Cnc Turning Face Grooving Program . The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle G72 facing cycle on a cnc lathe. The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). Precision coolant improves chip evacuation and. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. Grooving to the periphery is achieved by moving in the x axis as in face turning. G74 end face grooving cycle:. Here is a cnc programming example of g75 canned cycle grooving. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle.

from gcodetutor.com

Grooving to the periphery is achieved by moving in the x axis as in face turning. Here is a cnc programming example of g75 canned cycle grooving. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. G72 facing cycle on a cnc lathe. Precision coolant improves chip evacuation and. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle.

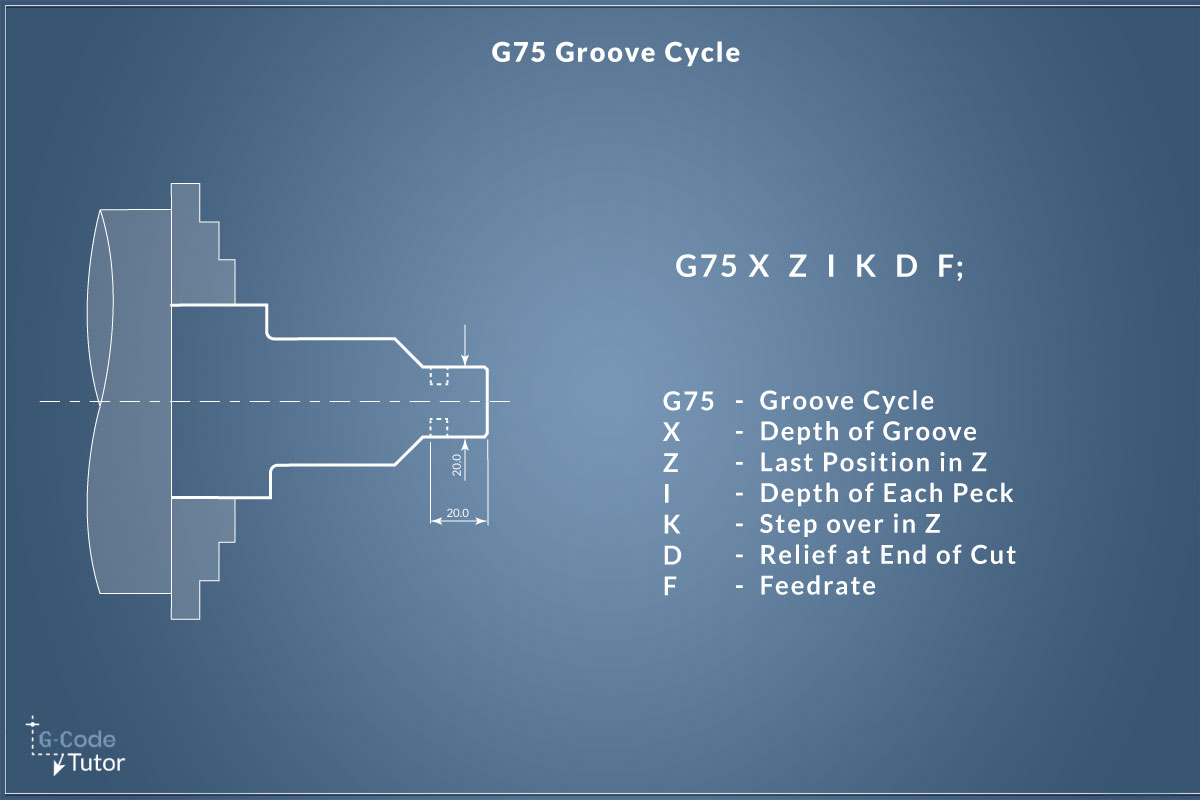

G75 Groove Cycle CNC Lathe GCode tutorial

Cnc Turning Face Grooving Program Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. G74 end face grooving cycle:. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. G72 facing cycle on a cnc lathe. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. Precision coolant improves chip evacuation and. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle Here is a cnc programming example of g75 canned cycle grooving. The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Grooving to the periphery is achieved by moving in the x axis as in face turning.

From www.mmc-carbide.com

GY Series Products MITSUBISHI MATERIALS CORPORATION Cnc Turning Face Grooving Program The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Precision coolant improves chip evacuation and. Here is a cnc programming example of g75 canned cycle grooving. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)).. Cnc Turning Face Grooving Program.

From www.youtube.com

CAMWorks Turning Tutorial 4 Face Grooving & Some Tricks YouTube Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). Precision coolant improves chip evacuation and.. Cnc Turning Face Grooving Program.

From www.youtube.com

CNC part program for FACING, TAPER TURNING & GROOVING operation on Cnc Turning Face Grooving Program The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your. Cnc Turning Face Grooving Program.

