Spot Welding Different Thickness Material . These modifications allow you to weld different. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. When the thickness difference between workpieces is within three. Here it is suitable to use electrodes of different working end. Compare spot welding with seam welding and plug welding, and see. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Spot welding of low carbon steel with different thicknesses. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations.

from welditu.com

The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Here it is suitable to use electrodes of different working end. When the thickness difference between workpieces is within three. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Compare spot welding with seam welding and plug welding, and see. These modifications allow you to weld different. Spot welding of low carbon steel with different thicknesses. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure.

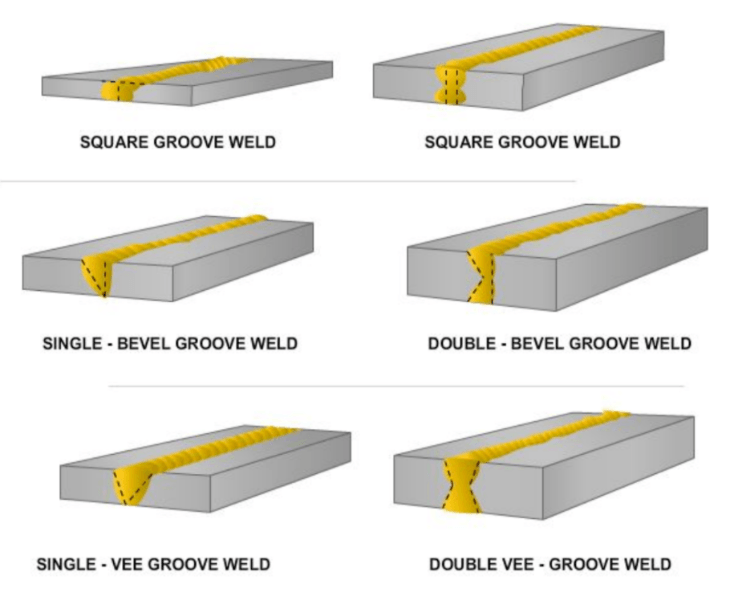

Types of Welding Joints and Welds Color Graphics • WelditU

Spot Welding Different Thickness Material Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Spot welding of low carbon steel with different thicknesses. Compare spot welding with seam welding and plug welding, and see. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. When the thickness difference between workpieces is within three. Here it is suitable to use electrodes of different working end. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. These modifications allow you to weld different.

From mavink.com

Welding Thickness Chart Spot Welding Different Thickness Material When the thickness difference between workpieces is within three. Compare spot welding with seam welding and plug welding, and see. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Spot welding of low carbon steel with different thicknesses. A considerably different situation is at welding of sheets of. Spot Welding Different Thickness Material.

From www.youtube.com

Spot Welding Practice Tig Welding / 1.5mm Stainless Steel Tube YouTube Spot Welding Different Thickness Material The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Here it is suitable to use electrodes of different working end. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of. Spot Welding Different Thickness Material.

From www.youtube.com

HOW TO SPOT WELD DIFFERENT THICKNESSES AND MATERIALS? YouTube Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. Spot welding of low carbon steel with different thicknesses. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Here it is suitable. Spot Welding Different Thickness Material.

From bil-ibs.be

Friction spot welding Belgian Welding Institute Spot Welding Different Thickness Material Here it is suitable to use electrodes of different working end. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Spot welding of low carbon steel with different thicknesses. These modifications allow you to weld different. When the thickness difference between workpieces is within three. Compare spot welding. Spot Welding Different Thickness Material.

From ahssinsights.org

Spot Weld Strength Improvement by PWHT AHSS Guidelines Spot Welding Different Thickness Material Spot welding of low carbon steel with different thicknesses. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Compare spot welding with seam welding and plug welding, and see. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high. Spot Welding Different Thickness Material.

From bil-ibs.be

Friction spot welding Belgian Welding Institute Spot Welding Different Thickness Material Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Here it is suitable to use electrodes of different working end. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. These modifications allow you to weld different.. Spot Welding Different Thickness Material.

