Tool Wear Out . There is an entire shop full of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. In machining, flank wear is the most common and desirable type of tool wear. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri It is the easiest to identify and predict among tool. This guide will show you 11 ways to radically increase your tool life and reduce tool wear.

from www.slideserve.com

It is the easiest to identify and predict among tool. There is an entire shop full of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. It is a natural and unavoidable phenomenon that occurs due. In machining, flank wear is the most common and desirable type of tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure.

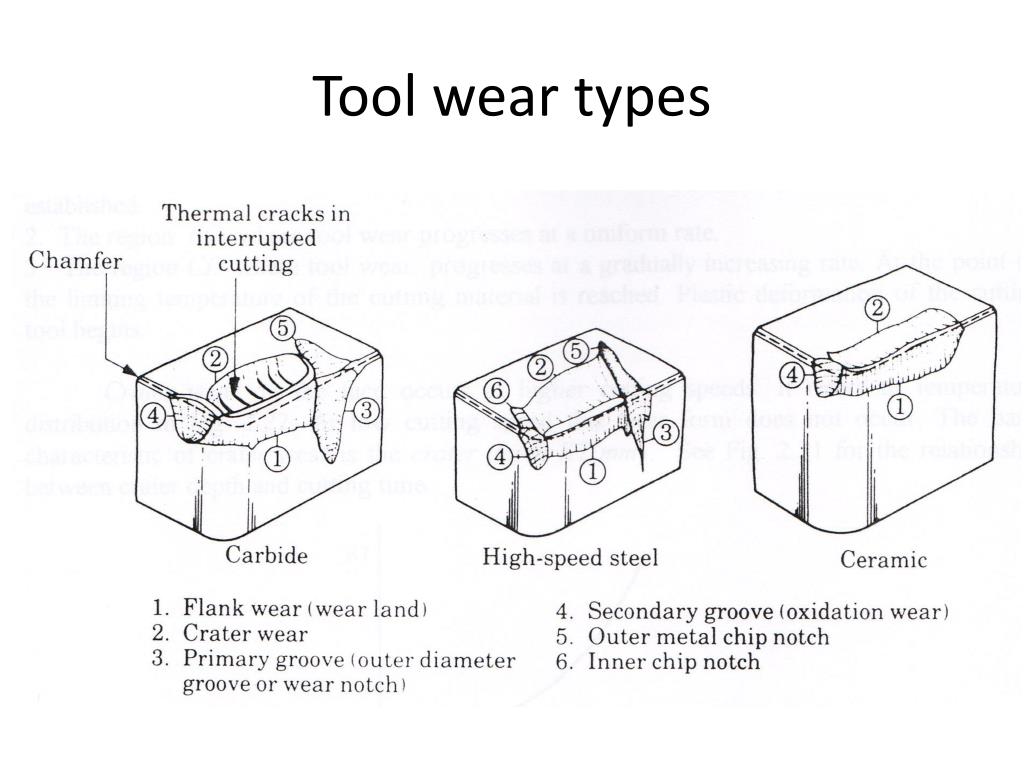

PPT Theory of cutting Tool wear PowerPoint Presentation, free

Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. There is an entire shop full of tool wear. It is a natural and unavoidable phenomenon that occurs due. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is the easiest to identify and predict among tool. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri

From www.mdpi.com

Sensors Free FullText Development of Online Tool WearOut Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. Tool wear refers to the gradual loss or deterioration. Tool Wear Out.

From www.slideserve.com

PPT Metal Machining PowerPoint Presentation, free download ID2292716 Tool Wear Out There is an entire shop full of tool wear. It is a natural and unavoidable phenomenon that occurs due. In machining, flank wear is the most common and desirable type of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is the easiest to identify and. Tool Wear Out.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. It is a natural and unavoidable phenomenon that occurs due. There is an entire shop full of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading. Tool Wear Out.

From www.slideserve.com

PPT Traditional Machining PowerPoint Presentation, free download ID Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri This guide will show you 11 ways to radically increase your tool life and reduce tool wear.. Tool Wear Out.

From www.researchgate.net

(PDF) Reducing Carbide Cutting Tool Wear Out For Hds Materials Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. There is an entire shop full of tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool. Tool Wear Out.

From www.sumipol.com

11 Tips เพิ่ม Tool Life ลด Tool Wear ในงาน Machining Sumipol Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri It is the easiest to identify and predict among tool. There is an entire shop full of tool wear. Tool. Tool Wear Out.

From www.mdpi.com

Sensors Free FullText Development of Online Tool WearOut Tool Wear Out Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. There is an entire shop full of tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri It is a natural and unavoidable phenomenon that occurs due. It is. Tool Wear Out.

From www.harveyperformance.com

How to Avoid 4 Major Types of Tool Wear In The Loupe Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. There is an entire shop full of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is a natural and unavoidable phenomenon that occurs due.. Tool Wear Out.

From mytoolsmyrule.com

How to Wear a Tool Belt A Beginner's Guide Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. There is an entire shop full of tool. Tool Wear Out.

From article.sapub.org

A Review on Tool Wear Monitoring System Tool Wear Out There is an entire shop full of tool wear. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool. Tool Wear Out.

From toolsbuyingguide.com

How to Wear a Tool Belt A Guide for the DIY Enthusiast Tool Wear Out It is the easiest to identify and predict among tool. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear refers to the gradual loss or deterioration of material. Tool Wear Out.

