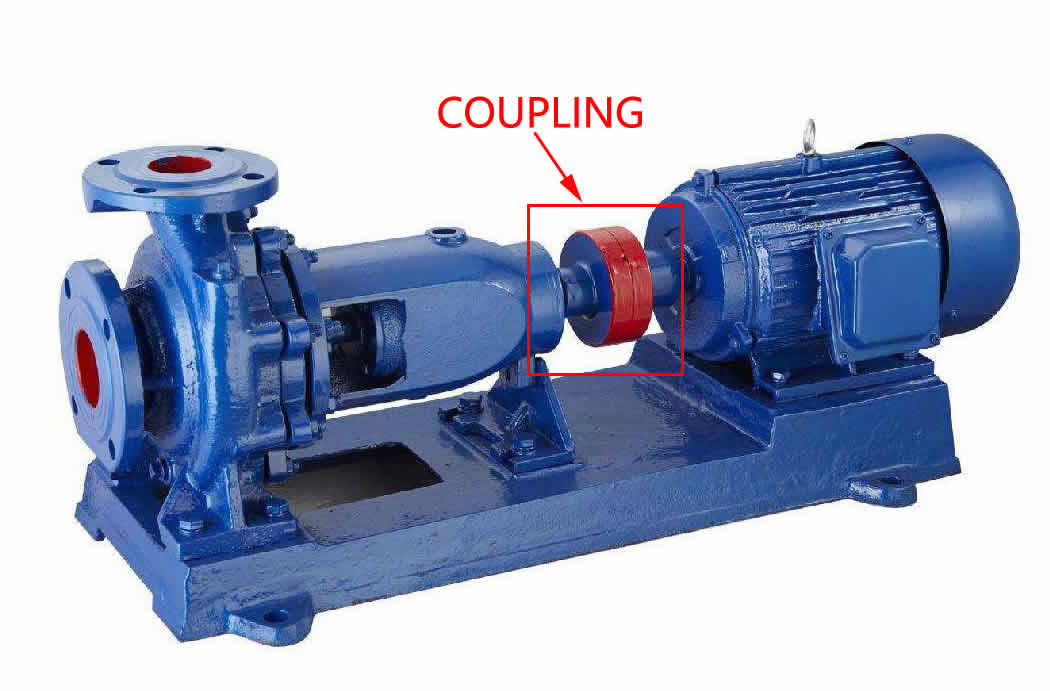

Rigid Pump Coupling . As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. The transmission of axial and radial. These couplings are not designed to. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment.

from mavink.com

The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. These couplings are not designed to. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance.

Pump Coupling Types

Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. The transmission of axial and radial. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. These couplings are not designed to. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts.

From www.youtube.com

Compare the Parts Rigid Coupling v. Flexible Coupling YouTube Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. The shaft coupling is the connecting element between the electric motor. Rigid Pump Coupling.

From www.linquip.com

7 Main Types of Rigid Couplings + Working Principles Linquip Rigid Pump Coupling These couplings are not designed to. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. The most common configuration for rigid couplings are. Rigid Pump Coupling.

From www.indiamart.com

Rigid Coupling at Rs 2100/piece Rigid Couplings in Ahmedabad ID Rigid Pump Coupling Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size.. Rigid Pump Coupling.

From klaeflhwp.blob.core.windows.net

Types Of Pump Coupling at Duane Stuart blog Rigid Pump Coupling Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to.. Rigid Pump Coupling.

From cad.timken.com

Rigid Compression Couplings On The Timken Company Rigid Pump Coupling The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. Its primary function is to transmit power while accommodating misalignment, reducing shock loads,. Rigid Pump Coupling.

From www.lovejoy-inc.com

Rigid Compression Coupling Lovejoy a Timken company Rigid Pump Coupling The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The shaft coupling is the connecting element between the electric motor and. Rigid Pump Coupling.

From www.johncrane.com

Rigid Couplings John Crane Rigid Pump Coupling These couplings are not designed to. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. Rigid couplings, also known as rigid shaft couplings, are used to transmit power. Rigid Pump Coupling.

From www.linquip.com

What Are The Different Types of Pump Couplings? Linquip Rigid Pump Coupling Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings. Rigid Pump Coupling.

From engineeringlearn.com

Shaft Coupling Definition, Types, Uses, Working Principle & Advantages Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and. Rigid Pump Coupling.

From empoweringpumps.com

Vertical Rigid Couplings Empowering Pumps and Equipment Rigid Pump Coupling These couplings are not designed to. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and. Rigid Pump Coupling.

From couplingcorp.com

Vertical Pump Coupling Rigid by CouplingCorp Rigid Pump Coupling The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. The transmission of axial and radial. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment. Rigid Pump Coupling.

From www.vic.com.my

Rigid Coupling VIC Engineering Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and. Rigid Pump Coupling.

From www.reddit.com

Different Types of Couplings r/coolguides Rigid Pump Coupling The transmission of axial and radial. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. These couplings are not designed to. The most common configuration for rigid couplings are flange, sleeve, clamp, ring,. Rigid Pump Coupling.

