Mig Welding How Much Gas Flow . These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. This chart can help figure out what flow rate you need based on the size Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Be aware of the unit of measurement. Typically, you need 15 to 40. But make sure to take into account the different variables while selecting the flow rate. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding.

from www.open.edu

But make sure to take into account the different variables while selecting the flow rate. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. This chart can help figure out what flow rate you need based on the size Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Typically, you need 15 to 40. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job. These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. The correct gas flow rate in mig welding ranges between 15 to 25 cfh.

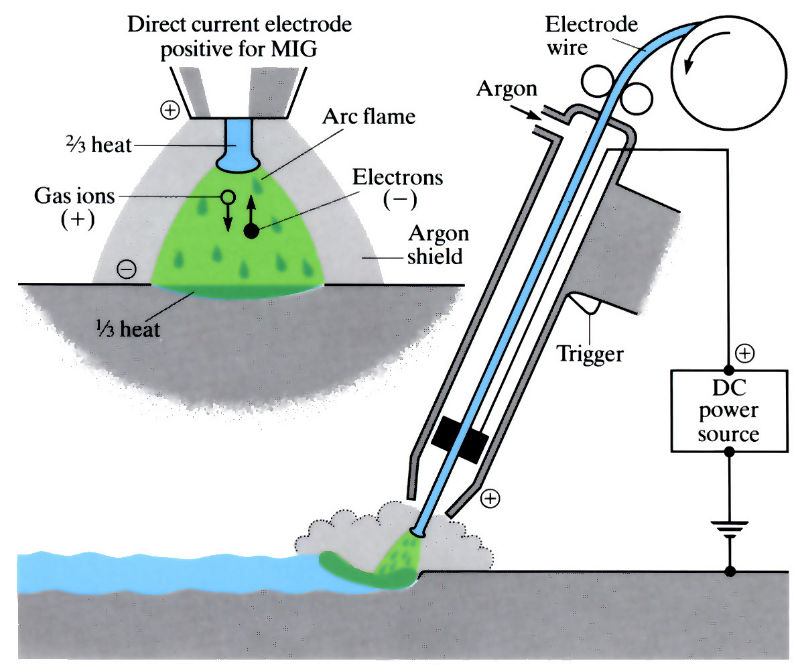

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open

Mig Welding How Much Gas Flow To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. This chart can help figure out what flow rate you need based on the size Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job. Be aware of the unit of measurement. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Typically, you need 15 to 40. But make sure to take into account the different variables while selecting the flow rate.

From www.twi-global.com

Metal Inert Gas (MIG) Welding Process and Applications TWI Mig Welding How Much Gas Flow This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. To figure out how much pressure and the flow rate is. Mig Welding How Much Gas Flow.

From www.youtube.com

Gas Flow Settings for MIG & TIG Welding YouTube Mig Welding How Much Gas Flow This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. This chart can help figure out what flow rate you need based on the size To figure out how much pressure and the flow rate is needed for the shield gas,. Mig Welding How Much Gas Flow.

From weldempire.com

What Should Be the Gas Pressure for MIG Welding? Weld Empire Mig Welding How Much Gas Flow This chart can help figure out what flow rate you need based on the size The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Setting. Mig Welding How Much Gas Flow.

From itstillruns.com

How to Set the Gas on an MIG Welder It Still Runs Mig Welding How Much Gas Flow To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Be. Mig Welding How Much Gas Flow.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Mig Welding How Much Gas Flow But make sure to take into account the different variables while selecting the flow rate. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for. Mig Welding How Much Gas Flow.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding How Much Gas Flow Typically, you need 15 to 40. This chart can help figure out what flow rate you need based on the size Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. But make sure to take into account the different variables while selecting the flow rate. The gas flow rate. Mig Welding How Much Gas Flow.

From weldingmastermind.com

MIG Gas Settings How to Set Gas on MIG Welder Welding Mastermind Mig Welding How Much Gas Flow Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. This article will show you how. Mig Welding How Much Gas Flow.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Mig Welding How Much Gas Flow But make sure to take into account the different variables while selecting the flow rate. Typically, you need 15 to 40. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. To figure out how much pressure and the flow. Mig Welding How Much Gas Flow.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Mig Welding How Much Gas Flow Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Typically, you need 15 to 40. Be aware of the. Mig Welding How Much Gas Flow.

