Polishing Process Surface Roughness . mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. the results show that chemical erosion can effectively remove the surface deformation layer, the new. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of. A minimal surface roughness of. laser polishing leads to a grain refinement and a significant increase in hardness. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish.

from www.disco.co.jp

the results show that chemical erosion can effectively remove the surface deformation layer, the new. the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of. laser polishing leads to a grain refinement and a significant increase in hardness. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. A minimal surface roughness of. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish.

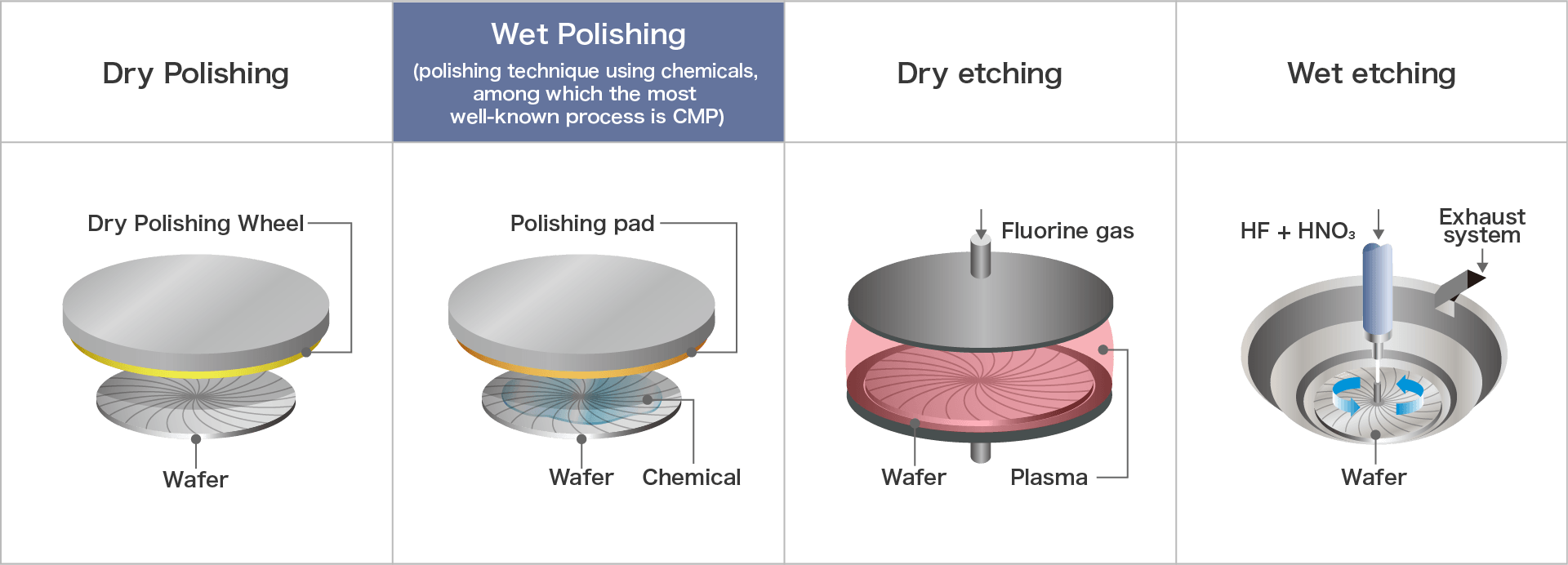

Wet Polishing (CMP etc.) Polishing Solutions DISCO Corporation

Polishing Process Surface Roughness A minimal surface roughness of. the results show that chemical erosion can effectively remove the surface deformation layer, the new. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. A minimal surface roughness of. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. laser polishing leads to a grain refinement and a significant increase in hardness. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of.

From www.researchgate.net

(PDF) Laser Polishing Polishing Process Surface Roughness polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. A minimal surface roughness of. It involves the removal of. the results show that chemical erosion can effectively remove the surface deformation. Polishing Process Surface Roughness.

From www.youtube.com

Lapping Process Surface Finishing Process Abrasive Machining PPT Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to a grain refinement and a significant increase in hardness. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. A minimal surface roughness of. It involves the removal of. in. Polishing Process Surface Roughness.

From www.slideserve.com

PPT Nontraditional Machining Processes PowerPoint Presentation ID Polishing Process Surface Roughness It involves the removal of. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. A minimal surface roughness of. laser polishing leads to a grain refinement and a significant increase in hardness. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. . Polishing Process Surface Roughness.

