Thread Milling Depth Of Cut . Staggered tooth thread mills have every other tooth removed in a staggered. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. No matter the type of holemaking, allied is here to help you. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Whether you’re a production facility. The right strategy for breaking and chip removal.

from ecoreprap.com

In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. Whether you’re a production facility. No matter the type of holemaking, allied is here to help you. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread.

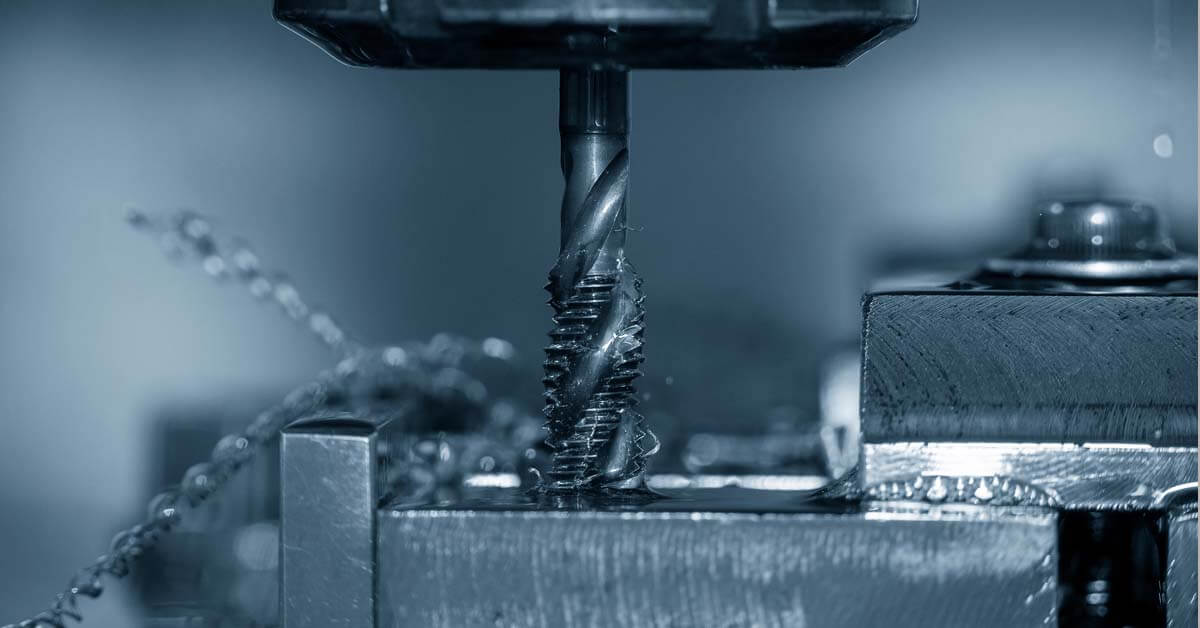

What is Thread Milling in CNC Machining?

Thread Milling Depth Of Cut Whether you’re a production facility. Staggered tooth thread mills have every other tooth removed in a staggered. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The right strategy for breaking and chip removal. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. No matter the type of holemaking, allied is here to help you. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Whether you’re a production facility. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. The helical thread mills over 0.187 diameter will also cut both internal and external threads.

From www.nextgentooling.com

Thread Milling Techniques NEXT GENERATION TOOLING Thread Milling Depth Of Cut The right strategy for breaking and chip removal. No matter the type of holemaking, allied is here to help you. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. The threadoctor provides cutting conditions recommendations based. Thread Milling Depth Of Cut.

From www.youtube.com

Speeds Feeds and Depth of Cut for Milling YouTube Thread Milling Depth Of Cut No matter the type of holemaking, allied is here to help you. Whether you’re a production facility. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The threadoctor provides cutting conditions recommendations based on. Thread Milling Depth Of Cut.

From www.harveyperformance.com

Understanding Threads & Thread Mills In The Loupe Thread Milling Depth Of Cut The helical thread mills over 0.187 diameter will also cut both internal and external threads. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. Whether you’re a production facility. The right strategy for breaking and chip. Thread Milling Depth Of Cut.

From www.sandvik.coromant.com

Thread milling application tips Thread Milling Depth Of Cut In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Whether you’re a production facility. The right strategy for breaking and chip removal. Staggered tooth thread mills have every other tooth removed in a staggered. The radial depth of cut (ae or rdoc),. Thread Milling Depth Of Cut.

