Brazing Fixtures . Torch or manual brazing, induction brazing, resistance brazing, and vacuum. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. there are four main types of brazing heating methods: — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for.

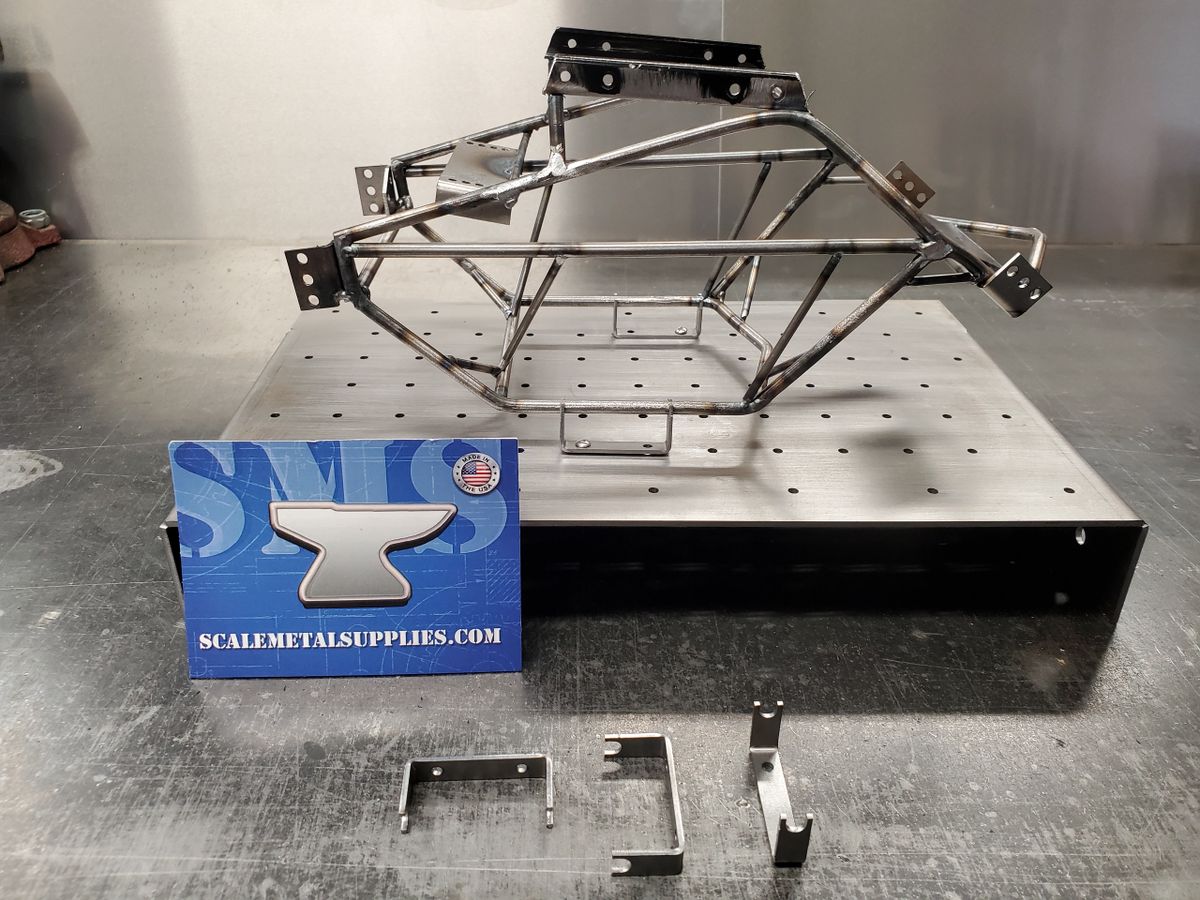

from scalemetalsupplies.com

brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. there are four main types of brazing heating methods: — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for. Torch or manual brazing, induction brazing, resistance brazing, and vacuum.

