Assembly Line Balancing Bottleneck . — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. what is line balancing? — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. — line balancing means assigning work to a smallest number of workstations in a line process to equalize.

from www.semanticscholar.org

— in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. what is line balancing? Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency.

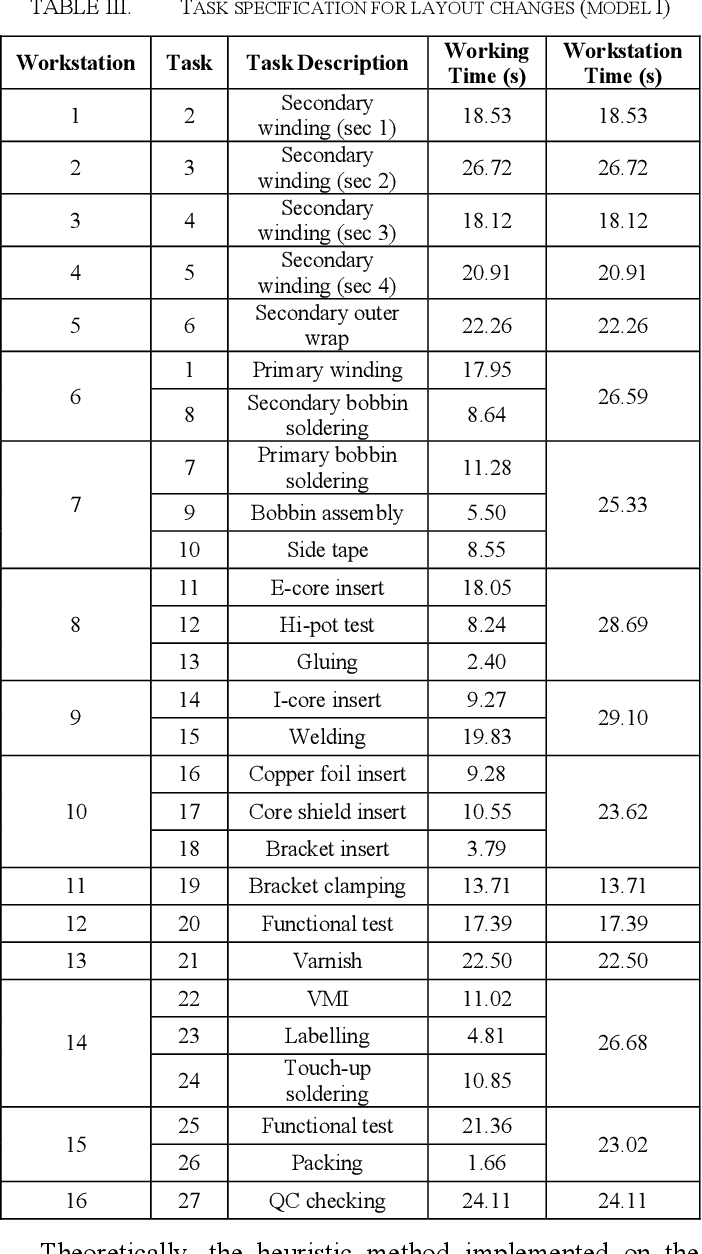

Minimization of Bottleneck and Workstations for Assembly Line Balancing

Assembly Line Balancing Bottleneck — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. what is line balancing? — among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. Effective balancing minimizes waste and ensures that production lines run efficiently. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. However, line balancing means different things to different manufacturers. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck what is line balancing? — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. Line balancing is the process of evenly distributing the workload across various workstations or stations in. Assembly Line Balancing Bottleneck.

From www.researchgate.net

(PDF) Incorporating shifting bottleneck identification in assembly line Assembly Line Balancing Bottleneck in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — in the manufacturing context, line. Assembly Line Balancing Bottleneck.

From www.researchgate.net

(PDF) Minimization of Bottleneck and Workstations for Assembly Line Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — line. Assembly Line Balancing Bottleneck.

From industri.istts.ac.id

Line Balancing Method, Mengatasi Bottleneck Hingga Mengoptimalkan Assembly Line Balancing Bottleneck Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. However, line balancing means different things to different manufacturers. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. Effective balancing minimizes waste and ensures that. Assembly Line Balancing Bottleneck.

From evisualcontrol.com

สมดุลการผลิต Line Balancing Factory Visual Control รับทำ Assembly Line Balancing Bottleneck Effective balancing minimizes waste and ensures that production lines run efficiently. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. what is line balancing? — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of. Assembly Line Balancing Bottleneck.

From www.youtube.com

What is Bottleneck Analysis in Lean manufacturing ? Bottleneck Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. what is line balancing? — optimizing workflow on an assembly line is not as dangerous, but it requires a. Assembly Line Balancing Bottleneck.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Bottleneck — line balancing means assigning work to a smallest number of workstations in a line process to equalize. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. However, line balancing means different things to different manufacturers. Effective balancing minimizes waste and ensures that. Assembly Line Balancing Bottleneck.

From www.youtube.com

Line Balancing and bottleneck Formation YouTube Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. However, line balancing means different things to different manufacturers. Line balancing is the process of evenly distributing the workload across various. Assembly Line Balancing Bottleneck.

From accountinguide.com

Bottleneck in Production Definition Example Solution Accountinguide Assembly Line Balancing Bottleneck Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck Effective balancing minimizes waste and ensures that production lines run efficiently. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. what is line balancing? — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — optimizing workflow on an assembly line is not. Assembly Line Balancing Bottleneck.

From www.scribd.com

Bottleneck Analysis and Line Balancing Presentation PDF Systems Assembly Line Balancing Bottleneck — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. Line. Assembly Line Balancing Bottleneck.