From www.mscdirect.com

Tungaloy Milling Tip Inserts; Milling Tip Type Thread; Milling Tip Thread Milling Depth Of Cut Whether you’re a production facility. No matter the type of holemaking, allied is here to help you. The right strategy for breaking and chip removal. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The helical thread mills over 0.187 diameter will also cut both internal and external threads. Thread. Thread Milling Depth Of Cut.

From www.machinemfg.com

10 Types of Milling Cutters Uses and Selection Principles MachineMFG Thread Milling Depth Of Cut The right strategy for breaking and chip removal. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Whether you’re a production facility. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece.. Thread Milling Depth Of Cut.

From www.protool-ltd.co.uk

An InDepth Pitch On Thread Milling The Ultimate Guide! Protool Thread Milling Depth Of Cut The helical thread mills over 0.187 diameter will also cut both internal and external threads. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which. Thread Milling Depth Of Cut.

From www.scribd.com

Thread Data Charts Cutting Tools Machining Thread Milling Depth Of Cut Staggered tooth thread mills have every other tooth removed in a staggered. No matter the type of holemaking, allied is here to help you. The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will also cut both internal and external threads. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and. Thread Milling Depth Of Cut.

From www.ebay.com

Lathe Thread Cutting Chart Depth of Compound for SAE Threads 3 Thread Milling Depth Of Cut No matter the type of holemaking, allied is here to help you. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Chip removal is. Thread Milling Depth Of Cut.

From www.protolabs.com

Gewindeschneiden Standardbohrungen Thread Milling Depth Of Cut The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. Whether you’re a production facility. Staggered tooth thread mills have every other tooth removed in a staggered. The threadoctor provides cutting conditions. Thread Milling Depth Of Cut.

From parts-badger.com

Thread Milling Parts Badger Thread Milling Depth Of Cut Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The helical thread mills over 0.187 diameter. Thread Milling Depth Of Cut.

From www.machinistguides.com

F CNC Code Explained An Easy Intro for Beginners [Feedrate Thread Milling Depth Of Cut The right strategy for breaking and chip removal. No matter the type of holemaking, allied is here to help you. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The radial depth of cut (ae or. Thread Milling Depth Of Cut.

From www.easiahome.com

The Ultimate Thread Milling Guide Definition, Process, Operations Thread Milling Depth Of Cut Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. In internal thread milling applications, the relationship between threading diameter,. Thread Milling Depth Of Cut.

From woodworkingset.com

Threading Lathe Tool A Beginner's Guide to Perfect Thread Cuts. Thread Milling Depth Of Cut The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will also cut both internal and external threads. No matter the type of holemaking, allied is here to help you. Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or. Thread Milling Depth Of Cut.

From tungaloy.com

ThreadMilling Milling Products Tungaloy Corporation Thread Milling Depth Of Cut No matter the type of holemaking, allied is here to help you. The helical thread mills over 0.187 diameter will also cut both internal and external threads. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Thread milling is a machining process. Thread Milling Depth Of Cut.

From www.youtube.com

cutting parameter kaise jane vmc programming tutorial cutting Thread Milling Depth Of Cut The helical thread mills over 0.187 diameter will also cut both internal and external threads. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much.. Thread Milling Depth Of Cut.

From www.youtube.com

Axial and radial depth of cut in milling operations YouTube Thread Milling Depth Of Cut Staggered tooth thread mills have every other tooth removed in a staggered. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Thread milling. Thread Milling Depth Of Cut.

From www.researchgate.net

Schematic diagram of the thread milling toolpath (D = 16 mm, d = 6 mm Thread Milling Depth Of Cut In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. No matter the type of holemaking, allied is here to help you. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The radial depth of cut (ae or. Thread Milling Depth Of Cut.

From mavink.com

Npt Thread Depth Chart Thread Milling Depth Of Cut Whether you’re a production facility. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. No matter the type. Thread Milling Depth Of Cut.

From www.youtube.com

Cutting Parameters Cutting Speed, Feed, Depth of cut CNCLearning Thread Milling Depth Of Cut The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will also cut both internal and external threads. No matter the type of holemaking, allied is here to help you. Whether you’re a production facility. Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The radial depth of cut (ae. Thread Milling Depth Of Cut.

From www.minaprem.com

What is Depth of Cut in Machining? Its Unit, Value, Effects and Selection Thread Milling Depth Of Cut Whether you’re a production facility. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Chip removal is crucial in thread milling to prevent tool. Thread Milling Depth Of Cut.

