Pump Seal Quenching . It is normally used if short periods of dry running are expected. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. The quench fluid acts as barrier in between atmosphere and process. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. As illustrated bellow, the fluid is introduced into. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. Product crystallization can be prevented by using temperature controls,. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. A quench plan, as the name indicates, is designed to quench or cool the seal. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. The packing gland is a chamber that houses the packing material,.

from www.slideshare.net

An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. It is normally used if short periods of dry running are expected. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. The quench fluid acts as barrier in between atmosphere and process. As illustrated bellow, the fluid is introduced into. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. Product crystallization can be prevented by using temperature controls,.

Mechanical Seal Vs Gland Packing

Pump Seal Quenching By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. It is normally used if short periods of dry running are expected. The quench fluid acts as barrier in between atmosphere and process. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. Product crystallization can be prevented by using temperature controls,. The packing gland is a chamber that houses the packing material,. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. As illustrated bellow, the fluid is introduced into. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. A quench plan, as the name indicates, is designed to quench or cool the seal. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system.

From www.ess4solutions.com

Seal Support Systems for Oil and Gas — ESS Pump & Seal Pump Seal Quenching The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. An external fluid stream is brought to atmospheric. Pump Seal Quenching.

From cecbqncb.blob.core.windows.net

Mechanical Seal Quenching at Kati Anderson blog Pump Seal Quenching By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. Product crystallization can be prevented by using temperature controls,. A quench plan, as the name indicates, is designed to quench or cool the seal. The quench fluid acts as barrier in between atmosphere and process. With a properly designed seal. Pump Seal Quenching.

From hevvypumps.com

Differences Between Flush and Quench In Slurry Pump Seal Support Plans Pump Seal Quenching Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. A quench plan, as the name indicates, is designed to quench or cool the seal. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. The packing gland is a. Pump Seal Quenching.

From northerncal.swagelok.com

Understand Seal Support Quench Systems to Avoid Costly Problems Pump Seal Quenching However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. Gland water, also known as flush water or quench water, is used to. Pump Seal Quenching.

From steamquench.com

Steamquench Pump Seal Quenching The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. Gland water, also known as flush water or. Pump Seal Quenching.

From cowseal.com

Mechanical Seal Flush vs Quench What Is the Difference Pump Seal Quenching The packing gland is a chamber that houses the packing material,. Product crystallization can be prevented by using temperature controls,. The quench fluid acts as barrier in between atmosphere and process. It is normally used if short periods of dry running are expected. By proactively flushing debris that can damage seal faces, you extend the life of the seal and. Pump Seal Quenching.

From www.jrfurnace.net

Sealed Quench Furnace SQF Furnace Heat Treatment Systems Pump Seal Quenching As illustrated bellow, the fluid is introduced into. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. Product crystallization can be prevented by using temperature controls,. It is normally used if. Pump Seal Quenching.

From hydromarque.com

Pumping Cooling Water For Quenching Hydromarque Pump Seal Quenching It is normally used if short periods of dry running are expected. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. Gland water, also known as. Pump Seal Quenching.

From www.youtube.com

INOXPA SLR ROTARY LOBE PUMP FLUSHED MECHANICAL SEALS (QUENCH) YouTube Pump Seal Quenching The quench fluid acts as barrier in between atmosphere and process. A quench plan, as the name indicates, is designed to quench or cool the seal. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. An external fluid stream is brought to atmospheric side. Pump Seal Quenching.

From hegerpumps.com

Heger internal mechanical shaft seal quench01 Heger Pumps, Inc. Pump Seal Quenching By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. As illustrated bellow, the fluid is introduced into. Product crystallization can be prevented by using. Pump Seal Quenching.

