Tank Jet Mixer Calculation . Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. The jet mixing time can be calculated from the following equation: See the equations, the factors. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Mixing is one of the common unit operation employed in chemical industries. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. A mechanical agitator is generally more efficient for higher. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout.

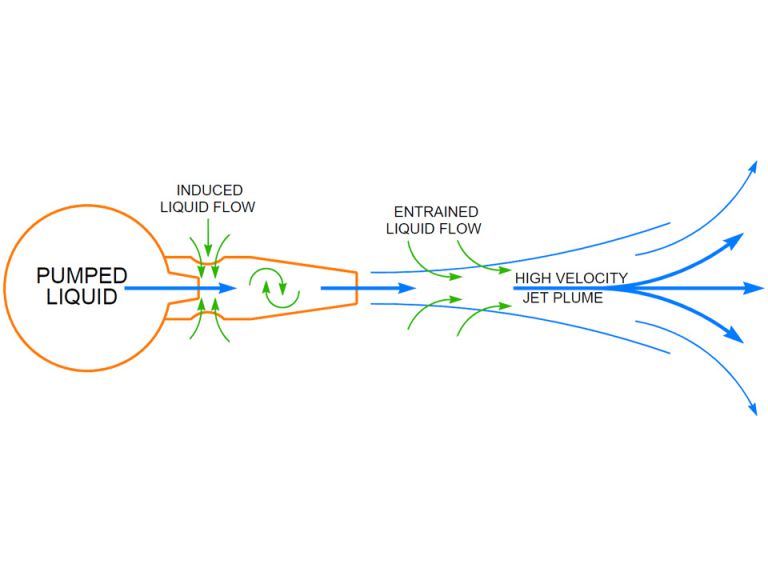

from mtsjets.com

Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; A mechanical agitator is generally more efficient for higher. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Mixing is one of the common unit operation employed in chemical industries. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. See the equations, the factors. The jet mixing time can be calculated from the following equation: Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream.

Jet Mixing Systems Mass Transfer Systems

Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. See the equations, the factors. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; A mechanical agitator is generally more efficient for higher. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. The jet mixing time can be calculated from the following equation: Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Mixing is one of the common unit operation employed in chemical industries.

From www.fed.it

Tank mixing systems Tank Jet Mixer Calculation Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. A mechanical. Tank Jet Mixer Calculation.

From www.researchgate.net

Scheme of a counterflow jet mixer for fluids 1 working nozzle; 2 Tank Jet Mixer Calculation Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks. Tank Jet Mixer Calculation.

From www.wmprocess.com

Mixer Selection Calculator Calculate Mixer & Mix Tank Size Tank Jet Mixer Calculation There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. See the equations, the factors. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s.. Tank Jet Mixer Calculation.

From www.academia.edu

(PDF) Jet mixer velocity calculation Hari Pacha Gounder Academia.edu Tank Jet Mixer Calculation Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. See the. Tank Jet Mixer Calculation.

From www.jongia.com

The Jet mixer for efficiently dissolving of solids Tank Jet Mixer Calculation See the equations, the factors. The jet mixing time can be calculated from the following equation: A mechanical agitator is generally more efficient for higher. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Learn how to size a jet mixer for a tank. Tank Jet Mixer Calculation.

From www.semanticscholar.org

Figure 1 from Overview of Pulse Jet Mixer/Hybrid Mixing System Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. See the equations, the factors. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Mixing is one. Tank Jet Mixer Calculation.

From www.moodydirect.com

Alfa Laval IM 10 Rotary Jet Mixer Moody Direct Tank Jet Mixer Calculation Mixing is one of the common unit operation employed in chemical industries. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. See the equations, the factors. A mechanical agitator is generally more efficient for higher. Conventional mixers are equipped with impellers but are expensive for. Tank Jet Mixer Calculation.

From loadingzones.website2.me

Agitator Design Software loadingzones Tank Jet Mixer Calculation See the equations, the factors. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. A mechanical agitator is generally more efficient for higher. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. For a jet mixer consider. Tank Jet Mixer Calculation.

From proquipinc.com

New Tank Agitator Data Sheet ProQuip Mixers Tank Jet Mixer Calculation Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. See the equations, the factors. Learn how liquid jet mixers work, what are their advantages and applications, and how to select. Tank Jet Mixer Calculation.

From mk-design.co.in

M.K. DESIGN AND ENGINEERING CO Tank Jet Mixer Calculation See the equations, the factors. Mixing is one of the common unit operation employed in chemical industries. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; For a jet mixer consider a minimum jet nozzle velocity of 9. Tank Jet Mixer Calculation.

From www.researchgate.net

A schematic of the inline jet mixer during resuspension of accumulated Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. The jet mixing time can be calculated from the following equation: A mechanical agitator is generally more efficient for higher. See the equations, the factors. Mixing is one of the common unit operation employed in chemical industries. Learn how liquid jet mixers work, what are their advantages. Tank Jet Mixer Calculation.

From www.transvac.co.uk

Utilising CFD Analysis For Perfect Tank Mixing Transvac Tank Jet Mixer Calculation The jet mixing time can be calculated from the following equation: Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Mixing is one of the common unit. Tank Jet Mixer Calculation.

From pharmacyscope.com

Jet Mixer Principle And How it works? Tank Jet Mixer Calculation See the equations, the factors. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. A mechanical agitator is generally more efficient for higher. Conventional mixers are equipped with impellers but are. Tank Jet Mixer Calculation.

From www.transvac.co.uk

Tank Mixing with Jet Mixers Transvac Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Learn how liquid jet mixers. Tank Jet Mixer Calculation.

