Epoxy Concrete Lining . In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. By working closely with key. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Mechanical methods include shot blasting,. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating.

from www.conpipe.com

In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Mechanical methods include shot blasting,. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. By working closely with key. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years.

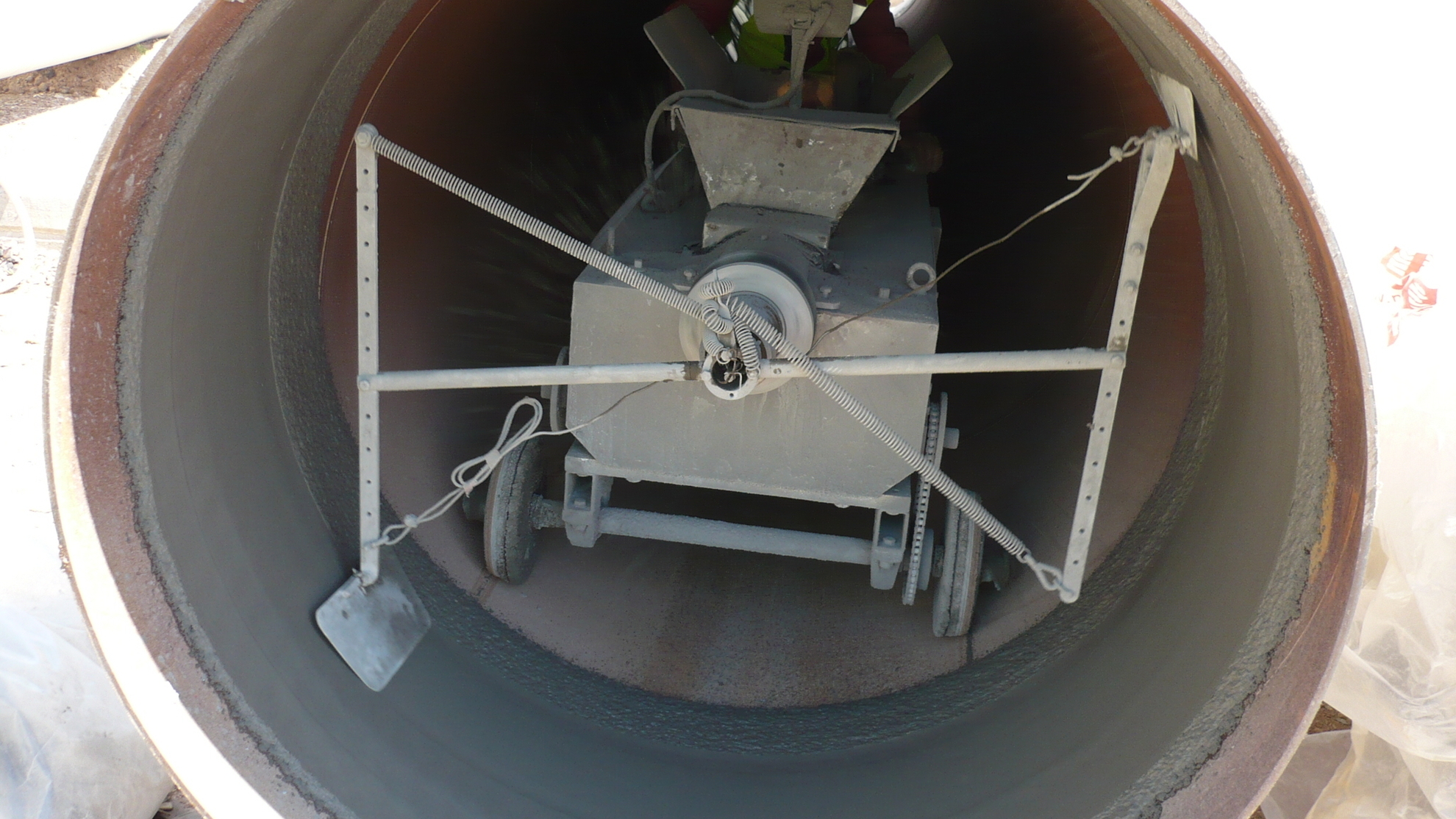

On site cementlining

Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our polyurea technology is known for its rapid curing time, fast return to. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Mechanical methods include shot blasting,. Our linings can be applied by brush, roller and airless or plural feed. By working closely with key. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an.