From www.youtube.com

Rigid Couplings Types of Couplings YouTube Rigid Pump Coupling The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. The transmission of axial and radial. As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. Rigid couplings. Rigid Pump Coupling.

From www.victaulic.com

Victaulic Style 107N QuickVic™ Rigid Coupling Rigid Pipe Joining Rigid Pump Coupling Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and. Rigid Pump Coupling.

From www.directindustry.com

Rigid coupling C series John Crane for pump / for agitators / gearbox Rigid Pump Coupling Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The shaft coupling is the connecting element between the. Rigid Pump Coupling.

From tpmcsteel.com

Rigid grooved coupling UL Listed / FM Approved TPMCSTEEL Rigid Pump Coupling The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. The transmission of axial and radial. These couplings are not designed to. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. As their name suggests, rigid couplings connect the pump and. Rigid Pump Coupling.

From akita-mitsubishi.co.jp

Industrial Mechanical Power Transmission Industrial Rigid Couplings 1 Rigid Pump Coupling The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. These couplings are not designed to. The shaft coupling is the connecting. Rigid Pump Coupling.

From eganagroup.com

Rigid couplings vs flexible couplings analysis Rigid Pump Coupling These couplings are not designed to. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. The transmission of axial and radial. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts.. Rigid Pump Coupling.

From empoweringpumps.com

AVS Series Rigid Couplings for Vertical Turbine Pumps in Refinery Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads. Rigid Pump Coupling.

From www.huco.com

Rigid Couplings Rigid Pump Coupling These couplings are not designed to. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system.. Rigid Pump Coupling.

From couplingcorp.com

Rigid coulping vertical Coupling Corporation of America Rigid Pump Coupling Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline. Rigid Pump Coupling.

From mavink.com

Pump Coupling Types Rigid Pump Coupling The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. These couplings are not designed to. A pump coupling is a mechanical device used to connect two shafts, typically one from. Rigid Pump Coupling.

From rathicouplings.com

Rigid Couplings / RR Rathi Couplings Rigid Pump Coupling The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from. Rigid Pump Coupling.

From www.iqsdirectory.com

Shaft Coupling What Is It? How Is it Used? Types Of, Roles Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance.. Rigid Pump Coupling.

From www.directindustry.com

Rigid coupling RFK … TBO RINGSPANN shafts / conveyor / compact Rigid Pump Coupling A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. Rigid couplings offer high torsional rigidity and are suitable for applications with. Rigid Pump Coupling.

From www.theengineerspost.com

13 Types of Coupling Definition, Drawings, Uses & (PDF) Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between. Rigid Pump Coupling.

From blog.craneengineering.net

The Quick And Dirty Guide To Pump Coupling Types Rigid Pump Coupling The transmission of axial and radial. These couplings are not designed to. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a breakpoint for maintenance. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine.. Rigid Pump Coupling.

From flavored.ph

Power Transmission Products Rigid Couplings 13/8 Inch Bore 6 Tooth Rigid Pump Coupling The transmission of axial and radial. Rigid couplings offer high torsional rigidity and are suitable for applications with minimal misalignment. Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. The shaft coupling is the connecting element. Rigid Pump Coupling.

From www.youtube.com

Rigid Coupling Type of Coupling Rigid Coupling Vs Flexible Rigid Pump Coupling Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. The shaft coupling is the. Rigid Pump Coupling.

From yw-transmission.com

Rigid Couplings Youwinn International Transmission Rigid Pump Coupling The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. Rigid couplings, also known as rigid shaft couplings, are used to transmit power and rotation between the drive and driven equipment shafts. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to. Rigid Pump Coupling.

From www.directindustry.com

Rigid coupling R series OEP Couplings flange Rigid Pump Coupling The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw and spline couplings. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. The transmission of axial and radial. The rigid coupling connects the driver and. Rigid Pump Coupling.

From dxppacific.com

When to Use Rigid Coupling on Pumps DXP Pacific Rigid Pump Coupling As their name suggests, rigid couplings connect the pump and motor shafts together very firmly, which allows them to. A pump coupling is a mechanical device used to connect two shafts, typically one from the pump’s impeller and the other from the motor or engine. These couplings are not designed to. Rigid couplings offer high torsional rigidity and are suitable. Rigid Pump Coupling.

From www.raghuveergearcoupling.com

Rigid Coupling Manufacturers in Ahmedabad, Gear Couplings Exporters in Rigid Pump Coupling The shaft coupling is the connecting element between the electric motor and the pump hydraulic system. As their name suggests, rigid couplings connect the pump and motor shafts very firmly, which allows them to transmit more power to the pump than flexible couplings of comparable size. The most common configuration for rigid couplings are flange, sleeve, clamp, ring, set screw. Rigid Pump Coupling.

From www.pumpsandsystems.com

Selecting the Right Coupling Pumps & Systems Rigid Pump Coupling Its primary function is to transmit power while accommodating misalignment, reducing shock loads, and isolating vibrations. Although rigid couplings are the most basic, they are also often the most cost effective and their simple structure makes for easy assembly and maintenance. The rigid coupling connects the driver and driven shafts, transmits torque, transmits axial and radial loads and provides a. Rigid Pump Coupling.