Valve Grinding Angles . There are so many options nowadays, from lapping, grinding to full blown cnc profile. When doing your next valve job, make sure you aren’t solely relying on the flow bench; And lastly, that the steepness of your angles matches how much lift the engine has. This is done with a fine lapping compound and a lapping tool. And the width of those cuts match how much air you’ll need for the rpm of the engine; Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. Using these angles can often improve airflow 8 to 15 cfm or more. The diagram below shows the three angles: So, what is the proper way to machine a valve seat? Use light pressure and a twisting motion. Change the angle of the lapping tool to prevent uneven wear. After the valves have been lapped, a backcut is placed on the. The angles on the valve face and seat can really make or break an engine’s performance potential.

from blueprint.fastenal.com

There are so many options nowadays, from lapping, grinding to full blown cnc profile. Using these angles can often improve airflow 8 to 15 cfm or more. Change the angle of the lapping tool to prevent uneven wear. When doing your next valve job, make sure you aren’t solely relying on the flow bench; Use light pressure and a twisting motion. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. The angles on the valve face and seat can really make or break an engine’s performance potential. The diagram below shows the three angles: After the valves have been lapped, a backcut is placed on the. And lastly, that the steepness of your angles matches how much lift the engine has.

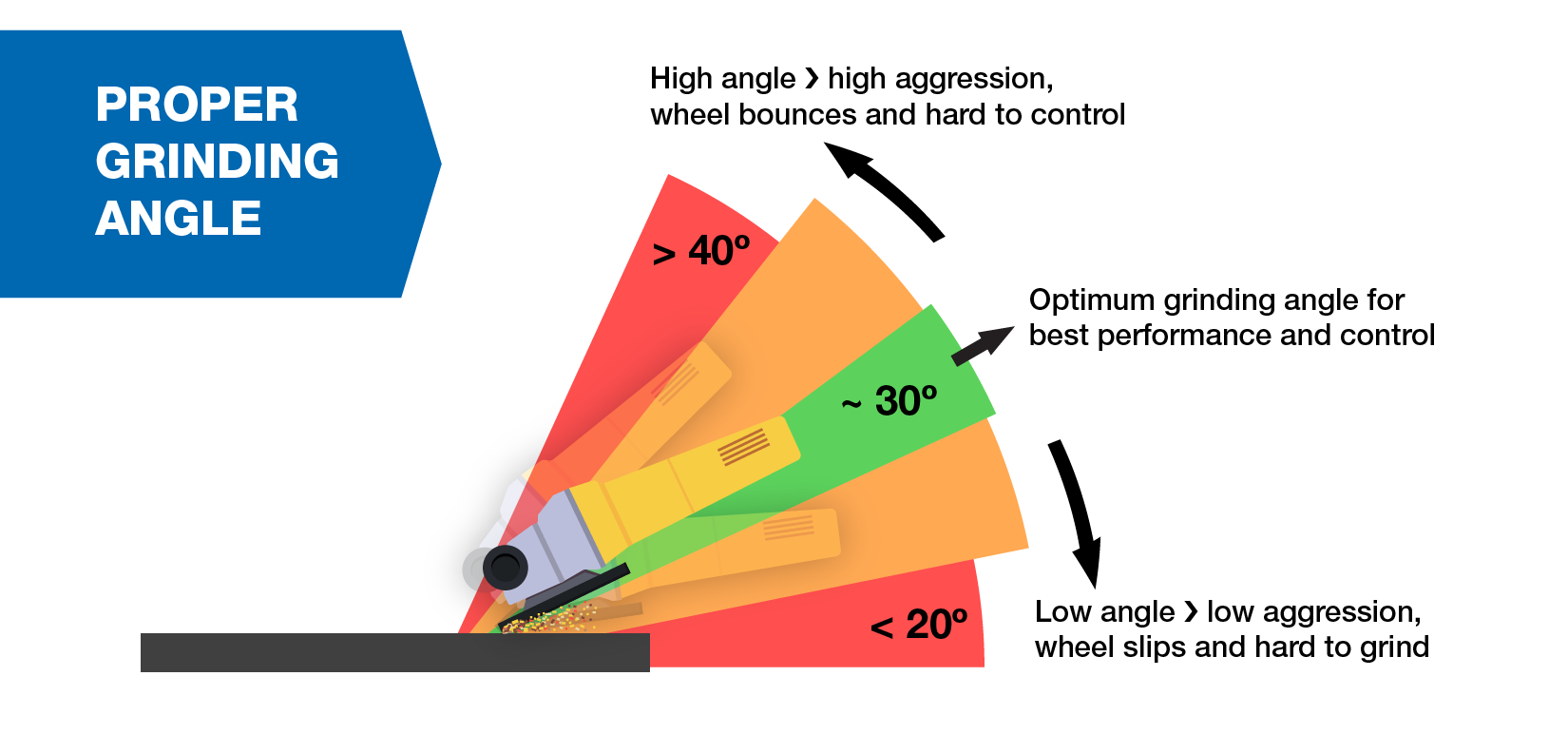

How to Get the Most Out of Your Grinding Wheel THE BLUE PRINT

Valve Grinding Angles Use light pressure and a twisting motion. Using these angles can often improve airflow 8 to 15 cfm or more. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. And lastly, that the steepness of your angles matches how much lift the engine has. There are so many options nowadays, from lapping, grinding to full blown cnc profile. The angles on the valve face and seat can really make or break an engine’s performance potential. This is done with a fine lapping compound and a lapping tool. The diagram below shows the three angles: After the valves have been lapped, a backcut is placed on the. So, what is the proper way to machine a valve seat? When doing your next valve job, make sure you aren’t solely relying on the flow bench; And the width of those cuts match how much air you’ll need for the rpm of the engine; Change the angle of the lapping tool to prevent uneven wear. Use light pressure and a twisting motion.

From larslap.com

Industrial valve grinding & valve lapping procedure LarsLap® Valve Grinding Angles The angles on the valve face and seat can really make or break an engine’s performance potential. And lastly, that the steepness of your angles matches how much lift the engine has. The diagram below shows the three angles: Use light pressure and a twisting motion. This is done with a fine lapping compound and a lapping tool. Change the. Valve Grinding Angles.

From www.autozone.com

Repair Guides Piston Engine Mechanical Valves Valve Grinding Angles Change the angle of the lapping tool to prevent uneven wear. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. There are so many options nowadays, from lapping, grinding to full blown cnc. Valve Grinding Angles.