From www.newtonwaterproofing.co.uk

High Build Epoxy Floor Coating Newton Waterproofing Epoxy Concrete Lining Our polyurea technology is known for its rapid curing time, fast return to. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Use a mechanical or chemical method to. Epoxy Concrete Lining.

From liquidfloors.com

Epoxy vs. Urethane Concrete Floor Coatings Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our linings can be applied by brush, roller and airless or plural feed. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings. Epoxy Concrete Lining.

From www.lazada.com.ph

BUILDRITE BLOCKTITE ETL( EPOXY TANK LINING) Epoxy Tank Lining 3.8KG Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Use a. Epoxy Concrete Lining.

From www.linedpipesystems.com

The Pros and Cons of Epoxy Pipe Lining Lined Pipe Systems Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Our polyurea technology is known for its rapid curing time, fast return to. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Use a mechanical or. Epoxy Concrete Lining.

From www.selmers.com

Wind Tower / Monopile Coating Plant Selmers Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our polyurea technology is known for its rapid curing time, fast return to. By working closely with key. Use a mechanical or chemical method to create a suitable. Epoxy Concrete Lining.

From www.brickintheyard.com

Polygem Sinmast 4 Regular Laminating System brickintheyard Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over. Epoxy Concrete Lining.

From www.water-tanks.co.uk

Epoxy Tank Coating and Lining Nationwide Water Solutions Ltd Epoxy Concrete Lining By working closely with key. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion. Epoxy Concrete Lining.

From liquidapplied.co.uk

Factory Epoxy Floor Coating Philton Polythene Converters LAM GRP Epoxy Concrete Lining Our polyurea technology is known for its rapid curing time, fast return to. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. We have. Epoxy Concrete Lining.

From specialistliningservices.co.uk

Concrete Water Tank GRP Lining System Specialist Lining Services Epoxy Concrete Lining Mechanical methods include shot blasting,. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our polyurea technology is known for its rapid curing time, fast return to. In summary, epoxy pipe coating involves. Epoxy Concrete Lining.

From craft-art.com

Epoxy Cement What is the Best Concrete Crack Repair Epoxy? Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. We have. Epoxy Concrete Lining.

From www.premiercoatings.com

Archco 436™ Epoxy Pipe Lining Premier Epoxy Concrete Lining We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Our polyurea technology is known for its rapid curing time, fast return to. Our linings can be applied by brush, roller and airless or plural feed. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion. Epoxy Concrete Lining.

From www.water-tanks.co.uk

Epoxy Tank Coating and Lining Nationwide Water Solutions Ltd Epoxy Concrete Lining Our linings can be applied by brush, roller and airless or plural feed. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Mechanical methods include shot blasting,. Use a mechanical or chemical method to create a suitable profile on. Epoxy Concrete Lining.

From savyandsons.com

UCONN Wastewater Tanks Expert Epoxy Restoration Triumph Epoxy Concrete Lining Mechanical methods include shot blasting,. Our linings can be applied by brush, roller and airless or plural feed. By working closely with key. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Use a mechanical or chemical. Epoxy Concrete Lining.

From homerproject.org

Five Things You Need To Know About Epoxy Floor Coating Epoxy Concrete Lining Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. In summary, epoxy pipe coating involves applying a. Epoxy Concrete Lining.

From concrete-solutions.ca

Five Advantages of Epoxy Floor Coatings that You Need to Know Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Our linings can be applied by brush, roller and airless or plural. Epoxy Concrete Lining.

From www.lazada.com.ph

Destiny Epoline Epoxy Tank Lining, White Lazada PH Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. Use a. Epoxy Concrete Lining.

From vipdrainservices.com

The Pros and Cons of Epoxy Pipe Lining Epoxy Concrete Lining Mechanical methods include shot blasting,. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our linings can be applied by brush, roller and airless or plural feed. By working closely with key. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Fibreglass (grp). Epoxy Concrete Lining.

From www.selmers.com

Concrete Weight Coating Plant (CWC) Selmers Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. By working closely with key.. Epoxy Concrete Lining.

From gtstoneworks.com.ph

GT Stoneworks product_details Epoxy Concrete Lining Mechanical methods include shot blasting,. Our linings can be applied by brush, roller and airless or plural feed. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. By working closely with key. We have been installing seamless. Epoxy Concrete Lining.

From www.shop.gtstoneworks.com.ph

MOJAVE EPOXY TANK LINING PART A&B GAL / SET GT Stone Works Shop Epoxy Concrete Lining Our linings can be applied by brush, roller and airless or plural feed. By working closely with key. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our polyurea technology is known for its rapid curing time, fast return to. In summary, epoxy pipe coating involves applying. Epoxy Concrete Lining.