From www.youtube.com

Cnc Machine Operating With Face grooving cycle YouTube Cnc Turning Face Grooving Program The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. Here is a cnc programming example of g75 canned cycle grooving. Precision coolant improves chip evacuation and. G72 facing cycle on a cnc lathe. The cnc programming example below shows how face grooving can be machined. Cnc Turning Face Grooving Program.

From www.youtube.com

Fusion 360 Face Grooving on a CNC Lathe! FF65 YouTube Cnc Turning Face Grooving Program The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. Here is a cnc programming example of g75 canned cycle grooving. G74 end face grooving cycle:. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example. Cnc Turning Face Grooving Program.

From www.youtube.com

G74 Face Grooving Cycle in Fanuc System. G74 Cycle. G74. Face Grooving Cnc Turning Face Grooving Program The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. Grooving to the periphery is achieved by moving in the x axis as in face turning. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. With. Cnc Turning Face Grooving Program.

From www.youtube.com

G74 part2 "face grooving cycle" cnc programming for beginners in Cnc Turning Face Grooving Program Here is a cnc programming example of g75 canned cycle grooving. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle Grooving to the periphery is achieved by moving in the x axis as in face turning. The d code can be used for grooving. Cnc Turning Face Grooving Program.

From www.youtube.com

Face groov का offset कैसे लें grooving tool offset in cnc machine Cnc Turning Face Grooving Program The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). The g72 works in much the same way as the g71 but cuts in a facing. Cnc Turning Face Grooving Program.

From www.youtube.com

Grooving Cycle 2 Groove Program ShopTurn Manual Programming Cnc Turning Face Grooving Program Here is a cnc programming example of g75 canned cycle grooving. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. G72 facing cycle on a cnc lathe. G74 end face grooving cycle:. The cnc programming example below shows how face grooving can be machined with. Cnc Turning Face Grooving Program.

From cncprograming.blogspot.com

Face Grooving Cycle G74 Or Longitudinal CutOff Cycle CNC Programming Cnc Turning Face Grooving Program With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. G72 facing cycle on a cnc lathe. The cnc programming example below shows how face grooving can be machined. Cnc Turning Face Grooving Program.

From www.youtube.com

Face grooving ka Program kaise बनाएं G74 canned cycle g74 cycle Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). Grooving to the periphery is achieved by moving in the x axis as in face turning. Precision coolant improves chip evacuation and. The g72 works in much the same way. Cnc Turning Face Grooving Program.

From www.youtube.com

Part Program on CNC TurningI Design to Manufacturing CAD/CAM/CAE Cnc Turning Face Grooving Program The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle Precision coolant improves chip evacuation and. Grooving to the periphery is achieved by moving in. Cnc Turning Face Grooving Program.

From www.youtube.com

How to take Geometry offset of Grooving tool in CNC turning machine Cnc Turning Face Grooving Program Here is a cnc programming example of g75 canned cycle grooving. G72 facing cycle on a cnc lathe. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. Precision coolant improves chip evacuation and. G74 end face grooving cycle:. The d code can be used for grooving and turning to provide. Cnc Turning Face Grooving Program.

From www.youtube.com

G75 OD GROOVING CANNED CYCLE PRACTICAL How to cut groove in G75 Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. G74 end face grooving cycle:. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. Grooving to the periphery. Cnc Turning Face Grooving Program.

From www.youtube.com

CNC GROOVING CYCLE! FANUC G75 GROOVING CYCLE! CNC PROGRAMMING! CNC Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. G74 end face grooving cycle:. Fanuc g75. Cnc Turning Face Grooving Program.

From www.youtube.com

INTERNAL GROOVING PRACTICAL CNCTURNING How to cut internal groove in Cnc Turning Face Grooving Program G74 end face grooving cycle:. Precision coolant improves chip evacuation and. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Grooving to the periphery is achieved. Cnc Turning Face Grooving Program.

From mechutopia.com

CNC Lathe Grooving with G Code Examples Mechutopia Cnc Turning Face Grooving Program In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. G72 facing cycle on a cnc lathe. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. G74 end face grooving cycle:. Precision coolant improves chip evacuation and. Use. Cnc Turning Face Grooving Program.

From www.youtube.com

Internal Grooving. Inner grooving program YouTube Cnc Turning Face Grooving Program G74 end face grooving cycle:. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. The d code can be used for grooving. Cnc Turning Face Grooving Program.

From cncprograming.blogspot.com

Face Grooving Cycle G74 Or Longitudinal CutOff Cycle CNC Programming Cnc Turning Face Grooving Program The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. G74 end face grooving cycle:. The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. Grooving to the periphery is achieved by moving in the x axis as in. Cnc Turning Face Grooving Program.

From www.youtube.com

Mazatrol Programming Lathe Grooving Face Mazak YouTube Cnc Turning Face Grooving Program The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). The g72 works in much the same way as the g71 but cuts in a facing. Cnc Turning Face Grooving Program.

