Countersink Process . Once you’ve got your countersink drill set, follow these steps: Dive into the essentials of countersinks with ruko. Learn how to countersink screws to give your projects a professional look! This easy technique allows you to hide screw heads in. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. This technique not only provides a clean, aesthetic. Select the drill bit that matches up with the size of your screw. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Understand the structure, types, and practical applications of countersinks in.

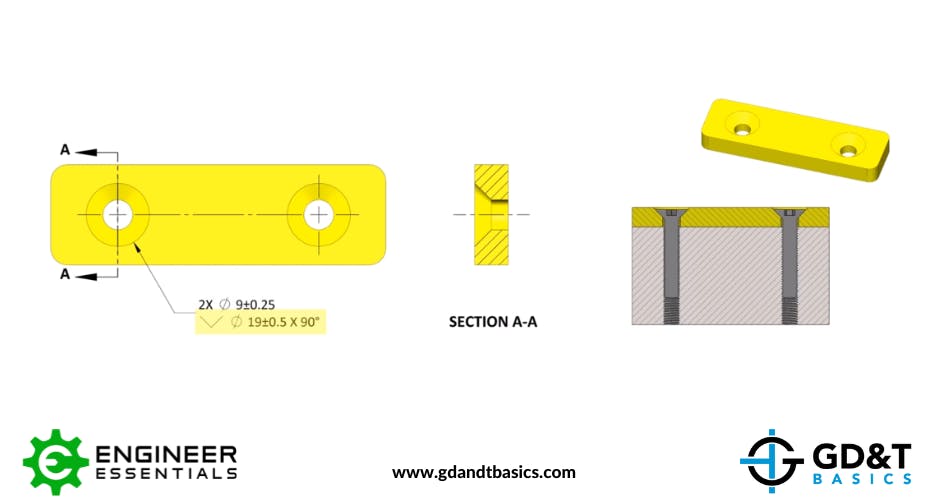

from www.gdandtbasics.com

Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Once you’ve got your countersink drill set, follow these steps: Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Select the drill bit that matches up with the size of your screw. This technique not only provides a clean, aesthetic. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Dive into the essentials of countersinks with ruko. Understand the structure, types, and practical applications of countersinks in. This easy technique allows you to hide screw heads in.

Countersink GD&T Basics

Countersink Process Dive into the essentials of countersinks with ruko. This technique not only provides a clean, aesthetic. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Once you’ve got your countersink drill set, follow these steps: Understand the structure, types, and practical applications of countersinks in. This easy technique allows you to hide screw heads in. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Learn how to countersink screws to give your projects a professional look! Dive into the essentials of countersinks with ruko. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Select the drill bit that matches up with the size of your screw.

From jetposting.com

What are Countersinks, Their Types and Applications? Countersink Process Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Once you’ve got your countersink drill set, follow these steps:. Countersink Process.

From www.cstmanufacturingservices.com

Countersink Tools Cleveland Steel Tool Countersink Process Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting. Countersink Process.

From www.researchgate.net

Details of the countersink drilling sequence (continued). Download Countersink Process This technique not only provides a clean, aesthetic. Understand the structure, types, and practical applications of countersinks in. Select the drill bit that matches up with the size of your screw. Once you’ve got your countersink drill set, follow these steps: Learn how to countersink screws to give your projects a professional look! Countersunk holes are a type of engineering. Countersink Process.

From www.youtube.com

The MultiSink® Combination Drill & Countersink Tool YouTube Countersink Process This technique not only provides a clean, aesthetic. Once you’ve got your countersink drill set, follow these steps: Dive into the essentials of countersinks with ruko. Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersunk holes are a. Countersink Process.

From pcbassemblymanufacturing.com

PCB Countersink special via technology in the process of making PCB Countersink Process Dive into the essentials of countersinks with ruko. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Understand the structure, types, and practical applications of. Countersink Process.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Process Understand the structure, types, and practical applications of countersinks in. Dive into the essentials of countersinks with ruko. This technique not only provides a clean, aesthetic. Select the drill bit that matches up with the size of your screw. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below,. Countersink Process.

