Sheet Metal Engineering Drawing Pdf . Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Because of this added complexity sheet metal drawings can be particularly tricky to create. Design engineer should consider the following: Cutting and forming thin sheets of metal usually performed as cold working. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing.

from www.engineersrule.com

Metallic sheet typically < 6 mm thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal parts often require multiple manufacturing processes to produce correctly. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. A how to guide for engineers and drafters designing sheet metal parts. Cutting and forming thin sheets of metal usually performed as cold working. Design engineer should consider the following: Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick.

SOLIDWORKS 2017 Archives Engineers Rule

Sheet Metal Engineering Drawing Pdf Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Metallic sheet typically < 6 mm thick. Cutting and forming thin sheets of metal usually performed as cold working. Because of this added complexity sheet metal drawings can be particularly tricky to create. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Design engineer should consider the following: Sheet metal parts often require multiple manufacturing processes to produce correctly. A how to guide for engineers and drafters designing sheet metal parts.

From www.pinterest.com

Pin on solidworks Sheet Metal Engineering Drawing Pdf Sheet metal parts often require multiple manufacturing processes to produce correctly. Design engineer should consider the following: Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Metallic sheet typically < 6. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.pt

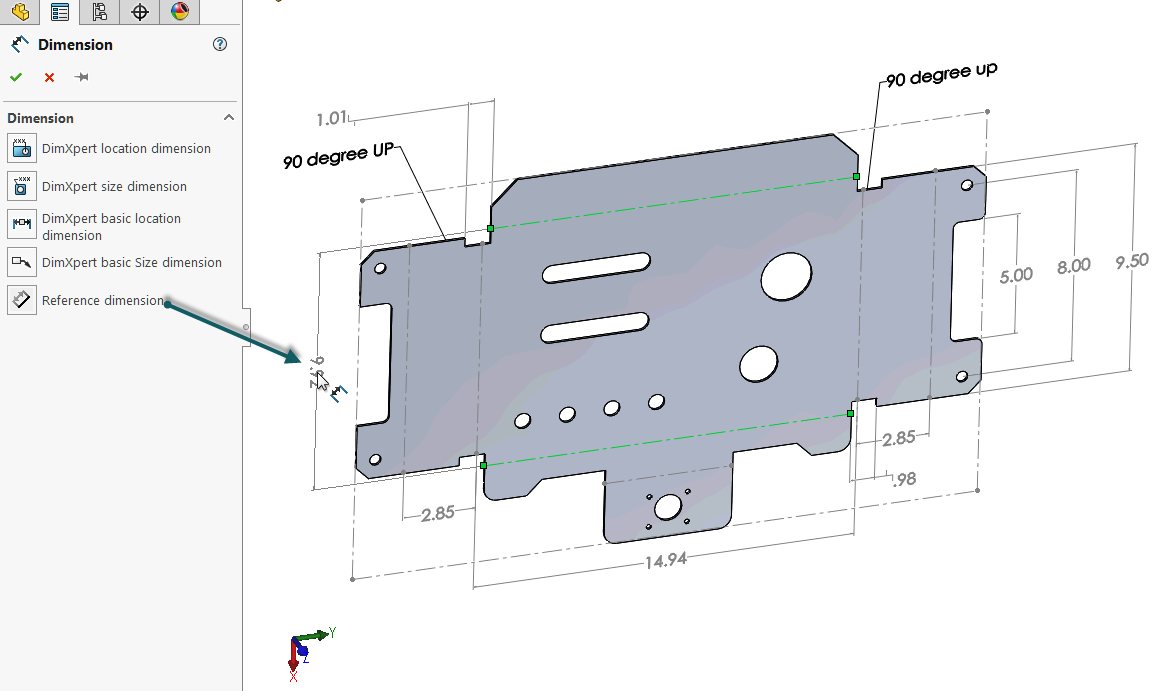

olidWorks Sheet metal Exercise Basic Features Sheet Metal Drawing Sheet Metal Engineering Drawing Pdf Design engineer should consider the following: A how to guide for engineers and drafters designing sheet metal parts. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Metallic sheet typically < 6 mm thick. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal. Sheet Metal Engineering Drawing Pdf.

From www.engineersrule.com

How to Present the MBD Data of Sheet Metal Parts Engineers Rule Sheet Metal Engineering Drawing Pdf A how to guide for engineers and drafters designing sheet metal parts. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Design engineer should consider the following: Because of this added complexity sheet metal drawings can be particularly tricky to create. Sheet metal parts often require multiple manufacturing processes to produce correctly. The document lists 40 sheet metal cad. Sheet Metal Engineering Drawing Pdf.

From paintingvalley.com

Sheet Drawing at Explore collection of Sheet Drawing Sheet Metal Engineering Drawing Pdf The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Because of this added complexity sheet metal drawings can be particularly tricky to create. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. For parts with small radius forms, high carbon spring steel or another heat treatable metal. Sheet Metal Engineering Drawing Pdf.

