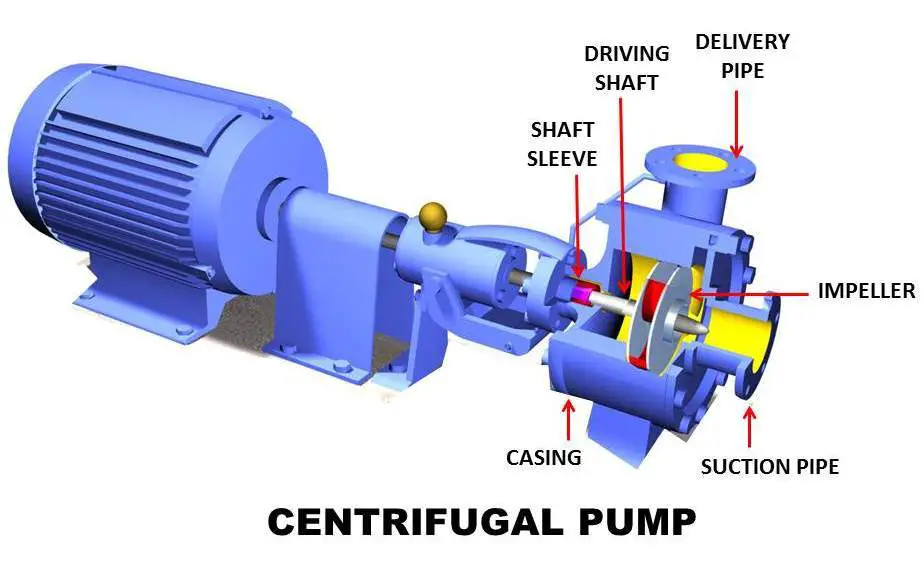

Industrial Pump Components . Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Key components of centrifugal pumps. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Below are the basic components that every centrifugal pump has: Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. The first and central component is the. The five fundamental elements most industrial pumps have in common are: Their main function is to generate flow.

from engineeringexploration.com

Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. The first and central component is the. The five fundamental elements most industrial pumps have in common are: Below are the basic components that every centrifugal pump has: Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Key components of centrifugal pumps. Their main function is to generate flow. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The impeller is the rotating component of the pump that is responsible for transferring the energy from the.

Centrifugal Pump Components, Types, and Applications Engineering

Industrial Pump Components Their main function is to generate flow. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. Their main function is to generate flow. The five fundamental elements most industrial pumps have in common are: Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. The first and central component is the. The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Below are the basic components that every centrifugal pump has: Key components of centrifugal pumps.

From a-l-lequipment.com

Industrial Pumps & Pump Services ALL Equipment Industrial Pump Components Key components of centrifugal pumps. Below are the basic components that every centrifugal pump has: The first and central component is the. The impeller is the rotating component of the pump that is responsible for transferring the energy from the. The five fundamental elements most industrial pumps have in common are: Their main function is to generate flow. In this. Industrial Pump Components.

From schematicpartlas.z13.web.core.windows.net

Pump Parts Diagram And Description Industrial Pump Components The five fundamental elements most industrial pumps have in common are: Key components of centrifugal pumps. Their main function is to generate flow. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Below are the basic components that every centrifugal pump has: In this article, we will delve into the detailed breakdown of. Industrial Pump Components.

From mechatronics122.blogspot.com

electromechanical systems (Pumps) / Different Types of Pumps Working Industrial Pump Components Below are the basic components that every centrifugal pump has: Key components of centrifugal pumps. The five fundamental elements most industrial pumps have in common are: The first and central component is the. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across. Industrial Pump Components.

From www.mechanical-knowledge.com

Introduction To Centrifugal Pumps Pdf Industrial Pump Components Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The impeller is the rotating component of the pump that is responsible for transferring the energy from the. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate. Industrial Pump Components.

From engineeringlearn.com

What is Pump? Types of Pump, Uses, Working & Application [with Pictures Industrial Pump Components Key components of centrifugal pumps. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The first and central component is the. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. The five fundamental elements. Industrial Pump Components.