From www.transvac.co.uk

Tank Mixing with Jet Mixers Transvac Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Mixing is one of the common unit operation employed in chemical industries. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. See the equations, the factors. Jet mixing. Tank Jet Mixer Calculation.

From pharmacyscope.com

Jet Mixer Principle And How it works? Tank Jet Mixer Calculation Mixing is one of the common unit operation employed in chemical industries. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. See. Tank Jet Mixer Calculation.

From www.thechemicalengineer.com

Rules of Thumb Jet Mixing Features The Chemical Engineer Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. See the equations, the factors. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp;. Tank Jet Mixer Calculation.

From www.mixing.com

Directional Jet Mixers Tank Jet Mixer Calculation The jet mixing time can be calculated from the following equation: For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. A mechanical agitator is generally more efficient for higher. Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. There are numerous considerations that go into. Tank Jet Mixer Calculation.

From www.kusumateknik.co.id

PT. KUSUMA TEKNIK PERSADA Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. Learn how to size a jet mixer for a tank or reactor using the kinetic energy. Tank Jet Mixer Calculation.

From dokumen.tips

(XLSX) Calculation for Jet Mixer DOKUMEN.TIPS Tank Jet Mixer Calculation There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right. Tank Jet Mixer Calculation.

From mtsjets.com

Jet Mixing Systems Mass Transfer Systems Tank Jet Mixer Calculation A mechanical agitator is generally more efficient for higher. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Mixing is one of the common unit operation employed in chemical industries. The jet mixing time can be calculated from the following equation: For a jet mixer consider a minimum jet nozzle velocity of. Tank Jet Mixer Calculation.

From www.jongia.com

Jet Mixer Jongia Mixing Technology Tank Jet Mixer Calculation Mixing is one of the common unit operation employed in chemical industries. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; See the equations, the factors. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Conventional mixers are equipped. Tank Jet Mixer Calculation.

From www.researchgate.net

Images of the three mixers, including a confined impinging jet mixer Tank Jet Mixer Calculation There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. The jet mixing time can be calculated from the following equation: Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; See the equations, the factors. Mixing is one of the. Tank Jet Mixer Calculation.

From www.jongia.com

The Jet mixer the solution for the dissolving of solids Tank Jet Mixer Calculation Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. For a jet mixer consider a minimum jet nozzle. Tank Jet Mixer Calculation.

From www.scribd.com

Tank Jet Mixing Systems Tank Jet Mixer Calculation Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. Mixing is one of the common unit operation employed in chemical industries. A mechanical agitator. Tank Jet Mixer Calculation.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Tank Jet Mixer Calculation Mixing is one of the common unit operation employed in chemical industries. Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. See the equations, the factors. The jet mixing time can be. Tank Jet Mixer Calculation.

From www.semanticscholar.org

Figure 3 from CFD MODELING OF TURBULENT JET MIXING IN A WATER STORAGE Tank Jet Mixer Calculation Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a pumped stream. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. See the equations, the factors. A mechanical agitator is generally more efficient for higher. Jet mixing is normally used for liquids and slurries having viscosities below 1,000. Tank Jet Mixer Calculation.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. See the equations, the factors. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. Mixing is one of the common unit operation employed in chemical industries. The jet mixing time can be calculated from the following equation: Learn how. Tank Jet Mixer Calculation.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Tank Jet Mixer Calculation See the equations, the factors. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. The jet mixing time can be calculated from the following equation: Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp;. Tank Jet Mixer Calculation.

From www.transvac.co.uk

Utilising CFD Analysis For Perfect Tank Mixing Transvac Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. Jet mixing is normally used for liquids and slurries having viscosities below 1,000 cp; A mechanical agitator is generally more efficient for higher. Mixing is one of the common unit operation employed in chemical industries. Conventional mixers are equipped with impellers but are expensive for mixing in. Tank Jet Mixer Calculation.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. See the equations, the factors. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Learn how to size a jet mixer for a tank or reactor using the kinetic energy of a. Tank Jet Mixer Calculation.

From dciinc.com

Agitators and Mixers Stainless Steel Mixers Liquid or Dry DCI Inc. Tank Jet Mixer Calculation The jet mixing time can be calculated from the following equation: Mixing is one of the common unit operation employed in chemical industries. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. A mechanical agitator is generally more efficient for higher. Learn how to. Tank Jet Mixer Calculation.

From www.iqsdirectory.com

Tank Mixers Components, Types, Regulations, and Considerations Tank Jet Mixer Calculation A mechanical agitator is generally more efficient for higher. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. Mixing is one of the common unit operation employed in chemical industries. See. Tank Jet Mixer Calculation.

From www.kusumateknik.co.id

PT. KUSUMA TEKNIK PERSADA Tank Jet Mixer Calculation For a jet mixer consider a minimum jet nozzle velocity of 9 m/s. A mechanical agitator is generally more efficient for higher. Mixing is one of the common unit operation employed in chemical industries. There are numerous considerations that go into designing a jet mixing system based on the application, materials being mixed and their unique attributes, tank layout. See. Tank Jet Mixer Calculation.

From www.youtube.com

Using Eductors for NonPowered Tank Mixing YouTube Tank Jet Mixer Calculation Conventional mixers are equipped with impellers but are expensive for mixing in large storage tanks and underground. Learn how liquid jet mixers work, what are their advantages and applications, and how to select the right size and pump for your tank. Mixing is one of the common unit operation employed in chemical industries. The jet mixing time can be calculated. Tank Jet Mixer Calculation.