From www.conpipe.com

Epoxy lining / coating Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our linings can be applied by brush, roller and airless or plural feed. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion. Epoxy Concrete Lining.

From ctech-llc.com

Novolac Epoxy Coating CTechLLC Epoxy Concrete Lining Our polyurea technology is known for its rapid curing time, fast return to. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy. Epoxy Concrete Lining.

From uniteqindustries.com

Waterproofing Solution For Concrete ETPSTP Tanks, Services, Thane Epoxy Concrete Lining In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our polyurea technology is known for its rapid curing time, fast return to. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our. Epoxy Concrete Lining.

From www.indiamart.com

Foster Beck & Ardex & Fosroc & Foceial Epoxy Polyurethane Flooring Epoxy Concrete Lining Mechanical methods include shot blasting,. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our polyurea technology is known for its rapid curing time, fast return to. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the. Epoxy Concrete Lining.

From www.nuflowmidwest.com

Does Epoxy Pipe Lining Work? NuFlow Midwest Epoxy Concrete Lining Mechanical methods include shot blasting,. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Our polyurea technology is known for its. Epoxy Concrete Lining.

From clsa.us

Quikrete Epoxy Industrial Floor Coating Clsa Flooring Guide Epoxy Concrete Lining Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our linings can be applied by brush, roller and airless or plural feed. By working closely with key. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. In summary, epoxy pipe. Epoxy Concrete Lining.

From www.denso.net

Archco 453™ Epoxy Pipe Lining Denso Epoxy Concrete Lining Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our polyurea technology is known for its rapid curing time, fast return to. Our linings can be applied by brush, roller and airless or plural feed. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion. Epoxy Concrete Lining.

From www.youtube.com

Rhino Linings Epoxy Garage Floor Coating YouTube Epoxy Concrete Lining Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. In summary, epoxy pipe coating involves applying a layer of epoxy to the interior of the pipe, while epoxy pipe lining involves creating a seamless liner inside the existing pipe using an. Our polyurea technology is known for its rapid curing time, fast return to. Our. Epoxy Concrete Lining.

From book4yours.blogspot.com

Méthode Injection d'époxy pour la réparation de fissures dans le béton Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return to. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. Use a mechanical or chemical. Epoxy Concrete Lining.

From bundlining.com

Epoxy Resin Flooring Bund Lining Systems Epoxy Concrete Lining Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our polyurea technology is known for its rapid curing time, fast return to. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Mechanical methods include shot blasting,. Our polyurethane, epoxy and polyurea coating. Epoxy Concrete Lining.

From www.conpipe.com

On site cementlining Epoxy Concrete Lining Mechanical methods include shot blasting,. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our polyurea technology is known for its rapid curing time, fast return to. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. By working closely with key. We. Epoxy Concrete Lining.

From www.rimabs.com

Epoxy Tank Lining Rimab's Specialty Building Products Inc. Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our linings can be applied by brush, roller and airless or plural feed. Our polyurea technology is known for its rapid curing time, fast return. Epoxy Concrete Lining.

From www.lifetimeepoxyutah.com

Lifetime Coatings How to Choose the Best Epoxy Floor Coating Epoxy Concrete Lining Mechanical methods include shot blasting,. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Fibreglass (grp) linings and coatings provide a significant benefit to concrete surfaces and structures. Our polyurea technology is known for its rapid curing time, fast return to. Our polyurethane, epoxy and polyurea coating. Epoxy Concrete Lining.

From almcoplumbing.com

Epoxy pipe lining Almco Plumbing Epoxy Concrete Lining Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. We have been installing seamless epoxy, polyurethane and lately polyurea tank linings for over 30 years. By working closely with key. Mechanical methods include shot blasting,. Our linings can be applied by brush, roller and airless or plural feed. Use a mechanical or chemical method to create. Epoxy Concrete Lining.

From tianyisuns.en.made-in-china.com

Internal Cement Lining External Epoxy / Zinc Coating Watering Ductile Epoxy Concrete Lining Our linings can be applied by brush, roller and airless or plural feed. Use a mechanical or chemical method to create a suitable profile on the concrete surface to enhance adhesion of the epoxy coating. Our polyurethane, epoxy and polyurea coating systems have excellent chemical and corrosion resistance. Our polyurea technology is known for its rapid curing time, fast return. Epoxy Concrete Lining.