Compressor Bundle Definition . Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Dismantling, cleaning, checking of seal assembly components and assembling with new. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas.

from medium.com

Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Dismantling, cleaning, checking of seal assembly components and assembling with new. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application.

Gas Compressor Types, Sizes and Functions by Helmi Wicaksono

Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Dismantling, cleaning, checking of seal assembly components and assembling with new. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may. Compressor Bundle Definition.

From cartoondealer.com

Bundle Of Gas Turbine Compressor And Turbine Engine At Offshore Oil And Compressor Bundle Definition Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Dismantling, cleaning, checking of seal assembly components and assembling with new. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the. Compressor Bundle Definition.

From pcmeng.com

PCL COMPRESSOR BUNDLE DEAL PCM Engineering Compressor Bundle Definition Dismantling, cleaning, checking of seal assembly components and assembling with new. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Multiple compression trains are normally supplied in parallel. Compressor Bundle Definition.

From tr.roland.com

Roland Compressor Bundle VS PlugIn by Universal Audio Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired. Compressor Bundle Definition.

From medium.com

Gas Compressor Types, Sizes and Functions by Helmi Wicaksono Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor.. Compressor Bundle Definition.

From www.slideshare.net

Types of compressors Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired. Compressor Bundle Definition.

From turbomag.mjhassoc.com

Reciprocating and centrifugal compressors of DresserRand Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Multiple compression trains are normally supplied in parallel. Compressor Bundle Definition.

From thecompressorstore.co.uk

3kW Screw Compressed Air Bundle The Compressor Store Compressor Bundle Definition As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Dismantling, cleaning, checking of seal assembly components and assembling with new. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside. Compressor Bundle Definition.

From www.audiodeluxe.com

Solid State Logic Harrison and SSL Compressor Bundle AudioDeluxe Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Dismantling, cleaning, checking of seal assembly components and assembling with new. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels. Compressor Bundle Definition.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Compressor Bundle Definition Dismantling, cleaning, checking of seal assembly components and assembling with new. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Cleaning of bundle components (rotor, seals, labyrinth grooves). Compressor Bundle Definition.

From www.evomart.co.uk

Vol 7 Fundamentals Part 7 Compressors (Continued) Evomart Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Dismantling, cleaning, checking of seal assembly components and assembling with new. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. As we know liquids are incompressible (theoretically) whereas gases or air. Compressor Bundle Definition.

From www.engineeringchoice.com

What Is Air Compressor? Definition, Types And Working Engineering Choice Compressor Bundle Definition As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Dismantling, cleaning, checking of seal assembly components and assembling with new. Operations outside the limits may result in performance shortfalls,. Compressor Bundle Definition.

From www.researchgate.net

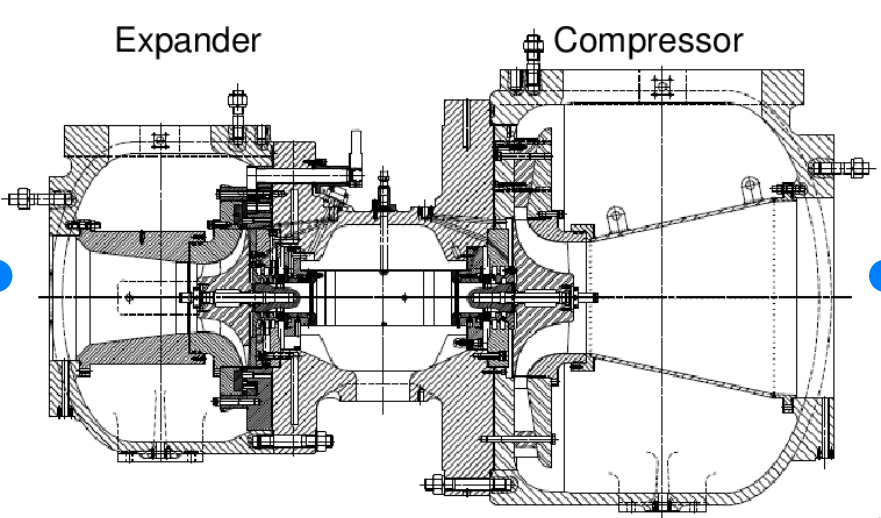

General view of centrifugal compressor 1 outer casing; 2 front Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Dismantling, cleaning, checking of seal assembly components and assembling with new. In a. Compressor Bundle Definition.

From chemicalengineeringworld.com

Types of Compressors Chemical Engineering World Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances. Compressor Bundle Definition.