From godbolt.me

ENGINEERING DRAWING BY ND BHATT 50TH EDITION PDF Sheet Metal Engineering Drawing Pdf Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. A how to guide for engineers and drafters designing sheet metal parts. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Cutting and forming thin sheets of metal. Sheet Metal Engineering Drawing Pdf.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Sheet Metal Engineering Drawing Pdf Cutting and forming thin sheets of metal usually performed as cold working. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. A how to guide for engineers and drafters designing sheet metal parts. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Sheet metal = 0.4. Sheet Metal Engineering Drawing Pdf.

From in.pinterest.com

CHASSIS DRAWING SHEET Sheet metal drawing, Drawing sheet, Sheet metal Sheet Metal Engineering Drawing Pdf Because of this added complexity sheet metal drawings can be particularly tricky to create. Cutting and forming thin sheets of metal usually performed as cold working. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Metallic sheet. Sheet Metal Engineering Drawing Pdf.

From in.pinterest.com

Autodesk Inventor Sheet metal Drawing Tutorial Basics YouTube in 2021 Sheet Metal Engineering Drawing Pdf Design engineer should consider the following: Metallic sheet typically < 6 mm thick. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. A how to guide for engineers and drafters designing sheet metal parts. Sheet metal. Sheet Metal Engineering Drawing Pdf.

From zalaco.com

Mechanical Engineering Services Zalaco, LLC Sheet Metal Engineering Drawing Pdf A how to guide for engineers and drafters designing sheet metal parts. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Because of this added complexity sheet metal drawings can be particularly tricky to create. Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal. Sheet Metal Engineering Drawing Pdf.

From alysebritton.blogspot.com

sheet metal drawings for practice pdf Alyse Britton Sheet Metal Engineering Drawing Pdf Sheet metal parts often require multiple manufacturing processes to produce correctly. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Cutting and forming thin sheets of metal usually performed as cold working. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Design engineer should consider. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.jp

Mechanical Engineering Drawing Book Pdf Beautiful Chris Kordecki Sheet Metal Engineering Drawing Pdf Cutting and forming thin sheets of metal usually performed as cold working. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Sheet metal parts often require multiple manufacturing processes to produce correctly. Sheet metal = 0.4. Sheet Metal Engineering Drawing Pdf.

From worksheetlistule.z13.web.core.windows.net

Sheet Metal Drawing For Practice Sheet Metal Engineering Drawing Pdf Because of this added complexity sheet metal drawings can be particularly tricky to create. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Design engineer should consider the following: The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. A how to guide for engineers and drafters designing. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.es

Pin on Mechanical design Sheet Metal Engineering Drawing Pdf Design engineer should consider the following: A how to guide for engineers and drafters designing sheet metal parts. Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal usually performed as cold working. Metallic sheet typically < 6 mm thick. The document lists 40 sheet metal cad exercises numbered from 1 to. Sheet Metal Engineering Drawing Pdf.

From www.engineersrule.com

SOLIDWORKS 2017 Archives Engineers Rule Sheet Metal Engineering Drawing Pdf Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. For parts with small radius forms, high carbon spring steel or another. Sheet Metal Engineering Drawing Pdf.

From easydrawingstep.netlify.app

Sheet Metal Drawing Pdf EASY DRAWING STEP Sheet Metal Engineering Drawing Pdf A how to guide for engineers and drafters designing sheet metal parts. Because of this added complexity sheet metal drawings can be particularly tricky to create. Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal usually performed as cold working. Solidworks has specific sheet metal features that allow the creation of. Sheet Metal Engineering Drawing Pdf.

From www.reddit.com

[Tutorial Link in Comment] Sheet Metal Exercise in Solidworks 2022 Sheet Metal Engineering Drawing Pdf The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Sheet metal parts often require multiple manufacturing processes to produce correctly. Metallic sheet typically < 6 mm thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. Design engineer should consider the following: Cutting and forming thin sheets of metal. Sheet Metal Engineering Drawing Pdf.

From proleantech.com

O guia definitivo para a leitura de desenhos 2D para fabricação de Sheet Metal Engineering Drawing Pdf Because of this added complexity sheet metal drawings can be particularly tricky to create. A how to guide for engineers and drafters designing sheet metal parts. Design engineer should consider the following: The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Cutting and forming thin sheets of metal usually performed as cold working. Metallic. Sheet Metal Engineering Drawing Pdf.

From microdra.com

Fabrication drawings Microdra Design Solutions Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Design engineer should consider. Sheet Metal Engineering Drawing Pdf.

From paintingvalley.com

Part Drawing at Explore collection of Part Drawing Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Because of this added complexity sheet metal drawings can be particularly tricky to create. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Cutting and forming thin sheets of metal usually performed as cold working. The. Sheet Metal Engineering Drawing Pdf.

