Blanket Gas Vessel . Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. It provides improved process safety and better product quality, along with a longer equipment life cycle. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition.

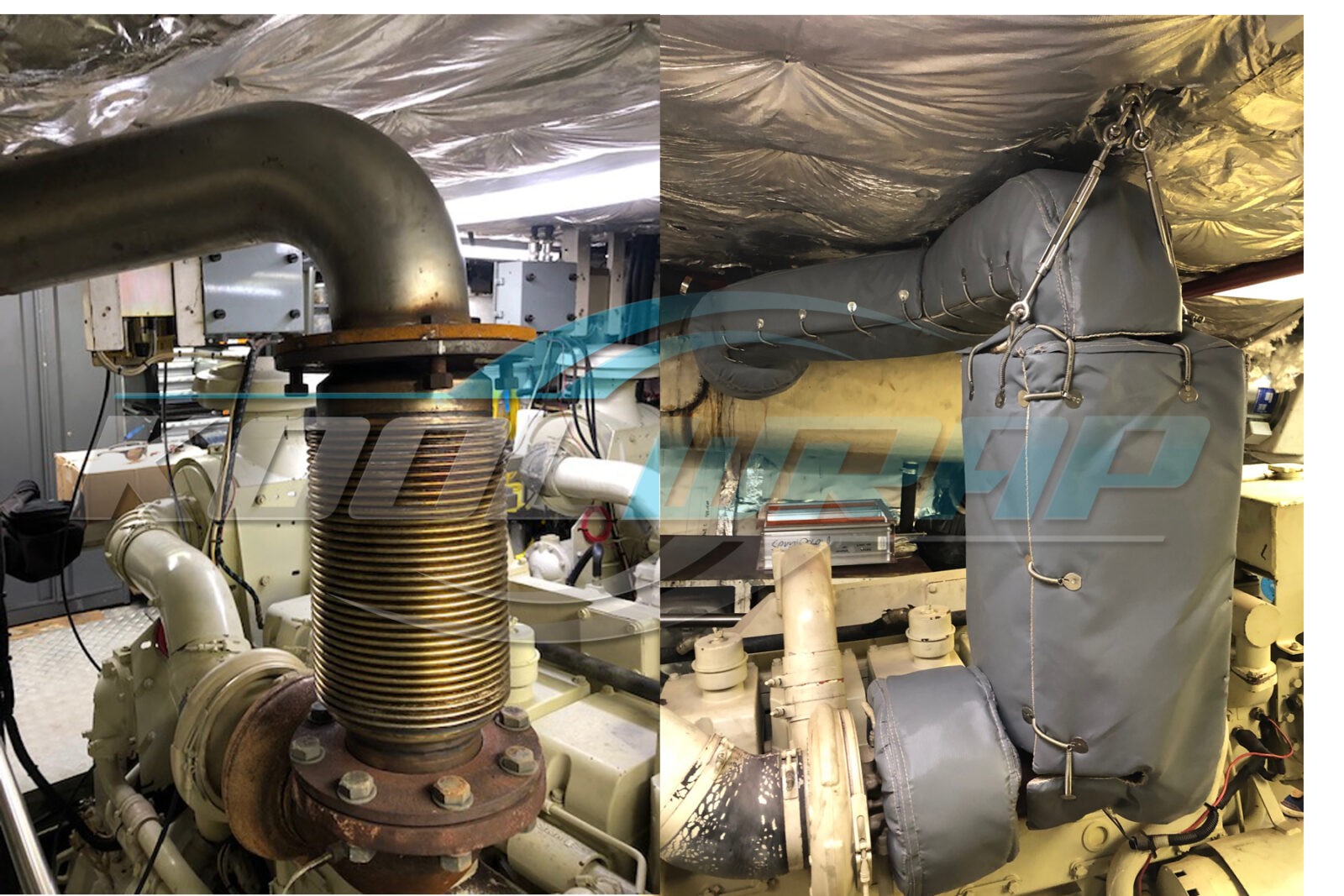

from koolwrap.com.au

This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination.