From en.wikipedia.org

Countersink Wikipedia Countersink Process This easy technique allows you to hide screw heads in. This technique not only provides a clean, aesthetic. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Understand the structure, types, and practical applications of countersinks in. Learn how to countersink screws to give your projects a professional look! Once you’ve. Countersink Process.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Process Understand the structure, types, and practical applications of countersinks in. This easy technique allows you to hide screw heads in. Once you’ve got your countersink drill set, follow these steps: Dive into the essentials of countersinks with ruko. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product. Countersink Process.

From www.theengineeringknowledge.com

What is Countersink vs. Counterbore Holes in Machining The Countersink Process Dive into the essentials of countersinks with ruko. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Learn how to countersink screws to give your projects a professional look! Once you’ve got your countersink drill set, follow these steps: Understand the structure, types, and practical applications of countersinks in. This easy. Countersink Process.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Process Dive into the essentials of countersinks with ruko. This easy technique allows you to hide screw heads in. This technique not only provides a clean, aesthetic. Understand the structure, types, and practical applications of countersinks in. Once you’ve got your countersink drill set, follow these steps: Select the drill bit that matches up with the size of your screw. The. Countersink Process.

From www.researchgate.net

Two machine operations of the drillingcountersinking process Countersink Process Dive into the essentials of countersinks with ruko. This easy technique allows you to hide screw heads in. This technique not only provides a clean, aesthetic. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Understand the structure, types, and practical applications of. Countersink Process.

From www.wilsontool.com

Countersink Video Wilson Tool International Resources Countersink Process This technique not only provides a clean, aesthetic. Understand the structure, types, and practical applications of countersinks in. Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Once you’ve got your countersink drill set, follow these steps: Countersinking is. Countersink Process.

From pcbassemblymanufacturing.com

PCB Countersink special via technology in the process of making PCB Countersink Process This easy technique allows you to hide screw heads in. Once you’ve got your countersink drill set, follow these steps: Select the drill bit that matches up with the size of your screw. Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the. Countersink Process.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Process The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Once you’ve got your countersink drill set, follow these steps: Understand the structure, types, and practical applications of. Countersink Process.

From www.researchgate.net

Two machine stages of the drillingcountersinking process Download Countersink Process This technique not only provides a clean, aesthetic. Select the drill bit that matches up with the size of your screw. This easy technique allows you to hide screw heads in. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Dive into the essentials of countersinks with ruko. Countersinking is a. Countersink Process.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Process Once you’ve got your countersink drill set, follow these steps: Select the drill bit that matches up with the size of your screw. Understand the structure, types, and practical applications of countersinks in. Learn how to countersink screws to give your projects a professional look! This technique not only provides a clean, aesthetic. Countersinking is a method used to allow. Countersink Process.

From creatorskills.com

What is Countersinking Creator Skills Countersink Process The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. This easy technique allows you to hide screw heads in. Dive into the essentials of countersinks with ruko. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of. Countersink Process.

From www.manufacturingguide.com

Countersink milling Find suppliers, processes & material Countersink Process Understand the structure, types, and practical applications of countersinks in. Dive into the essentials of countersinks with ruko. Once you’ve got your countersink drill set, follow these steps: Select the drill bit that matches up with the size of your screw. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersinking. Countersink Process.

From www.differencebetween.net

Difference Between Counterbore and Countersink Difference Between Countersink Process Dive into the essentials of countersinks with ruko. Select the drill bit that matches up with the size of your screw. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Countersinking is a method used to allow the head of a flat or countersunk screw. Countersink Process.

From www.ablcircuits.co.uk

PCB Hole Types Counterbore vs Countersink ABL Circuits Countersink Process Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Understand the structure, types, and practical applications of countersinks in. Dive into the essentials of countersinks with ruko. Once you’ve got your countersink drill set, follow these steps: Countersinking is. Countersink Process.

From parweld.com

RUKO Countersink Type C Parweld Countersink Process Understand the structure, types, and practical applications of countersinks in. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Dive into the essentials of countersinks with ruko. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper. Countersink Process.