From www.homemadeturbo.com

Homemade valve regrinding machine. HomemadeTurbo DIY Turbo Forum Valve Grinding Angles Use light pressure and a twisting motion. The angles on the valve face and seat can really make or break an engine’s performance potential. Using these angles can often improve airflow 8 to 15 cfm or more. And the width of those cuts match how much air you’ll need for the rpm of the engine; Change the angle of the. Valve Grinding Angles.

From www.youtube.com

5 Angle Valve Job YouTube Valve Grinding Angles Change the angle of the lapping tool to prevent uneven wear. Using these angles can often improve airflow 8 to 15 cfm or more. After the valves have been lapped, a backcut is placed on the. The angles on the valve face and seat can really make or break an engine’s performance potential. The diagram below shows the three angles:. Valve Grinding Angles.

From www.enginelabs.com

Valve Seats Will 50 or 55degree Angles Work For Your Engine? Valve Grinding Angles And the width of those cuts match how much air you’ll need for the rpm of the engine; Change the angle of the lapping tool to prevent uneven wear. When doing your next valve job, make sure you aren’t solely relying on the flow bench; There are so many options nowadays, from lapping, grinding to full blown cnc profile. And. Valve Grinding Angles.

From kerzan.co.nz

Standard Series Valve Seat Cutters Valve Grinding Angles When doing your next valve job, make sure you aren’t solely relying on the flow bench; Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. And lastly, that the steepness of your angles. Valve Grinding Angles.

From www.youtube.com

Grinding vs. Cutting Creating Valve Seat Angles YouTube Valve Grinding Angles The diagram below shows the three angles: Change the angle of the lapping tool to prevent uneven wear. And lastly, that the steepness of your angles matches how much lift the engine has. This is done with a fine lapping compound and a lapping tool. After the valves have been lapped, a backcut is placed on the. And the width. Valve Grinding Angles.

From www.youtube.com

How To Lap or Grind Engine Valves Part 144 YouTube Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. This is done with a fine lapping compound and a lapping tool. Change the angle of the lapping tool to prevent uneven wear. So, what is the proper way to machine a valve seat? The diagram below shows the three angles: And the width of those. Valve Grinding Angles.

From www.youtube.com

Valve Grinding YouTube Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. After the valves have been lapped, a backcut is placed on the. This is done with a fine lapping compound and a lapping tool. The diagram below shows the three angles: When doing your next valve job, make sure you aren’t solely relying on the flow. Valve Grinding Angles.

From www.youtube.com

Grinding valve seat to 3 angles in YouTube Valve Grinding Angles And the width of those cuts match how much air you’ll need for the rpm of the engine; The diagram below shows the three angles: And lastly, that the steepness of your angles matches how much lift the engine has. The angles on the valve face and seat can really make or break an engine’s performance potential. Use light pressure. Valve Grinding Angles.