Welding, Brazing Tables and Fixtures

Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing is a method of joining two pieces of metal together with a third, molten filler metal. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages.

From machine-tools-international.com

Brazing frames and Fixtures Machine & Tools International LLC Brazing Fixtures Of all the methods available for. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. brazing is a method of joining two pieces of metal together with a third, molten filler metal. — fixtures should be designed for quick changeover when brazing a family of parts with the same. Brazing Fixtures.

From thrmachinery.us

ALUMINUM BRAZING EQUIPMENT AND FIXTURES THR Machinery Brazing Fixtures Of all the methods available for. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: brazing is a method of joining two pieces of metal. Brazing Fixtures.

From www.mechero.my

What is Brazing Process? Brazing Types & Applications Brazing Fixtures — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal.. Brazing Fixtures.

From thrmachinery.us

ALUMINUM BRAZING EQUIPMENT AND FIXTURES THR Machinery Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The. Brazing Fixtures.

From thrmachinery.us

ALUMINUM BRAZING EQUIPMENT AND FIXTURES THR Machinery Brazing Fixtures — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. Of all the methods available for. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. The weld should be small, just enough. Brazing Fixtures.

From machine-tools-international.com

Brazing frames and Fixtures Machine & Tools International LLC Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for. Brazing Fixtures.

From www.indiamart.com

Polished Stainless Steel Brazing Fixture, For Industrial at Rs 825000 Brazing Fixtures Torch or manual brazing, induction brazing, resistance brazing, and vacuum. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. — fundamental criteria. Brazing Fixtures.

From scalemetalsupplies.com

Welding, Brazing Tables and Fixtures Brazing Fixtures there are four main types of brazing heating methods: brazing is a method of joining two pieces of metal together with a third, molten filler metal. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. Of all the methods available for. — fixtures should be designed for. Brazing Fixtures.

From www.ajaxtocco.de

Brazing fixtures Inductor Manufacturing Products AjaxTOCCO Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a method of joining two pieces. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Rotating Welding Fixture Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The accurate positioning of components. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Rotating Welding Fixture Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal.. Brazing Fixtures.

From machine-tools-international.com

Brazing frames and Fixtures Machine & Tools International LLC Brazing Fixtures there are four main types of brazing heating methods: The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The accurate positioning of components relative to each other. Brazing Fixtures.

From blog.lucasmilhaupt.com

Fixtures for Brazing & Soldering Brazing Fixtures brazing is a method of joining two pieces of metal together with a third, molten filler metal. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Rotating Welding Fixture Brazing Fixtures The accurate positioning of components relative to each other is mandatory for many brazed assemblies. there are four main types of brazing heating methods: The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fundamental criteria that brazing personnel needs to fully understand and. Brazing Fixtures.

From blog.lucasmilhaupt.com

Fixtures for Brazing & Soldering Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. The accurate positioning of components relative to each. Brazing Fixtures.

From www.tradeindia.com

Brazing Fixture For Copper Tube at 30000.00 INR in Noida M/s K.t Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. Of all the methods available for. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. brazing is a method of joining two pieces of metal together with a third, molten. Brazing Fixtures.

From www.ajaxtocco.de

Brazing fixtures Inductor Manufacturing Products AjaxTOCCO Brazing Fixtures — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing is a method of joining two pieces of metal together with a third, molten filler metal. Of all the methods available for. The weld should be small, just enough to hold the parts together until it. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Custom Welding Fixture Brazing Fixtures Torch or manual brazing, induction brazing, resistance brazing, and vacuum. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The accurate positioning of components relative to each other is. Brazing Fixtures.

From thrmachinery.us

ALUMINUM BRAZING EQUIPMENT AND FIXTURES THR Machinery Brazing Fixtures there are four main types of brazing heating methods: — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The weld should be small, just enough to hold the parts together until. Brazing Fixtures.

From www.tridan.com

Brazing Fixture NBF Available From Tridan International Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. — fundamental criteria. Brazing Fixtures.

