Welded Plates . Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. The tee joint is, as the name describes, a joint in the shape of a t. Below are the six types of welding joints. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Want to weld thin plate? This is usually done when the. Our expert guide will help you get started. Fillet welds are most common and used in all structures. Learn about common welding processes for thin plate and choose the best one. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553.

from www.alamy.com

One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Fillet welds are most common and used in all structures. Want to weld thin plate? Our expert guide will help you get started. This is usually done when the. Below are the six types of welding joints. The tee joint is, as the name describes, a joint in the shape of a t. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Learn about common welding processes for thin plate and choose the best one.

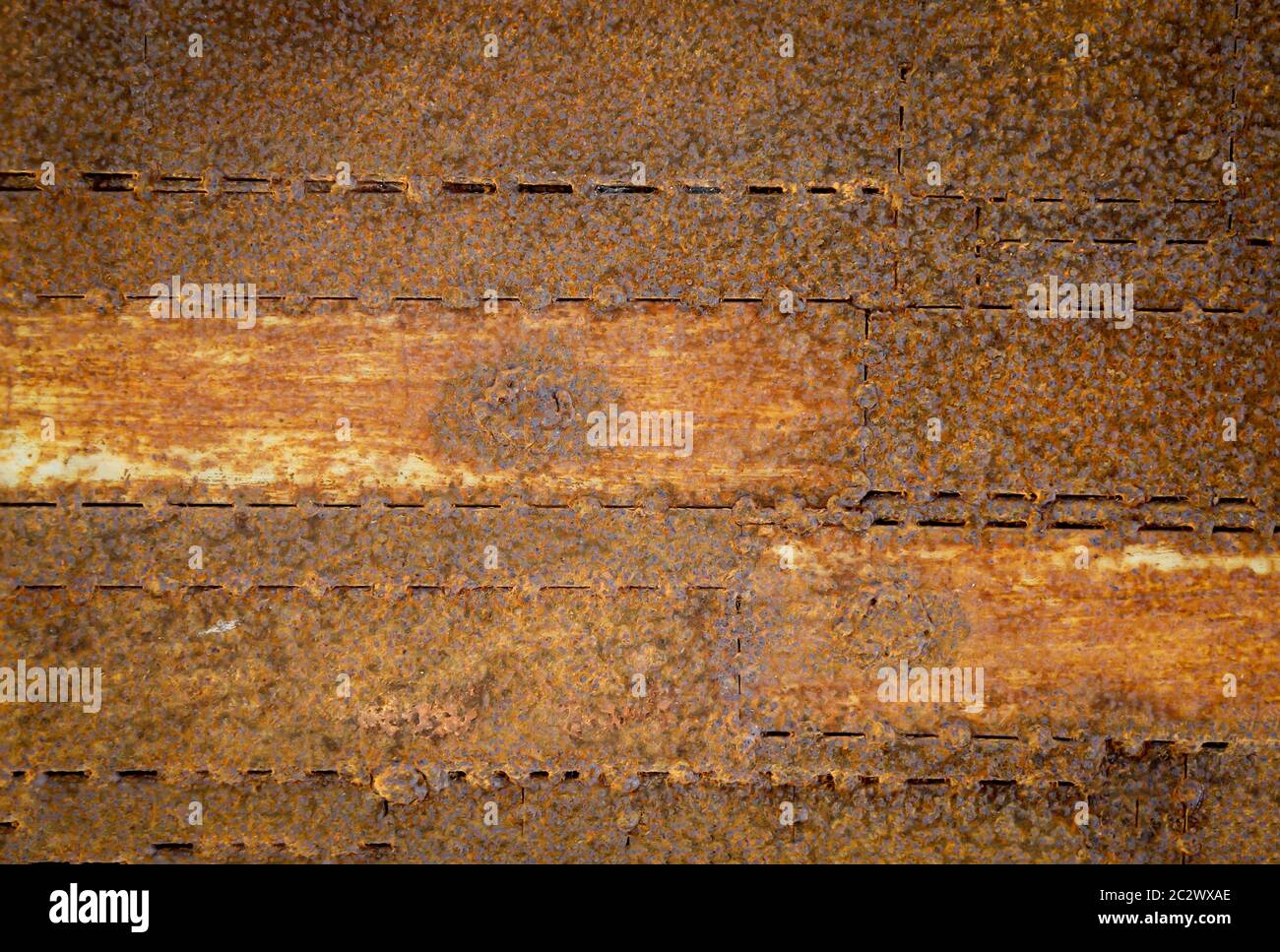

rusty welded plates of iron as a texture Stock Photo Alamy

Welded Plates Below are the six types of welding joints. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Fillet welds are most common and used in all structures. Want to weld thin plate? The tee joint is, as the name describes, a joint in the shape of a t. This is usually done when the. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Below are the six types of welding joints. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Our expert guide will help you get started. Learn about common welding processes for thin plate and choose the best one.