From weldguru.com

Spot Welding Explained What is It? And How Does it Work? Spot Welding Different Thickness Material Spot welding of low carbon steel with different thicknesses. These modifications allow you to weld different. When the thickness difference between workpieces is within three. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength. Spot Welding Different Thickness Material.

From nissho-astec.com

Spot Welding NISSHO ASTEC CO., LTD. Spot Welding Different Thickness Material The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Compare spot welding with seam welding and. Spot Welding Different Thickness Material.

From www.engineeringbyte.com

To spot welding process on two sheet metal pieces Spot Welding Different Thickness Material Spot welding of low carbon steel with different thicknesses. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. These modifications allow you to weld different. Here it is suitable to use electrodes of different working end. Learn how to select and adjust resistance spot welding (rsw) parameters for. Spot Welding Different Thickness Material.

From www.mdpi.com

Metals Free FullText Resistance Spot Welding of Aluminum Alloy and Spot Welding Different Thickness Material A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Spot welding of low carbon steel with different thicknesses. When the thickness difference between workpieces is within three. The entire spot welding process can. Spot Welding Different Thickness Material.

From www.slideserve.com

PPT Spot Weld Mechanical Properties 2 PowerPoint Presentation, free Spot Welding Different Thickness Material Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Compare spot welding with seam welding and plug welding, and see. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Here it is suitable to use electrodes of different working end.. Spot Welding Different Thickness Material.

From weldguru.com

How to Weld Stainless Steel A Complete Guide Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. Spot welding of low carbon steel with different thicknesses. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Here it is suitable to use electrodes of different working end. Learn how to select and adjust resistance spot. Spot Welding Different Thickness Material.

From fractory.com

Spot Welding Explained Fractory Spot Welding Different Thickness Material These modifications allow you to weld different. Compare spot welding with seam welding and plug welding, and see. When the thickness difference between workpieces is within three. Here it is suitable to use electrodes of different working end. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn everything about spot welding,. Spot Welding Different Thickness Material.

From www.researchgate.net

Conventional solid spot welding electrodes used in the study Spot Welding Different Thickness Material A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. These modifications allow you to weld different. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Compare spot welding with seam welding and plug welding, and see. Here it is suitable to use. Spot Welding Different Thickness Material.

From tjsnow.com

How To Improve Spot Welding Performance T. J. Snow Resistance Welding Spot Welding Different Thickness Material These modifications allow you to weld different. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Here it is suitable to use electrodes of different working end. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Spot welding of low carbon steel. Spot Welding Different Thickness Material.

From www.matuschek.de

Spot Welding of Aluminium Sheets Spot Welding Different Thickness Material Here it is suitable to use electrodes of different working end. Compare spot welding with seam welding and plug welding, and see. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels.. Spot Welding Different Thickness Material.

From www.eng-tips.com

Maximum weld thickness Welding, Bonding & Fastener engineering EngTips Spot Welding Different Thickness Material These modifications allow you to weld different. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. When the thickness difference between workpieces is within three. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Here it is suitable to use. Spot Welding Different Thickness Material.

From app.aws.org

MIG settings for welding different thickness mild steel Spot Welding Different Thickness Material When the thickness difference between workpieces is within three. These modifications allow you to weld different. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Compare spot welding with seam welding and plug welding, and see. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by. Spot Welding Different Thickness Material.

From www.semanticscholar.org

Process Parameter Optimization in Resistance Spot Welding of Dissimilar Spot Welding Different Thickness Material Spot welding of low carbon steel with different thicknesses. These modifications allow you to weld different. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Here it is suitable to use electrodes of different working end. When the thickness difference between workpieces is within three. Learn everything about spot welding, a form. Spot Welding Different Thickness Material.

From www.welderdestiny.com

the Base Metal Thickness Essential Variable for Welding Procedures is Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. These modifications allow you to weld different. Spot welding of low carbon steel with different thicknesses. Here it is suitable to use electrodes of different working end. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. The entire spot welding process can be. Spot Welding Different Thickness Material.

From bil-ibs.be

Friction spot welding Belgian Welding Institute Spot Welding Different Thickness Material The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Spot welding of low carbon steel with different thicknesses. When the thickness difference between workpieces is within three. A considerably different situation. Spot Welding Different Thickness Material.

