Types Of Coupling For Pumps . Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Application considerations when selecting a coupling include: So, what are the different types of pump coupling and when should they be used? As their name suggests, rigid couplings connect the. Like everything else on the pump, selecting the right coupling. 2.4 coupling service factors for pumping applications. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 3.1 purpose of a flexible coupling. However, the most common types. There are several types of pump couplings, each with its unique features and applications.

from mechanicaljungle.com

Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. So, what are the different types of pump coupling and when should they be used? Application considerations when selecting a coupling include: There are several types of pump couplings, each with its unique features and applications. However, the most common types. 3.1 purpose of a flexible coupling. As their name suggests, rigid couplings connect the. 2.4 coupling service factors for pumping applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Like everything else on the pump, selecting the right coupling.

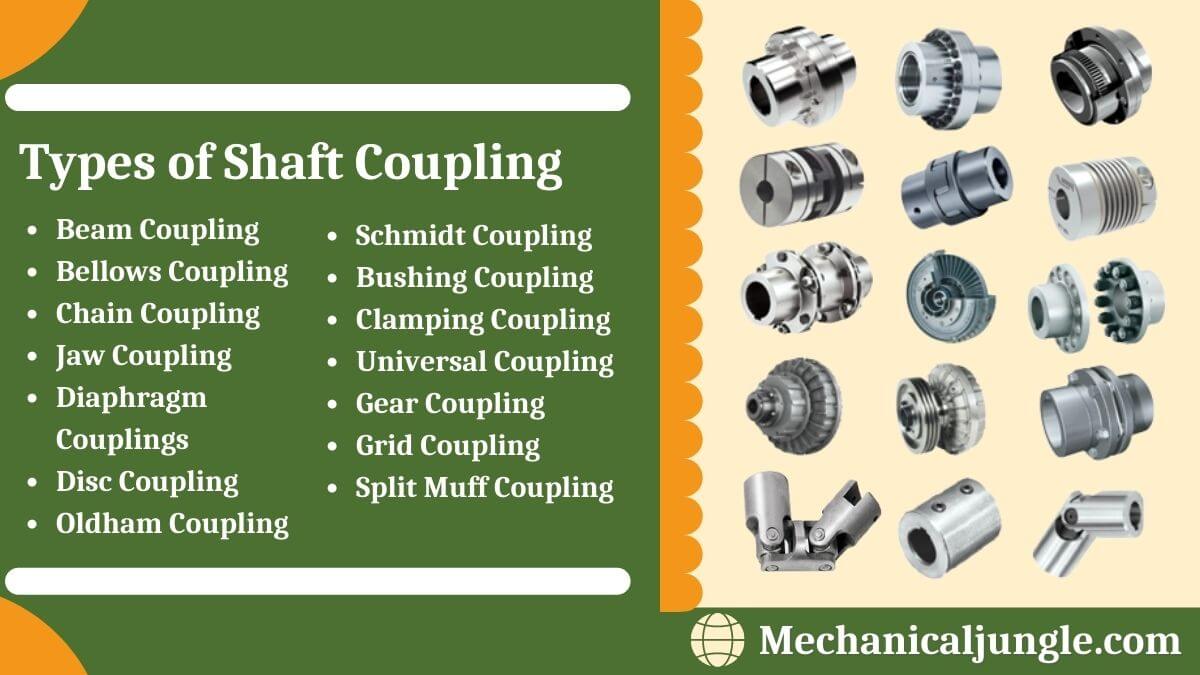

What Is a Coupling? How Does a Shaft Coupling Work? Types of Shaft

Types Of Coupling For Pumps There are several types of pump couplings, each with its unique features and applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. As their name suggests, rigid couplings connect the. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. So, what are the different types of pump coupling and when should they be used? There are several types of pump couplings, each with its unique features and applications. Application considerations when selecting a coupling include: Like everything else on the pump, selecting the right coupling. 2.4 coupling service factors for pumping applications. However, the most common types. 3.1 purpose of a flexible coupling. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump.

From klaeflhwp.blob.core.windows.net

Types Of Pump Coupling at Duane Stuart blog Types Of Coupling For Pumps Application considerations when selecting a coupling include: There are several types of pump couplings, each with its unique features and applications. 2.4 coupling service factors for pumping applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. So, what are the different types of pump coupling and when should they be used? Pump couplings. Types Of Coupling For Pumps.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Types Of Coupling For Pumps 2.4 coupling service factors for pumping applications. As their name suggests, rigid couplings connect the. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Like everything else on the pump, selecting the. Types Of Coupling For Pumps.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Types Of Coupling For Pumps 2.4 coupling service factors for pumping applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Like everything else on the pump, selecting the right coupling. So, what are the different types of pump coupling and when should they be used? Pump couplings connect the pump shaft and motor shaft together in order for. Types Of Coupling For Pumps.

From www.youtube.com

Types of Couplings, Usage and Applications YouTube Types Of Coupling For Pumps However, the most common types. 3.1 purpose of a flexible coupling. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. So, what are the different types of pump coupling and when should they be used? Pump couplings connect the pump shaft and motor shaft together in order for the motor. Types Of Coupling For Pumps.

