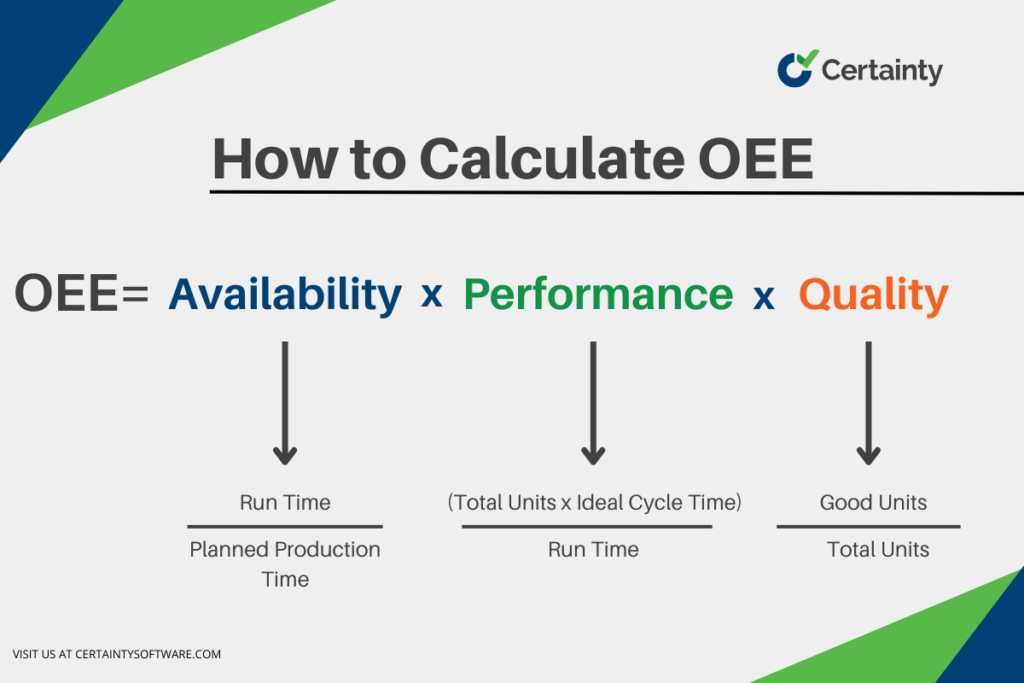

Industry Standard Oee . Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. It suits any industry or process. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. What are the oee scores for different industries? Availability takes into account all events that stop. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Often, it’s a component of an overall lean manufacturing process. Oee is the result of three factors,. Based on our data, the graph below shows the average oee for manufacturers using. Oee is calculated by multiplying the three oee factors:

from www.certaintysoftware.com

Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is the result of three factors,. Based on our data, the graph below shows the average oee for manufacturers using. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Availability takes into account all events that stop. Oee is calculated by multiplying the three oee factors: Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. What are the oee scores for different industries? Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized.

OEE Meaning in Manufacturing How to Optimize Efficiency

Industry Standard Oee Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Often, it’s a component of an overall lean manufacturing process. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is calculated by multiplying the three oee factors: Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Availability takes into account all events that stop. It suits any industry or process. Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Based on our data, the graph below shows the average oee for manufacturers using. Oee is the result of three factors,. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. What are the oee scores for different industries?

From www.oee.com

What Is OEE (Overall Equipment Effectiveness)? OEE Industry Standard Oee It suits any industry or process. Oee is the result of three factors,. Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Based on our data, the graph below shows the average oee for manufacturers using. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production. Industry Standard Oee.

From www.linkedin.com

OEE Impacts Optimized Production Cycle Time Industry Standard Oee Based on our data, the graph below shows the average oee for manufacturers using. Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. What are the oee scores for different industries? Oee is the result of three factors,. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity.. Industry Standard Oee.

From www.opc-router.com

What is OEE? Evaluation of equipment effectiveness Industry Standard Oee Based on our data, the graph below shows the average oee for manufacturers using. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is the result of three factors,. Oee is calculated by multiplying the three oee factors: What are the oee scores for different industries? Often,. Industry Standard Oee.

From www.convergencetraining.com

Online Overall Equipment Effectiveness (OEE) Training Video Industry Standard Oee What are the oee scores for different industries? Oee is calculated by multiplying the three oee factors: Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Based on our data, the graph below shows the average oee for manufacturers using. Oee is the result of three factors,. Oee, in a nutshell, measures how much of the. Industry Standard Oee.