From www.ess4solutions.com

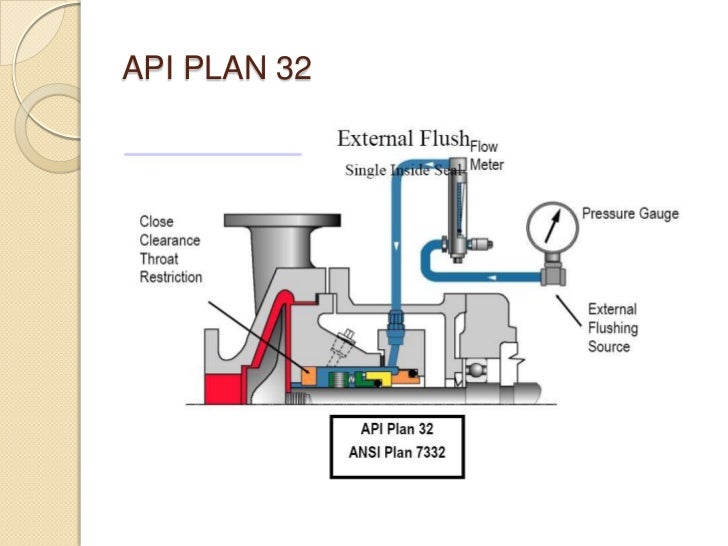

API Plan 32 — ESS Pump & Seal Pump Seal Quenching Product crystallization can be prevented by using temperature controls,. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. The quench fluid acts. Pump Seal Quenching.

From www.youtube.com

Pump Seal Selection YouTube Pump Seal Quenching The packing gland is a chamber that houses the packing material,. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump. Pump Seal Quenching.

From cecbqncb.blob.core.windows.net

Mechanical Seal Quenching at Kati Anderson blog Pump Seal Quenching However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. The flush system is used to cool and lubricate the process side of. Pump Seal Quenching.

From www.slideshare.net

Mechanical Seal Vs Gland Packing Pump Seal Quenching The packing gland is a chamber that houses the packing material,. As illustrated bellow, the fluid is introduced into. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem. Pump Seal Quenching.

From trisun.en.made-in-china.com

AES Smss Cartridge Seal with Big Flush Bore and Quench China Mechanical Seal and Pump Seal Pump Seal Quenching Product crystallization can be prevented by using temperature controls,. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. It is normally used if short periods of dry. Pump Seal Quenching.

From www.slideshare.net

Mechanical Seal Vs Gland Packing Pump Seal Quenching As illustrated bellow, the fluid is introduced into. The packing gland is a chamber that houses the packing material,. It is normally used if short periods of dry running are expected. The quench fluid acts as barrier in between atmosphere and process. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the. Pump Seal Quenching.

From sealomech.com

What are the API plans 682 and 610 for mechanical seals Pump Seal Quenching The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. It is normally used if short periods of dry running are expected. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost. Pump Seal Quenching.

From steamquench.com

Steamquench Pump Seal Quenching A quench plan, as the name indicates, is designed to quench or cool the seal. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid. Pump Seal Quenching.

From www.eagleburgmann.com

Mechanical seals for pumps Sealing Solutions Pump Seal Quenching Product crystallization can be prevented by using temperature controls,. In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. The quench fluid acts as barrier in between atmosphere and process. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. An external fluid stream. Pump Seal Quenching.

From pumps-systems.netzsch.com

Accessories and Optional Equipment for Pumps & Systems NETZSCH Pumps & Systems Pump Seal Quenching With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency and reliability of critical pumps. A quench plan, as the name indicates, is designed to quench or cool the seal. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. The. Pump Seal Quenching.

From www.pumpsandsystems.com

Determine the Best Piping Plan for Supporting Mechanical Seals in Vertical Pumps Pumps & Systems Pump Seal Quenching However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. As illustrated bellow, the fluid is introduced into. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. It is normally used if short periods of dry. Pump Seal Quenching.

From www.youtube.com

Mechanical Seal flush plan 62 Atmospheric side seal flush plan 61 & 62 Seal flushing in Pump Pump Seal Quenching By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. As illustrated bellow, the fluid is introduced into. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan,. Pump Seal Quenching.

