive rake and relief. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. That is, use a razor sharp tool with a flat. The optimum shape depends upon durometer. The use of precise cutting to get excellent outcomes. Turning rubber on a lathe is doable. You can cut rubber faster than grinding it but the finish is generally better done by grinding. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; It's different, but not as much as you'd think. This page walks you through the best ones for. To turn it you're going to want to broadnose.

from www.lzqtech.com

You can cut rubber faster than grinding it but the finish is generally better done by grinding. That is, use a razor sharp tool with a flat. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. This page walks you through the best ones for. Turning rubber on a lathe is doable. To turn it you're going to want to broadnose. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; You must achieve a minimum depth of. Looking for the best full size carbide turning tool, but not sure where to start?

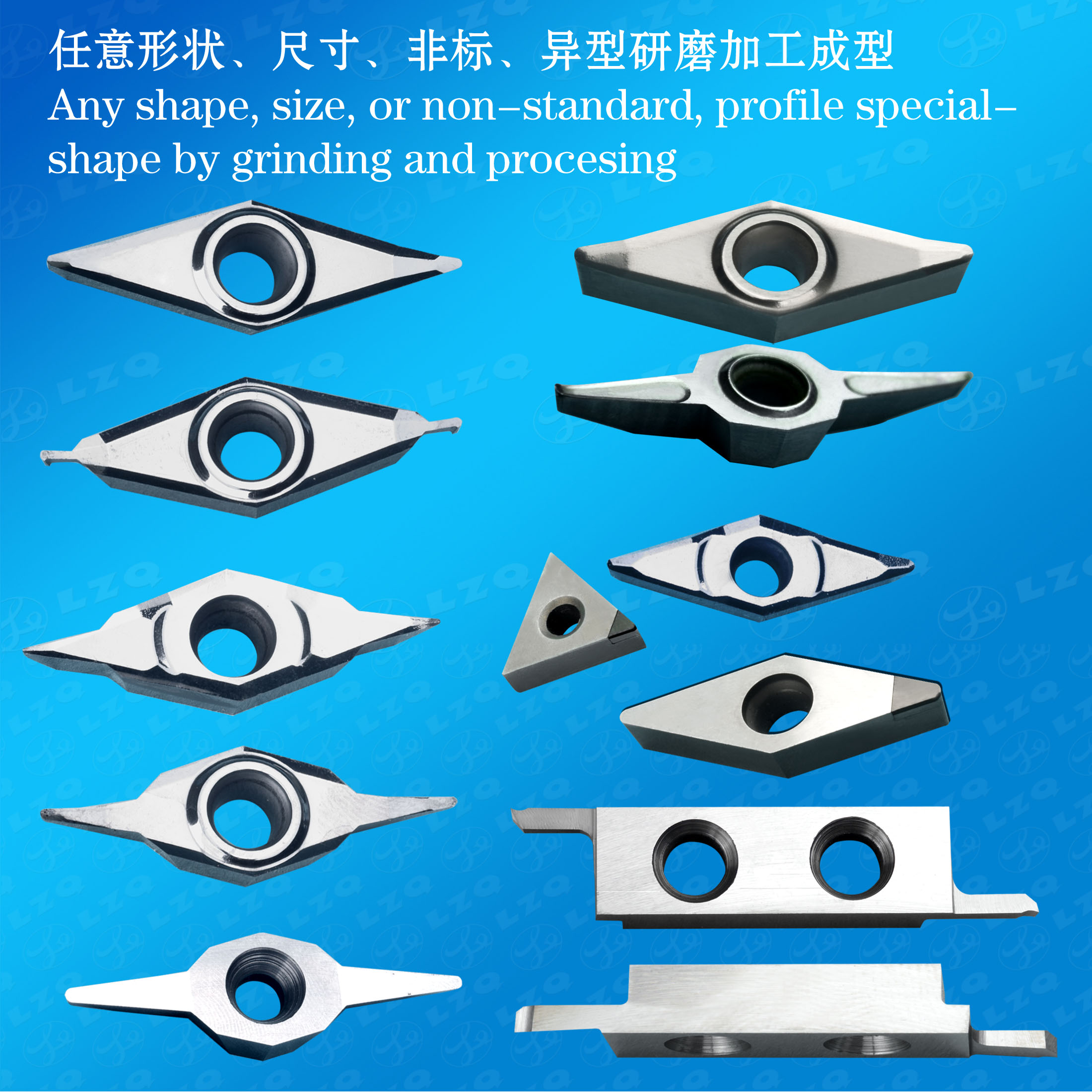

Thread Turning Tool, Precision Turning Tool, Mechanically Clamped

Turning Tools For Rubber Looking for the best full size carbide turning tool, but not sure where to start? Looking for the best full size carbide turning tool, but not sure where to start? It's different, but not as much as you'd think. To turn it you're going to want to broadnose. You must achieve a minimum depth of. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. The use of precise cutting to get excellent outcomes. Turning rubber on a lathe is doable. That is, use a razor sharp tool with a flat. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. High speed steel, ground to a spoon shape, lots of positive rake and relief. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; The optimum shape depends upon durometer. You can cut rubber faster than grinding it but the finish is generally better done by grinding. This page walks you through the best ones for.