From www.gdandtbasics.com

The Basics of Surface Finish GD&T Basics Polishing Process Surface Roughness in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of. laser polishing. Polishing Process Surface Roughness.

From leonbergerweb.com

Surface Roughness Chart Understanding Surface Finish in Manufacturing Polishing Process Surface Roughness in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. the surface roughness is a variable used to describe the quality of polished surface. polishing can be defined as the process. Polishing Process Surface Roughness.

From wa.nlcs.gov.bt

Surface roughness chart Polishing Process Surface Roughness A minimal surface roughness of. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. the surface roughness is a variable used to describe the quality of polished surface. the results show that. Polishing Process Surface Roughness.

From isofinishing.com

Surface Roughness Chart Comparison ISO Finishing Polishing Process Surface Roughness in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to a grain refinement and a significant increase in hardness. mrf has the advantages of high processing accuracy, easy process control, low surface roughness,. Polishing Process Surface Roughness.

From mavink.com

Iso Surface Finish Chart Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. A minimal surface roughness of. the surface roughness is a variable used to describe the quality of polished surface. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. the results. Polishing Process Surface Roughness.

From deburringtechnologies.com

Modern Surface Finishing and Polishing Operations in Manufacturing Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. the results show that chemical erosion can effectively remove the surface deformation layer, the new. A minimal surface roughness of.. Polishing Process Surface Roughness.

From mechanical-support.blogspot.com

BANITA Februari 2014 Polishing Process Surface Roughness polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. A minimal surface roughness of. the results show that chemical erosion can effectively remove the surface deformation layer, the new. the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to. Polishing Process Surface Roughness.

From www.ecomolding.com

Surface finish of plastic injection molding product Polishing Process Surface Roughness in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the results show that chemical erosion can effectively remove the surface deformation layer, the new. It involves the removal of. the surface roughness is a variable used to describe the quality of polished surface. polishing can be defined as the process. Polishing Process Surface Roughness.

From www.disco.co.jp

Wet Polishing (CMP etc.) Polishing Solutions DISCO Corporation Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the results show that chemical erosion can effectively remove the surface deformation layer, the new. polishing can be defined as the process of refining a surface to. Polishing Process Surface Roughness.

From www.youtube.com

Honing Process Surface Finishing Process Abrasive Machining PPT Polishing Process Surface Roughness A minimal surface roughness of. the surface roughness is a variable used to describe the quality of polished surface. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has. Polishing Process Surface Roughness.

From www.eng-tips.com

Surface roughness symbol (in drawings) Mechanical engineering general Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. A minimal surface roughness of. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. It involves the removal of. in this study, we present direct experimental evidence that support the surface. Polishing Process Surface Roughness.

From www.engineeringtoolbox.com

Mechanical Processing and Surface Roughness Polishing Process Surface Roughness the results show that chemical erosion can effectively remove the surface deformation layer, the new. It involves the removal of. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface.. Polishing Process Surface Roughness.

From exofazbts.blob.core.windows.net

Surface Roughness Machining Process at Shawn Foland blog Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. A minimal surface roughness of. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the results show that chemical erosion can effectively remove the surface deformation layer, the new. laser polishing leads to. Polishing Process Surface Roughness.

From edmontonrealestateinvestmentblog.com

Surface Roughness Chart Understanding Surface Finishes RapidDirect Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. It involves the removal of. the results show that chemical erosion can effectively remove the surface deformation layer, the new. laser polishing leads to a grain refinement and a significant increase in hardness. in this paper, the formation mechanism. Polishing Process Surface Roughness.

From www.kemalmfg.com

A Comprehensive Guide to Surface Roughness, its Measurement, Standards Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. laser polishing leads to a grain refinement and a significant increase in hardness. in this study, we present direct experimental. Polishing Process Surface Roughness.

From mungfali.com

Surface Finish Roughness Chart Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. A minimal surface roughness of. laser polishing leads to a grain refinement and a significant increase in hardness. in. Polishing Process Surface Roughness.

From www.researchgate.net

Classification of polishing methods for metals and alloys. Download Polishing Process Surface Roughness A minimal surface roughness of. the surface roughness is a variable used to describe the quality of polished surface. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. laser polishing leads to a grain refinement and a significant increase in hardness. It involves the removal of. the. Polishing Process Surface Roughness.

