Line Balance Definition . A balanced production line is stable and flexible enough to adapt to. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing reduces variations within a production line. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. what is line balancing?

from knowindustrialengineering.com

The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. what is line balancing? A balanced production line is stable and flexible enough to adapt to. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. line balancing reduces variations within a production line.

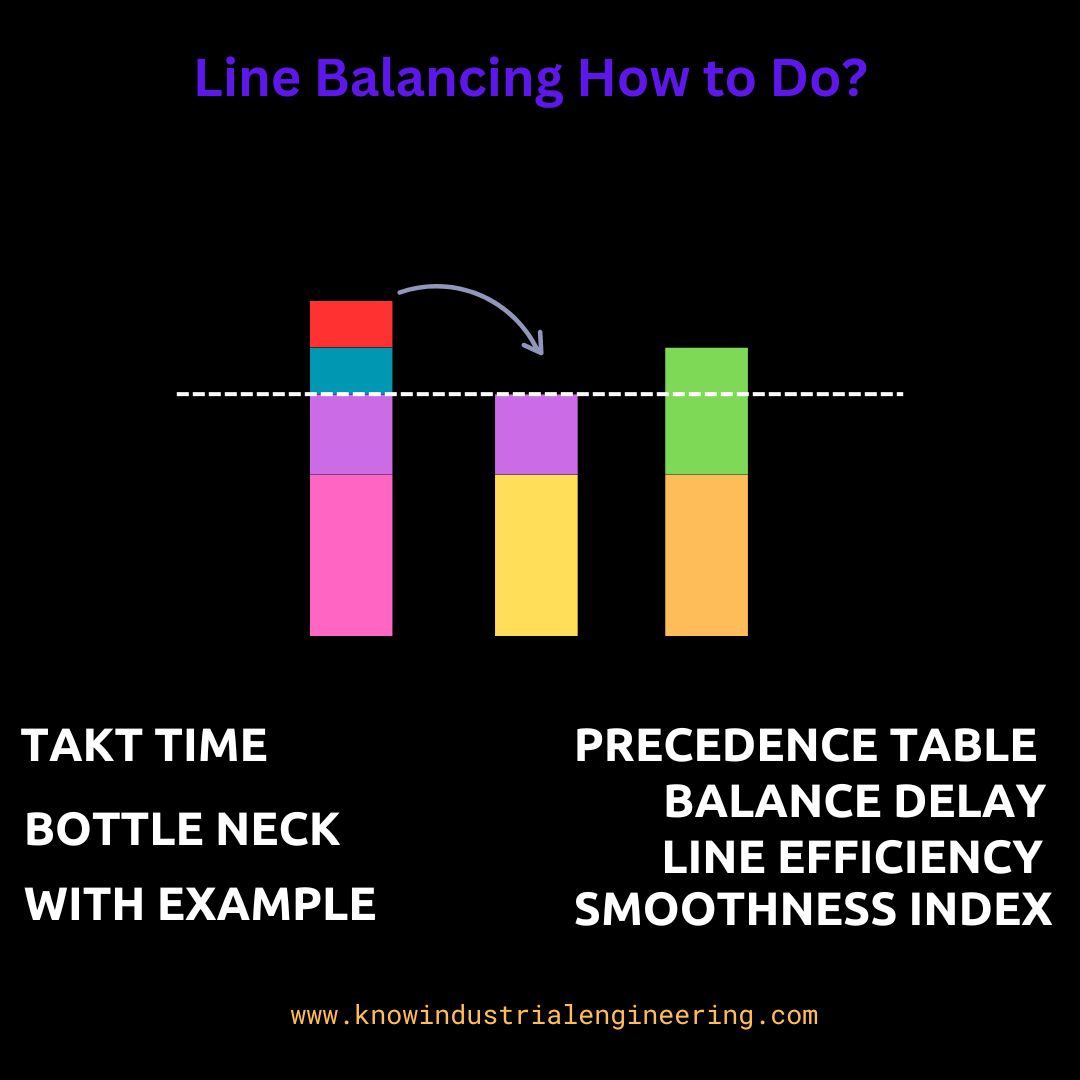

Line Balancing How to do it (With Example)

Line Balance Definition A balanced production line is stable and flexible enough to adapt to. what is line balancing? Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. A balanced production line is stable and flexible enough to adapt to. line balancing reduces variations within a production line. The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to.

From www.erp-information.com

Definition of Line balancing ERP Information Line Balance Definition what is line balancing? A balanced production line is stable and flexible enough to adapt to. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line balancing reduces variations within a production. Line Balance Definition.

From www.youtube.com

How to calculate line balancing ratio YouTube Line Balance Definition The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing reduces variations within a production line. Line balancing, or production leveling, is a process whereby operator time and machine time. Line Balance Definition.

From www.youtube.com

Engineering Management ,Lect 9, Line of Balance , Example 2 YouTube Line Balance Definition Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing reduces variations within a production line. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers. Line Balance Definition.

From www.smlease.com

What is production Line Balancing and How to implement it? Line Balance Definition A balanced production line is stable and flexible enough to adapt to. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing reduces variations within a production line. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. in the manufacturing. Line Balance Definition.

From studylib.net

Line_of_Balance Line Balance Definition line balancing reduces variations within a production line. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. A balanced production line is stable and flexible enough to adapt to. in the manufacturing. Line Balance Definition.

From www.slideshare.net

Line balancing Line Balance Definition what is line balancing? line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique. Line Balance Definition.