From www.eliter-packaging.com

How to Find and Reduce Bottlenecks in Production? ÉLITER Packaging Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. . Assembly Line Balancing Bottleneck.

From ar.inspiredpencil.com

Bottleneck Management Assembly Line Balancing Bottleneck in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. Effective balancing minimizes waste and ensures that production lines run efficiently. — in the manufacturing context, line balancing, also often called load balancing and production. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck — line balancing means assigning work to a smallest number of workstations in a line process to equalize. what is line balancing? — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as. Assembly Line Balancing Bottleneck.

From www.academia.edu

(PDF) Bottleneck easingbased assignment of work and product mixture Assembly Line Balancing Bottleneck what is line balancing? in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. — in the manufacturing context, line balancing, also often called load balancing and. Assembly Line Balancing Bottleneck.

From www.youtube.com

10 Way to improve Bottleneck in garments Production line YouTube Assembly Line Balancing Bottleneck — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. — in the manufacturing context, line balancing, also often called load balancing. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Table 1 from An algorithm for integrated worker assignment, mixedmodel Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. However, line balancing means different things to different manufacturers. — among the most elementary optimization problems in this context is. Assembly Line Balancing Bottleneck.

From www.slideserve.com

PPT Assembly Line Balance PowerPoint Presentation, free download ID Assembly Line Balancing Bottleneck — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. However, line balancing means different things to. Assembly Line Balancing Bottleneck.

From www.youtube.com

𝐋𝐢𝐧𝐞 𝐁𝐚𝐥𝐚𝐧𝐜𝐢𝐧𝐠 Production Line Balancing ? Assembly Line Balancing Assembly Line Balancing Bottleneck what is line balancing? — line balancing means assigning work to a smallest number of workstations in a line process to equalize. Effective balancing minimizes waste and ensures that production lines run efficiently. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is the process of evenly. Assembly Line Balancing Bottleneck.

From www.academia.edu

(PDF) Metaheuristic procedures for the lexicographic bottleneck Assembly Line Balancing Bottleneck However, line balancing means different things to different manufacturers. what is line balancing? Effective balancing minimizes waste and ensures that production lines run efficiently. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines run efficiently. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. However, line balancing means. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Table II from Minimization of Bottleneck and Workstations for Assembly Assembly Line Balancing Bottleneck Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. — optimizing workflow on an assembly line is not as dangerous, but it requires a. Assembly Line Balancing Bottleneck.

From www.vecteezy.com

Disruption of the industrial production chain. Halting the assembly Assembly Line Balancing Bottleneck what is line balancing? — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. Effective balancing minimizes waste and ensures that production lines run efficiently. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — line balancing means assigning work to a smallest number of workstations in a line process. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Minimization of Bottleneck and Workstations for Assembly Line Balancing Assembly Line Balancing Bottleneck in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. what is line balancing? — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. — in the manufacturing context, line balancing, also often. Assembly Line Balancing Bottleneck.

From www.onlineclothingstudy.com

7 Things You Need to Balance a Stitching Line Assembly Line Balancing Bottleneck what is line balancing? — optimizing workflow on an assembly line is not as dangerous, but it requires a similar set of skills. However, line balancing means different things to different manufacturers. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. — line balancing means assigning work to. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Figure 1 from Lexicographic bottleneck mixedmodel assembly line Assembly Line Balancing Bottleneck However, line balancing means different things to different manufacturers. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — optimizing workflow on an assembly line is not. Assembly Line Balancing Bottleneck.

From www.slideshare.net

Line Balancing In Garments Industry Assembly Line Balancing Bottleneck what is line balancing? — line balancing means assigning work to a smallest number of workstations in a line process to equalize. — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

A Mathematical Model for the Lexicographic Bottleneck MixedModel Assembly Line Balancing Bottleneck Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. in the domain of manufacturing, assembly line balancing methods are pivotal for optimizing production efficiency. — line balancing means assigning work to a smallest number of workstations in a line process to equalize.. Assembly Line Balancing Bottleneck.

From www.chegg.com

Solved Line Balancing Problem HW What is the bottleneck? Assembly Line Balancing Bottleneck Effective balancing minimizes waste and ensures that production lines run efficiently. — line balancing means assigning work to a smallest number of workstations in a line process to equalize. Line balancing is the process of evenly distributing the workload across various workstations or stations in a production line to minimize bottlenecks and maximize efficiency. However, line balancing means different. Assembly Line Balancing Bottleneck.

From www.semanticscholar.org

Table I from Minimization of Bottleneck and Workstations for Assembly Assembly Line Balancing Bottleneck — line balancing means assigning work to a smallest number of workstations in a line process to equalize. Effective balancing minimizes waste and ensures that production lines run efficiently. — among the most elementary optimization problems in this context is the assembly line balancing problem, which. Line balancing is the process of evenly distributing the workload across various. Assembly Line Balancing Bottleneck.

From ashwinmore.com

What is Bottleneck analysis? Understand with example Assembly Line Balancing Bottleneck — in the manufacturing context, line balancing, also often called load balancing and production leveling, refers to a production technique to optimize machine time and operator time to eliminate bottlenecks so it can be as efficient as possible. However, line balancing means different things to different manufacturers. — among the most elementary optimization problems in this context is. Assembly Line Balancing Bottleneck.

From engineeringwithmanagement.com

Lean Manufacturing Engineering with Management Assembly Line Balancing Bottleneck — line balancing means assigning work to a smallest number of workstations in a line process to equalize. what is line balancing? Effective balancing minimizes waste and ensures that production lines run efficiently. However, line balancing means different things to different manufacturers. Line balancing is the process of evenly distributing the workload across various workstations or stations in. Assembly Line Balancing Bottleneck.