From www.youtube.com

Cnc turning programme Face grooving operation YouTube Cnc Turning Face Grooving Program Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. Here is a cnc programming example of g75 canned cycle grooving. Fanuc g75 grooving cycle can be used. Cnc Turning Face Grooving Program.

From gcodetutor.com

G75 Groove Cycle CNC Lathe GCode tutorial Cnc Turning Face Grooving Program G74 end face grooving cycle:. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. The d code can be used for grooving and turning to provide. Cnc Turning Face Grooving Program.

From www.youtube.com

External grooving operation cnc turning groove operation Manual Cnc Turning Face Grooving Program Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc. Cnc Turning Face Grooving Program.

From www.youtube.com

FACE GROOVING CYCLE II G74 FACE GROOVING PROGRAME II CNC PROGRAMING IN Cnc Turning Face Grooving Program With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. G74 end face grooving cycle:. Precision coolant improves chip evacuation and. Here is a cnc programming example of g75 canned cycle grooving. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low. Cnc Turning Face Grooving Program.

From www.youtube.com

types of face grooming holder face grooving face grooving tool Cnc Turning Face Grooving Program Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. G72 facing cycle on a cnc lathe. Precision coolant improves chip evacuation and.. Cnc Turning Face Grooving Program.

From www.dailymotion.com

G74 Face grooving cycle!! Face grooving cycle on cnc lathe!! Face Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine is low (7‒10 bar (102‒145 psi)). With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. The d code can be used for grooving and turning to. Cnc Turning Face Grooving Program.

From www.youtube.com

CNC turning program for face grooving in FANUC controller YouTube Cnc Turning Face Grooving Program Grooving to the periphery is achieved by moving in the x axis as in face turning. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. The d code can be used for grooving and turning to provide material clearance when returning to starting plane s.. Cnc Turning Face Grooving Program.

From www.youtube.com

cnc turning facing cycle program cnc program for step turning Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. Here is a cnc programming example of g75 canned cycle grooving. Fanuc g75 grooving cycle can be used for outside (external) or inside (internal) grooving, here is a cnc program example with fanuc g75 grooving cycle The g72 works in much the same way as the g71 but cuts in a facing direction. Cnc Turning Face Grooving Program.

From www.youtube.com

Grooving On CNC Lathes // CNC Lathe Grooving Program // YouTube Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the part. Here is a cnc programming example of g75 canned cycle grooving. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned. Cnc Turning Face Grooving Program.

From www.youtube.com

Multiple operational CNC programming Turning Chamfer Grooving and Cnc Turning Face Grooving Program G74 end face grooving cycle:. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. Precision coolant improves chip evacuation and. Here is a cnc programming example of g75 canned cycle grooving. Use face grooving tools with precision coolant supply even if the maximum coolant pressure in your machine. Cnc Turning Face Grooving Program.

From www.youtube.com

OD GROOVING PRACTICAL IN CNC TURNNG What is od grooving How to do Cnc Turning Face Grooving Program Grooving to the periphery is achieved by moving in the x axis as in face turning. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned. Cnc Turning Face Grooving Program.

From www.youtube.com

Multiple tool programming practical Turning grooving and Threading Cnc Turning Face Grooving Program The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. With face grooving operations the tool is fed axially rather than radially toward the end surface of the workpiece. G74 end face grooving cycle:. G72 facing cycle on a cnc lathe. Use face grooving tools with precision coolant supply even. Cnc Turning Face Grooving Program.

From www.youtube.com

Face grooving and Neutral CNC turning toolsAll tools of CNC machine Cnc Turning Face Grooving Program The cnc programming example below shows how face grooving can be machined with the help of g74 peck drilling canned cycle. Here is a cnc programming example of g75 canned cycle grooving. G72 facing cycle on a cnc lathe. In the cnc lathe, a channel can be opened on the cylindrical surface as well as on the forehead of the. Cnc Turning Face Grooving Program.

From www.youtube.com

CNC turning programme G75 OD grooving cycle.cnc Fanuc control YouTube Cnc Turning Face Grooving Program G72 facing cycle on a cnc lathe. Precision coolant improves chip evacuation and. The g72 works in much the same way as the g71 but cuts in a facing direction towards the centre line of the part. Here is a cnc programming example of g75 canned cycle grooving. With face grooving operations the tool is fed axially rather than radially. Cnc Turning Face Grooving Program.

From www.youtube.com

face grooving grooving cycle grooving inserts cnc turning Cnc Turning Face Grooving Program The d code can be used for grooving and turning to provide material clearance when returning to starting plane s. G72 facing cycle on a cnc lathe. Grooving to the periphery is achieved by moving in the x axis as in face turning. The cnc programming example below shows how face grooving can be machined with the help of g74. Cnc Turning Face Grooving Program.