From ar.inspiredpencil.com

Oee Excel Template Industry Standard Oee Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Often, it’s a component of an overall lean manufacturing process. Oee is the result of three factors,. It suits any industry or process. Overall equipment effectiveness (oee). Industry Standard Oee.

From pdfslide.net

(PDF) 1OEE Calculation OEE Industry StandardOEE Industry Standard Industry Standard Oee Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Oee is. Industry Standard Oee.

From www.ordinal.fr

Performance analysis Indicators OEE KPI Realtime graph display Industry Standard Oee Oee is calculated by multiplying the three oee factors: Availability takes into account all events that stop. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. What are the oee scores for different industries? Often,. Industry Standard Oee.

From www.oee.com

Free OEE Tools Measure and Improve Production OEE Industry Standard Oee Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Based on our data, the graph below shows the average oee for manufacturers using. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. It suits any industry or process. Often, it’s a component of an overall lean manufacturing. Industry Standard Oee.

From www.tetrahedron.in

OEE Training Overall Equipment Effectiveness Training Industry Standard Oee Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Often, it’s a component of an overall lean manufacturing process. Based on our data, the graph below shows the average. Industry Standard Oee.

From consyst.biz

Overall Equipment Effectiveness for Manufacturing Industries OEE Industry Standard Oee Oee is the result of three factors,. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Availability takes into account all events that stop. Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Overall equipment effectiveness. Industry Standard Oee.

From toughnickel.com

How to Calculate Your Overall Equipment Effectiveness (OEE) ToughNickel Industry Standard Oee Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Based on our data, the graph below shows the average oee for manufacturers using. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. What are the oee scores for different industries?. Industry Standard Oee.

From objt.com

Significantly impacting your production productivity with OEE Objective Industry Standard Oee Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Availability takes into account all events that stop. Based on our data, the graph below shows the average oee for manufacturers using. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Overall equipment effectiveness (oee) is. Industry Standard Oee.

From www.leanproduction.com

Understanding OEE in Lean Manufacturing Lean Production Industry Standard Oee Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: It suits any industry or process. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time. Industry Standard Oee.

From industrial-innovation.it

OEE definizione, significato e cos'è Industrial Innovation Industry Standard Oee Oee is the result of three factors,. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Oee is calculated by multiplying the three oee factors: Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Availability takes into account all events that stop. What are the oee. Industry Standard Oee.

From www.leanproduction.com

Understanding OEE in Lean Manufacturing Lean Production Industry Standard Oee Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. What are the oee scores for different industries? Oee is the result of three factors,. Based on our data, the graph below shows the average oee for manufacturers using. Often, it’s a component of an overall lean manufacturing process. Oee (overall equipment effectiveness) is the gold standard. Industry Standard Oee.

From productivity.imtma.in

Measuring productivity through Overall Equipment Effectiveness (OEE Industry Standard Oee What are the oee scores for different industries? Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Based on our data, the graph below shows the average oee for manufacturers using. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Often, it’s a component of an overall lean manufacturing process. Overall equipment effectiveness. Industry Standard Oee.

From www.kripya.com

Six Big Losses in Manufacturing aligned with Overall Equipment Industry Standard Oee Often, it’s a component of an overall lean manufacturing process. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. It suits any industry or process. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Oee is the result of three factors,. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the. Industry Standard Oee.

From grvsoftware.com.br

Como calcular o OEE (Overall Equipment Effectiveness)? GRV Software Industry Standard Oee Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. It suits any industry or process. Oee is calculated by multiplying the three oee. Industry Standard Oee.

From www.oee.com

Six Big Losses in Manufacturing OEE Industry Standard Oee It suits any industry or process. Based on our data, the graph below shows the average oee for manufacturers using. Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is the result of three factors,. Oee, in a. Industry Standard Oee.

From www.crossmuller.com.au

OEE and its place in Industry 4.0 News CROSSMULLER Industry Standard Oee Oee is the result of three factors,. Oee is calculated by multiplying the three oee factors: Often, it’s a component of an overall lean manufacturing process. What are the oee scores for different industries? Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Based on our data, the graph below shows the average oee for manufacturers using.. Industry Standard Oee.

