How To Check A Surface Plate For Flatness . Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. This will give the height difference. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. To do so, the first step is to acquire points on the. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The overall flatness is often checked with a laser. how to measure flatness. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. When we look at a surface closely enough, it will never be perfectly flat (wavy). there are various methods are available for flatness testing. The most protruding part and the.

from extrudesign.com

how to measure flatness. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. The most protruding part and the. To do so, the first step is to acquire points on the. there are various methods are available for flatness testing. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. When we look at a surface closely enough, it will never be perfectly flat (wavy). The overall flatness is often checked with a laser.

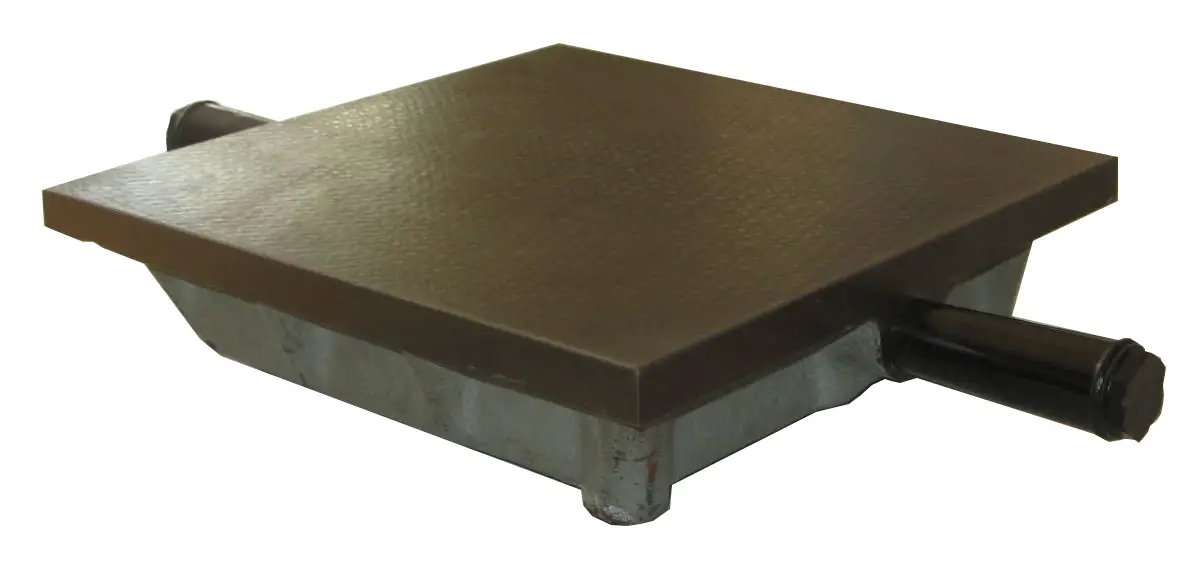

Surface plate, Surface Table 001 ExtruDesign

How To Check A Surface Plate For Flatness This will give the height difference. how to measure flatness. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. there are various methods are available for flatness testing. The most protruding part and the. The overall flatness is often checked with a laser. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. When we look at a surface closely enough, it will never be perfectly flat (wavy). This will give the height difference. To do so, the first step is to acquire points on the.

From www.youtube.com

Granite Surface Plate The Foundation of Metrology YouTube How To Check A Surface Plate For Flatness how to measure flatness. there are various methods are available for flatness testing. The most protruding part and the. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. When we look at a surface closely enough, it will never be perfectly flat (wavy).. How To Check A Surface Plate For Flatness.

From fractory.com

Flatness (GD&T) Explained Fractory How To Check A Surface Plate For Flatness how to measure flatness. This will give the height difference. When we look at a surface closely enough, it will never be perfectly flat (wavy). to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. Measuring flatness consists of analyzing a surface to find how. How To Check A Surface Plate For Flatness.

From microflatdatums.com

Surface Plates with Centre Attachments, Precision Inspection Bench How To Check A Surface Plate For Flatness how to measure flatness. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. there are various methods are available for. How To Check A Surface Plate For Flatness.

From mavink.com

How To Measure Flatness Of A Surface How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. To do so, the first step is to acquire points on the. When we look at a surface closely enough, it will never be perfectly flat (wavy). The most protruding part and the. there are various methods are available. How To Check A Surface Plate For Flatness.