From www.oreilly.com

Chapter 13. Sheet Metal Drawings Engineering Design Graphics with Sheet Metal Engineering Drawing Pdf Design engineer should consider the following: Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Metallic sheet typically < 6 mm thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. Cutting and forming thin sheets of metal usually performed as cold working. A how to guide for. Sheet Metal Engineering Drawing Pdf.

From thors.com

Engineering Drawings for Castings Course Sheet Metal Engineering Drawing Pdf The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Metallic sheet typically < 6 mm thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. Design engineer should consider the following: Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Sheet metal. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.ca

Advanced Sheet metal Exercise in SolidWorks Sheet metal drawing Sheet Metal Engineering Drawing Pdf A how to guide for engineers and drafters designing sheet metal parts. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Solidworks has specific sheet metal features. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.fr

Sheet Metal Part 2D Drawing by Ace on Cad Crowd Mechanical Engineering Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Design engineer should consider the following: Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal usually performed as cold working. Because of this added complexity sheet metal drawings can be particularly tricky to create.. Sheet Metal Engineering Drawing Pdf.

From www.researchgate.net

Engineering drawing of the example part. Download Scientific Diagram Sheet Metal Engineering Drawing Pdf Metallic sheet typically < 6 mm thick. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Design engineer should consider the following: For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal parts often require multiple manufacturing processes to produce correctly. A how to. Sheet Metal Engineering Drawing Pdf.

From edu.svet.gob.gt

Sheet Metal Design Including 3D Model,DXF File ,PDF Drawing Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Cutting and forming thin sheets of metal usually performed as cold working. Because of this added complexity sheet metal drawings can be particularly tricky to create. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. The document lists 40 sheet metal cad. Sheet Metal Engineering Drawing Pdf.

From ravens.nckl.gov.kh

Drawing Metal Sheet Sheet Metal Engineering Drawing Pdf Design engineer should consider the following: Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet metal parts often require multiple manufacturing processes to produce correctly. Cutting and forming thin sheets of metal usually performed as cold working. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Because of this added complexity sheet. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.com

How I Successfuly Organized My Very Own Sheet Metal 9d Drawings Pdf Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Because of this added complexity sheet metal drawings can be particularly tricky to create. Design engineer should consider the following: Sheet metal parts often require multiple manufacturing processes to produce correctly. Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64). Sheet Metal Engineering Drawing Pdf.

From getdrawings.com

Engineering Drawing at GetDrawings Free download Sheet Metal Engineering Drawing Pdf Sheet metal parts often require multiple manufacturing processes to produce correctly. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Cutting and forming thin sheets of metal usually performed as cold working. Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Because of this. Sheet Metal Engineering Drawing Pdf.

From www.artofit.org

Extreme solidworks Artofit Sheet Metal Engineering Drawing Pdf Metallic sheet typically < 6 mm thick. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet metal parts often require multiple manufacturing processes to produce correctly. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. A how to guide for engineers and drafters designing sheet metal parts. Cutting and forming. Sheet Metal Engineering Drawing Pdf.

From www.pinterest.de

Pin on solid draw Sheet Metal Engineering Drawing Pdf Metallic sheet typically < 6 mm thick. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. A how to guide for engineers and drafters designing sheet metal parts. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Solidworks has specific sheet metal features that allow the. Sheet Metal Engineering Drawing Pdf.

From www.youtube.com

Create a Drawing for a Sheet metal Part in Autodesk inventor YouTube Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Because of this added complexity sheet metal drawings can be particularly tricky to create. Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. A how to. Sheet Metal Engineering Drawing Pdf.

From microdra.com

Fabrication drawings Microdra Design Solutions Sheet Metal Engineering Drawing Pdf Solidworks has specific sheet metal features that allow the creation of sheet metal bodies very quickly. Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Design engineer should consider the. Sheet Metal Engineering Drawing Pdf.

From hlhrapid.com

How to Prepare a Perfect 2D Technical Drawing for CNC Machining Sheet Metal Engineering Drawing Pdf For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Sheet metal parts often require multiple manufacturing processes to produce correctly. The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. Metallic sheet typically < 6 mm thick.. Sheet Metal Engineering Drawing Pdf.

From aestheticdrawingideas.netlify.app

Sheet Metal Drawings For Practice Pdf Aesthetic Drawing Sheet Metal Engineering Drawing Pdf The document lists 40 sheet metal cad exercises numbered from 1 to 40 without providing. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. Metallic sheet typically < 6 mm thick. Cutting and forming thin sheets of metal usually performed as cold working. Design engineer should consider the following: Because of this. Sheet Metal Engineering Drawing Pdf.

From www.fiveflute.com

Five Flute Engineering design review platform for modern hardware teams Sheet Metal Engineering Drawing Pdf Cutting and forming thin sheets of metal usually performed as cold working. Sheet metal parts often require multiple manufacturing processes to produce correctly. Sheet metal = 0.4 (1/64) to 6 mm (1/4in) thick. Metallic sheet typically < 6 mm thick. For parts with small radius forms, high carbon spring steel or another heat treatable metal with good. A how to. Sheet Metal Engineering Drawing Pdf.