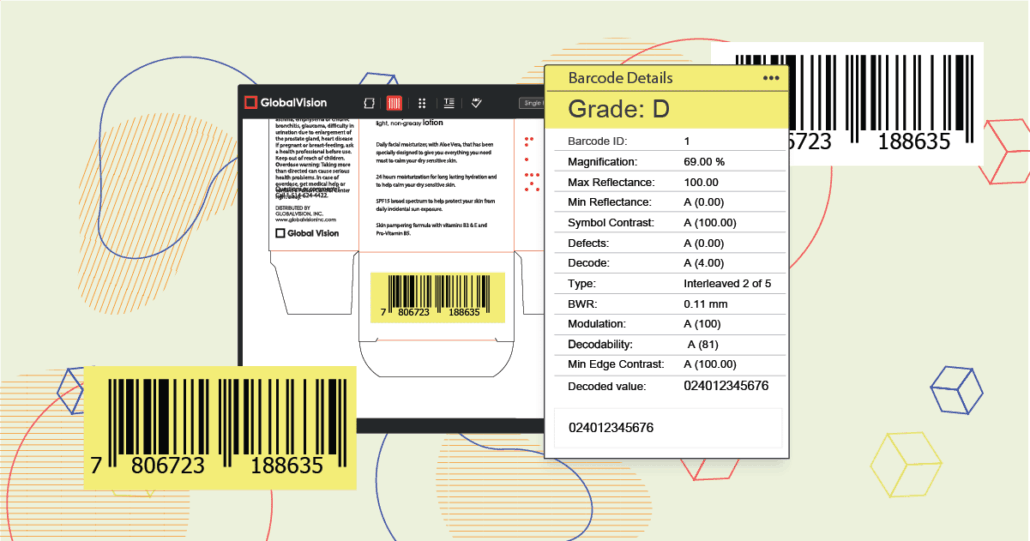

Barcode Reader Grade . A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. It is typical that an application standard. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Verifiers analyze a barcode and assign a quality grade,. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Each scan line is graded against nine different parameters to assess.

from blog.globalvision.co

Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. It is typical that an application standard. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Each scan line is graded against nine different parameters to assess. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Verifiers analyze a barcode and assign a quality grade,.

The Ultimate Layman’s Guide to Barcode Types and Printing

Barcode Reader Grade Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Each scan line is graded against nine different parameters to assess. Verifiers analyze a barcode and assign a quality grade,. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. It is typical that an application standard.

From globalvision.co

Barcode Inspection Solution Verify, Decode, and Grade Barcodes Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Verifiers analyze a barcode and assign a quality grade,. Within the center area that makes up 80% of. Barcode Reader Grade.

From comtrolsolutions.com

1D Or 2D Barcodes An InDepth Analysis Of Both Label Types Comtrol Solutions Barcode Reader Grade It is typical that an application standard. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. A barcode quality grade is intended. Barcode Reader Grade.

From www.amazon.com

NADAMOO Wireless Barcode Scanner 328 Feet Transmission Distance USB Cordless 1D Barcode Reader Grade It is typical that an application standard. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in. Barcode Reader Grade.

From www.thermofisher.com

VisionMate™ Wireless Barcode Reader Barcode Reader Grade A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Within the center area that makes up 80% of the barcode (excluding the. Barcode Reader Grade.

From www.kennedygrp.com

ANSI/ISO Barcode Quality Grade A Deep Dive into 9 Quality Parameters Labeling Solutions The Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. It is typical that an application standard. Each scan line is graded against nine different parameters to assess. A barcode quality grade is intended to do just that — verify the quality of your printed barcode. Barcode Reader Grade.

From www.smithcorona.com

Barcode 101 Information You Need to Know Barcode Blog Barcode Reader Grade A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. In the iso 15415 standard for 2d codes printed on. Barcode Reader Grade.

From globalvision.co

Barcode Inspection Solution Verify, Decode, and Grade Barcodes Barcode Reader Grade Verifiers analyze a barcode and assign a quality grade,. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed. Barcode Reader Grade.

From www.barcodesinc.com

AveryDennison 9485 Portable Printer Barcode Reader Grade It is typical that an application standard. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Verifiers analyze. Barcode Reader Grade.

From www.riotec.com.tw

Fixed Mount Barcode Scanner 2D FS5020J Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Each scan line is graded against nine different parameters to assess. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Barcode verifiers analyze a barcode and assign. Barcode Reader Grade.

From globalvision.co

Barcode Inspection Solution Verify, Decode, and Grade Barcodes Barcode Reader Grade Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Verifiers analyze a barcode and assign a quality grade,. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Each scan line. Barcode Reader Grade.

From www.cognex.com

Imagebased Barcode Readers Cognex Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Verifiers analyze a barcode and assign a quality grade,. Using the iso 15416 grading process, 1d barcodes. Barcode Reader Grade.

From bytescout.com

Reading Barcodes with ByteScout Barcode Reader SDK ByteScout Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. It is typical that an application standard. Barcode verifiers analyze a barcode and. Barcode Reader Grade.

From www.walmart.com

300 Times/Second Decoding Barcode Reader 15mil ±50° pitch/35° tilt/±55° skew Barcode Scanner Barcode Reader Grade Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Verifiers analyze a barcode and assign a quality grade,. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed. Barcode Reader Grade.

From www.indiamart.com

Wired Handheld Barcode Reader, Rs 2200 /piece Amcode Infotech ID 21748345988 Barcode Reader Grade Verifiers analyze a barcode and assign a quality grade,. Each scan line is graded against nine different parameters to assess. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. In the iso 15415 standard for 2d codes. Barcode Reader Grade.