From www.theengineeringknowledge.com

What are Countersink Holes in Engineering? The Engineering Knowledge Countersink Process Dive into the essentials of countersinks with ruko. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Select the drill bit that matches up with the size of your screw. Understand the structure, types, and practical applications of countersinks in. Learn how to countersink screws to give your projects a professional. Countersink Process.

From pcbassemblymanufacturing.com

PCB Countersink special via technology in the process of making PCB Countersink Process The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Select the drill bit that matches up with the size of your screw. This easy technique allows you to hide screw heads in. Understand the structure, types, and practical applications of countersinks in. Once you’ve got your countersink drill set, follow these. Countersink Process.

From www.precisiontoolingchina.com

What is Countersinking? machined turning metal product CNC Countersink Process This easy technique allows you to hide screw heads in. This technique not only provides a clean, aesthetic. Once you’ve got your countersink drill set, follow these steps: Dive into the essentials of countersinks with ruko. Learn how to countersink screws to give your projects a professional look! Understand the structure, types, and practical applications of countersinks in. Countersinking is. Countersink Process.

From www.youtube.com

Drilling Machine Operations Boring, Reaming, Counter Sinking, Spot Countersink Process This technique not only provides a clean, aesthetic. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Learn how to countersink screws to give your projects a professional look! The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring. Countersink Process.

From www.novacam.com

3D countersink measurement noncontact and automated Novacam Countersink Process Learn how to countersink screws to give your projects a professional look! Understand the structure, types, and practical applications of countersinks in. This technique not only provides a clean, aesthetic. Dive into the essentials of countersinks with ruko. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product. Countersink Process.

From www.gdandtbasics.com

Countersink GD&T Basics Countersink Process Learn how to countersink screws to give your projects a professional look! This easy technique allows you to hide screw heads in. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Select the drill bit that matches up with the size of your. Countersink Process.

From www.youtube.com

12mm Mild Steel 4 Kinds Screw Countersink Process/Edgeline Beveling Countersink Process The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Dive into the essentials of countersinks with ruko. Countersinking is a method used to allow the head of. Countersink Process.

From www.youtube.com

How to countersink a countersunk screw YouTube Countersink Process Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product surface smoother. Select the drill bit that matches up with the size of your screw. Dive into the essentials of countersinks with ruko. Once you’ve got your countersink drill set, follow these steps: This technique not only provides. Countersink Process.

From leatherworker.net

Pattern making How Do I Do That? Countersink Process This technique not only provides a clean, aesthetic. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. Once you’ve got your countersink drill set, follow. Countersink Process.

From www.youtube.com

What are Counterbore and Countersink? PCB Knowledge YouTube Countersink Process Dive into the essentials of countersinks with ruko. This technique not only provides a clean, aesthetic. Once you’ve got your countersink drill set, follow these steps: Select the drill bit that matches up with the size of your screw. Learn how to countersink screws to give your projects a professional look! Countersinking is a method used to allow the head. Countersink Process.

From www.cartertools.com

5 Doing it — Countersinking 1 documentation Countersink Process Understand the structure, types, and practical applications of countersinks in. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. This easy technique allows you to hide screw heads in. Countersunk holes are a type of engineering hole most commonly used for the aesthetic flush fitting of fasteners to render a product. Countersink Process.

From www.youtube.com

Countersink laser holes YouTube Countersink Process Once you’ve got your countersink drill set, follow these steps: The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Learn how to countersink screws to give your projects a professional look! This easy technique allows you to hide screw heads in. Countersinking is a method used to allow the head of. Countersink Process.

From sendcutsend.com

The Benefits of Countersinking SendCutSend Countersink Process Select the drill bit that matches up with the size of your screw. Countersinking is a method used to allow the head of a flat or countersunk screw to sit flush with, or below, the surface of the material. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. This easy technique. Countersink Process.

From www.semanticscholar.org

Figure 11 from Avoiding knifeedge countersinks in GLARE through Countersink Process Learn how to countersink screws to give your projects a professional look! Once you’ve got your countersink drill set, follow these steps: Understand the structure, types, and practical applications of countersinks in. The countersinking process requires precision, from choosing the correct countersink drill bit to ensuring the proper countersink angle. Dive into the essentials of countersinks with ruko. This easy. Countersink Process.