From www.assurich.com

Valve Grinding Equipment LarsLap® Assurich Industries Pte Ltd Valve Grinding Angles So, what is the proper way to machine a valve seat? Using these angles can often improve airflow 8 to 15 cfm or more. The angles on the valve face and seat can really make or break an engine’s performance potential. And lastly, that the steepness of your angles matches how much lift the engine has. There are so many. Valve Grinding Angles.

From www.enginelabs.com

Valve Seats Will 50 or 55degree Angles Work For Your Engine? Valve Grinding Angles Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. After the valves have been lapped, a backcut is placed on the. Using these angles can often improve airflow 8 to 15 cfm or. Valve Grinding Angles.

From www.youtube.com

Valve Grinding YouTube Valve Grinding Angles So, what is the proper way to machine a valve seat? After the valves have been lapped, a backcut is placed on the. Change the angle of the lapping tool to prevent uneven wear. Using these angles can often improve airflow 8 to 15 cfm or more. The diagram below shows the three angles: There are so many options nowadays,. Valve Grinding Angles.

From www.youtube.com

Cylinder Head 105 Valve Job Basics YouTube Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. Using these angles can often improve airflow 8 to 15 cfm or more. When doing your next valve job, make sure you aren’t solely relying on the flow bench; Change the angle of the lapping tool to prevent uneven wear. So, what is the proper way. Valve Grinding Angles.

From www.wakefield.co.jp

Wakefield Corporation Valve Spindle and Valve Seat Grinding Machine Valve Grinding Angles Using these angles can often improve airflow 8 to 15 cfm or more. The diagram below shows the three angles: The angles on the valve face and seat can really make or break an engine’s performance potential. There are so many options nowadays, from lapping, grinding to full blown cnc profile. Change the angle of the lapping tool to prevent. Valve Grinding Angles.

From blueprint.fastenal.com

How to Get the Most Out of Your Grinding Wheel THE BLUE PRINT Valve Grinding Angles Use light pressure and a twisting motion. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. Using these angles can often improve airflow 8 to 15 cfm or more. So, what is the. Valve Grinding Angles.

From www.youtube.com

Cylinder Head Valve Grinding YouTube Valve Grinding Angles This is done with a fine lapping compound and a lapping tool. Change the angle of the lapping tool to prevent uneven wear. So, what is the proper way to machine a valve seat? After the valves have been lapped, a backcut is placed on the. The diagram below shows the three angles: When doing your next valve job, make. Valve Grinding Angles.

From www.aliexpress.com

High Quality Valve Seat Repair Tools 45 Degree Angle Diamond Grinding Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. And the width of those cuts match how much air you’ll need for the rpm of the engine; And lastly, that the steepness of your angles matches how much lift the engine has. The angles on the valve face and seat can really make or break. Valve Grinding Angles.

From www.autozone.com

Repair Guides Piston Engine Mechanical Valves Valve Grinding Angles This is done with a fine lapping compound and a lapping tool. The diagram below shows the three angles: The angles on the valve face and seat can really make or break an engine’s performance potential. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet. Valve Grinding Angles.

From www.youtube.com

How To Grind Valves On a VW Engine YouTube Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. This is done with a fine lapping compound and a lapping tool. And the width of those cuts match how much air you’ll need for the rpm of the engine; And lastly, that the steepness of your angles matches how much lift the engine has. Change. Valve Grinding Angles.

From www.youtube.com

3 Angle Valve Grind on an AMC 360 YouTube Valve Grinding Angles And lastly, that the steepness of your angles matches how much lift the engine has. This is done with a fine lapping compound and a lapping tool. So, what is the proper way to machine a valve seat? Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both. Valve Grinding Angles.

From www.youtube.com

Facing the valves and grinding valve seats YouTube Valve Grinding Angles Using these angles can often improve airflow 8 to 15 cfm or more. So, what is the proper way to machine a valve seat? The diagram below shows the three angles: Use light pressure and a twisting motion. Change the angle of the lapping tool to prevent uneven wear. The angles on the valve face and seat can really make. Valve Grinding Angles.

From library.parsianind.com

7748841_US page163 Document View Valve Grinding Angles Change the angle of the lapping tool to prevent uneven wear. This is done with a fine lapping compound and a lapping tool. The angles on the valve face and seat can really make or break an engine’s performance potential. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time. Valve Grinding Angles.