From blog.globalvision.co

The Ultimate Layman’s Guide to Barcode Types and Printing Barcode Reader Grade A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. It is typical that an application standard. Each scan line is graded against nine different parameters to assess. Verifiers analyze a barcode and assign a quality grade,. Using. Barcode Reader Grade.

From www.aeroexpo.online

Portable barcode reader MX1000 series Cognex 2D / 1D / USB Barcode Reader Grade Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture. Barcode Reader Grade.

From www.amazon.com

Tera 1D 2D QR Barcode Scanner Wireless and Wired with Battery Level Indicator Barcode Reader Grade It is typical that an application standard. Verifiers analyze a barcode and assign a quality grade,. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. Using the. Barcode Reader Grade.

From www.csensors.com

Online Sales of USB, Wireless, CCD, Bluetooth, Barcode Scanner, Barcode Reader, Bar Code Scanners Barcode Reader Grade Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. Each scan line is graded against nine different parameters to assess. Using the. Barcode Reader Grade.

From bytescout.com

Barcode Scanner Online Free from Camera, Barcode Reader Online ByteScout Barcode Reader Grade Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Each scan line is graded against nine different parameters to assess. It is typical that an application standard. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. Within. Barcode Reader Grade.

From legacytechnologyservices.blogspot.com

Legacy Technology Services Blog Barcode Scanners and Printers, Mobile Computers, Point of Sale Barcode Reader Grade A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Using the iso 15416 grading process, 1d barcodes are graded by averaging the. Barcode Reader Grade.

From www.walmart.com

Costech Wireless USB Barcode Scanner 2.4GHz, [Plug & Play] Wireless Handheld Bar Code Reader Barcode Reader Grade A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Each scan line is graded against nine different parameters to assess. Verifiers analyze a barcode and assign a quality grade,. In the iso 15415 standard for 2d codes. Barcode Reader Grade.

From www.cometelectronic.com

,factory,manufacturer Barcode Reader Grade It is typical that an application standard. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Barcode verifiers. Barcode Reader Grade.

From okcredit.in

How does a Barcode Reader work? Know the functioning, types & more Barcode Reader Grade Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. Verifiers analyze a barcode and assign a quality grade,. A barcode quality grade. Barcode Reader Grade.

From barcodelive.org

Barcodes Standards All Things You Should Know Barcode Reader Grade Verifiers analyze a barcode and assign a quality grade,. It is typical that an application standard. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Each scan line is graded against nine different parameters to assess. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results. Barcode Reader Grade.

From www.eyoyousa.com

Eyoyo EYH2 Handheld USB 2D Barcode Scanner QR PDF417 Data Matrix 1D Bar Code Scanner Wired Barcode Reader Grade Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Each scan line is graded against nine different parameters to assess. Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. It is typical that an application. Barcode Reader Grade.

From barcodelive.org

Barcode Grader Why Use And How Barcode Grading Work Barcode Reader Grade Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Using the iso 15416 grading process, 1d barcodes are graded by averaging. Barcode Reader Grade.

From www.youtube.com

How to Read Barcodes YouTube Barcode Reader Grade It is typical that an application standard. Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode quality grade is intended to do just that —. Barcode Reader Grade.

From globalvision.co

Barcode Inspection Solution Verify, Decode, and Grade Barcodes Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Within the center area that makes up 80% of the barcode (excluding. Barcode Reader Grade.

From www.techstore.pk

Laser Bar Code Reader Techstore Barcode Reader Grade Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only. Barcode Reader Grade.

From globalvision.co

Barcode Inspection Solution Verify, Decode, and Grade Barcodes Barcode Reader Grade In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Using the iso 15416 grading process, 1d barcodes are graded by averaging. Barcode Reader Grade.

From www.amazon.in

NISHICA Laser Barcode Scanner, Handheld 1 D USB Wired Barcode Reader Optical Laser High Speed Barcode Reader Grade It is typical that an application standard. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. Each scan line is graded against nine different parameters to assess. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size. Barcode Reader Grade.

From infoscan.en.made-in-china.com

Industrial Grade Compact FixedMount Barcode Code Reader Scanner FV105 China Industrial Fixed Barcode Reader Grade Using the iso 15416 grading process, 1d barcodes are graded by averaging the results of 10 scan lines. A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. Within the center area that makes up 80% of the. Barcode Reader Grade.

From www.amazon.ca

Alacrity 2D Industrial Wireless Barcode Scanner with Charging Stand, Bluetooth Drop Resistant Barcode Reader Grade Within the center area that makes up 80% of the barcode (excluding the top and bottom 10%), 10 scans. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f) or a numerical. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture. Barcode Reader Grade.

From infoscan.en.made-in-china.com

Industrial Grade FixedMount QR Barcode Reader Bar Code Scanner China Barcode Reader and Barcode Reader Grade A barcode quality grade is intended to do just that — verify the quality of your printed barcode so you know you can count on it to perform in its necessary setting. In the iso 15415 standard for 2d codes printed on a label, you must set the aperture size in accordance with your application standard. Within the center area. Barcode Reader Grade.

From barcodelive.org

How to read a barcode? [A Definite Guide in 2022] Barcode Reader Grade A barcode grader enables you to rate each barcode's quality, as opposed to a scanner, which can only tell you whether it can. It is typical that an application standard. Verifiers analyze a barcode and assign a quality grade,. Barcode verifiers analyze a barcode and assign a quality grade to them, typically expressed as a letter grade (a through f). Barcode Reader Grade.