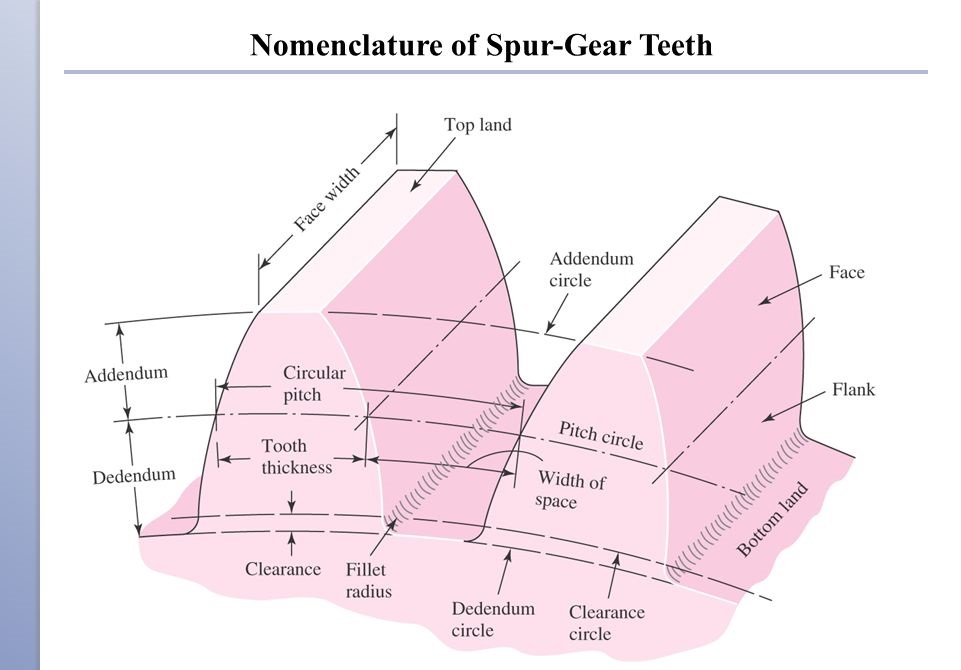

Gear Teeth Design Formula . The form factor in the lewis equation is the unit less factor based on the geometry. The geometry of a simple spur gear tooth is complex. Understanding gear profile and gear module. In an involute gear, the profiles of the teeth are involutes of a. (inch units applicable for constants) spur gear. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. After considering the gear tooth as a cantilever beam, lewis derived the following equation. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Calculate the key dimensions for your external spur gear. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The involute gear profile is the most commonly used system for gearing today. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and.

from design.udlvirtual.edu.pe

40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In an involute gear, the profiles of the teeth are involutes of a. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. Calculate the key dimensions for your external spur gear. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. (inch units applicable for constants) spur gear. The involute gear profile is the most commonly used system for gearing today. After considering the gear tooth as a cantilever beam, lewis derived the following equation.

Spur Gear Calculations And Formulas Design Talk

Gear Teeth Design Formula (inch units applicable for constants) spur gear. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Calculate the key dimensions for your external spur gear. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The geometry of a simple spur gear tooth is complex. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Understanding gear profile and gear module. The involute gear profile is the most commonly used system for gearing today. After considering the gear tooth as a cantilever beam, lewis derived the following equation. (inch units applicable for constants) spur gear. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. The form factor in the lewis equation is the unit less factor based on the geometry. In an involute gear, the profiles of the teeth are involutes of a.

From www.engineersedge.com

Gear Tooth Contact Stress Number Equation and Calculator Gear Teeth Design Formula The involute gear profile is the most commonly used system for gearing today. After considering the gear tooth as a cantilever beam, lewis derived the following equation. (inch units applicable for constants) spur gear. In an involute gear, the profiles of the teeth are involutes of a. Calculate the key dimensions for your external spur gear. Gears come in all. Gear Teeth Design Formula.

From www.slideshare.net

Gear tooth terminology Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The form factor in the lewis equation is the unit less factor based on the geometry. Calculate the key dimensions for your external spur gear. In an involute gear, the profiles of the teeth are involutes of a. 40 rows. Gear Teeth Design Formula.

From eng-shady-mohsen.blogspot.com

Eng. Shady Mohsen blog Involute spur gear design Gear Teeth Design Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. Calculate the key dimensions for your external spur gear. Understanding gear profile and gear module. 40 rows spur. Gear Teeth Design Formula.

From www.tec-science.com

Construction and design of involute gears tecscience Gear Teeth Design Formula Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The form factor in the lewis equation is the unit less factor based on the geometry. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small. Gear Teeth Design Formula.