From info.craneengineering.net

Mechanical Seal Basics Learn How Mechanical Seals For Pumps Work Pump Seal Quenching However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. With a properly designed seal support quench system, you can avoid costly problems that undermine the efficiency. Pump Seal Quenching.

From www.youtube.com

37 API plan No.62 mechanical seal Quench مخططات الميكانيكل سيل YouTube Pump Seal Quenching A quench plan, as the name indicates, is designed to quench or cool the seal. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in. Pump Seal Quenching.

From www.idrochemical.com

MECHANICAL SEALS SYSTEMS Idrochemical Pump Seal Quenching As illustrated bellow, the fluid is introduced into. The packing gland is a chamber that houses the packing material,. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. It is normally used if short periods of dry running are expected. An external fluid stream. Pump Seal Quenching.

From www.ess4solutions.com

API Plan 53B — ESS Pump & Seal Pump Seal Quenching In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. Product crystallization can be prevented by using temperature controls,. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. Gland water, also known as flush water or quench water, is used to seal and lubricate the. Pump Seal Quenching.

From trisun.en.made-in-china.com

Double CarTex Cartridge Mechanical Seal with Quench DCB02q65mm China Mechanical Seal and Pump Seal Quenching A quench plan, as the name indicates, is designed to quench or cool the seal. Product crystallization can be prevented by using temperature controls,. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. The quench fluid acts as barrier. Pump Seal Quenching.

From enggcyclopedia.com

Common types of pumps mechanical seal piping plans Single seals EnggCyclopedia Pump Seal Quenching The quench fluid acts as barrier in between atmosphere and process. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. It is normally used if short periods of dry running are expected. The flush system is used to cool and lubricate the process side of the seal, while the. Pump Seal Quenching.

From cecbqncb.blob.core.windows.net

Mechanical Seal Quenching at Kati Anderson blog Pump Seal Quenching The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. As illustrated bellow, the fluid is introduced into. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming. Pump Seal Quenching.

From www.lepuseal.com

OEM high quality mechanical seal quench cartridge company bulk production Lepu Seal Pump Seal Quenching By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. However, if you’re doing more seal flushing than indicated on. Pump Seal Quenching.

From hevvypumps.com

Differences Between Flush and Quench In Slurry Pump Seal Support Plans Pump Seal Quenching The flush system is used to cool and lubricate the process side of the seal, while the quench system provides a barrier fluid on the atmospheric side of the seal. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. With a properly designed seal support quench system, you can. Pump Seal Quenching.

From www.sepco.com

Infographic Pump System Sealing SEPCO, Inc. Pump Seal Quenching An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. The quench fluid acts as barrier in between atmosphere and process. The packing gland is a chamber that houses the packing material,. As illustrated bellow, the fluid is introduced into. The flush system is used to cool and lubricate the process side. Pump Seal Quenching.

From www.eagleburgmann.com

API Plan 62 EN Pump Seal Quenching In other cases, the pump product may crystallize, abrading the sealing interface and causing premature wear. As illustrated bellow, the fluid is introduced into. The packing gland is a chamber that houses the packing material,. Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. Product crystallization can. Pump Seal Quenching.

From www.maharith.in

Quenching Furnace Sealed Quench Furnace Maharith Thermal Pvt. Ltd. Maharith Thermal Pump Seal Quenching Gland water, also known as flush water or quench water, is used to seal and lubricate the packing gland in a pump. An external fluid stream is brought to atmospheric side of the seal faces using quench and drain connections. The flush system is used to cool and lubricate the process side of the seal, while the quench system provides. Pump Seal Quenching.

From eddypump.com

What are the Benefits of the Seal Support System on an EDDY Pump? EDDY Pump Pump Seal Quenching It is normally used if short periods of dry running are expected. By proactively flushing debris that can damage seal faces, you extend the life of the seal and boost pump reliability. However, if you’re doing more seal flushing than indicated on your scheduled maintenance plan, it’s likely that the problem is an underperforming seal support system. Gland water, also. Pump Seal Quenching.