From mavink.com

Npt Thread Depth Chart Thread Milling Depth Of Cut The helical thread mills over 0.187 diameter will also cut both internal and external threads. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. No matter the type of holemaking, allied is here to help you. The right strategy for breaking and chip removal. The threadoctor provides cutting conditions. Thread Milling Depth Of Cut.

From ecoreprap.com

What is Thread Milling in CNC Machining? Thread Milling Depth Of Cut The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The helical thread. Thread Milling Depth Of Cut.

From engmachineshop.wustl.edu

VThread depth calculation McKelvey School of Engineering Student Thread Milling Depth Of Cut The right strategy for breaking and chip removal. Whether you’re a production facility. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. The helical. Thread Milling Depth Of Cut.

From www.minaprem.com

What is Depth of Cut (DOC) in Machining? Machining Principles Thread Milling Depth Of Cut No matter the type of holemaking, allied is here to help you. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The right strategy for breaking and chip removal. The threadoctor provides cutting conditions. Thread Milling Depth Of Cut.

From www.rapiddirect.com

The Ultimate Guide to Machining Thread RapidDirect Blog Thread Milling Depth Of Cut The right strategy for breaking and chip removal. Whether you’re a production facility. The helical thread mills over 0.187 diameter will also cut both internal and external threads. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Chip removal is crucial in. Thread Milling Depth Of Cut.

From www.youtube.com

Thread Depth, Tool Tip Width and Length of Cut NO TRIG NEEDED YouTube Thread Milling Depth Of Cut Chip removal is crucial in thread milling to prevent tool breakage and ensure a. Whether you’re a production facility. Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The radial depth of cut (ae or rdoc), is. Thread Milling Depth Of Cut.

From caddesignr.com

Milling machine operations photos Cad Designer Thread Milling Depth Of Cut Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or on the. Thread Milling Depth Of Cut.

From www.youtube.com

How to Cut Screw Threads on a CNC Lathe Using G32 YouTube Thread Milling Depth Of Cut Chip removal is crucial in thread milling to prevent tool breakage and ensure a. The right strategy for breaking and chip removal. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. No matter the type of holemaking, allied is here to help. Thread Milling Depth Of Cut.

From sctools.online

Axial Depth of Cut (Milling AP) FM Carbide Thread Milling Depth Of Cut The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Whether you’re a production facility. No matter the type of holemaking, allied is here to help you. The helical thread mills over 0.187 diameter will also cut both internal and external threads. The radial depth of cut (ae or rdoc), is. Thread Milling Depth Of Cut.

From www.practicalmachinist.com

How to calculate thread depth of an M thread Thread Milling Depth Of Cut The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The radial depth of cut (ae or rdoc), is the length that the tool engages a workpiece perpendicular. Staggered tooth thread mills have every other tooth removed in a staggered. The helical thread mills over 0.187 diameter will also cut both. Thread Milling Depth Of Cut.

From webshop.smicut.hansahosting.se

SmiCut THREAD MILLING Tools TECHNICAL INFORMATION Thread Milling Depth Of Cut Whether you’re a production facility. The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will also cut both internal and external threads. In internal thread milling applications, the relationship between threading diameter, cutting diameter, and pitch will affect the true radial depth of cut, ae eff, which becomes much. Staggered tooth thread mills have. Thread Milling Depth Of Cut.

From www.researchgate.net

The schematic diagram of cutting depth changing in end milling Thread Milling Depth Of Cut Staggered tooth thread mills have every other tooth removed in a staggered. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. Whether you’re a production facility. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The right strategy for. Thread Milling Depth Of Cut.

From www.iqsdirectory.com

Thread Rolling What Is It? How Does It Work? Process, Types Thread Milling Depth Of Cut Whether you’re a production facility. Thread milling is a machining process used to produce threads in holes or on the external surfaces of a workpiece. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. The right strategy for breaking and chip removal. The helical thread mills over 0.187 diameter will. Thread Milling Depth Of Cut.

From toolnotes.com

Cutting Parameters for Milling ToolNotes Thread Milling Depth Of Cut The helical thread mills over 0.187 diameter will also cut both internal and external threads. The threadoctor provides cutting conditions recommendations based on the selected thread and raw material for the 3 main thread. Staggered tooth thread mills have every other tooth removed in a staggered. No matter the type of holemaking, allied is here to help you. The right. Thread Milling Depth Of Cut.