From www.alibaba.com

Flatness Measuring Black Granite Lapping Base Check Stand Surface How To Check A Surface Plate For Flatness The overall flatness is often checked with a laser. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. When we look at a surface closely enough, it will never be perfectly flat (wavy). To do so, the first step is to acquire points on the. to measure flatness,. How To Check A Surface Plate For Flatness.

From www.thestructuralengineer.info

Calculation Example Design bolted connection of tension plates (EC3 How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. there are various methods are available for flatness testing. The overall flatness is often checked with a laser. The most protruding part and the. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat.. How To Check A Surface Plate For Flatness.

From www.scribd.com

Base Plate Calculation Civil Engineering Building Engineering How To Check A Surface Plate For Flatness there are various methods are available for flatness testing. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. When we look at a surface closely enough, it will never be perfectly flat (wavy). This will give the height difference. Measuring flatness consists of analyzing a surface to find. How To Check A Surface Plate For Flatness.

From www.slideserve.com

PPT Squares and Surface Plates PowerPoint Presentation, free download How To Check A Surface Plate For Flatness To do so, the first step is to acquire points on the. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. The most protruding part and the. When we look at a surface closely enough, it will never be perfectly flat (wavy). there are various. How To Check A Surface Plate For Flatness.

From www.microflatdatums.com

Flatness Checking Equipment, Flatness Measurement Suppliers, Gujarat How To Check A Surface Plate For Flatness to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. When we look at a surface closely enough, it will never be perfectly flat (wavy). This will give the height difference. there are various methods are available for flatness testing. how to measure flatness. . How To Check A Surface Plate For Flatness.

From engineeringlibrary.org

Analysis of Plates in Bending Engineering Library How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. how to measure flatness. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. Measuring flatness consists of analyzing a surface to find how it is. How To Check A Surface Plate For Flatness.

From vibadirect.com

Flatness Tolerance ViBaDirect How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. to measure flatness, the part being measured is placed on the surface plate and a. How To Check A Surface Plate For Flatness.

From www.spectrum-metrology.co.uk

Talyvel flatness check for calibration of surface plates and granite How To Check A Surface Plate For Flatness to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. The most protruding part and the. how to measure flatness. This will give the height difference. To do so, the first step is to acquire points on the. there are various methods are available for. How To Check A Surface Plate For Flatness.

From ngpd.nikon.com

Processing of flat surfaces and common flat surfaces|Precision How To Check A Surface Plate For Flatness how to measure flatness. This will give the height difference. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. When we look at a surface closely enough, it will never be perfectly flat (wavy). when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface. How To Check A Surface Plate For Flatness.

From www.gdandtbasics.com

GDandT Symbol GD&T Basics Part 2 How To Check A Surface Plate For Flatness Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. This will give the height difference. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. how to measure flatness. When we look at a surface closely enough, it will. How To Check A Surface Plate For Flatness.

From www.youtube.com

Surface plate flatness checking by using dial indicator YouTube How To Check A Surface Plate For Flatness The overall flatness is often checked with a laser. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The most protruding part and the. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. Measuring. How To Check A Surface Plate For Flatness.

From www.animalia-life.club

Surface Flatness Measurement How To Check A Surface Plate For Flatness to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. To do so, the first step is to acquire points on the. The most protruding part and the. This will give the height difference. The overall flatness is often checked with a laser. when measuring. How To Check A Surface Plate For Flatness.

From www.stahliusa.com

Inspection of Lapping Plate How To Check A Surface Plate For Flatness to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. When we look at a surface closely enough, it will never be perfectly flat (wavy). Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. This will give the height difference.. How To Check A Surface Plate For Flatness.

From www.youtube.com

Glass Flatness Measuring Instrument YouTube How To Check A Surface Plate For Flatness To do so, the first step is to acquire points on the. there are various methods are available for flatness testing. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The overall flatness is often checked with a laser. how to measure flatness. This will give the. How To Check A Surface Plate For Flatness.

From extrudesign.com

Surface plate, Surface Table 001 ExtruDesign How To Check A Surface Plate For Flatness The most protruding part and the. there are various methods are available for flatness testing. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. When we look at a. How To Check A Surface Plate For Flatness.

From www.youtube.com

Flatness Measurement with TriAngle Autocollimator TRIOPTICS YouTube How To Check A Surface Plate For Flatness to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. This will give the height difference. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The overall flatness is often checked with a laser. Measuring flatness. How To Check A Surface Plate For Flatness.