From www.quincycompressor.com

How Does an Air Compressors Work? Quincy Compressor Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration,. Compressor Bundle Definition.

From mechanicstips.blogspot.com

Compressor Basic Types MechanicsTips Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Dismantling, cleaning, checking of seal assembly components and assembling with new. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the. Compressor Bundle Definition.

From www.compressortech2.com

Siemens To Unveil New Compressor Package At GMRC CompressorTECH² Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Operations outside the limits may result in performance shortfalls, leading to high levels. Compressor Bundle Definition.

From www.machinerylubrication.com

Compressor Lubrication Best Practices Compressor Bundle Definition As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Cleaning of bundle. Compressor Bundle Definition.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Compressor Bundle Definition Dismantling, cleaning, checking of seal assembly components and assembling with new. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Compressor upgrade is typically done by. Compressor Bundle Definition.

From www.toolstop.co.uk

SIP 05300 Airmate PX3/150B Compressor Toolstop Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Dismantling, cleaning, checking of seal assembly components and assembling with new. As we know liquids are incompressible. Compressor Bundle Definition.

From www.youtube.com

BEST ANALOG TYPE COMPRESSORS? Arturia Compressor Bundle & GIVEAWAY Compressor Bundle Definition Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Dismantling, cleaning, checking of seal assembly components and assembling with new. As we. Compressor Bundle Definition.

From thepipingtalk.com

Centrifugal compressor parts & their function The piping talk Compressor Bundle Definition Dismantling, cleaning, checking of seal assembly components and assembling with new. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Cleaning of bundle components (rotor, seals,. Compressor Bundle Definition.

From www.northerntool.com

EMAX Silent Air Industrial Plus 10 HP, 3Phase, 460 Volt, 80Gallon Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Dismantling, cleaning, checking of seal assembly components and assembling with new. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a. Compressor Bundle Definition.

From gascompressorhodakan.blogspot.com

Gas Compressor Gas Compressor Bundle Compressor Bundle Definition In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Operations outside the. Compressor Bundle Definition.

From www.summitracing.com

Emax Compressor EP20H120V3PKG EMAX Piston Compressor with Dryer Bundles Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor.. Compressor Bundle Definition.

From www.grc.nasa.gov

Compressors Compressor Bundle Definition Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances. Compressor Bundle Definition.

From gascompressorhodakan.blogspot.com

Gas Compressor Gas Compressor Bundle Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). In a centrifugal compressor, energy is transferred from a set of. Compressor Bundle Definition.

From engineeringlearn.com

7 Types of Air Compressor Definition, Uses & Working Principle Compressor Bundle Definition As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above atmospheric pressure). In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains. Compressor Bundle Definition.

From www.youtube.com

compressor bundle kese nikalte hen/how to takeout compressor bundle Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to. Compressor Bundle Definition.

From medium.com

Gas Compressor Types, Sizes and Functions by Helmi Wicaksono Compressor Bundle Definition Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Dismantling, cleaning, checking of seal. Compressor Bundle Definition.

From schematicfixpulpits.z21.web.core.windows.net

Centrifugal Compressor Parts Diagram Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. As we know liquids are incompressible (theoretically) whereas. Compressor Bundle Definition.

From www.dreamstime.com

Turbine Gas Compressor Bundle with Tubing Piping Seal System Stock Compressor Bundle Definition In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,.. Compressor Bundle Definition.

From www.dreamstime.com

Gas Turbine Compressor Bundle, Centrifugal and Multi Stage Type of Gas Compressor Bundle Definition Operations outside the limits may result in performance shortfalls, leading to high levels of vibration, temperature rise, or even serious damage to the compressor. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. As we know liquids are incompressible (theoretically) whereas gases or air can be compressed to a desired pressure (above. Compressor Bundle Definition.

From stock.adobe.com

Gas compressor bundle on offshore oil and gas industry with piping and Compressor Bundle Definition In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. Compressor upgrade is typically done by changing the internal (impeller and diaphragm) increasing the performances and usually the efficiency,. Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Operations outside the limits may. Compressor Bundle Definition.

From www.geemit.com

NEW ARRIVAL COMPRESSOR BUNDLE 272B2/2 / Compressor Bundle Definition Multiple compression trains are normally supplied in parallel to achieve total flow and head requirements of a specific application. Dismantling, cleaning, checking of seal assembly components and assembling with new. Cleaning of bundle components (rotor, seals, labyrinth grooves) 2. In a centrifugal compressor, energy is transferred from a set of rotating impeller blades to the gas. As we know liquids. Compressor Bundle Definition.