From www.pinterest.com

In a World Class Manufacturing one of the metrics of high impact is the Industry Standard Oee Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Availability takes into account all events that stop. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee is calculated by multiplying the three oee factors: What are the. Industry Standard Oee.

From www.cems-en.com

What is OEE and why is it important? blogCeMS Industry Standard Oee Oee is the result of three factors,. Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Availability takes into account all events that stop. It suits any industry or process. Oee is calculated by multiplying the three oee factors: Oee, in a nutshell, measures how much of the production time. Industry Standard Oee.

From www.qualitydigest.com

What Is Overall Equipment Effectiveness (OEE)? Quality Digest Industry Standard Oee Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Often, it’s a component of an overall lean manufacturing process. Availability takes into account. Industry Standard Oee.

From craft3-gthy.frb.io

Calculating Overall Effective Equipment (OEE) Clearmark Industry Standard Oee Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Availability takes into account all events that stop. Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that. Industry Standard Oee.

From decide4action.com

DECIDE4ACTION Industry Standard Oee Often, it’s a component of an overall lean manufacturing process. Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. It suits any industry or process. Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to. Industry Standard Oee.

From www.acusys.co.za

OEE (Overall Equipment Effectiveness) Industry Standard Oee Oee is calculated by multiplying the three oee factors: Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. What are the oee scores for different industries? It suits any industry or process. Based on our data, the graph below shows the average oee for manufacturers using. Oee (overall equipment effectiveness). Industry Standard Oee.

From sensemore.io

What is Overall Equipment Effectiveness (OEE) ? Sensemore Industry Standard Oee Based on our data, the graph below shows the average oee for manufacturers using. Often, it’s a component of an overall lean manufacturing process. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Oee (overall equipment effectiveness) is a “best practices” metric that identifies. Industry Standard Oee.

From www.researchgate.net

OEE analysis, drill down scenario Download Scientific Diagram Industry Standard Oee Availability takes into account all events that stop. It suits any industry or process. Oee is the result of three factors,. Based on our data, the graph below shows the average oee for manufacturers using. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components:. Industry Standard Oee.

From www.monitor-box.com

OEE software for Manufacturing Industry Standard Oee What are the oee scores for different industries? Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned. Industry Standard Oee.

From www.toolshero.com

Overall Equipment Efficiency (OEE) Toolshero Industry Standard Oee Oee (overall equipment effectiveness) is the gold standard for measuring manufacturing productivity. Overall equipment effectiveness (oee) is an industry standard, versatile measurement for production efficiency. It suits any industry or process. Oee is the result of three factors,. What are the oee scores for different industries? Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to. Industry Standard Oee.

From zerynth.com

Measuring Industry 4.0 through OEE Overall Equipment Effectiveness Industry Standard Oee Oee is the result of three factors,. Often, it’s a component of an overall lean manufacturing process. Availability takes into account all events that stop. Based on our data, the graph below shows the average oee for manufacturers using. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while. Industry Standard Oee.

From innius.com

Understand OEE Calculation, Components, Comparisons and Tips Industry Standard Oee What are the oee scores for different industries? Oee is calculated by multiplying the three oee factors: Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production time that is truly productive. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering. Industry Standard Oee.

From leanmanufacturing.online

Optimizing Manufacturing Efficiency with Overall Equipment Industry Standard Oee Availability takes into account all events that stop. Overall equipment effectiveness (oee) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Oee is the result of three factors,. Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Often,. Industry Standard Oee.

From www.bol.com

Oee Industry Standard V2003, Arno Koch 9781463550042 Boeken Industry Standard Oee Based on our data, the graph below shows the average oee for manufacturers using. It suits any industry or process. What are the oee scores for different industries? Oee is calculated by multiplying the three oee factors: Oee is the result of three factors,. Oee (overall equipment effectiveness) is a “best practices” metric that identifies the percentage of planned production. Industry Standard Oee.

From www.certaintysoftware.com

OEE Meaning in Manufacturing How to Optimize Efficiency Industry Standard Oee Oee, in a nutshell, measures how much of the production time your manufacturing line is running at its full capacity while considering three different components: Oee is calculated by multiplying the three oee factors: What are the oee scores for different industries? Often, it’s a component of an overall lean manufacturing process. Based on our data, the graph below shows. Industry Standard Oee.