From www.lzqtech.com

PU Cutter,Rubber Blades,Rubber Turning Tool LZQ TOOL CO., LTD. Turning Tools For Rubber High speed steel, ground to a spoon shape, lots of positive rake and relief. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; It's different, but not as much as you'd think. To turn it you're going to want to broadnose. The rubber will rub under the cutting edge causing the aparent push away, and. Turning Tools For Rubber.

From www.sealey.co.uk

Tips for Lathe Turning Tool Set SM3025CS6 SM3025CS6R Sealey Turning Tools For Rubber This page walks you through the best ones for. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. Looking for the best full size carbide turning tool, but not sure where to start? Turning rubber on a lathe is doable. Use the sw001 k20 brazed carbide tipped lathe tool to get the most. Turning Tools For Rubber.

From chileb.cl

New 5pcs 10MM Shank Turning Tool Holder Set With Inserts Lathe Tool Turning Tools For Rubber To turn it you're going to want to broadnose. You can cut rubber faster than grinding it but the finish is generally better done by grinding. You must achieve a minimum depth of. That is, use a razor sharp tool with a flat. High speed steel, ground to a spoon shape, lots of positive rake and relief. It's different, but. Turning Tools For Rubber.

From www.chronos.ltd.uk

Set of 8 SCT Solid HSS Lathe Turning Tools 16mm Square Chronos Turning Tools For Rubber High speed steel, ground to a spoon shape, lots of positive rake and relief. Turning rubber on a lathe is doable. This page walks you through the best ones for. You must achieve a minimum depth of. You can cut rubber faster than grinding it but the finish is generally better done by grinding. To turn it you're going to. Turning Tools For Rubber.

From www.lzqtech.com

Thread Turning Tool, Precision Turning Tool, Mechanically Clamped Turning Tools For Rubber This page walks you through the best ones for. That is, use a razor sharp tool with a flat. It's different, but not as much as you'd think. High speed steel, ground to a spoon shape, lots of positive rake and relief. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; The optimum shape depends. Turning Tools For Rubber.

From engineeringlearn.com

14 Types of Lathe Cutting Tools and Their Uses Guide Turning Tools For Rubber You must achieve a minimum depth of. This page walks you through the best ones for. Looking for the best full size carbide turning tool, but not sure where to start? It's different, but not as much as you'd think. To turn it you're going to want to broadnose. Use the sw001 k20 brazed carbide tipped lathe tool to get. Turning Tools For Rubber.

From www.aliexpress.com

Wood Rubber Handle 3 Piece Set Woodworking Tool Changeable Tungsten Turning Tools For Rubber To turn it you're going to want to broadnose. You can cut rubber faster than grinding it but the finish is generally better done by grinding. The optimum shape depends upon durometer. This page walks you through the best ones for. That is, use a razor sharp tool with a flat. Turning rubber on a lathe is doable. It's different,. Turning Tools For Rubber.

From www.pinterest.com

Pin on Wood turning projects Turning Tools For Rubber Turning rubber on a lathe is doable. To turn it you're going to want to broadnose. You can cut rubber faster than grinding it but the finish is generally better done by grinding. High speed steel, ground to a spoon shape, lots of positive rake and relief. The use of precise cutting to get excellent outcomes. That is, use a. Turning Tools For Rubber.

From www.alibaba.com

Rubber Cutting Tools Lathe Machine Cutting Tool Holder Turning Tool Set Turning Tools For Rubber Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; You must achieve a minimum depth of. To turn it you're going to want to broadnose. It's different, but not as much as you'd think. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. This page walks you through. Turning Tools For Rubber.

From www.sumipol.com

Turning Tools Nano polycrystalline diamond ultra precision cutting Turning Tools For Rubber You must achieve a minimum depth of. The use of precise cutting to get excellent outcomes. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; It's different, but not as much as you'd think. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. Turning rubber on. Turning Tools For Rubber.

