Electrochemical Etching Anisotropic . The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in.

from www.protoexpress.com

Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all.

Wet PCB Etching Using Acidic & Alkaline Sierra Circuits

Electrochemical Etching Anisotropic Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully.

From www.researchgate.net

11 Description of the etching process. (a) anisotropic etching of Electrochemical Etching Anisotropic Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all.. Electrochemical Etching Anisotropic.

From www.thierry-corp.com

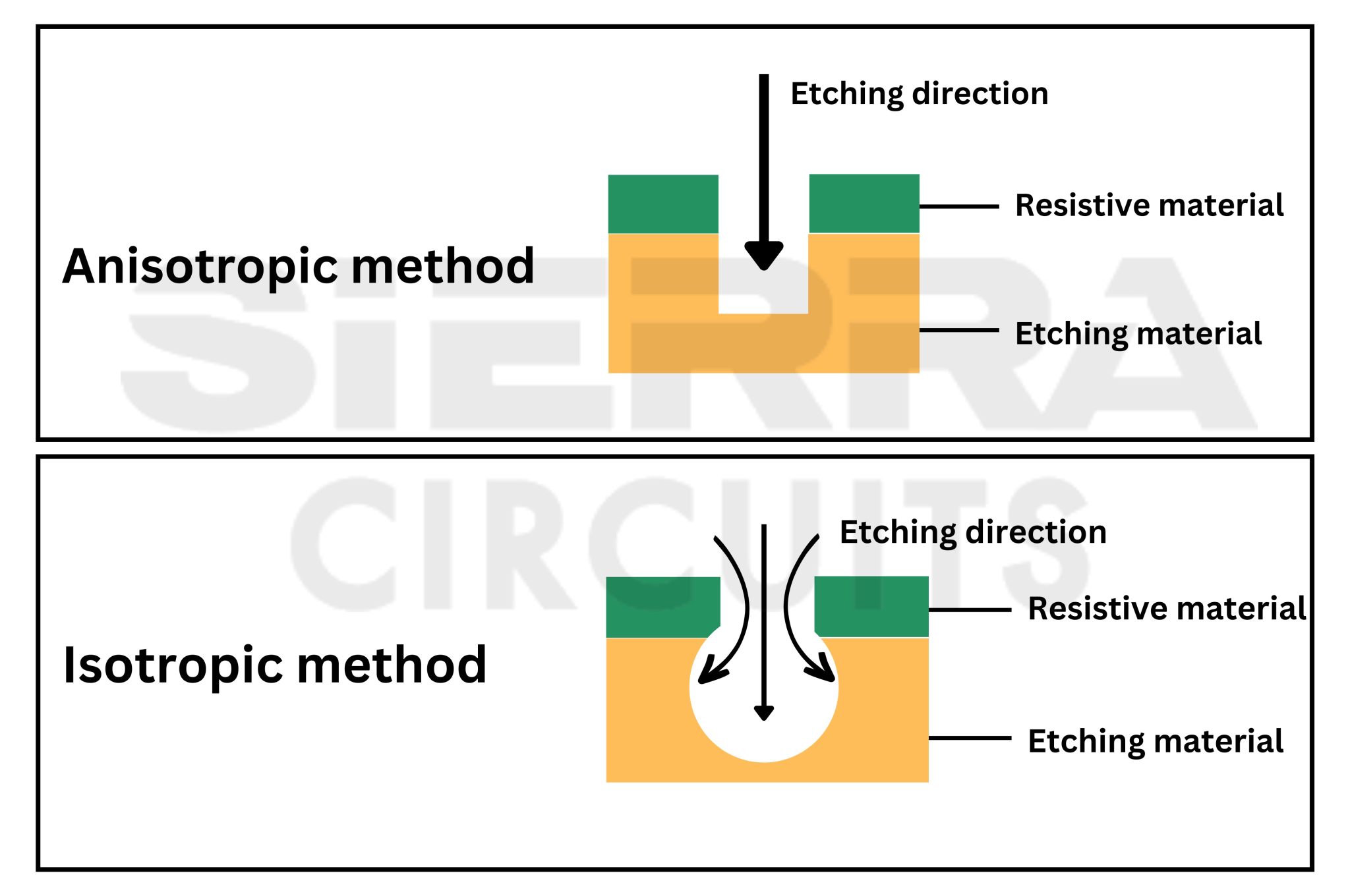

Anisotropic Etching vs. Isotropic Etching Electrochemical Etching Anisotropic Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. The so called. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic demonstration of the wet anisotropically etched profiles of Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. In this paper we presents a brief overview. Electrochemical Etching Anisotropic.

From www.researchgate.net

(PDF) Communication—Anisotropic Electrochemical Etching of Porous Electrochemical Etching Anisotropic In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to a simple setup with unspecific electrolyte flow. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic representation of the setup for electrochemical etching of Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. In this paper we. Electrochemical Etching Anisotropic.

From www.cambridge.org

Photoelectrochemical etch enables damagefree device fabrication Electrochemical Etching Anisotropic Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. The wet etching. Electrochemical Etching Anisotropic.

From www.researchgate.net

The electrochemical etching system. Download Scientific Diagram Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. The so called inverted pyramid. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic diagram of electrochemical etching of the GaN wafer Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Here, we propose an. Electrochemical Etching Anisotropic.

From www.researchgate.net

Basic schematic of electrochemical etching method Download Scientific Electrochemical Etching Anisotropic When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. The wet etching. Electrochemical Etching Anisotropic.