From www.researchgate.net

Welded Plates of 1000 rpm Download Scientific Diagram Welded Plates Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Want to weld thin plate? Below are the six types of welding joints. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso. Welded Plates.

From oceanfabricators.com

houstonweldedplate Houston Laser Metal Cutting & Subsea / Offshore Welded Plates Our expert guide will help you get started. This is usually done when the. Want to weld thin plate? Learn about common welding processes for thin plate and choose the best one. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553.. Welded Plates.

From simplefix.co.nz

Zinc Plated Welded Base Plate Simplefix Welded Plates There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Fillet welds are most common and used in all structures. Below are the six types of welding joints. Welded joints can be categorized as follows based on the shape of the weld. Welded Plates.

From aero3d.fr

Welded Plate AF12501342WELD Welded Plates Fillet welds are most common and used in all structures. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. This is usually. Welded Plates.

From www.youtube.com

Welding Plate & Sheet Metal Fabrication Series 10 YouTube Welded Plates One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Below are the six types of welding joints. The tee joint is, as the name describes, a joint in the shape of a t. This is usually done when the. Learn about common welding processes for thin plate and choose the. Welded Plates.

From metest.ee

Welded beams Metest Producing of Welded beams, NSCProfiles, Steel Welded Plates One piece of metal lays down flat, while another section is welded standing on its side or end upwards. The tee joint is, as the name describes, a joint in the shape of a t. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4. Welded Plates.

From www.cnc-lasercut.com

10mm Welded Steel Embed Plates In Embedded Concrete Concrete Steel Plate Welded Plates There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. The tee joint is, as the name describes, a joint in the shape of a t. Our expert guide will help you get started. Learn about common welding processes for thin plate. Welded Plates.

From www.fencewarehouse.com.au

Buy DIY STEEL POSTS (WELDED BASE PLATES) in Melbourne Australia Welded Plates Below are the six types of welding joints. Our expert guide will help you get started. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Fillet welds are most common and used in all structures. The tee joint is, as the. Welded Plates.

From www.youtube.com

simple and easylearn to welding platehow to weld plate thick and Welded Plates The tee joint is, as the name describes, a joint in the shape of a t. Want to weld thin plate? This is usually done when the. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Below are the six types of welding joints. Learn about common welding processes for. Welded Plates.

From curlygirlsteel.com

welded plates Curly Girl Steel Welded Plates Want to weld thin plate? Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Below are the six types of welding joints. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso. Welded Plates.

From www.alamy.com

rusty welded plates of iron as a texture Stock Photo Alamy Welded Plates Learn about common welding processes for thin plate and choose the best one. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso. Welded Plates.

From simplefix.co.nz

Hot Dipped Galvanised Welded Base Plate Simplefix Welded Plates There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Fillet welds are most common and used in all structures. Want to weld thin plate? Below are the six types of welding joints. Learn about common welding processes for thin plate and. Welded Plates.

From www.embedplates.com

Embed Plates Steel Supply L.P. Houston TX Welded Plates Want to weld thin plate? This is usually done when the. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. The tee joint is, as the name describes, a joint in the shape of a t. Fillet welds are most common. Welded Plates.

From www.alpsupply.com

Embed and Weld Plates Results Page 1 ALP Supply Welded Plates One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Below are the six types of welding joints. Learn about common welding processes for thin plate and choose the best one. This is usually done when the. Our expert guide will help you get started. There are many different types of. Welded Plates.

From www.dreamstime.com

Closeup of a Solidified on a Welded Joint. Two Metal Plates Welded Welded Plates Below are the six types of welding joints. Fillet welds are most common and used in all structures. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. This is usually done when the. Welded joints can be categorized as follows based. Welded Plates.

From www.pinterest.com

Stitch welding 1/4 6061 plates to 5086 Marine Grade Aluminum Welded Plates This is usually done when the. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Below are the six types of welding joints. One piece of metal lays down flat, while another section is welded standing on its side or end. Welded Plates.

From duckrolldesigns.wordpress.com

301 Moved Permanently Welded Plates Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. The tee joint is, as the name describes, a joint in the shape of a t. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Fillet welds are most common. Welded Plates.

From duckrolldesigns.wordpress.com

301 Moved Permanently Welded Plates The tee joint is, as the name describes, a joint in the shape of a t. Fillet welds are most common and used in all structures. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. There are many different types of welds and joints, each with its own weld joint. Welded Plates.

From www.dreamstime.com

Rusty Welded Metal Plates with Alternative Panel Layout, Derelict Welded Plates Below are the six types of welding joints. Our expert guide will help you get started. This is usually done when the. Learn about common welding processes for thin plate and choose the best one. Fillet welds are most common and used in all structures. One piece of metal lays down flat, while another section is welded standing on its. Welded Plates.

