What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface . This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance.

from www.nuclear-power.com

Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth.

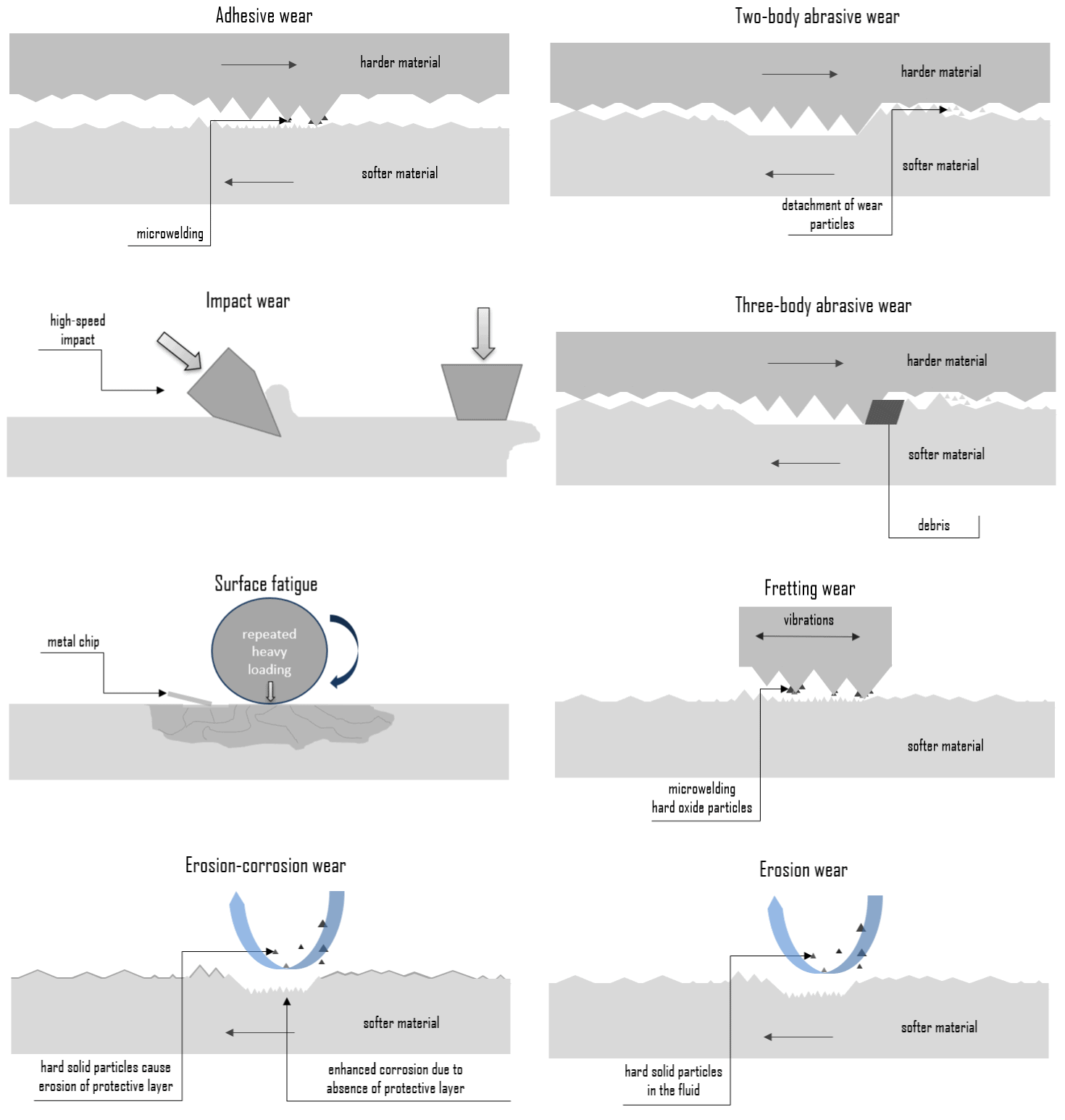

Diffusive Wear Mechanisms and Characteristics

What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. The results indicated that adding 50wt% tic composite coating has the best wear resistance. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. However, most studies focus on the. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv.

