Gear Grinding Time . Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. To address the stricter form deviation. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. The process of gear grinding is one of the final steps of producing gears. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,.

from www.hmcgears.com

Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. The process of gear grinding is one of the final steps of producing gears. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. To address the stricter form deviation.

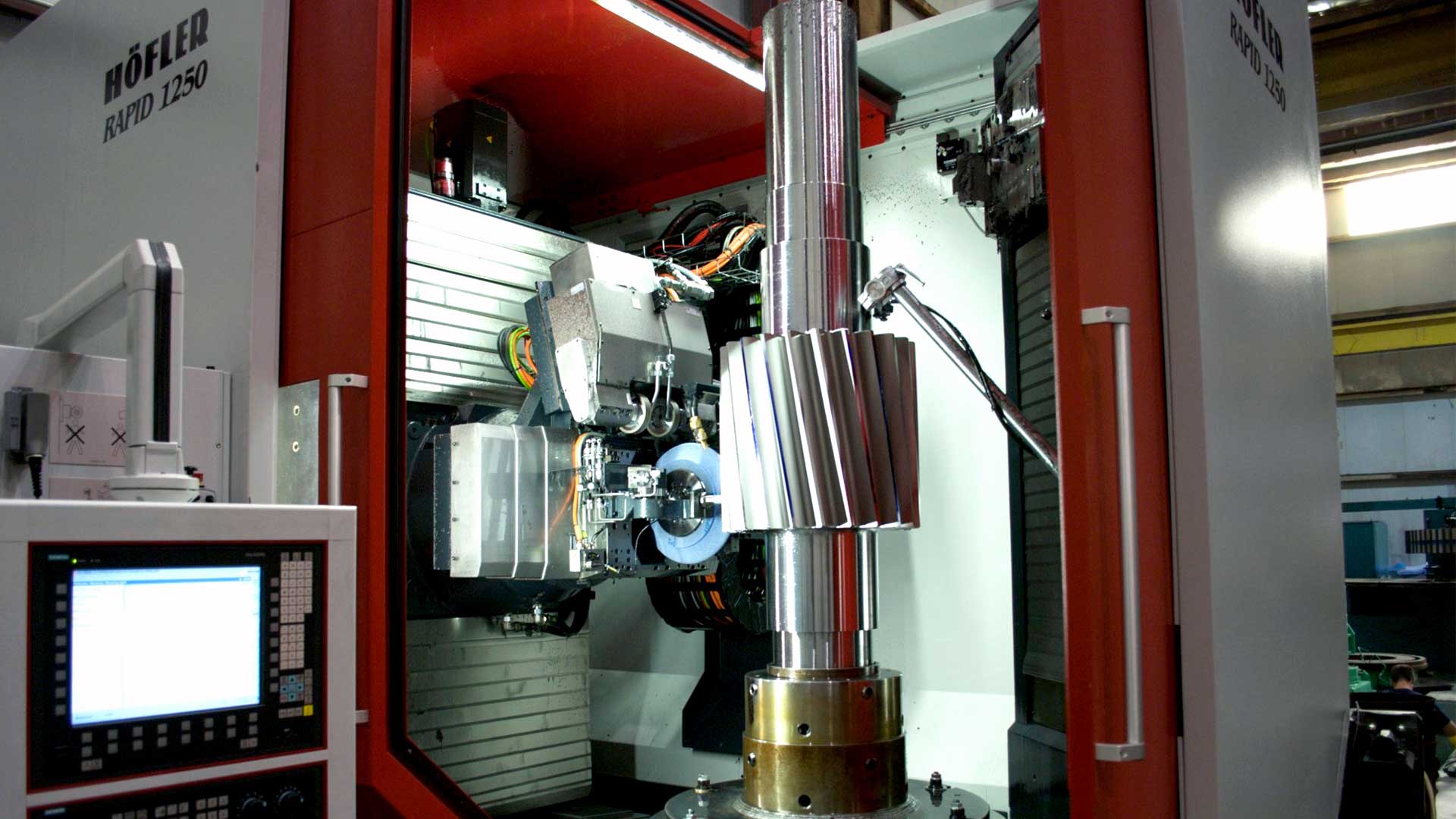

Hofler RAPID 1250 Gear Grinder HMC Gears

Gear Grinding Time There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. To address the stricter form deviation. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. The process of gear grinding is one of the final steps of producing gears.

