Dewetting Solder Joint . Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of several different issues. — reduced electrical conductivity: Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to the ability of molten solder to uniformly spread and.

from dxooqpqrm.blob.core.windows.net

Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — reduced electrical conductivity: poor solder wetting can be the result of several different issues. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to the ability of molten solder to uniformly spread and.

Solder Defects List at Emily Black blog

Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. poor solder wetting can be the result of several different issues. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — reduced electrical conductivity: — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to the ability of molten solder to uniformly spread and. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of.

From www.youtube.com

Wave Soldering Defect Part 2, Types of Soldering Defects. YouTube Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. — reduced electrical conductivity: Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. poor solder wetting can be the result. Dewetting Solder Joint.

From www.youtube.com

Nonwetting and Dewetting during Soldering PCB Knowledge YouTube Dewetting Solder Joint — reduced electrical conductivity: Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. poor solder wetting can be the result of several different issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction. Dewetting Solder Joint.

From www.raypcb.com

What is wetting Soldering, Causes, and How to prevent them? RAYPCB Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to the ability of molten solder to uniformly spread and. poor solder wetting can be the result of several different issues. — reduced electrical conductivity: Solder dewetting can create voids or gaps in the solder. Dewetting Solder Joint.

From www.semlab.com

QFN Solder Joint Evaluation SEM Lab Inc. Dewetting Solder Joint Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to. Dewetting Solder Joint.

From dxooqpqrm.blob.core.windows.net

Solder Defects List at Emily Black blog Dewetting Solder Joint poor solder wetting can be the result of several different issues. — reduced electrical conductivity: Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. — solder dewetting is a common issue in soldering. Dewetting Solder Joint.

From www.youtube.com

Soldering Through Hole Tips & Tricks (4K) YouTube Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to the ability of molten solder to uniformly spread and. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of. Dewetting Solder Joint.

From www.mdpi.com

Materials Free FullText Reliability Study of Solder Paste Alloy Dewetting Solder Joint poor solder wetting can be the result of several different issues. — reduced electrical conductivity: — wetting refers to the ability of molten solder to uniformly spread and. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. Solder dewetting can create voids or gaps in the solder joint, which can reduce. Dewetting Solder Joint.

From www.youtube.com

Soldering Through Hole Components Soldering Basics Soldering for Dewetting Solder Joint — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — wetting refers to the ability of molten. Dewetting Solder Joint.

From www.researchgate.net

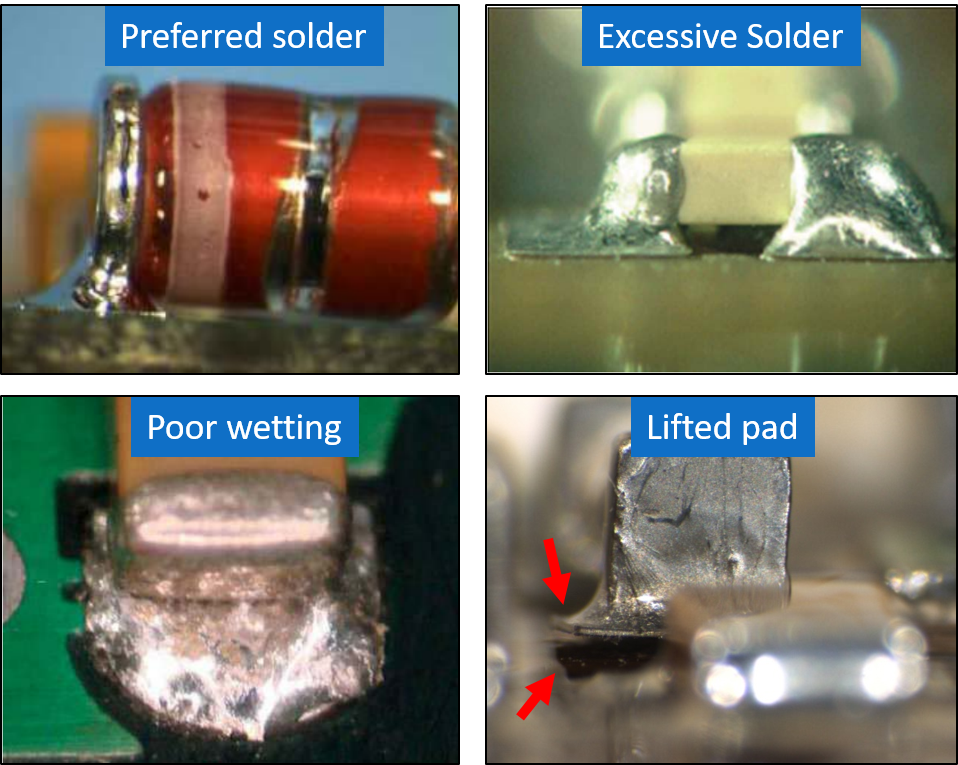

Common solder joint defects [23] Download Scientific Diagram Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — reduced electrical conductivity: — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered.. Dewetting Solder Joint.

From dxokkmdhl.blob.core.windows.net

How To Get A Good Solder Joint at Brent Miller blog Dewetting Solder Joint poor solder wetting can be the result of several different issues. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — reduced electrical conductivity: — wetting refers to the ability of molten solder to uniformly spread and. Get tips on causes, inspection methods, repair techniques, and best. Dewetting Solder Joint.

From www.youtube.com

Soldering 101 6. Soldering a Wire to a Terminal YouTube Dewetting Solder Joint — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. Get tips on causes, inspection methods,. Dewetting Solder Joint.