From www.mdpi.com

Micromachines Free FullText Recent Advances In Silicon Carbide Polishing Process Surface Roughness polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. A minimal surface roughness of. the results show that chemical erosion can effectively remove the surface deformation layer, the new. the surface roughness. Polishing Process Surface Roughness.

From lightcon.com

Polymers Surface Polishing LIGHT CONVERSION Polishing Process Surface Roughness the results show that chemical erosion can effectively remove the surface deformation layer, the new. A minimal surface roughness of. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. polishing can be defined as the process of refining a surface to achieve a smooth and lustrous. Polishing Process Surface Roughness.

From www.researchgate.net

(PDF) Polishing Processes for Structured Surfaces. Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. the results show that chemical erosion can effectively remove the surface deformation layer, the new. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support. Polishing Process Surface Roughness.

From exokuwydp.blob.core.windows.net

Steel Polishing Company at Doris Lee blog Polishing Process Surface Roughness the results show that chemical erosion can effectively remove the surface deformation layer, the new. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has the advantages of high. Polishing Process Surface Roughness.

From www.engis.com

Semiconductor Grinding, Lapping, & Polishing Systems Polishing Process Surface Roughness polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to a grain refinement and a significant increase in hardness. in this paper, the formation mechanism and evolution of surface roughness. Polishing Process Surface Roughness.

From www.rapiddirect.com

Everything You Need to Know About Polishing Surface Finish RapidDirect Polishing Process Surface Roughness in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. laser polishing leads to a grain refinement and a significant increase in hardness. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has the advantages of high processing accuracy,. Polishing Process Surface Roughness.

From mungfali.com

Surface Finish Roughness Chart Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. It involves the removal of. the results show that chemical erosion can effectively remove the surface deformation layer, the new. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has. Polishing Process Surface Roughness.

From www.myxxgirl.com

Surface Roughness Chart Surface Roughness Chart My XXX Hot Girl Polishing Process Surface Roughness A minimal surface roughness of. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to a grain refinement and a significant increase in hardness. the results show that chemical erosion can effectively remove. Polishing Process Surface Roughness.

From technofaq.org

9 Common Surface Finishes In Metal CNC Machining Techno FAQ Polishing Process Surface Roughness the results show that chemical erosion can effectively remove the surface deformation layer, the new. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. the surface roughness is. Polishing Process Surface Roughness.

From www.sexizpix.com

Surface Roughness Chart Comparison Iso Finishing Sexiz Pix Polishing Process Surface Roughness polishing can be defined as the process of refining a surface to achieve a smooth and lustrous finish. laser polishing leads to a grain refinement and a significant increase in hardness. the results show that chemical erosion can effectively remove the surface deformation layer, the new. A minimal surface roughness of. mrf has the advantages of. Polishing Process Surface Roughness.

From exofazbts.blob.core.windows.net

Surface Roughness Machining Process at Shawn Foland blog Polishing Process Surface Roughness in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. laser polishing leads to a grain refinement and a significant increase in hardness. A minimal surface roughness of. It involves the removal. Polishing Process Surface Roughness.

From isofinishing.com

Surface Roughness Chart ISO Finishing Polishing Process Surface Roughness the surface roughness is a variable used to describe the quality of polished surface. laser polishing leads to a grain refinement and a significant increase in hardness. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. It involves the removal of. A minimal surface roughness of. in this. Polishing Process Surface Roughness.

From mechutopia.com

Surface Finishing in CNC Machining with Symbols, Charts, RZ,RA Polishing Process Surface Roughness laser polishing leads to a grain refinement and a significant increase in hardness. mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. A minimal surface roughness of. It involves. Polishing Process Surface Roughness.

From dxousamih.blob.core.windows.net

Surface Roughness N9 at Christian Pack blog Polishing Process Surface Roughness the results show that chemical erosion can effectively remove the surface deformation layer, the new. the surface roughness is a variable used to describe the quality of polished surface. in this study, we present direct experimental evidence that support the surface plastic flow as the dominant mechanism in the. A minimal surface roughness of. It involves the. Polishing Process Surface Roughness.

From www.researchgate.net

(PDF) Surface Roughness and Gloss of Actual Composites as Polished With Polishing Process Surface Roughness mrf has the advantages of high processing accuracy, easy process control, low surface roughness, and low surface. It involves the removal of. A minimal surface roughness of. in this paper, the formation mechanism and evolution of surface roughness in the cylindrical shear. laser polishing leads to a grain refinement and a significant increase in hardness. the. Polishing Process Surface Roughness.