From www.youtube.com

Straight edge survey to measure surface flatness YouTube How To Check A Surface Plate For Flatness The overall flatness is often checked with a laser. This will give the height difference. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. how to measure flatness. When we look at a surface closely enough, it will never be perfectly flat (wavy). to measure flatness, the part being measured is placed. How To Check A Surface Plate For Flatness.

From extrudesign.com

What are the different Flatness Testing Methods for Surface Plates How To Check A Surface Plate For Flatness Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the. How To Check A Surface Plate For Flatness.

From extrudesign.com

What are the different Flatness Testing Methods for Surface Plates How To Check A Surface Plate For Flatness how to measure flatness. there are various methods are available for flatness testing. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The most protruding part and the. To do so, the first step is to acquire points on the. This will give the height difference. . How To Check A Surface Plate For Flatness.

From www.flexbar.com

Surface Roughness Testers and Comparator Plates — Flexbar Machine How To Check A Surface Plate For Flatness When we look at a surface closely enough, it will never be perfectly flat (wavy). Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. when measuring flatness, you are checking. How To Check A Surface Plate For Flatness.

From www.youtube.com

How to measure flatness and straightness of surface Flatness How To Check A Surface Plate For Flatness to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band. The overall flatness is often checked with a laser. The most protruding part and the. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. This will give the height difference.. How To Check A Surface Plate For Flatness.

From www.excelcalcs.com

base plate thickness calculation How To Check A Surface Plate For Flatness to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. This will. How To Check A Surface Plate For Flatness.

From andygokerichardson.blogspot.com

How to Calculate Plate Height in Chromatography How To Check A Surface Plate For Flatness Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. This will give the height difference. The most protruding part and the. to accurately measure the level of flatness, count the number of dark. How To Check A Surface Plate For Flatness.

From www.youtube.com

Visual Inpection of Surface Roughness YouTube How To Check A Surface Plate For Flatness When we look at a surface closely enough, it will never be perfectly flat (wavy). To do so, the first step is to acquire points on the. The overall flatness is often checked with a laser. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of the light band.. How To Check A Surface Plate For Flatness.

From fractory.com

Sheet Metal Materials, Standard Sizes & Forming Processes How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. This will give the height difference. When we look at a surface closely enough, it will never be perfectly flat (wavy). to accurately measure the level of flatness, count the number of dark lines and multiply this by the. How To Check A Surface Plate For Flatness.

From www.electronics-inc.com

Flatness Gage Electronics Inc How To Check A Surface Plate For Flatness there are various methods are available for flatness testing. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. When we look at a surface closely enough, it will never be perfectly flat (wavy). how to measure flatness. when measuring flatness, you are checking. How To Check A Surface Plate For Flatness.

From www.youtube.com

Height / Surface gauge DIY YouTube How To Check A Surface Plate For Flatness The most protruding part and the. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. To do so, the first step is to acquire points on the. The overall flatness is often checked with a laser. how to measure flatness. This will give the height difference. to accurately measure the level of. How To Check A Surface Plate For Flatness.

From learnwithseu.com

Punching Shear Review for Concrete Flat Plates Continuing Education How To Check A Surface Plate For Flatness Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. When we. How To Check A Surface Plate For Flatness.

From www.youtube.com

Used Surface Plate Inspection, Checking, and Stand Modification. YouTube How To Check A Surface Plate For Flatness when measuring flatness, you are checking for unevenness in the surface, to see how precisely flat a surface is. The overall flatness is often checked with a laser. how to measure flatness. Measuring flatness consists of analyzing a surface to find how it is not perfectly flat. The most protruding part and the. To do so, the first. How To Check A Surface Plate For Flatness.

From www.gdandtbasics.com

Flatness GD&T Basics How To Check A Surface Plate For Flatness how to measure flatness. To do so, the first step is to acquire points on the. This will give the height difference. When we look at a surface closely enough, it will never be perfectly flat (wavy). The most protruding part and the. when measuring flatness, you are checking for unevenness in the surface, to see how precisely. How To Check A Surface Plate For Flatness.

From www.youtube.com

SURFACE PLATE CALIBRATION BY USING WYLER LEVEL AND CROSS CHECKING WITH How To Check A Surface Plate For Flatness This will give the height difference. there are various methods are available for flatness testing. to measure flatness, the part being measured is placed on the surface plate and a dial indicator is used to measure the. to accurately measure the level of flatness, count the number of dark lines and multiply this by the width of. How To Check A Surface Plate For Flatness.