From www.bhansalicomponent.com

Machined and CNC Precision Components for Pumps Manufacturing Industrial Pump Components Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Industrial pumps are mechanical devices designed to transfer liquid. Industrial Pump Components.

From blog.thepipingmart.com

13 Different Types Of Pumps and Their Uses Industrial Pump Components Their main function is to generate flow. The five fundamental elements most industrial pumps have in common are: Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Below are the basic components that every centrifugal pump has: Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to. Industrial Pump Components.

From www.mechanical-knowledge.com

Types Of Pumps And Its Applications Pdf Industrial Pump Components The five fundamental elements most industrial pumps have in common are: The first and central component is the. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Though industrial pumps can come in various sizes, shapes, and configurations, most include five. Industrial Pump Components.

From www.industrybuying.com

Types of Pressure Pumps IndustryBuying Blog Industrial Pump Components The five fundamental elements most industrial pumps have in common are: Below are the basic components that every centrifugal pump has: The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Key components of centrifugal pumps.. Industrial Pump Components.

From www.pumpindustry.com.au

Rotodynamic pumps Pump Industry Magazine Industrial Pump Components Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Key components of centrifugal pumps. The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Their main function is to generate flow. The first and central component is the.. Industrial Pump Components.

From ar.inspiredpencil.com

Vertical Centrifugal Pump Diagram Industrial Pump Components Below are the basic components that every centrifugal pump has: Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Key components of centrifugal pumps. The five fundamental elements most industrial. Industrial Pump Components.

From www.ruhrpumpen.com

Ruhrpumpen Group site Consider MagDrive Pumps fo complex Industrial Pump Components Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Key components of centrifugal pumps. The first and central component is the. Below are the basic components that every centrifugal pump has: In this article, we will delve into the detailed breakdown of the parts of a. Industrial Pump Components.

From www.sintechpumps.com

Stepbystep guide for overhauling centrifugal pumps Sintech Industrial Pump Components The first and central component is the. The five fundamental elements most industrial pumps have in common are: In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Below are the basic components that every centrifugal pump has: The impeller is the. Industrial Pump Components.

From www.researchgate.net

1. Main components of a centrifugal pump (Taken from [47]) Download Industrial Pump Components The five fundamental elements most industrial pumps have in common are: In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Below are the basic components. Industrial Pump Components.

From www.dreamstime.com

Industrial pump system stock image. Image of pressure 1787417 Industrial Pump Components The first and central component is the. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. Below are the basic components that every centrifugal pump. Industrial Pump Components.

From www.sundyne.com

How Do Centrifugal Compressors Work? Sundyne Industrial Pump Components The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Key components of centrifugal pumps. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Though industrial pumps can come in various sizes, shapes,. Industrial Pump Components.

From www.theengineersperspectives.com

What Is A Centrifugal Pump? The Engineer's Perspective Industrial Pump Components The five fundamental elements most industrial pumps have in common are: The impeller is the rotating component of the pump that is responsible for transferring the energy from the. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Key components of. Industrial Pump Components.

From www.vrogue.co

Parts Of Centrifugal Pump And Their Function Engineer vrogue.co Industrial Pump Components The five fundamental elements most industrial pumps have in common are: Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Key components of centrifugal pumps.. Industrial Pump Components.

From www.nationalbronze.com

Bronze Components for the Pump and Valve Industries National Bronze Industrial Pump Components Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. The first and central component is the. Below are the basic components that every centrifugal pump has: The five fundamental elements most industrial pumps have in common are: The impeller is the rotating component of the pump that is responsible for transferring the energy. Industrial Pump Components.

From www.youtube.com

Centrifugal Pump Parts Explained Basics About Eight Components YouTube Industrial Pump Components Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Below are the basic components that every centrifugal pump has: Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids. Industrial Pump Components.

From www.ipmpumps.co.uk

Industrial Pumps and Motor Supply, Repairs, Sales Industrial Pump Components The impeller is the rotating component of the pump that is responsible for transferring the energy from the. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Though industrial pumps can come in various sizes, shapes, and configurations, most include five. Industrial Pump Components.