From www.taruenterprises.com

BRAZING FIXTURE BRAZING FIXTURES FOR INDUSTRIAL AND AUTOMOTIVE PARTS Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is. Brazing Fixtures.

From www.ajaxtocco.de

Brazing fixtures Inductor Manufacturing Products AjaxTOCCO Brazing Fixtures Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a method of joining two pieces of metal together with a third, molten filler metal. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. Of all the methods available for. there are four main types of brazing heating methods: . Brazing Fixtures.

From machine-tools-international.com

Brazing frames and Fixtures Machine & Tools International LLC Brazing Fixtures Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. brazing is a method of joining two pieces of metal together with a third, molten filler metal. — fundamental criteria that brazing personnel needs to fully understand and follow in. Brazing Fixtures.

From machine-tools-international.com

Brazing frames and Fixtures Machine & Tools International LLC Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. there are four main types of brazing heating methods: Of all the methods available for. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. — fundamental criteria that brazing personnel needs to fully understand. Brazing Fixtures.

From shahab-co.com

What is Induction brazing Brazing uses heat and a filler metal (alloy Brazing Fixtures — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. The weld should be small, just enough to hold the parts together until. Brazing Fixtures.

From www.ajaxtocco.de

Brazing fixtures Inductor Manufacturing Products AjaxTOCCO Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. — fundamental criteria that brazing personnel needs to fully understand. Brazing Fixtures.

From www.tradeindia.com

Brazing Fixture For Copper Tubes at Best Price in Noida M/S K.T Brazing Fixtures there are four main types of brazing heating methods: Of all the methods available for. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a method of joining two pieces of metal together with a third,. Brazing Fixtures.

From www.researchgate.net

Horizontal brazing fixture. Download Scientific Diagram Brazing Fixtures Of all the methods available for. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. there are four main types of brazing heating methods: — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold. Brazing Fixtures.

From marketplace.aviationweek.com

FullService Vacuum Brazing and HeatTreating Aviation Products Brazing Fixtures The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold and burner positions. — fundamental criteria that brazing personnel needs to fully understand and follow in order. Brazing Fixtures.

From www.indiamart.com

Custom Brazing Fixture at best price in Noida by M/S K.T.Mechanical Brazing Fixtures — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. brazing is a method of joining two pieces of metal together with a third, molten filler metal. — fixtures should be designed for quick changeover when brazing a family. Brazing Fixtures.

From www.indiamart.com

Custom Brazing Fixture at best price in Noida by M/S K.T.Mechanical Brazing Fixtures — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. The accurate positioning of components relative to each other is mandatory for many brazed assemblies. Torch or manual brazing, induction brazing, resistance brazing,. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Rotating Welding Fixture Brazing Fixtures there are four main types of brazing heating methods: brazing is a method of joining two pieces of metal together with a third, molten filler metal. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The weld should be small, just enough to hold the parts together until. Brazing Fixtures.

From www.indiamart.com

Welding / Brazing Fixture at best price in Noida by M/S K.T.Mechanical Brazing Fixtures brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. The weld should be small, just enough to hold the parts together until it can put into the brazing furnace for subsequent brazing. — fixtures should be designed for quick changeover when brazing a family of parts with the same manifold. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Custom Welding Fixture Brazing Fixtures The accurate positioning of components relative to each other is mandatory for many brazed assemblies. brazing and glass to metal sealing fixtures and jigs are used to encapsulate today’s sophisticated electronic packages. Of all the methods available for. there are four main types of brazing heating methods: brazing is a method of joining two pieces of metal. Brazing Fixtures.

From www.ktautomations.com

Welding, Brazing & Drilling Fixtures Rotating Welding Fixture Brazing Fixtures The accurate positioning of components relative to each other is mandatory for many brazed assemblies. Torch or manual brazing, induction brazing, resistance brazing, and vacuum. — fundamental criteria that brazing personnel needs to fully understand and follow in order to ensure good brazing. The weld should be small, just enough to hold the parts together until it can put. Brazing Fixtures.