Abrasives In Grinding Wheel . In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. These powerful abrasives precisely shape, sharpen, and smooth materials. Discover how they’re made, and learn how to. The abrasive grains act as. Even natural diamonds have been replaced in some instances by synthetic diamonds. Safety in the use of abrasive wheels. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. But only when used correctly is it true. Two types of abrasives are used in grinding wheels:

from www.wembleytools.co.zw

Even natural diamonds have been replaced in some instances by synthetic diamonds. Two types of abrasives are used in grinding wheels: These powerful abrasives precisely shape, sharpen, and smooth materials. Safety in the use of abrasive wheels. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Discover how they’re made, and learn how to. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. But only when used correctly is it true. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance.

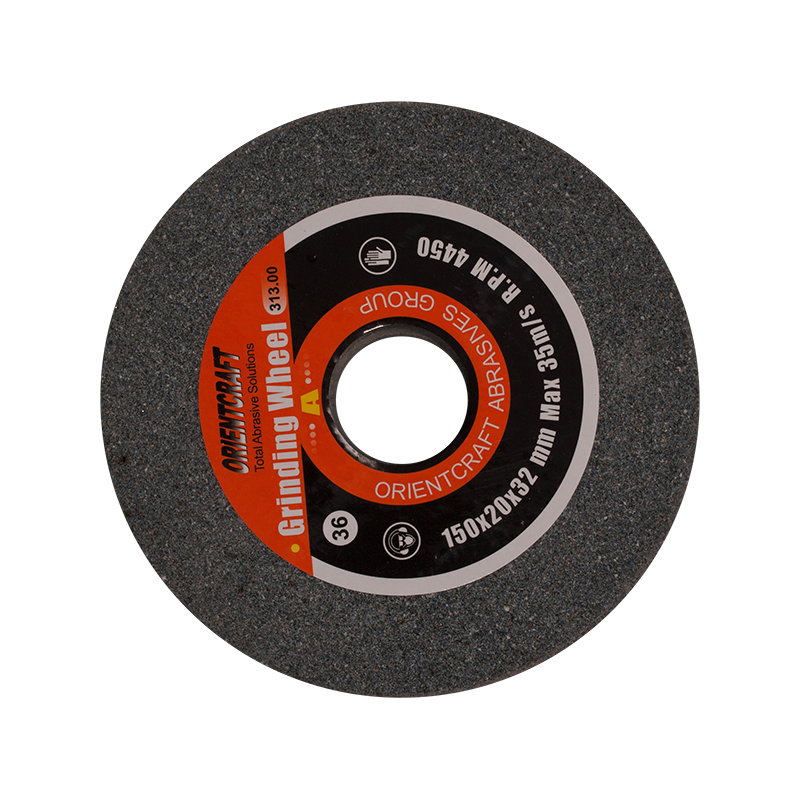

Orientcraft Abrasives Grinding Wheel 36 GRIT 150MM X20MM Wembleytools

Abrasives In Grinding Wheel Even natural diamonds have been replaced in some instances by synthetic diamonds. Safety in the use of abrasive wheels. Two types of abrasives are used in grinding wheels: Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. The abrasive grains act as. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Even natural diamonds have been replaced in some instances by synthetic diamonds. These powerful abrasives precisely shape, sharpen, and smooth materials. Discover how they’re made, and learn how to. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. But only when used correctly is it true. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products.

From fareastabrasive.en.made-in-china.com

Resin Bond Grinding Wheel/ Abrasive Wheel China Grinding Wheel and Abrasives In Grinding Wheel But only when used correctly is it true. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Safety in the use of abrasive wheels. Two types of abrasives are used in grinding wheels: These powerful abrasives precisely shape, sharpen, and smooth materials. The abrasive. Abrasives In Grinding Wheel.

From www.sears.com

Norton Abrasives St. Gobain Grinding Wheel, T1, 12x3/4x3, Aluminum Abrasives In Grinding Wheel Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Two types of abrasives are used in grinding wheels: Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. These powerful abrasives precisely shape, sharpen, and smooth materials. Even natural diamonds have been replaced in some instances by synthetic diamonds.. Abrasives In Grinding Wheel.