From moellerpunch.com

4 Ways to Reduce Precision Tool Wear • Moeller Precision Tool Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. Tool wear refers to the gradual loss or deterioration. Tool Wear Out.

From www.harveyperformance.com

How to Avoid 4 Major Types of Tool Wear In The Loupe Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is a natural and. Tool Wear Out.

From www.canadianmetalworking.com

Identifying tool wear Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. In machining, flank wear is the most common and desirable type of tool wear. It is a natural and unavoidable phenomenon that. Tool Wear Out.

From www.researchgate.net

Types of tool wear. Download Scientific Diagram Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is a natural and unavoidable phenomenon that occurs due. There is an entire shop full of tool wear.. Tool Wear Out.

From www.mdpi.com

Sensors Free FullText Development of Online Tool WearOut Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. There is an entire shop full of tool wear. Tool. Tool Wear Out.

From www.youtube.com

How To Wear a Tool Belt like a PRO YouTube Tool Wear Out It is the easiest to identify and predict among tool. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri It is a natural and unavoidable phenomenon that occurs due. In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways. Tool Wear Out.

From toolbeltguru.com

How to properly wear a Tool belt [Ultimate Guide] Tool Wear Out In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. It is the easiest to identify and predict among tool. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during. Tool Wear Out.

From www.harveyperformance.com

How to Avoid 4 Major Types of Tool Wear In The Loupe Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. In machining, flank wear is the most common and desirable type of tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri This guide will show you 11 ways to radically increase your tool life and reduce tool wear.. Tool Wear Out.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Tool Wear Out This guide will show you 11 ways to radically increase your tool life and reduce tool wear. It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear refers to the gradual loss or deterioration of material from the surface. Tool Wear Out.

From www.youtube.com

tool wear Types of Tool Wear Crater Wear Flank Wear Factor Tool Wear Out There is an entire shop full of tool wear. Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. This guide will show you 11. Tool Wear Out.

From www.harveyperformance.com

How to Avoid 4 Major Types of Tool Wear In The Loupe Tool Wear Out Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is a natural and unavoidable phenomenon that occurs due. In machining, flank wear is the most common and desirable type of tool wear. There is an entire shop full of tool wear. It is the easiest to identify and. Tool Wear Out.

From www.canadianmetalworking.com

Identifying tool wear Tool Wear Out This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri It is the easiest to identify and predict among tool. There is an entire shop full of tool wear. In machining, flank wear is. Tool Wear Out.

From www.researchgate.net

Microscopic photograph of tool wear after 328 min of cutting time with Tool Wear Out There is an entire shop full of tool wear. In machining, flank wear is the most common and desirable type of tool wear. It is the easiest to identify and predict among tool. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. It is a natural and unavoidable phenomenon that occurs due.. Tool Wear Out.

From www.linkedin.com

Tools Wear Out Too Fast? Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable. Tool Wear Out.

From www.yumpu.com

Types of tool wear Flank Tool Wear Out It is the easiest to identify and predict among tool. There is an entire shop full of tool wear. In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Plus it will explain the details and mechanisms of tool. Tool Wear Out.

From www.slideserve.com

PPT Theory of cutting Tool wear PowerPoint Presentation, free Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. In machining, flank wear is the most common and desirable type of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. Plus it will explain the. Tool Wear Out.

From www.youtube.com

Criteria for Tool Wear Tool Life and Machining Economics Machining Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is the easiest to identify and predict among tool. In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11. Tool Wear Out.

From toolsmechanism.com

How To Wear a Tool Belt? A Fast and Easy Guide Tools Mechanism Tool Wear Out Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. It is a natural and unavoidable phenomenon that occurs due. There is an entire shop full of tool wear. In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways. Tool Wear Out.

From www.mdpi.com

Sensors Free FullText Development of Online Tool WearOut Tool Wear Out Tool wear refers to the gradual loss or deterioration of material from the surface of a cutting tool during its use. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri There is an. Tool Wear Out.

From www.scribd.com

Tool Wear Wear Machining Tool Wear Out It is the easiest to identify and predict among tool. It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri In machining, flank wear is the most common and desirable type of tool wear. This guide will show you 11 ways. Tool Wear Out.

From www.machinemetrics.com

How to Identify and Reduce Tool Wear to Improve Quality Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. This guide will show you 11 ways to radically increase your. Tool Wear Out.

From www.mdpi.com

Sensors Free FullText Development of Online Tool WearOut Tool Wear Out It is a natural and unavoidable phenomenon that occurs due. There is an entire shop full of tool wear. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. Plus it will explain the details and mechanisms of tool wear, discuss how to calculate tool wear, and descri Tool wear refers to the. Tool Wear Out.

From www.researchgate.net

Cutting tool wearout monitoring setup. Download Scientific Diagram Tool Wear Out This guide will show you 11 ways to radically increase your tool life and reduce tool wear. It is a natural and unavoidable phenomenon that occurs due. There is an entire shop full of tool wear. It is the easiest to identify and predict among tool. Plus it will explain the details and mechanisms of tool wear, discuss how to. Tool Wear Out.

From toolsprofy.com

How to Wear a Tool Belt? Guide for Beginners ToolsProfy Tool Wear Out There is an entire shop full of tool wear. Tool wear is the gradual breakdown of machine tools as a result of cutting operation, eventually leading to tool failure. This guide will show you 11 ways to radically increase your tool life and reduce tool wear. In machining, flank wear is the most common and desirable type of tool wear.. Tool Wear Out.