From waterwelders.com

What is Spot Welding? Understanding it Thoroughly WaterWelders Spot Welding Different Thickness Material Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Here it is suitable to use electrodes of different working end. A considerably different situation is at welding of sheets of thickness. Spot Welding Different Thickness Material.

From ahssinsights.org

Process, Microstructure and Fracture Mode of Thick StackUps of Spot Welding Different Thickness Material Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. When the thickness difference between workpieces is within three. Here it is suitable to use electrodes of different working end. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Spot welding of low. Spot Welding Different Thickness Material.

From marinerspointpro.com

Spot Welding Marinerspoint Pro Spot Welding Different Thickness Material These modifications allow you to weld different. Spot welding of low carbon steel with different thicknesses. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Compare spot welding with seam welding. Spot Welding Different Thickness Material.

From www.youtube.com

Basic Spot Welding YouTube Spot Welding Different Thickness Material Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Compare spot welding with seam welding and plug welding, and see. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. A considerably different situation is at welding of sheets of thickness. Spot Welding Different Thickness Material.

From www.mdpi.com

A Novel Friction Stir Deposition Technique to Refill Keyhole of Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Spot welding of low carbon steel with different thicknesses. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. A considerably. Spot Welding Different Thickness Material.

From blog.thepipingmart.com

How to Spot Weld with Sheet Metal A Complete Guide Spot Welding Different Thickness Material Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Here it is suitable to use electrodes of different working end. When the thickness difference between workpieces is within three. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. A considerably. Spot Welding Different Thickness Material.

From journals.sagepub.com

Influence of resistance spot welding process parameters on dissimilar Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. These modifications allow you to weld different. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Learn how to select and adjust. Spot Welding Different Thickness Material.

From blog.thepipingmart.com

Tack Welding vs Spot Welding What’s the Difference? Spot Welding Different Thickness Material A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Compare spot welding with seam welding and plug welding, and see. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. These modifications allow you to weld different. When the thickness difference between workpieces. Spot Welding Different Thickness Material.

From www.fleetmaintenance.com

Welding Types and Positions poster Fleet Maintenance Spot Welding Different Thickness Material These modifications allow you to weld different. When the thickness difference between workpieces is within three. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Compare spot welding with seam welding and plug welding, and see. Spot welding of low carbon steel with different thicknesses. Learn everything about. Spot Welding Different Thickness Material.

From punchlistzero.com

Spot Welding Process, Machine, Metals, and Alternatives Punchlist Zero Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. When the thickness difference between workpieces is within three. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. A considerably. Spot Welding Different Thickness Material.

From welditu.com

Types of Welding Joints and Welds Color Graphics • WelditU Spot Welding Different Thickness Material Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Spot welding of low carbon steel with different thicknesses. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Here it is suitable to use electrodes of different working end. When the. Spot Welding Different Thickness Material.

From inchbyinch.de

INCH Technical English weld types Spot Welding Different Thickness Material When the thickness difference between workpieces is within three. Spot welding of low carbon steel with different thicknesses. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. These modifications allow you to weld different. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric. Spot Welding Different Thickness Material.

From www.mdpi.com

Metals Free FullText The Role of Mechanical Connection during Spot Welding Different Thickness Material Compare spot welding with seam welding and plug welding, and see. Learn everything about spot welding, a form of resistance welding that joins sheets of metal by applying electric current and pressure. Here it is suitable to use electrodes of different working end. A considerably different situation is at welding of sheets of thickness 1 + 4.5 mm. Spot welding. Spot Welding Different Thickness Material.

From www.protocase.com

Spot Welding for Your Custom Enclosure Spot Welding Different Thickness Material These modifications allow you to weld different. The entire spot welding process can be modified by applying different pressure, electrical input, and current durations. Learn how to select and adjust resistance spot welding (rsw) parameters for different grades and thicknesses of advanced high strength steels. Compare spot welding with seam welding and plug welding, and see. Here it is suitable. Spot Welding Different Thickness Material.