From www.aliexpress.com

PA abrasive grinding wheel for chainsaw sharpening Diameter 100 Abrasives In Grinding Wheel Safety in the use of abrasive wheels. These powerful abrasives precisely shape, sharpen, and smooth materials. The abrasive grains act as. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Grinding wheels play an important role in many applications and are one. Abrasives In Grinding Wheel.

From www.grainger.com

NORTON Straight Grinding Wheel 14 in Abrasive Wheel Dia, 1 1/2 in Abrasives In Grinding Wheel Even natural diamonds have been replaced in some instances by synthetic diamonds. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. But only when used correctly is it true. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Safety in the use of abrasive wheels. These powerful abrasives precisely shape, sharpen,. Abrasives In Grinding Wheel.

From news.thomasnet.com

Norton Abrasives to Exhibit Precision Vitrified Grinding Wheels with Abrasives In Grinding Wheel Two types of abrasives are used in grinding wheels: Safety in the use of abrasive wheels. Even natural diamonds have been replaced in some instances by synthetic diamonds. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Discover how. Abrasives In Grinding Wheel.

From www.shalomabrasives.com

Grinding wheels Manufacturer in Chennai » Shalom Abrasives Abrasives In Grinding Wheel Two types of abrasives are used in grinding wheels: Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. But only when used correctly is it true. These powerful abrasives precisely shape, sharpen, and smooth materials. The abrasive grains act as. Safety in the use of abrasive wheels. Discover how they’re. Abrasives In Grinding Wheel.

From www.indiamart.com

Round Asia Abrasives DC Grinding Wheel, Thickness Of Wheel 6mm at Rs Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. But only when used correctly is it true. Safety in the use of abrasive wheels. Two types of abrasives are used in grinding wheels: Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Grinding wheels contain abrasive grains and layers of fiberglass bonded into. Abrasives In Grinding Wheel.

From www.mscdirect.com

Radiac Abrasives Surface Grinding Wheel 46 Grit MSC Direct Abrasives In Grinding Wheel Discover how they’re made, and learn how to. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. These powerful abrasives precisely shape, sharpen, and smooth materials. Safety in the use of abrasive wheels.. Abrasives In Grinding Wheel.

From kr.kompass.com

Resin Bonded Abrasive Wheels (by Cheil Grinding Wheel Ind, Co., Ltd.) Abrasives In Grinding Wheel Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Even natural diamonds have been replaced in some instances by synthetic diamonds. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. But only when used correctly is it true. Discover how they’re made, and learn how to. These. Abrasives In Grinding Wheel.

From rapidabrasives.ca

Learning about Grinding Wheels Rapid Abrasives & Accessories Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Safety in the use of abrasive wheels. Two types of abrasives are used in grinding wheels: Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Discover how they’re made, and learn how to. Grinding wheels contain abrasive grains and layers of fiberglass bonded into. Abrasives In Grinding Wheel.

From www.kinikusa.com

Conventional Grinding Wheels KINIKUSA Abrasives In Grinding Wheel Discover how they’re made, and learn how to. The abrasive grains act as. Two types of abrasives are used in grinding wheels: Even natural diamonds have been replaced in some instances by synthetic diamonds. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for. Abrasives In Grinding Wheel.

From www.penntoolco.com

CGW Abrasives Surface Grinding Wheel 59011 59435511 Penn Tool Co., Inc Abrasives In Grinding Wheel These powerful abrasives precisely shape, sharpen, and smooth materials. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Discover how they’re made, and learn how to. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Grinding wheels play an important role in many applications and are one of the. Abrasives In Grinding Wheel.

From extrudesign.com

Grinding Wheel Abrasives, Properties, Shape and Structures Abrasives In Grinding Wheel Discover how they’re made, and learn how to. Safety in the use of abrasive wheels. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Two types of abrasives are used in grinding wheels: Even natural diamonds have been replaced in some instances by synthetic diamonds. These powerful abrasives precisely shape,. Abrasives In Grinding Wheel.