From www.slideserve.com

PPT Introduction to etching. Wet chemical etching isotropic Electrochemical Etching Anisotropic Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. In this paper we presents. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic of isotropic versus anisotropic plasma etching. Download Electrochemical Etching Anisotropic Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. When a material is attacked by a liquid or. Electrochemical Etching Anisotropic.

From www.jos.ac.cn

Anisotropic etching mechanisms of 4HSiC Experimental and first Electrochemical Etching Anisotropic When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Compared to a simple setup. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic diagram of silicon anisotropic wet etching system. The Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. When a material is attacked by a liquid or vapor. Electrochemical Etching Anisotropic.

From www.researchgate.net

Schematic model of the etching process to explain anisotropic and Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Compared to the. Electrochemical Etching Anisotropic.

From www.researchgate.net

Effect of temperature on the etch rate anisotropy in 25 wt TMAH + 0.1 Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. The wet etching of gan, aln, and sic is reviewed. Electrochemical Etching Anisotropic.

From wiringschema.com

[DIAGRAM] Encyclopedia Diagram Etching Electrochemical Etching Anisotropic Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. The so called inverted pyramid arrays,. Electrochemical Etching Anisotropic.

From www.youtube.com

Wet Etching Process SiO2 Etching Si3N4 Etching Aluminium Etching Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. When a material is attacked by a liquid. Electrochemical Etching Anisotropic.

From www.researchgate.net

(PDF) Difference in anisotropic etching characteristics of alkaline and Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface.. Electrochemical Etching Anisotropic.

From www.spie.org

Highly selective dryplasmafree chemical etch technique for advanced Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Compared to a simple. Electrochemical Etching Anisotropic.

From www.semanticscholar.org

Figure 1 from Optical properties of photoelectrochemical etching of Electrochemical Etching Anisotropic In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in.. Electrochemical Etching Anisotropic.

From pv-manufacturing.org

Electrochemical Etching Anisotropic In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in.. Electrochemical Etching Anisotropic.

From nationaldefensepac.org

Anisotropic Etching Of Silicon In KOH Triton X100 For 45°, 53 OFF Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. When a material is attacked by. Electrochemical Etching Anisotropic.

From www.protoexpress.com

Wet PCB Etching Using Acidic & Alkaline Sierra Circuits Electrochemical Etching Anisotropic In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. Compared to. Electrochemical Etching Anisotropic.

From www.researchgate.net

Electrochemical etching process. (a) At a beginning step. (b) At an Electrochemical Etching Anisotropic Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. When a. Electrochemical Etching Anisotropic.

From www.researchgate.net

Anisotropic lithography mechanism and characteristics of the SIOLES a Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Compared to a simple setup with unspecific. Electrochemical Etching Anisotropic.

From slidetodoc.com

Etching Chapters 11 20 21 we will return Electrochemical Etching Anisotropic When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to a simple setup with unspecific electrolyte flow and. Electrochemical Etching Anisotropic.

From www.semanticscholar.org

Figure 2 from Different behavior of photoluminescence anisotropy in Electrochemical Etching Anisotropic Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Silicon wet anisotropic. Electrochemical Etching Anisotropic.

From www.researchgate.net

(a) A silicon template is patterned with anisotropic KOH etching with Electrochemical Etching Anisotropic In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Here, we propose an electrochemical etching strategy that solely. Electrochemical Etching Anisotropic.

From slideplayer.com

Material removal etching processes ppt video online download Electrochemical Etching Anisotropic Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. Compared to a simple setup with unspecific electrolyte flow. Electrochemical Etching Anisotropic.

From sites.utexas.edu

MetalAssisted Chemical Etching (MacEtch) Electrochemical Etching Anisotropic When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. In this paper we. Electrochemical Etching Anisotropic.

From www.slideserve.com

PPT MEMS Fabrication Process Flows and Bulk Silicon Etching Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. Here, we propose an electrochemical etching strategy that solely relies on defining etchable volumina by implantation of p. When a material is attacked by a liquid or. Electrochemical Etching Anisotropic.

From www.slideserve.com

PPT Chapter 10 Etching PowerPoint Presentation ID1945566 Electrochemical Etching Anisotropic Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface.. Electrochemical Etching Anisotropic.

From www.researchgate.net

Crosssectional diagram of a combination of anisotropic etching (DRIE Electrochemical Etching Anisotropic The so called inverted pyramid arrays, outperforming conventional upright pyramid textures, have been successfully. Compared to the extrinsic way to achieve anisotropic wetting, if intrinsic patterns can be depicted directly by chemical etching of. Silicon wet anisotropic etching is extensively used in silicon bulk micromachining for the fabrication of microelectromechanical. When a material is attacked by a liquid or vapor. Electrochemical Etching Anisotropic.

From www.researchgate.net

Working principle of the electrochemical etching with a micromachined Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface. Compared to a simple setup with unspecific electrolyte flow and full area etching, a significant improvement in microscopic and. Compared. Electrochemical Etching Anisotropic.

From www.researchgate.net

(PDF) Anisotropic etching of silicon in SF 6 plasma Electrochemical Etching Anisotropic The wet etching of gan, aln, and sic is reviewed including conventional etching in aqueous solutions, electrochemical etching in. When a material is attacked by a liquid or vapor etchant, the material will be removed isotropically (uniformly in all. In this paper we presents a brief overview of recent advancements in anisotropic etching methodologies, elucidating their role in tailoring surface.. Electrochemical Etching Anisotropic.