Marine Engine Exhaust Blanket Insulation Genset Heat Blankets

Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. It provides improved process safety and better product quality, along with a longer equipment life cycle. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen.

From loejbntak.blob.core.windows.net

What Is The Meaning Of Blanket Gas at Aracely Dubois blog Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. It provides improved process safety and better product quality, along with a longer equipment life cycle. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”,. Blanket Gas Vessel.

From www.maritimeprofessional.com

Wärtsilä Win Evergas LNG Carriers Contract Blanket Gas Vessel It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. This article. Blanket Gas Vessel.

From klajisnvo.blob.core.windows.net

What Is Tank Blanketing at Elnora Johnson blog Blanket Gas Vessel Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to. Blanket Gas Vessel.

From www.alibaba.com

Rockwool Blanket Wire Mesh Bonded Insulation For Exhaust Gas Duct Pipe Blanket Gas Vessel Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a. Blanket Gas Vessel.

From process-engineer-must-know.blogspot.com

Process Engineer Tank Blanketing or padding Blanket Gas Vessel Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation. Blanket Gas Vessel.

From sethermal.com

HEATED INSULATION BLANKETS Southeast Thermal Systems Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Blanketing. Blanket Gas Vessel.

From fluidhandlingpro.com

Oxygen Content in Blanket Gas Applications with Panametrics • Fluid Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Nitrogen blanketing is the process of supplying. Blanket Gas Vessel.

From bursting-discs.co.uk

Tank Storage Blanket Gas (Nitrogen) Regulators Assentech Limited Blanket Gas Vessel This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head. Blanket Gas Vessel.

From www.flowstarvalveshop.com

Tank Blanketing, Gas Blanketing, Tank Padding Flowstar (UK) Limited Blanket Gas Vessel Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. A gas phase maintained above a. Blanket Gas Vessel.

From mybios.me

Ethanol Storage Tanks Nitrogen Blanketing My Bios Blanket Gas Vessel Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination,. Blanket Gas Vessel.

From www.heat-inc.com

Inert Gas Blanketing Systems HEAT Exchange and Transfer, Inc. Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. Nitrogen blanketing is the process of supplying the n 2 (or other. Blanket Gas Vessel.

From kspc.com.vn

N2 Blanketing Valve Type DST100 Blanket Gas Vessel Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. A gas phase maintained above a liquid in a vessel to protect. Blanket Gas Vessel.

From www.water-trailer.com

Propane Tank Heater Blanket Increase Tank Efficiency, Lower Costs Call Now Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Blanketing with. Blanket Gas Vessel.

From blog.polyprocessing.com

What You Need to Know About Tank Blanketing Systems Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. It provides improved process safety. Blanket Gas Vessel.

From www.jordanvalve.com

What is Tank Blanketing? Jordan Valve Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty. Blanket Gas Vessel.

From valvesalesinc.com

3000 Series Blanket Gas Regulator from Valve Sales Inc. Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. It provides improved process safety and better product. Blanket Gas Vessel.

From www.bakerhughes.com

Process Analyzers Panametrics Moisture and Gas Systems Blanket Gas Vessel Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Nitrogen blanketing is the process of supplying. Blanket Gas Vessel.

From www.heat-inc.com

Inert Gas Blanketing Systems HEAT Exchange and Transfer, Inc. Blanket Gas Vessel Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. It provides improved process safety and better product quality, along with a. Blanket Gas Vessel.

From www.thermaxxjackets.com

Removable Insulation Blankets For Exhaust Systems Thermaxx Jackets Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. It provides improved process safety and better product quality, along with a longer equipment life cycle. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. This article. Blanket Gas Vessel.

From www.researchgate.net

Existing CHL carbon bed vessel with heater blankets Download Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. Tank blanketing, sometimes referred to as “tank padding”. Blanket Gas Vessel.