From www.youtube.com

Gear Grinding on Höfler Cylindrical Gear Grinding Machine RAPID 1250 Gear Grinding Time There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. The process of gear grinding is one of the final steps of producing gears. Using incorrect programming parameters in. Gear Grinding Time.

From www.youtube.com

Grinding Gearshift Explained YouTube Gear Grinding Time It is an intricate process used to remove surface materials on. As a machine element, the gear wheel is an elementary component of almost all modern machines. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in. Gear Grinding Time.

From www.geartechnology.com

Force Modeling in Generating Gear Grinding Considering the Grinding Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time. Gear Grinding Time.

From www.dreamstime.com

Gear Grinding Machine in Operation, Grinding of Teeth of a Wheel with Gear Grinding Time It is an intricate process used to remove surface materials on. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. The process of gear grinding is one of the final steps of producing gears. There are two main methods of. Gear Grinding Time.

From extrudergearbox.net

Gear Grinding The Process and Its Benefits Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. To address the stricter form deviation. There are two main methods of bevel gear grinding—“plunge grinding” and. Gear Grinding Time.

From www.holroyd.com

Holroyd HG350G gear grinding centre is first to use Siemens’ Sinumerik Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. As a machine element, the gear wheel is an elementary component of almost all modern machines. To address the stricter form deviation. It is an intricate process used to remove surface materials on. Using incorrect programming parameters in the profile grinding process can result in increased. Gear Grinding Time.

From www.researchgate.net

Gear machining on the HOFLER RAPID 1250 gear grinding machine Gear Grinding Time As a machine element, the gear wheel is an elementary component of almost all modern machines. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. To address the stricter form deviation. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. The. Gear Grinding Time.

From www.mactool.com

Gear Grinding Machine Tools (India) Limited Gear Grinding Time There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It is an intricate process used to remove surface materials on. Using. Gear Grinding Time.

From www.researchgate.net

Schematic illustration of gear form grinding by a grinding wheel Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It is an intricate process used to remove surface materials on. To address the stricter form deviation. The process of gear grinding is one of the final steps of producing gears.. Gear Grinding Time.

From www.samputensili.com

Gear Generating Grinding machine G 450 Samputensili Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. It is an intricate process used to remove surface materials on. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part. Gear Grinding Time.

From www.geartechnology.com

Large Gear Grinding Gear Technology Magazine Gear Grinding Time As a machine element, the gear wheel is an elementary component of almost all modern machines. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of. Gear Grinding Time.

From www.researchgate.net

Kinematics of gear grinding Download Scientific Diagram Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. As a machine element, the gear wheel is an elementary component of. Gear Grinding Time.

From www.hmcgears.com

Hofler RAPID 1250 Gear Grinder HMC Gears Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the. Gear Grinding Time.

From emergencygears.com

Gear Grinding Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. The process of gear grinding is one of the final steps of producing gears. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear. Gear Grinding Time.

From www.geartechnology.com

Technology Advances for Continuous Generating Gear Grinding in EV and Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final steps of producing gears. As a machine element, the gear. Gear Grinding Time.

From link.springer.com

Gear Grinding SpringerLink Gear Grinding Time As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. The process of gear grinding is one of the final steps of producing gears. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles. Gear Grinding Time.

From www.manufacturingguide.com

Gear profile grinding Find suppliers, processes & material Gear Grinding Time To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. The process of gear grinding is one of the. Gear Grinding Time.

From hopwoodgears.com

Gear Grinding Hopwood Gear Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. As a machine element, the gear wheel is an elementary component of almost all modern machines. The process of gear grinding is one of the final steps of producing gears. There. Gear Grinding Time.

From www.dreamstime.com

Gear Grinding Machine in Operation, Grinding of Teeth of a Wheel with Gear Grinding Time As a machine element, the gear wheel is an elementary component of almost all modern machines. The process of gear grinding is one of the final steps of producing gears. To address the stricter form deviation. It is an intricate process used to remove surface materials on. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.”. Gear Grinding Time.