From calbizjournal.com

Valve Grinding Made Easy California Business Journal Valve Grinding Angles The diagram below shows the three angles: After the valves have been lapped, a backcut is placed on the. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. This is done with a. Valve Grinding Angles.

From www.tqhq.ee

tqhq.ee foorum 3angle valve job??? Valve Grinding Angles So, what is the proper way to machine a valve seat? Using these angles can often improve airflow 8 to 15 cfm or more. Change the angle of the lapping tool to prevent uneven wear. And lastly, that the steepness of your angles matches how much lift the engine has. After the valves have been lapped, a backcut is placed. Valve Grinding Angles.

From ronixtools.com

Three Steps in Professional Angle Grinding Ronix Blog Valve Grinding Angles This is done with a fine lapping compound and a lapping tool. Use light pressure and a twisting motion. Change the angle of the lapping tool to prevent uneven wear. And the width of those cuts match how much air you’ll need for the rpm of the engine; There are so many options nowadays, from lapping, grinding to full blown. Valve Grinding Angles.

From www.autozone.com

Repair Guides Piston Engine Mechanical Valves Valve Grinding Angles Change the angle of the lapping tool to prevent uneven wear. Use light pressure and a twisting motion. So, what is the proper way to machine a valve seat? And the width of those cuts match how much air you’ll need for the rpm of the engine; When doing your next valve job, make sure you aren’t solely relying on. Valve Grinding Angles.

From dannysengineportal.com

Valve Seats Installing And Grinding Valve Seats Learn The Basics Valve Grinding Angles So, what is the proper way to machine a valve seat? And lastly, that the steepness of your angles matches how much lift the engine has. This is done with a fine lapping compound and a lapping tool. Using these angles can often improve airflow 8 to 15 cfm or more. The angles on the valve face and seat can. Valve Grinding Angles.

From backcountrypilot.org

3angle valve grind ? Backcountry Pilot Valve Grinding Angles Change the angle of the lapping tool to prevent uneven wear. The diagram below shows the three angles: When doing your next valve job, make sure you aren’t solely relying on the flow bench; There are so many options nowadays, from lapping, grinding to full blown cnc profile. Finding the angles that work best with a given cylinder head, camshaft. Valve Grinding Angles.

From www.classic-motorcycle-build.com

What Is A ThreeAngle Valve Job Valve Grinding Angles This is done with a fine lapping compound and a lapping tool. There are so many options nowadays, from lapping, grinding to full blown cnc profile. The diagram below shows the three angles: Change the angle of the lapping tool to prevent uneven wear. The angles on the valve face and seat can really make or break an engine’s performance. Valve Grinding Angles.

From www.autozone.com

Repair Guides Piston Engine Mechanical Valves Valve Grinding Angles Use light pressure and a twisting motion. So, what is the proper way to machine a valve seat? There are so many options nowadays, from lapping, grinding to full blown cnc profile. When doing your next valve job, make sure you aren’t solely relying on the flow bench; Change the angle of the lapping tool to prevent uneven wear. This. Valve Grinding Angles.

From www.autozone.com

Repair Guides Piston Engine Mechanical Valves Valve Grinding Angles The angles on the valve face and seat can really make or break an engine’s performance potential. So, what is the proper way to machine a valve seat? And the width of those cuts match how much air you’ll need for the rpm of the engine; Use light pressure and a twisting motion. There are so many options nowadays, from. Valve Grinding Angles.

From www.slideserve.com

PPT Intake and Exhaust Valves PowerPoint Presentation ID5488573 Valve Grinding Angles There are so many options nowadays, from lapping, grinding to full blown cnc profile. Finding the angles that work best with a given cylinder head, camshaft and valve combination requires a lot of time on both a wet and dry flow bench, as well as dyno testing and track time. Use light pressure and a twisting motion. The diagram below. Valve Grinding Angles.

From www.youtube.com

full tutorial grind valve 135lc YouTube Valve Grinding Angles The diagram below shows the three angles: The angles on the valve face and seat can really make or break an engine’s performance potential. When doing your next valve job, make sure you aren’t solely relying on the flow bench; Change the angle of the lapping tool to prevent uneven wear. This is done with a fine lapping compound and. Valve Grinding Angles.

From www.youtube.com

VALVE GRINDING HACKS, how to grind and install your valves MX5 TURBO Valve Grinding Angles And lastly, that the steepness of your angles matches how much lift the engine has. Use light pressure and a twisting motion. Change the angle of the lapping tool to prevent uneven wear. This is done with a fine lapping compound and a lapping tool. There are so many options nowadays, from lapping, grinding to full blown cnc profile. The. Valve Grinding Angles.