From www.scribd.com

Resistance To Deep Abrasion PDF Wear Volume What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From polymerservice.ee

Polymer Service Abrasion resistance service What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Abrasion wear of the coatings with. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.mdpi.com

Abrasion and Cavitation Erosion Resistance of MultiLayer Dip Coated What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

(PDF) Erosive and Abrasive Wear Resistance of Polyurethane Liners What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the.. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From blog.thepipingmart.com

What is Abrasion Resistance? What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. The results indicated that adding 50wt% tic composite coating has the best wear resistance.. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From dokumen.tips

(PDF) Abrasion, Erosion and Cavitation Erosion Wear Properties of What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www2.mdpi.com

Coatings Free FullText Abrasion, Erosion and Cavitation Erosion What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.nuclear-power.com

Diffusive Wear Mechanisms and Characteristics What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. This paper provides a comprehensive review of the recent progress on designs, properties, and. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From slpsb.com.my

The Complete Guide to Abrasion Resistant for 2021 SLPSB What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface The results indicated that adding 50wt% tic composite coating has the best wear resistance. However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. This. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.slideserve.com

PPT Dental materials biological, chemical and physhical properties What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. This. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

(PDF) On the Applicability of IronBased Coatings Against Abrasion and What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface The results indicated that adding 50wt% tic composite coating has the best wear resistance. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. Cr 3 c 2. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

Concrete wear process under the combined action of cavitation erosion What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Polyurethanes. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.mdpi.com

Abrasion and Cavitation Erosion Resistance of MultiLayer Dip Coated What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. The results indicated that adding 50wt% tic composite coating has the best wear resistance. This paper provides a comprehensive review. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From theconstructor.org

Abrasion Resistance Test on Concrete The Constructor What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. This paper provides a comprehensive review of the recent progress on designs, properties, and applications. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From blog.thepipingmart.com

What is Surface Abrasion, and How do we Resist It? What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

SEM images of wear mechanism a) Abrasion wear and EDS(Exp.No3) b What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.mdpi.com

Coatings Free FullText Cavitation Erosion Resistance and Wear What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. The results indicated that adding 50wt% tic composite coating has the best wear resistance. However, most studies focus on the. Abrasion wear of. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From moldedgroup.com

Taking A Closer Look at Abrasion Resistance Molded Dimensions Group What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From blog.thepipingmart.com

What is the Most Abrasion Resistant Material? What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Cr. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.avweld.com.au

AbrasaPlate Wear Plate Extreme Abrasion Resistance What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From blog.thepipingmart.com

Abrasion Resistance Testing and How to Do It? What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Abrasion wear of. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

Hardness, abrasion wear resistance, and cavitation erosion wear What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Cr 3 c 2 could enhance the wear resistance. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From inn.demokritos.gr

Wear, corrosion, weathering Erosion, abrasion, cavitation, galvanostat What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. This paper provides a comprehensive review of the recent progress on designs, properties, and applications. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.machinerylubrication.com

Hydraulic Cavitation Wear Explained and Illustrated What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.gester-instruments.com

What is the Purpose of the Abrasion Resistance What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Polyurethanes. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.mdpi.com

Abrasion and Cavitation Erosion Resistance of MultiLayer Dip Coated What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. However, most studies focus on the. Polyurethanes. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.youtube.com

M7033T WEAR 1 Part3 Abrasive wear YouTube What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and applications. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.slideshare.net

Abrasion Resistance and wear What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. The results indicated that adding 50wt% tic composite coating has the best wear resistance. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Abrasion wear of. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From michmet.com

Cavitation erosion Michigan Metrology What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. The results indicated that adding 50wt% tic composite coating has the best wear resistance. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Polyurethanes have been. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.researchgate.net

The effect of hardness of metals on their abrasion resistance What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. However, most studies focus on the. This paper provides a comprehensive review of the recent progress on designs, properties, and. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.nuclear-power.com

Adhesive Wear vs Abrasion Wear Mechanisms and Characteristics What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Abrasion wear of. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.ippmagazine.com

Abrasion Resistant and Wear Resistant Coatings Explained What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface However, most studies focus on the. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.scribd.com

Erosion Abrasion and Cavitation of Concrete Wear Erosion What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder grain growth. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Abrasion wear of. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.pinterest.com

Universal Wear Tester, to determine the wear and abrasion resistance of What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface The results indicated that adding 50wt% tic composite coating has the best wear resistance. This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. Polyurethanes have been long known for excellent abrasion resistance, especially when compared with other materials such as rubber , plastic,. Abrasion wear of the coatings with various compositions deposited. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.

From www.semanticscholar.org

[PDF] STUDY AND CHARACTERISTIC OF ABRASIVE WEAR MECHANISMS Semantic What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface This paper provides a comprehensive review of the recent progress on designs, properties, and applications of wear. However, most studies focus on the. Abrasion wear of the coatings with various compositions deposited at the amplitude of pulsed bias potential of 1.5 kv. Cr 3 c 2 could enhance the wear resistance of the coating due to its capability to hinder. What Is Used To Improve Wear Abrasion And Cavitation Resistance On The Surface.