From blog.thermaxxjackets.com

Steam Insulation Blankets Thermaxx Jackets Blanket Gas Vessel It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”,. Blanket Gas Vessel.

From koolwrap.com.au

Marine Engine Exhaust Blanket Insulation Genset Heat Blankets Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. Blanketing. Blanket Gas Vessel.

From www.youtube.com

Tank Blanketing Animation YouTube Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. It provides improved process safety and better product quality, along with a longer equipment life cycle. Blanketing with. Blanket Gas Vessel.

From kimray.com

What is a Blanket Gas Regulator? Kimray Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Tank. Blanket Gas Vessel.

From www.youtube.com

BLANKET GAS REGULATOR(Finekay® LOW PRESSURE TANK SAFETY DEVICE) YouTube Blanket Gas Vessel Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to. Blanket Gas Vessel.

From www.amazon.ca

Powerblanket Lite PBL1K Propane Tank Heating Blanket, Fits 1000gallon Blanket Gas Vessel Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation. Blanket Gas Vessel.

From www.ameritempgroup.com

Powerblanket GCW100100 LB Propane Gas Cylinder Blanket Blanket Gas Vessel Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. It provides improved process safety and better product quality, along with a longer equipment life cycle. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Blanketing with nitrogen is a safe and dependable method for constantly. Blanket Gas Vessel.

From www.grothcorp.com

Blanket Gas Regulators Groth Corporation Blanket Gas Vessel It provides improved process safety and better product quality, along with a longer equipment life cycle. Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Humid. Blanket Gas Vessel.

From www.heat-inc.com

Inert Gas Blanketing Systems HEAT Exchange and Transfer, Inc. Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation. Blanket Gas Vessel.

From www.thermaxxjackets.com

Marine Engine Room Insulation Blankets Thermaxx Jackets Blanket Gas Vessel Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. It provides improved process safety and better product quality, along with a longer equipment life cycle. Humid air in the head. Blanket Gas Vessel.

From kspc.com.vn

Nitrogen Blanketing Valve Type DST50 Blanket Gas Vessel This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas. Blanket Gas Vessel.

From www.youtube.com

BLANKET GAS REGULATOR(Finekay® LOW PRESSURE TANK SAFETY DEVICE) YouTube Blanket Gas Vessel It provides improved process safety and better product quality, along with a longer equipment life cycle. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert gas, most likely nitrogen, to reduce oxidation and product contamination. A gas phase maintained above a liquid. Blanket Gas Vessel.

From www.jordanvalve.com

What is Tank Blanketing? Jordan Valve Blanket Gas Vessel A gas phase maintained above a liquid in a vessel to protect the liquid against air contamination, to reduce the hazard of detonation or to pressurize. Humid air in the head space is replaced by high purity, inert and totally dry nitrogen. It provides improved process safety and better product quality, along with a longer equipment life cycle. Nitrogen blanketing. Blanket Gas Vessel.

From www.prismcorp.net

Tank Blanketing/GBC Prism Integrated Solutions Blanket Gas Vessel It provides improved process safety and better product quality, along with a longer equipment life cycle. This article discusses the basics of nitrogen blanketing and explains how to implement it effectively and efficiently. Tank blanketing, sometimes referred to as “tank padding” or “nitrogen blanketing”, is the process of filling the empty space of a liquid storage tank with an inert. Blanket Gas Vessel.

From lmkthermosafe.co.uk

vessell blanket LMK Thermosafe Drum & Container Heaters Blanket Gas Vessel Nitrogen blanketing is the process of supplying the n 2 (or other inert gas) gas to the vapor space of a container to control its composition. Blanketing with nitrogen is a safe and dependable method for constantly maintaining a protective layer of gas on top of the substance. A gas phase maintained above a liquid in a vessel to protect. Blanket Gas Vessel.