From design.udlvirtual.edu.pe

Spur Gear Calculations And Formulas Design Talk Gear Teeth Design Formula In an involute gear, the profiles of the teeth are involutes of a. The form factor in the lewis equation is the unit less factor based on the geometry. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear. After considering the gear tooth as a cantilever beam,. Gear Teeth Design Formula.

From www.youtube.com

Design Of Spur Gear with Equation in SolidWorks YouTube Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The geometry of a simple spur gear tooth is complex. After considering the gear tooth as a cantilever beam, lewis derived the following equation. Gears come in all shapes and sizes from square to circular, elliptical to conical and from. Gear Teeth Design Formula.

From www.degruyter.com

Mathematical description of tooth flank surface of globoidal worm gear Gear Teeth Design Formula Calculate the key dimensions for your external spur gear. The involute gear profile is the most commonly used system for gearing today. The geometry of a simple spur gear tooth is complex. (inch units applicable for constants) spur gear. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Gear dimensions are determined in accordance. Gear Teeth Design Formula.

From www.groschopp.com

Gear Terminology, Knowing your teeth Groschopp Blog Gear Teeth Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. (inch units applicable for constants) spur gear. Calculate the key dimensions for your external spur gear. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and. Gear Teeth Design Formula.

From teethwalls.blogspot.com

How To Calculate No Of Teeth In Gear TeethWalls Gear Teeth Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. (inch units applicable for constants) spur gear. Gear dimensions are determined in accordance. Gear Teeth Design Formula.

From sbainvent.com

Gearing Systems S.B.A. Invent Gear Teeth Design Formula In an involute gear, the profiles of the teeth are involutes of a. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. After considering the gear tooth as a cantilever beam, lewis derived the following equation. (inch units applicable for constants) spur gear. Gears come in all shapes. Gear Teeth Design Formula.

From www.pinterest.ca

Terminology of Gear Tooth Mechanical design, Mechanical engineering Gear Teeth Design Formula After considering the gear tooth as a cantilever beam, lewis derived the following equation. The involute gear profile is the most commonly used system for gearing today. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In the previous pages, we introduced the. Gear Teeth Design Formula.

From mentoredengineer.com

How to Choose the Correct Gear Diametral Pitch Mentored Engineer Gear Teeth Design Formula The geometry of a simple spur gear tooth is complex. (inch units applicable for constants) spur gear. Calculate the key dimensions for your external spur gear. The form factor in the lewis equation is the unit less factor based on the geometry. The involute gear profile is the most commonly used system for gearing today. 40 rows spur gear design. Gear Teeth Design Formula.

From www.martinsengineering.com

Gear Formula Information » Martins Corrugator Engineering Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In an involute gear, the profiles of the teeth are involutes of a. Calculate the key dimensions for your external spur gear. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and. Gear Teeth Design Formula.

From khkgears.net

Basic Gear Terminology and Calculation KHK Gears Gear Teeth Design Formula (inch units applicable for constants) spur gear. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. Calculate the key dimensions for your external spur gear. The geometry of a simple spur gear tooth is complex. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations. Gear Teeth Design Formula.

From makezine.com

Learn How To Easily Fabricate Your Own Gears Make Gear Teeth Design Formula In an involute gear, the profiles of the teeth are involutes of a. Understanding gear profile and gear module. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number. Gear Teeth Design Formula.

From www.geartechnology.com

The Basics of Gear Theory Gear Technology Magazine Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. After considering the gear tooth as a cantilever beam, lewis derived the following equation.. Gear Teeth Design Formula.

From www.mech4study.com

Gear Terminology Basic Definition Used in Gear Mech4study Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. The form factor in the lewis equation is the unit less factor based on. Gear Teeth Design Formula.

From snorrigiorgetti.com

Calculation of involute gears tecscience (2022) Gear Teeth Design Formula Understanding gear profile and gear module. Calculate the key dimensions for your external spur gear. The form factor in the lewis equation is the unit less factor based on the geometry. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Input the gear's tooth count, pitch (or module), and. Gear Teeth Design Formula.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Gear Teeth Design Formula The involute gear profile is the most commonly used system for gearing today. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Calculate the key dimensions for your external spur gear. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify. Gear Teeth Design Formula.

From mungfali.com

Spur Gear Tooth Dimensions Gear Teeth Design Formula Calculate the key dimensions for your external spur gear. The form factor in the lewis equation is the unit less factor based on the geometry. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. In an involute gear, the profiles of the teeth are involutes of a. Gear. Gear Teeth Design Formula.

From mechanicaltopdc.blogspot.com

Spur Gear Design Gear Teeth Design Formula Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical. Gear Teeth Design Formula.