From www.lowes.com

Firepower Type 1 Bench Grinding Wheel, 6 x 3/4, 80 Grit in the Abrasive Abrasives In Grinding Wheel Two types of abrasives are used in grinding wheels: Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. But only when used correctly is it true. The abrasive grains act as. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. In the dynamic realm of manufacturing and metalworking, abrasive. Abrasives In Grinding Wheel.

From www.premiumtool.com

Premium Tool & Abrasives UltraGrind Depressed Center Grinding Wheels Abrasives In Grinding Wheel Discover how they’re made, and learn how to. But only when used correctly is it true. These powerful abrasives precisely shape, sharpen, and smooth materials. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Even natural diamonds have been replaced in some instances by synthetic diamonds. Grinding wheels contain abrasive. Abrasives In Grinding Wheel.

From www.metabo.com

Rubberized abrasive grinding wheel 4 x 4", P 180 (623499000) Metabo Abrasives In Grinding Wheel These powerful abrasives precisely shape, sharpen, and smooth materials. The abrasive grains act as. Discover how they’re made, and learn how to. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Two types of abrasives are used in grinding. Abrasives In Grinding Wheel.

From duoprint.com.ec

A24HPS Grit Durable Abrasive Finishing Wheel with Arbor Hole Abrasives In Grinding Wheel In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Even natural diamonds have been replaced in some instances by synthetic diamonds. These powerful abrasives precisely shape, sharpen, and smooth materials. But only when used correctly is it true. Grinding wheels play an important role in many applications and are one of the most commonly. Abrasives In Grinding Wheel.

From www.grainger.com

NORTON Straight Grinding Wheel 5 in Abrasive Wheel Dia, 1 in Arbor Abrasives In Grinding Wheel Discover how they’re made, and learn how to. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Even natural diamonds have been replaced in some instances by synthetic diamonds. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Two types of abrasives are used in grinding wheels: Grinding wheels contain. Abrasives In Grinding Wheel.

From ilt.safetynow.com

How to Safely Use Abrasive Wheel Grinders SafetyNow ILT Abrasives In Grinding Wheel These powerful abrasives precisely shape, sharpen, and smooth materials. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Discover how they’re made, and learn how to. Safety in the use of abrasive wheels. Even natural diamonds have been replaced in some instances by synthetic diamonds. Guidance subsequent to the repeal. Abrasives In Grinding Wheel.

From www.championcuttingtool.com

Abrasives I 623 Grinding Wheels Abrasives In Grinding Wheel Discover how they’re made, and learn how to. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Grinding wheels play an important role in. Abrasives In Grinding Wheel.

From www.washingtonmills.com

Bonded Abrasives Washington Mills Abrasives In Grinding Wheel Grinding wheels play an important role in many applications and are one of the most commonly used abrasive products. Discover how they’re made, and learn how to. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Two types of abrasives are used in grinding wheels: The abrasive grains act as. Except for diamonds, manufactured abrasives have. Abrasives In Grinding Wheel.

From cepngunz.blob.core.windows.net

Abrasive Rubber Grinding Wheels at Jacqueline Goggins blog Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Two types of abrasives are used in grinding wheels: Discover how they’re made, and learn how to. Grinding wheels play an important role in many applications and are one of the most commonly used abrasive. Abrasives In Grinding Wheel.

From extrudesign.com

Grinding Wheel Abrasives, Properties, Shape and Structures Abrasives In Grinding Wheel In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Discover how they’re made, and learn how to. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Two types of abrasives are used in grinding wheels: But only when used correctly is it true. Grinding wheels contain abrasive grains and layers of. Abrasives In Grinding Wheel.

From www.sakabrasives.com

Super Abrasive Grinding Wheels SAK Abrasives Abrasives In Grinding Wheel These powerful abrasives precisely shape, sharpen, and smooth materials. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Safety in the use of abrasive wheels. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Discover how they’re made, and learn how to. Grinding wheels play an important role in. Abrasives In Grinding Wheel.

From www.chris-marine.com

Grinding Wheels ChrisMarine Abrasives In Grinding Wheel Safety in the use of abrasive wheels. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Two types of abrasives are used in grinding wheels: Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. But only when used correctly is it true. Guidance subsequent to the repeal of the. Abrasives In Grinding Wheel.