From www.ameridrives.com

Coupling Types for Different Applications Types Of Coupling For Pumps However, the most common types. Application considerations when selecting a coupling include: 2.4 coupling service factors for pumping applications. 3.1 purpose of a flexible coupling. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation,. Types Of Coupling For Pumps.

From mavink.com

Pump Coupling Types Types Of Coupling For Pumps Application considerations when selecting a coupling include: There are several types of pump couplings, each with its unique features and applications. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 2.4 coupling service factors for pumping applications. Jaw, wrap, sleeve, tire, grid, gear and disc are all. Types Of Coupling For Pumps.

From mavink.com

Pump Coupling Types Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. Application considerations when selecting a coupling include: Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. So, what are the different types of pump coupling and when should they be used? There are several types of pump couplings, each. Types Of Coupling For Pumps.

From www.linquip.com

What Are The Different Types of Pump Couplings? Linquip Types Of Coupling For Pumps Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. There are several types of pump couplings, each with its unique features and applications. Application considerations when selecting a coupling include: 2.4 coupling service factors for pumping applications. So, what are the different types of pump coupling and when should they. Types Of Coupling For Pumps.

From mavink.com

Pump Coupling Types Types Of Coupling For Pumps Application considerations when selecting a coupling include: 2.4 coupling service factors for pumping applications. So, what are the different types of pump coupling and when should they be used? 3.1 purpose of a flexible coupling. As their name suggests, rigid couplings connect the. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in. Types Of Coupling For Pumps.

From www.pumpsandsystems.com

Selecting the Right Coupling Pumps & Systems Types Of Coupling For Pumps 3.1 purpose of a flexible coupling. 2.4 coupling service factors for pumping applications. As their name suggests, rigid couplings connect the. So, what are the different types of pump coupling and when should they be used? Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. Jaw, wrap, sleeve, tire,. Types Of Coupling For Pumps.

From whatispiping.com

What is a Pump Coupling? Its Types, Functions, Applications (PDF Types Of Coupling For Pumps Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. 3.1 purpose of a flexible coupling. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. There are several types of pump couplings, each with its unique features. Types Of Coupling For Pumps.

From www.youtube.com

Types of Coupling YouTube Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. So, what are the different types of pump coupling and when should they be used? Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. There are several types of pump couplings, each with its unique features and applications. Different coupling types cater. Types Of Coupling For Pumps.

From empoweringpumps.com

AVS Series Rigid Couplings for Vertical Turbine Pumps in Refinery Types Of Coupling For Pumps Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. 3.1 purpose of a flexible coupling. Like everything else on the pump, selecting the right coupling. Application considerations when selecting a coupling include: Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in. Types Of Coupling For Pumps.

From www.pumpsandsystems.com

Grid Coupling vs. Gear Coupling Pumps & Systems Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. So, what are the different types of pump coupling and when. Types Of Coupling For Pumps.

From engineeringlearn.com

Types of Mechanical Coupling and Their Uses [with Pictures Types Of Coupling For Pumps 3.1 purpose of a flexible coupling. Application considerations when selecting a coupling include: Like everything else on the pump, selecting the right coupling. There are several types of pump couplings, each with its unique features and applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Pump couplings connect the pump shaft and motor. Types Of Coupling For Pumps.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. 3.1 purpose of a flexible coupling. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Like everything else on the pump, selecting the right coupling. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible. Types Of Coupling For Pumps.

From www.slideserve.com

PPT Couplings PowerPoint Presentation, free download ID9472255 Types Of Coupling For Pumps Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. As their name suggests, rigid couplings connect the. So, what are the different types of pump coupling and when should they be used? There are several types of pump couplings, each with its unique features and applications. 2.4 coupling service factors for pumping applications. Pump. Types Of Coupling For Pumps.

From www.johncrane.com

General Process Industries Couplings for Pumps and Agitators John Crane Types Of Coupling For Pumps Application considerations when selecting a coupling include: 3.1 purpose of a flexible coupling. So, what are the different types of pump coupling and when should they be used? Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. 2.4 coupling service factors for pumping applications. Jaw, wrap, sleeve, tire, grid,. Types Of Coupling For Pumps.

From exokfnvgp.blob.core.windows.net

Types Of Hydraulic Pump Coupling at Peter Kelley blog Types Of Coupling For Pumps So, what are the different types of pump coupling and when should they be used? Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Application considerations when selecting a coupling include: However, the most common types. There are several types of pump couplings, each with its unique features and applications. 3.1 purpose of a. Types Of Coupling For Pumps.

From heidyfersli.blogspot.com

Explain Different Types of Coupling With Suitable Example Types Of Coupling For Pumps However, the most common types. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Application considerations when selecting a coupling include: Like everything else on the pump, selecting the right coupling. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. There. Types Of Coupling For Pumps.