From www.iqsdirectory.com

Types of Gears Design, Types, Applications, and Materials Gear Teeth Design Formula Gears come in all shapes and sizes from square to circular, elliptical to conical and from as small as a pinhead to as large asa house. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. Numerous dimensional parameters define the shape of the tooth profile, determine how the. Gear Teeth Design Formula.

From www.youtube.com

Virtual Number of Teeth Design of Spur, Helical, Bevel and Worm gear Gear Teeth Design Formula The involute gear profile is the most commonly used system for gearing today. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. After considering the gear tooth as a cantilever beam, lewis derived the following equation. (inch units applicable for constants) spur gear. 40 rows spur gear design formula. Gear Teeth Design Formula.

From www.tessshebaylo.com

Gear Ratio Equation Teeth Tessshebaylo Gear Teeth Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. (inch units applicable for constants) spur gear. Calculate the key dimensions for your external spur gear. The involute gear profile is the most commonly used system for gearing today. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter,. Gear Teeth Design Formula.

From www.drivetrainhub.com

Basic Rack Geometry of basic racks for cylindrical involute gears Gear Teeth Design Formula In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. After considering the gear tooth as a cantilever beam, lewis derived the following equation. Input the gear's tooth count, pitch (or module), and pressure angle to calculate the pitch diameter, root diameter, and outer diameter. 40 rows spur gear. Gear Teeth Design Formula.

From www.researchgate.net

Geometry of the spur gear tooth Download Scientific Diagram Gear Teeth Design Formula The form factor in the lewis equation is the unit less factor based on the geometry. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous. Gear Teeth Design Formula.

From fractory.com

Types of Gears Gear Parameters & Tooth Profiles Fractory Gear Teeth Design Formula Numerous dimensional parameters define the shape of the tooth profile, determine how the gears fit together, and identify locations where forces act at the gear teeth. The involute gear profile is the most commonly used system for gearing today. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. In. Gear Teeth Design Formula.

From mungfali.com

Spur Gear Tooth Dimensions Gear Teeth Design Formula After considering the gear tooth as a cantilever beam, lewis derived the following equation. The involute gear profile is the most commonly used system for gearing today. Calculate the key dimensions for your external spur gear. The geometry of a simple spur gear tooth is complex. Numerous dimensional parameters define the shape of the tooth profile, determine how the gears. Gear Teeth Design Formula.

From www.youtube.com

Gear tooth nomenclature (Module 4) YouTube Gear Teeth Design Formula The involute gear profile is the most commonly used system for gearing today. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Understanding gear profile and gear module. After considering the gear tooth as a cantilever beam, lewis derived the following equation. 40 rows spur gear design formula. Gear Teeth Design Formula.

From aylin.gurkok.net

Gear Design Gear Teeth Design Formula Understanding gear profile and gear module. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The geometry of a simple spur gear tooth is complex. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The form factor in the lewis equation is the. Gear Teeth Design Formula.

From studylib.net

Gears Gear Teeth Design Formula After considering the gear tooth as a cantilever beam, lewis derived the following equation. The geometry of a simple spur gear tooth is complex. The form factor in the lewis equation is the unit less factor based on the geometry. Calculate the key dimensions for your external spur gear. In the previous pages, we introduced the basics of gears, including. Gear Teeth Design Formula.

From www.pinterest.es

Gear tooth geometry. Mechanical engineering, Wooden gears, Machine parts Gear Teeth Design Formula Understanding gear profile and gear module. In the previous pages, we introduced the basics of gears, including 'module', 'pressure angle', 'number of teeth' and 'tooth depth and. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. Gears come in all shapes and sizes from square to circular, elliptical to. Gear Teeth Design Formula.

From www.youtube.com

Standard System of Gear Tooth Design of Spur, Helical, Bevel and Worm Gear Teeth Design Formula After considering the gear tooth as a cantilever beam, lewis derived the following equation. Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The form factor in the lewis equation is the unit less factor based on the geometry. In the previous pages, we introduced the basics of gears,. Gear Teeth Design Formula.

From www.youtube.com

Spur Gear Tooth Profile Drawing Problem Spur gear design YouTube Gear Teeth Design Formula 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. The form factor in the lewis equation is the unit less factor based on the geometry. In an involute gear, the profiles of the teeth are involutes of a. Understanding gear profile and gear module. The geometry of a simple spur gear tooth is complex.. Gear Teeth Design Formula.

From www.engineersedge.com

Involute Gear Design Equations and Calculator Gear Teeth Design Formula Gear dimensions are determined in accordance with their specifications, such as module (m), number of teeth (z), pressureangle (α), and. The involute gear profile is the most commonly used system for gearing today. 40 rows spur gear design formula for geometry, pitch, tooth clearance and critical functional data. In the previous pages, we introduced the basics of gears, including 'module',. Gear Teeth Design Formula.