From innovativeweldsolutions.com

Aluminum Diamond Tread Plate Spot Welds Innovative Weld Solutions Welded Plates There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Learn about common welding processes for thin plate and choose the best. Welded Plates.

From www.walraven.com

BIS Stainless Steel Wall Plate with Welded Stud Bolt 672 Walraven Welded Plates Below are the six types of welding joints. Want to weld thin plate? Our expert guide will help you get started. Learn about common welding processes for thin plate and choose the best one. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or. Welded Plates.

From www.flawtech.com

P107 Welded Plate FlawTech Welded Plates Learn about common welding processes for thin plate and choose the best one. Fillet welds are most common and used in all structures. Below are the six types of welding joints. Want to weld thin plate? Our expert guide will help you get started. This is usually done when the. There are many different types of welds and joints, each. Welded Plates.

From simplefix.co.nz

Hot Dipped Galvanised Welded Base Plate Simplefix Welded Plates Below are the six types of welding joints. This is usually done when the. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or. Welded Plates.

From www.westermans.com

Weld Preparation Techniques Plate Bevelling Westermans Blog Welded Plates Fillet welds are most common and used in all structures. Below are the six types of welding joints. Want to weld thin plate? There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Learn about common welding processes for thin plate and. Welded Plates.

From yoderbrothersmachinery.com

60″ X 120″ X 6.75″ ACORN LAYOUT WELDING PLATES STOCK 13842 Welded Plates Want to weld thin plate? Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. There are many different types of welds and joints, each with its own weld joint configuration. Welded Plates.

From www.flawtech.com

P107 Welded Plate FlawTech Welded Plates Our expert guide will help you get started. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Learn about common welding processes for thin plate and choose the best one. Welded joints can be categorized as follows based on the shape. Welded Plates.

From www.steelsupplylp.com

Weld Tabs & Base Plates Order Online Steel Supply LP Welded Plates Fillet welds are most common and used in all structures. Learn about common welding processes for thin plate and choose the best one. The tee joint is, as the name describes, a joint in the shape of a t. This is usually done when the. Want to weld thin plate? There are many different types of welds and joints, each. Welded Plates.

From www.alpsupply.com

Embed and Weld Plates Results Page 1 ALP Supply Welded Plates Fillet welds are most common and used in all structures. Below are the six types of welding joints. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per. Welded Plates.

From materials-welding.blogspot.com

Materials & Welding [MW27331] P22 plate welding6MM plate Welded Plates The tee joint is, as the name describes, a joint in the shape of a t. Want to weld thin plate? Below are the six types of welding joints. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Learn about common welding processes for thin plate and choose the. Welded Plates.

From hwspools.com

1/8″x8″x8″ Welded Plates, (3″ OD, 1/8” or 3/16″ wall tube) Homer Welded Plates Our expert guide will help you get started. Want to weld thin plate? Learn about common welding processes for thin plate and choose the best one. This is usually done when the. One piece of metal lays down flat, while another section is welded standing on its side or end upwards. There are many different types of welds and joints,. Welded Plates.

From www.youtube.com

1G Plate Stick Welding SMAW YouTube Welded Plates Want to weld thin plate? Below are the six types of welding joints. The tee joint is, as the name describes, a joint in the shape of a t. Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. This is usually done when the. There are many different types. Welded Plates.

From www.dreamstime.com

Welded metal plates stock image. Image of gray, rectangular 43297629 Welded Plates Want to weld thin plate? Welded joints can be categorized as follows based on the shape of the weld component, the thickness of the weld. Learn about common welding processes for thin plate and choose the best one. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as. Welded Plates.

From www.indiamart.com

Ss Square Welded High Tensile Steel Plate, Thickness 515 inch, Size Welded Plates Our expert guide will help you get started. This is usually done when the. The tee joint is, as the name describes, a joint in the shape of a t. There are many different types of welds and joints, each with its own weld joint configuration and specially assigned welding symbol as per aws a2.4 or iso 2553. Fillet welds. Welded Plates.

From anchorboltsource.com

Galvanized Embedded Steel With Welded Plates Anchor Bolts and Cages Welded Plates One piece of metal lays down flat, while another section is welded standing on its side or end upwards. Fillet welds are most common and used in all structures. This is usually done when the. Learn about common welding processes for thin plate and choose the best one. Our expert guide will help you get started. The tee joint is,. Welded Plates.

From www.tsc-rohre.de

Explosionwelded Clad Plates tsc rohre GmbH Welded Plates This is usually done when the. Learn about common welding processes for thin plate and choose the best one. The tee joint is, as the name describes, a joint in the shape of a t. Fillet welds are most common and used in all structures. One piece of metal lays down flat, while another section is welded standing on its. Welded Plates.