From nasniconsultants.com

Industrial Pumps Choose KSB Omega Pumps for Bottle Manufacturing Plant Industrial Pump Components Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Key components of centrifugal pumps. Their main function is to generate flow. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The five fundamental elements. Industrial Pump Components.

From www.baltictimes.com

5 Types Of Pumps To Consider For Industrial Use Industrial Pump Components The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Their main function is to generate flow. The five fundamental elements most industrial pumps have in common are: Though. Industrial Pump Components.

From www.pumpengineering.net

Find the Right Industrial Pump Replacement Parts Pump Engineering Co Industrial Pump Components The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The first and central component is the. Below are the basic components that every centrifugal pump has: Industrial pumps are mechanical. Industrial Pump Components.

From www.pumps-systems.com

Pumps & Systems Industrial Pump Components The impeller is the rotating component of the pump that is responsible for transferring the energy from the. The first and central component is the. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by. Industrial Pump Components.

From empoweringpumps.com

Maag Industrial Introduces Stainless Steel G Series Pumps Industrial Pump Components In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Their main function is to generate flow. The five fundamental elements most industrial pumps have in common are: The first and central component is the. Industrial pumps are mechanical devices designed to. Industrial Pump Components.

From www.dreamstime.com

Close Up Cross Section Present Detail Component Inside Centrifugal Pump Industrial Pump Components Below are the basic components that every centrifugal pump has: Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. The five fundamental elements most industrial pumps have in common are: Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction.. Industrial Pump Components.

From mavink.com

Centrifugal Pump Parts And Function Industrial Pump Components Their main function is to generate flow. The five fundamental elements most industrial pumps have in common are: In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Below are the basic components that every centrifugal pump has: Key components of centrifugal. Industrial Pump Components.

From www.linquip.com

Pump Working Principles, Function & Diagram Linquip Industrial Pump Components Below are the basic components that every centrifugal pump has: In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Key components of centrifugal pumps. The. Industrial Pump Components.

From www.cientoveinte.com.ar

Industrial Pump 3D Cutaway View Videos for Industries Industrial Pump Components Their main function is to generate flow. In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Key components of centrifugal pumps. The five fundamental elements most industrial pumps have in common are: Though industrial pumps can come in various sizes, shapes,. Industrial Pump Components.

From engineeringexploration.com

Centrifugal Pump Components, Types, and Applications Engineering Industrial Pump Components The five fundamental elements most industrial pumps have in common are: The impeller is the rotating component of the pump that is responsible for transferring the energy from the. Key components of centrifugal pumps. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. The first and. Industrial Pump Components.

From www.pumpfundamentals.com

Centrifugal pump type chart Industrial Pump Components The five fundamental elements most industrial pumps have in common are: Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process. The first and central component is the. Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action. Industrial Pump Components.

From www.pumpindustry.com.au

Selecting the right centrifugal pump Pump Industry Magazine Industrial Pump Components The five fundamental elements most industrial pumps have in common are: In this article, we will delve into the detailed breakdown of the parts of a centrifugal pump, dissecting them to appreciate their function in industrial machinery across diverse. Industrial pumps are mechanical devices designed to transfer liquid or gas fluids from one location to another within an industrial process.. Industrial Pump Components.

From www.flowmorepumps.com

Range Industrial Pump Components The five fundamental elements most industrial pumps have in common are: Industrial pumps are mechanical devices (and include ansi pumps) designed to move fluids (including liquids, gases, and slurries) by mechanical action or suction. Below are the basic components that every centrifugal pump has: Key components of centrifugal pumps. The impeller is the rotating component of the pump that is. Industrial Pump Components.

From www.artofit.org

Different types of pumps and their uses complete guide Artofit Industrial Pump Components Though industrial pumps can come in various sizes, shapes, and configurations, most include five fundamental components. Below are the basic components that every centrifugal pump has: The first and central component is the. The five fundamental elements most industrial pumps have in common are: In this article, we will delve into the detailed breakdown of the parts of a centrifugal. Industrial Pump Components.