From www.lzqtech.com

PU Cutter,Rubber Blades,Rubber Turning Tool LZQ TOOL CO., LTD. Turning Tools For Rubber Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; To turn it you're going to want to broadnose. Turning rubber on a lathe is doable. That is, use a razor sharp tool with a flat. It's different, but not as much as you'd think. High speed steel, ground to a spoon shape, lots of positive. Turning Tools For Rubber.

From www.desertcart.ae

Buy Savannah 3 Piece Carbide Mini Turning Tool Set with Flush Fit Turning Tools For Rubber The use of precise cutting to get excellent outcomes. You can cut rubber faster than grinding it but the finish is generally better done by grinding. This page walks you through the best ones for. High speed steel, ground to a spoon shape, lots of positive rake and relief. The optimum shape depends upon durometer. Use the sw001 k20 brazed. Turning Tools For Rubber.

From www.ubuy.co.in

Buy Simple Woodturning Tools Set of 4 Carbide Lathe Turning Tools with Turning Tools For Rubber High speed steel, ground to a spoon shape, lots of positive rake and relief. The optimum shape depends upon durometer. To turn it you're going to want to broadnose. This page walks you through the best ones for. That is, use a razor sharp tool with a flat. The rubber will rub under the cutting edge causing the aparent push. Turning Tools For Rubber.

From www.glanze.co.uk

Set of 12 MM Glanze DCMT Mini Indexable Turning Tools Turning Tools For Rubber You can cut rubber faster than grinding it but the finish is generally better done by grinding. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. You must achieve a minimum depth of. This page walks you through the best ones for. Rubber chucky products, llc manufacturers and distributes rubber jam. Turning Tools For Rubber.

From www.sumipol.com

Turning Tools UltraPrecision UPC Sumipol Turning Tools For Rubber Turning rubber on a lathe is doable. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. This page walks you through the best ones for. You can cut rubber faster than grinding it but the finish is generally better done by grinding. You must achieve a minimum depth of. The use. Turning Tools For Rubber.

From imajeenyus.com

Cutting rubber tubing on the lathe with a razor blade Turning Tools For Rubber The optimum shape depends upon durometer. To turn it you're going to want to broadnose. You must achieve a minimum depth of. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. Looking for the best full size carbide turning tool, but not sure where to start? High speed steel, ground to. Turning Tools For Rubber.

From www.huttie.com

Indexable 8mm Lathe Turning Tool Set 5pc Huttie Turning Tools For Rubber The rubber will rub under the cutting edge causing the aparent push away, and dragging action. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; You must achieve a minimum depth of. That is, use a razor. Turning Tools For Rubber.

From www.aliexpress.com

3PKT100408R M TT9080 Carbide Inserts Lathe Cutter Turning Tool CNC Turning Tools For Rubber To turn it you're going to want to broadnose. That is, use a razor sharp tool with a flat. It's different, but not as much as you'd think. Turning rubber on a lathe is doable. Looking for the best full size carbide turning tool, but not sure where to start? Rubber chucky products, llc manufacturers and distributes rubber jam chucks. Turning Tools For Rubber.

From www.pinterest.com

Rubber Chucky Products, LLC manufacturers and distributes rubber jam Turning Tools For Rubber The rubber will rub under the cutting edge causing the aparent push away, and dragging action. To turn it you're going to want to broadnose. This page walks you through the best ones for. That is, use a razor sharp tool with a flat. It's different, but not as much as you'd think. You can cut rubber faster than grinding. Turning Tools For Rubber.

From www.familyhandyman.com

7 Basic Woodturning Tools To Start With Turning Tools For Rubber This page walks you through the best ones for. Turning rubber on a lathe is doable. The use of precise cutting to get excellent outcomes. Looking for the best full size carbide turning tool, but not sure where to start? High speed steel, ground to a spoon shape, lots of positive rake and relief. You must achieve a minimum depth. Turning Tools For Rubber.

From www.sumipol.com

Turning Tools Formed ultra precision cutting tool Sumipol Turning Tools For Rubber You can cut rubber faster than grinding it but the finish is generally better done by grinding. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; The rubber will rub under the cutting edge causing the aparent push away, and dragging action. To turn it you're going to want to broadnose. Use the sw001 k20. Turning Tools For Rubber.

From cjdropshipping.com

10piece Set Of Handheld Disposable Turning Tools CJdropshipping Turning Tools For Rubber It's different, but not as much as you'd think. The use of precise cutting to get excellent outcomes. Turning rubber on a lathe is doable. To turn it you're going to want to broadnose. This page walks you through the best ones for. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; Looking for the. Turning Tools For Rubber.