From www.pinterest.com

Different Types of Couplings and Their Applications Explained Types Of Coupling For Pumps Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. As their name suggests, rigid couplings connect the. So, what are the different types of pump coupling and when should they be used? However, the most common types. Different coupling types cater to specific requirements, such as torque. Types Of Coupling For Pumps.

From www.youtube.com

Different type of coupling used in industries types of coupling Types Of Coupling For Pumps Like everything else on the pump, selecting the right coupling. As their name suggests, rigid couplings connect the. There are several types of pump couplings, each with its unique features and applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. So, what are the different types of pump coupling and when should they. Types Of Coupling For Pumps.

From klaeflhwp.blob.core.windows.net

Types Of Pump Coupling at Duane Stuart blog Types Of Coupling For Pumps 3.1 purpose of a flexible coupling. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. There are several types of pump couplings, each with its unique features and applications. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Pump. Types Of Coupling For Pumps.

From klaeflhwp.blob.core.windows.net

Types Of Pump Coupling at Duane Stuart blog Types Of Coupling For Pumps So, what are the different types of pump coupling and when should they be used? However, the most common types. Like everything else on the pump, selecting the right coupling. Application considerations when selecting a coupling include: As their name suggests, rigid couplings connect the. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings. Types Of Coupling For Pumps.

From www.tbwoods.com

DuraFlex Elastomer Coupling for Pumps Market TB Wood's Types Of Coupling For Pumps However, the most common types. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 3.1 purpose of a flexible coupling. Application considerations when selecting a coupling include: Different. Types Of Coupling For Pumps.

From www.deppmann.com

HVAC Centrifugal Pump Coupling Types Close, Split, Flexible Types Of Coupling For Pumps Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. 3.1 purpose of a flexible coupling. As their name suggests, rigid couplings connect the. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. So, what are the different types of pump coupling. Types Of Coupling For Pumps.

From repairfixsolorzanori.z21.web.core.windows.net

Pump Motor Coupling Types Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. However, the most common types. So, what are the different types of pump coupling and when should they be used? Like everything else on the pump, selecting the right coupling. 2.4 coupling service factors for pumping applications.. Types Of Coupling For Pumps.

From www.pumpsandsystems.com

Disc Couplings in Oil & Gas Applications Pumps & Systems Types Of Coupling For Pumps Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. As their name suggests, rigid couplings connect the. However, the most common types. Like everything else on the pump, selecting the right coupling. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. 3.1 purpose of. Types Of Coupling For Pumps.

From exokfnvgp.blob.core.windows.net

Types Of Hydraulic Pump Coupling at Peter Kelley blog Types Of Coupling For Pumps However, the most common types. So, what are the different types of pump coupling and when should they be used? 3.1 purpose of a flexible coupling. There are several types of pump couplings, each with its unique features and applications. As their name suggests, rigid couplings connect the. Application considerations when selecting a coupling include: Like everything else on the. Types Of Coupling For Pumps.

From www.flex-couplings.com

Double Disc Pack Coupling / High Speed Flexible Coupling For Pumps Types Of Coupling For Pumps However, the most common types. So, what are the different types of pump coupling and when should they be used? Like everything else on the pump, selecting the right coupling. 3.1 purpose of a flexible coupling. Application considerations when selecting a coupling include: Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently. Types Of Coupling For Pumps.

From www.gouldspumps.com

VIC Vertical Industrial CanType Pumps Goulds Pumps Types Of Coupling For Pumps 2.4 coupling service factors for pumping applications. There are several types of pump couplings, each with its unique features and applications. So, what are the different types of pump coupling and when should they be used? As their name suggests, rigid couplings connect the. Pump couplings connect the pump shaft and motor shaft together in order for the motor to. Types Of Coupling For Pumps.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Types Of Coupling For Pumps Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Jaw, wrap, sleeve, tire, grid, gear and disc are all different types of flexible couplings used in pump systems. 2.4 coupling service factors for pumping applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment. Types Of Coupling For Pumps.

From www.youtube.com

3 coupling types (steel membrane plate pack ) YouTube Types Of Coupling For Pumps 3.1 purpose of a flexible coupling. However, the most common types. There are several types of pump couplings, each with its unique features and applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to. Types Of Coupling For Pumps.

From www.youtube.com

KTR couplings for PumpMotor applications YouTube Types Of Coupling For Pumps So, what are the different types of pump coupling and when should they be used? Pump couplings connect the pump shaft and motor shaft together in order for the motor to efficiently transmit power to the pump. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. As their name suggests, rigid couplings connect the.. Types Of Coupling For Pumps.

From mechanicaljungle.com

What Is a Coupling? How Does a Shaft Coupling Work? Types of Shaft Types Of Coupling For Pumps As their name suggests, rigid couplings connect the. Like everything else on the pump, selecting the right coupling. There are several types of pump couplings, each with its unique features and applications. Different coupling types cater to specific requirements, such as torque transmission, misalignment compensation, and vibration. 3.1 purpose of a flexible coupling. Application considerations when selecting a coupling include:. Types Of Coupling For Pumps.