From echo-3.co.uk

Guide to Abrasive Wheels What you need to know to work safely Abrasives In Grinding Wheel Safety in the use of abrasive wheels. These powerful abrasives precisely shape, sharpen, and smooth materials. Even natural diamonds have been replaced in some instances by synthetic diamonds. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. The abrasive grains act as. Discover how they’re made, and learn how to. Grinding wheels play an. Abrasives In Grinding Wheel.

From www.grainger.com

NORTON Straight Grinding Wheel 12 in Abrasive Wheel Dia, 1 1/4 in Abrasives In Grinding Wheel Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Two types of abrasives are used in grinding wheels: Even natural diamonds have been replaced in some instances by synthetic diamonds. These powerful abrasives precisely shape, sharpen, and smooth materials.. Abrasives In Grinding Wheel.

From yoderbrothersmachinery.com

14″ x 2″ x 5″ RADIAC ABRASIVES GRINDING WHEEL Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. Even natural diamonds have been replaced in some instances by synthetic diamonds. Safety in the use of abrasive wheels. Discover how they’re made, and learn how to. In the dynamic. Abrasives In Grinding Wheel.

From hindustanabrasives.tumblr.com

Hindustan Abrasives — Grinding Wheel & it’s Selection Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. But only when used correctly is it true. Safety in the use of abrasive wheels. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Discover how they’re made, and learn how to. Two types of abrasives are used in grinding wheels: These powerful abrasives. Abrasives In Grinding Wheel.

From kr.kompass.com

Cheil Grinding Wheel Ind, Co., Ltd., 34, Daesongro 101beongi... Abrasives In Grinding Wheel These powerful abrasives precisely shape, sharpen, and smooth materials. Discover how they’re made, and learn how to. Two types of abrasives are used in grinding wheels: In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Grinding wheels contain abrasive grains and layers. Abrasives In Grinding Wheel.

From www.cgwabrasives.com

Mini Depressed Center Grinding Wheels Grinding Wheels CGW Abrasives Abrasives In Grinding Wheel Two types of abrasives are used in grinding wheels: Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Even natural diamonds have been replaced in some instances by synthetic diamonds. Safety in the use of abrasive wheels. Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. But only when. Abrasives In Grinding Wheel.

From www.grainger.com

NORTON Straight Grinding Wheel 12 in Abrasive Wheel Dia, 5 in Arbor Abrasives In Grinding Wheel Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Two types of abrasives are used in grinding wheels: Safety in the use of abrasive wheels. The abrasive grains act as. These powerful abrasives precisely shape, sharpen, and smooth materials. Grinding wheels play an important. Abrasives In Grinding Wheel.

From www.grainger.com

NORTON Type 6 Aluminum Oxide Straight Cup Grinding Wheel, 5 in, 1 1/2 Abrasives In Grinding Wheel Grinding wheels contain abrasive grains and layers of fiberglass bonded into a wheel shape by another substance. These powerful abrasives precisely shape, sharpen, and smooth materials. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. Even natural diamonds have been replaced. Abrasives In Grinding Wheel.

From www.wembleytools.co.zw

Orientcraft Abrasives Grinding Wheel 36 GRIT 150MM X20MM Wembleytools Abrasives In Grinding Wheel Even natural diamonds have been replaced in some instances by synthetic diamonds. These powerful abrasives precisely shape, sharpen, and smooth materials. But only when used correctly is it true. The abrasive grains act as. Guidance subsequent to the repeal of the abrasive wheels regulations 1970 (encompassing relevant. Two types of abrasives are used in grinding wheels: Grinding wheels contain abrasive. Abrasives In Grinding Wheel.

From 911tooling.com

2 ReadyMOUNT BAY STATE ABRASIVES Grinding Wheel Discs 7 x 1/4 x 5/8 77 Abrasives In Grinding Wheel Except for diamonds, manufactured abrasives have almost entirely replaced natural abrasive materials. Even natural diamonds have been replaced in some instances by synthetic diamonds. In the dynamic realm of manufacturing and metalworking, abrasive grinding wheels are essential for shaping,. These powerful abrasives precisely shape, sharpen, and smooth materials. But only when used correctly is it true. The abrasive grains act. Abrasives In Grinding Wheel.