From www.franklingear.com

Gear Grinding Franklin Machine & Gear Corporation Gear Grinding Time There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. The process of gear grinding is one of the final steps of producing gears. To address the stricter form deviation. Making larger gears. Gear Grinding Time.

From gearmotions.com

Benefits of Precision Gear Grinding Gear Motions Gear Grinding Time To address the stricter form deviation. It is an intricate process used to remove surface materials on. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. Using incorrect programming parameters in the profile grinding process can result in increased cycle. Gear Grinding Time.

From www.dreamstime.com

Grinding Machine, Grinding with Sparks a Gear Wheel in the Automotive Gear Grinding Time There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. The process of gear grinding is one of the final steps of producing gears. To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process. Gear Grinding Time.

From www.researchgate.net

Gear form grinding with form wheel Download Scientific Diagram Gear Grinding Time As a machine element, the gear wheel is an elementary component of almost all modern machines. The process of gear grinding is one of the final steps of producing gears. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It. Gear Grinding Time.

From www.researchgate.net

Grit movement of gear grinding Download Scientific Diagram Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. As a machine element, the gear wheel is an elementary component of almost all modern machines. It is an intricate process used to remove surface materials on. To address the stricter form deviation. Using incorrect programming parameters in the profile grinding process can result in increased. Gear Grinding Time.

From www.sakabrasives.com

Thread and Gear Grinding Internal Thread Grinding Solutions SAK Gear Grinding Time To address the stricter form deviation. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. As a machine element, the gear wheel is an elementary component of almost all modern machines. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. The. Gear Grinding Time.

From www.slideserve.com

PPT GENERATING GEAR GRINDING PowerPoint Presentation, free download Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. The process of gear grinding is one of the final steps of producing gears. To address the stricter form deviation. Using incorrect programming parameters in the profile grinding process can result. Gear Grinding Time.

From www.dreamstime.com

Worker with a Grinding Machine Processes a Gear Wheel Production of Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. The process of gear grinding is one of the final steps of producing. Gear Grinding Time.

From www.canadianmetalworking.com

Technology Spotlight Largegear grinding Gear Grinding Time To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles. Gear Grinding Time.

From www.youtube.com

Grinding gears pt3 YouTube Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. To address the stricter form deviation. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Using incorrect programming parameters in the. Gear Grinding Time.

From chinagearmotions.com

Gear Grinding Precision Gear Manufacturing Services at China Gear Motions Gear Grinding Time To address the stricter form deviation. As a machine element, the gear wheel is an elementary component of almost all modern machines. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It is an intricate process used to remove surface. Gear Grinding Time.

From gearsolutions.com

Continuous improvement in generating gear grinding Gear Solutions Gear Grinding Time Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. To address the stricter form deviation. As a machine element, the gear wheel. Gear Grinding Time.

From learndriving.tips

Why Do Car Gears Grind? » Learn Driving Tips Gear Grinding Time The process of gear grinding is one of the final steps of producing gears. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. As a machine element, the gear wheel is an. Gear Grinding Time.

From minigears.co.uk

Gear Grinding Services High Precision Gear Finishing Gear Grinding Time Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high material/manufacturing costs, the pressure of a time deadline,. It is an intricate process used to remove surface materials on. To address the stricter form deviation. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge. Gear Grinding Time.

From ronsongears.com.au

Gear Cutting CNC Gear Cutting CNC Gear Grinding Ronson Gears Gear Grinding Time To address the stricter form deviation. There are two main methods of bevel gear grinding—“plunge grinding” and “generating grinding.” plunge grinding uses a grinding wheel. The process of gear grinding is one of the final steps of producing gears. Making larger gears in smaller lot sizes represents a challenge for all manufacturers, due in part to the hurdles of high. Gear Grinding Time.

From seibushoko.com

Profile Gear Grinding|MACHINES|Products|SEIBU SHOKO CO., LTD. Gear Grinding Time It is an intricate process used to remove surface materials on. As a machine element, the gear wheel is an elementary component of almost all modern machines. Using incorrect programming parameters in the profile grinding process can result in increased cycle time, poor gear quality,. To address the stricter form deviation. The process of gear grinding is one of the. Gear Grinding Time.