From www.lzqtech.com

PU Cutter,Rubber Blades,Rubber Turning Tool LZQ TOOL CO., LTD. Turning Tools For Rubber Looking for the best full size carbide turning tool, but not sure where to start? Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; You can cut rubber faster than grinding it but the finish is generally better done by grinding. The optimum shape depends upon durometer. You must achieve a minimum depth of. That. Turning Tools For Rubber.

From www.lzqtech.com

PU Cutter,Rubber Blades,Rubber Turning Tool LZQ TOOL CO., LTD. Turning Tools For Rubber Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; The rubber will rub under the cutting edge causing the aparent push away, and dragging action. The use of precise cutting to get excellent outcomes. This page walks. Turning Tools For Rubber.

From www.amazon.ca

YUFUTOL Carbide Woodturning Tool Mini Size (3 Piece Set) Includes Turning Tools For Rubber To turn it you're going to want to broadnose. The optimum shape depends upon durometer. High speed steel, ground to a spoon shape, lots of positive rake and relief. The use of precise cutting to get excellent outcomes. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. It's different, but not. Turning Tools For Rubber.

From www.youtube.com

Rubber turning YouTube Turning Tools For Rubber Looking for the best full size carbide turning tool, but not sure where to start? Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; That is, use a razor sharp tool with a flat. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. It's different, but. Turning Tools For Rubber.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Turning Tools For Rubber The use of precise cutting to get excellent outcomes. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. Looking for the best full size carbide turning tool, but not sure where to start? You can cut rubber faster than grinding it but the finish is generally better done by grinding. This page walks. Turning Tools For Rubber.

From nazya.com

Купить Токарные инструменты Simple Woodturning Tools STH Simple Turning Turning Tools For Rubber Turning rubber on a lathe is doable. High speed steel, ground to a spoon shape, lots of positive rake and relief. The use of precise cutting to get excellent outcomes. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. It's different, but not as much as you'd think. Use the sw001 k20 brazed. Turning Tools For Rubber.

From www.lzqtech.com

Seal Ring Blades, Rubber Blades, Rubber Turning Tool LZQ TOOL CO., LTD. Turning Tools For Rubber The optimum shape depends upon durometer. It's different, but not as much as you'd think. Looking for the best full size carbide turning tool, but not sure where to start? Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. That is, use a razor sharp tool with a flat. Turning rubber. Turning Tools For Rubber.

From www.pinterest.com

17" Interchangeable Handle with Foam Grip for Full Size Simple Turning Tools For Rubber You can cut rubber faster than grinding it but the finish is generally better done by grinding. Rubber chucky products, llc manufacturers and distributes rubber jam chucks and other woodturning aids; Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. You must achieve a minimum depth of. That is, use a. Turning Tools For Rubber.

From www.simplewoodturningtools.com

Simple Start Carbide Wood Turning Lathe Tools Simple Woodturning Tools Turning Tools For Rubber You can cut rubber faster than grinding it but the finish is generally better done by grinding. The rubber will rub under the cutting edge causing the aparent push away, and dragging action. The use of precise cutting to get excellent outcomes. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining.. Turning Tools For Rubber.

From www.alibaba.com

Cnc Lathe Rubber Cutting Tools Turning Insert Hard Alloy Insert,Carbide Turning Tools For Rubber That is, use a razor sharp tool with a flat. You must achieve a minimum depth of. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. High speed steel, ground to a spoon shape, lots of positive rake and relief. The rubber will rub under the cutting edge causing the aparent. Turning Tools For Rubber.

From www.indiamart.com

Carbide Turning Tool at Rs 1860/piece Cutting Tool in Mumbai ID Turning Tools For Rubber To turn it you're going to want to broadnose. The use of precise cutting to get excellent outcomes. Looking for the best full size carbide turning tool, but not sure where to start? You can cut rubber faster than grinding it but the finish is generally better done by grinding. The rubber will rub under the cutting edge causing the. Turning Tools For Rubber.

From www.china-machining.com

CNC Lathe Tools 6 Types for CNC Turning Projects Turning Tools For Rubber To turn it you're going to want to broadnose. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. You can cut rubber faster than grinding it but the finish is generally better done by grinding. The rubber will rub under the cutting edge causing the aparent push away, and dragging action.. Turning Tools For Rubber.

From www.familyhandyman.com

Best Wood Turning Tools You Need These Carbide Tipped Chisels Turning Tools For Rubber High speed steel, ground to a spoon shape, lots of positive rake and relief. You can cut rubber faster than grinding it but the finish is generally better done by grinding. To turn it you're going to want to broadnose. Use the sw001 k20 brazed carbide tipped lathe tool to get the most out of your rubber machining. The rubber. Turning Tools For Rubber.