From www.youtube.com

How to Solder Properly 5 Soldering Joint Splices YouTube Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — reduced electrical conductivity: Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result. Dewetting Solder Joint.

From www.pcbdirectory.com

What is Solder Dewetting? PCB Directory Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of several different issues. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing,. Dewetting Solder Joint.

From www.researchgate.net

The SEM crosssection figures of solder joint soldering at 250 °C Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of several different issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder. Dewetting Solder Joint.

From www.youtube.com

Soldering Wires to Wires Soldering Basics Soldering for Beginners Dewetting Solder Joint — reduced electrical conductivity: — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning.. Dewetting Solder Joint.

From www.raypcb.com

The Detailed Comparison of LeadFree and Lead Soldering Phenomenon of PCBs Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. — wetting refers to the ability of molten solder to uniformly spread and. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction. Dewetting Solder Joint.

From www.youtube.com

Soldering Soldering types Solder Specifications Good vs. Bad Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. poor solder wetting can be the result of several different issues. — wetting refers to the ability of molten solder to uniformly spread and.. Dewetting Solder Joint.

From smtnet.com

causes of solder dewetting SMT Electronics Manufacturing Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. — reduced electrical conductivity: — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Solder dewetting can create voids. Dewetting Solder Joint.

From www.semanticscholar.org

Figure 3 from Influence of PCBs coatings wettability on leadfree SMT Dewetting Solder Joint — reduced electrical conductivity: — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. poor solder wetting can be the result of several different issues. — wetting refers to the ability. Dewetting Solder Joint.

From exoczkcdq.blob.core.windows.net

Solder Joint Max Current at Michael Legg blog Dewetting Solder Joint Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — reduced electrical conductivity: poor solder wetting can be the result of several different issues. Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. — solder dewetting is a common issue in soldering. Dewetting Solder Joint.

From www.circuitbasics.com

Tips for Good Soldering Technique Circuit Basics Dewetting Solder Joint — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — wetting refers to the ability of molten solder to uniformly spread and. Get tips on causes, inspection methods, repair techniques, and best. Dewetting Solder Joint.

From exoflgrda.blob.core.windows.net

Solder Joints Thermal Shock at Tamara Demko blog Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — reduced electrical conductivity: . Dewetting Solder Joint.

From www.slideserve.com

PPT Proper IC Storage Counterfeiting “No Lead” Fuels the Dewetting Solder Joint — reduced electrical conductivity: Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — wetting refers to the ability of molten solder to uniformly spread and. poor solder wetting can be the result. Dewetting Solder Joint.

From rushpcb.com

What is a Solder Joint? RushPcb Dewetting Solder Joint — reduced electrical conductivity: Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. poor solder. Dewetting Solder Joint.

From www.electronicsandyou.com

Cold Solder Joint Symptoms, Prevent, Repair and Fix Cold Solder Joint Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. poor solder wetting can be the result of several different issues. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — wetting refers to the ability of molten solder to uniformly spread and.. Dewetting Solder Joint.

From resources.pcb.cadence.com

The Designer’s Guide to PCB Solder Defects Dewetting Solder Joint poor solder wetting can be the result of several different issues. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the. Dewetting Solder Joint.

From absolutepcbassembly.com

Cold Solder Joint Definitive Guide to Soldering Absolute Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. poor solder wetting can be the result of several different issues.. Dewetting Solder Joint.

From www.youtube.com

Hot Tips 3 Solder Wetting YouTube Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of several different issues. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder. Dewetting Solder Joint.

From www.youtube.com

SDG 066 Solder Throughhole Components Soldering Techniques 02 Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Get tips on causes, inspection. Dewetting Solder Joint.

From www.researchgate.net

Solder transfer layer dewetting. Download Scientific Diagram Dewetting Solder Joint — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Solder dewetting can create voids. Dewetting Solder Joint.

From www.earthquakerdevices.com

In Flux More Than You Ever Wanted To Know About Crafting Strong Solder Dewetting Solder Joint Solder dewetting can create voids or gaps in the solder joint, which can reduce the electrical conductivity of. poor solder wetting can be the result of several different issues. — wetting refers to the ability of molten solder to uniformly spread and. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. . Dewetting Solder Joint.

From www.youtube.com

Soldering & Desoldering Tutorial Beginners How To Video Temp, SMD Dewetting Solder Joint — reduced electrical conductivity: — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — wetting refers. Dewetting Solder Joint.

From dxokkmdhl.blob.core.windows.net

How To Get A Good Solder Joint at Brent Miller blog Dewetting Solder Joint — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity and wetting ability, leading to a reduction in solder adhesion to the surfaces being soldered. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — wetting refers to. Dewetting Solder Joint.

From exoigaaze.blob.core.windows.net

Bad Soldering Examples at Armando McDade blog Dewetting Solder Joint — reduced electrical conductivity: Get tips on causes, inspection methods, repair techniques, and best practices to minimize soldering issues. — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. — solder dewetting is a common issue in soldering processes, particularly in electronics manufacturing, where solder joints lose their integrity. Dewetting Solder Joint.

From www.nextpcb.com

Dry Solder Joints How to Identify and Fix Them? Dewetting Solder Joint — wetting refers to the ability of molten solder to uniformly spread and. poor solder wetting can be the result of several different issues. — reduced electrical conductivity: — learn how to identify and prevent the most common soldering defects like cold joints, bridging, and tombstoning. Get tips on causes, inspection methods, repair techniques, and best. Dewetting Solder Joint.