From zh.scribd.com

Examples Line Balancing Applied Mathematics Mathematics Line Balance Definition in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. A balanced production line is stable and flexible enough to adapt to. line balancing (lb) increases efficiency and throughput while. Line Balance Definition.

From www.slideshare.net

Line balancing and its formulation Line Balance Definition line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to. what is line balancing?. Line Balance Definition.

From mungfali.com

Line Balancing Diagram Line Balance Definition what is line balancing? in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. The line of balance is a project management tool that visually represents the status of various tasks or activities in. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs. Line Balance Definition.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. what is line balancing? in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. line balancing reduces variations within a production line. Line balancing, or production leveling, is a. Line Balance Definition.

From www.slideshare.net

Line balancing Line Balance Definition line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. line balancing reduces variations within a production line. what is line balancing? A balanced production line is stable and flexible. Line Balance Definition.

From www.youtube.com

Lecture 10 Line of Balance Technique YouTube Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. what is line balancing? in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production. Line Balance Definition.

From www.youtube.com

line balancing YouTube Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing reduces variations within a production line. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line of balance (lob) is a management control process for collecting, measuring, and presenting facts. Line Balance Definition.

From knowindustrialengineering.com

Line Balancing How to do it Know Industrial Engineering Line Balance Definition what is line balancing? line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating.. Line Balance Definition.

From www.slideserve.com

PPT Assembly Line Balancing PowerPoint Presentation, free download Line Balance Definition A balanced production line is stable and flexible enough to adapt to. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. what is line balancing? The line of balance is a project management tool that visually represents the status of various tasks or activities in. in the manufacturing context,. Line Balance Definition.

From www.slideshare.net

Line of balance Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. what is line balancing? The line of balance is a project management tool that visually represents the status of various tasks or activities in.. Line Balance Definition.

From www.slideshare.net

Line balancing example Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. what is line. Line Balance Definition.

From www.youtube.com

Line Of Balance Examples 3 3 YouTube Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. what is line balancing? Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. The line. Line Balance Definition.

From www.slideshare.net

Line balancing Line Balance Definition in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. what is line balancing? The line of balance is a project management tool that visually represents the status of various. Line Balance Definition.

From mungfali.com

Line Balancing Diagram Line Balance Definition A balanced production line is stable and flexible enough to adapt to. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing reduces variations within a production line. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line balancing. Line Balance Definition.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balance Definition line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. what is line balancing? A balanced production line is stable and flexible enough to adapt to. Line balancing, or production leveling, is a process. Line Balance Definition.

From knowindustrialengineering.com

Line Balancing How to do it (With Example) Line Balance Definition Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line balancing reduces variations within a production line. what is line balancing? line of balance (lob) is a management control process for. Line Balance Definition.

From www.slideshare.net

Line balancing Line Balance Definition what is line balancing? line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production. Line Balance Definition.

From www.onlineclothingstudy.com

Line Balancing Tool Based on Operator Skill Matrix Line Balance Definition line balancing reduces variations within a production line. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to. Line Balance Definition.

From www.youtube.com

Line Of Balance Introduction 1 3 YouTube Line Balance Definition what is line balancing? A balanced production line is stable and flexible enough to adapt to. line balancing reduces variations within a production line. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against. Line Balance Definition.

From studiousguy.com

Operations Management StudiousGuy Line Balance Definition line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line balancing reduces variations within a production line. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the. Line Balance Definition.

From www.slideshare.net

Line balancing Line Balance Definition line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. . Line Balance Definition.

From www.youtube.com

How to calculate Line Efficiency line balancing lean manufacturing Line Balance Definition Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. what is line balancing? The line of balance is a project management tool that visually represents the status of various tasks or activities in. A balanced production line is stable and flexible enough to adapt to. line of balance scheduling. Line Balance Definition.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Line Balance Definition line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. line of balance scheduling helps manage workflow by visualizing the progress of various tasks against the planned. A balanced production line is stable and flexible enough to adapt to. what is line balancing? The line of balance is a project management. Line Balance Definition.

From www.slideshare.net

Line balancing and its formulation Line Balance Definition line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. what is line balancing? in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to.. Line Balance Definition.

From www.youtube.com

What is Line Balancing YouTube Line Balance Definition line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing reduces variations within a production line. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to. Line Balance Definition.

From www.tetrahedron.in

Line Balancing in Manufacturing Training Tetrahedron Line Balance Definition line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. what is line balancing? line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines.. Line Balance Definition.

From www.slideserve.com

PPT Line Balancing in Operations Management PowerPoint Presentation Line Balance Definition what is line balancing? line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. The line of balance is a project management tool that visually represents the status of various tasks or activities in. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address.. Line Balance Definition.

From www.scribd.com

Line Balance Presentation PDF Business Line Balance Definition The line of balance is a project management tool that visually represents the status of various tasks or activities in. line balancing (lb) increases efficiency and throughput while simultaneously decreasing manpower and costs in production lines. Line balancing, or production leveling, is a process whereby operator time and machine time are optimized to address. line of balance (lob). Line Balance Definition.

From www.slideserve.com

PPT Line Balancing PowerPoint Presentation, free download ID1272475 Line Balance Definition The line of balance is a project management tool that visually represents the status of various tasks or activities in. line of balance (lob) is a management control process for collecting, measuring, and presenting facts relating. line balancing reduces variations within a production line. A balanced production line is stable and flexible enough to adapt to. what. Line Balance Definition.