From mavink.com

Mig Welding Gas Flow Chart Mig Welding How Much Gas Flow These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to. Mig Welding How Much Gas Flow.

From mavink.com

Mig Welding Gas Flow Chart Mig Welding How Much Gas Flow Typically, you need 15 to 40. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. These parameters can vary depending. Mig Welding How Much Gas Flow.

From www.cushyfamily.com

How Much Gas To Use When Mig Welding? (Answer Inside!) Mig Welding How Much Gas Flow These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. Setting up a mig welder involves adjusting several parameters, such as. Mig Welding How Much Gas Flow.

From mechanicaljungle.com

How to weld with flux core? What Is Shielding Gas Used for Fluxes Mig Welding How Much Gas Flow Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. But make sure to take into account the different variables while selecting the flow rate. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding. Mig Welding How Much Gas Flow.

From fractory.com

MIG Welding Explained Fractory Mig Welding How Much Gas Flow These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. This chart can help. Mig Welding How Much Gas Flow.

From www.perfectwelders.com

How To Optimize MIG Welding Shielding Gas Pressure PERFECT POWER Mig Welding How Much Gas Flow The correct gas flow rate in mig welding ranges between 15 to 25 cfh. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to. Mig Welding How Much Gas Flow.

From workshopinsider.com

Gas Metal Arc Welding (GMAW) MIG Welding Guide Mig Welding How Much Gas Flow But make sure to take into account the different variables while selecting the flow rate. This chart can help figure out what flow rate you need based on the size Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job.. Mig Welding How Much Gas Flow.

From electricalworkbook.com

What is Metal Inert Gas Arc (MIG) Welding? Process, Diagram, Advantages Mig Welding How Much Gas Flow But make sure to take into account the different variables while selecting the flow rate. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. To figure out how much pressure and the flow rate is needed for the shield gas, you need. Mig Welding How Much Gas Flow.

From mavink.com

Mig Welding Gas Flow Rate Chart Mig Welding How Much Gas Flow This chart can help figure out what flow rate you need based on the size These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. But make sure to take into account the different variables while selecting the flow rate. To. Mig Welding How Much Gas Flow.

From prowelderguide.com

Mig Welding Gas Best Types, Guide, TIG and Charts Pro Welder Guide Mig Welding How Much Gas Flow Typically, you need 15 to 40. But make sure to take into account the different variables while selecting the flow rate. This chart can help figure out what flow rate you need based on the size Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment.. Mig Welding How Much Gas Flow.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding How Much Gas Flow Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. This chart can help figure out what flow rate you need based on the size Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding. Mig Welding How Much Gas Flow.

From makemoneywelding.com

Explained Best MIG Welding Shielding Gas To Use Mig Welding How Much Gas Flow To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. This chart can help figure out what flow rate you need based on the size These parameters can vary depending on the type and thickness of the metal being welded,. Mig Welding How Much Gas Flow.

From www.technoxmachine.com

MIG vs TIG Welding Types, Materials, and Applications A Guide Mig Welding How Much Gas Flow This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. Be aware of the unit of measurement. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the. Mig Welding How Much Gas Flow.

From rst-web.com

Selecting the Right Shielding Gas For Your Welding Process RonSon's Mig Welding How Much Gas Flow The correct gas flow rate in mig welding ranges between 15 to 25 cfh. To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage,. Mig Welding How Much Gas Flow.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Mig Welding How Much Gas Flow Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. These parameters can vary depending on. Mig Welding How Much Gas Flow.

From www.open.edu

Gas shielded arc welding processes (TIG/MIG/MAG) OpenLearn Open Mig Welding How Much Gas Flow Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should be used with. Typically, you need 15 to 40. Be aware of the unit of measurement. Gas flow is primarily measured in cubic feet per hour, how much gas is being released each hour of use.. Mig Welding How Much Gas Flow.

From makemoneywelding.com

MIG Welding Gas Pressure Settings Mig Welding How Much Gas Flow This chart can help figure out what flow rate you need based on the size The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. Also, take into account the suggested gas flow rates for metals like aluminum or stainless. Mig Welding How Much Gas Flow.

From gowelding.org

MIG Welding How to MIG Weld, Process Overview and Machine Set Up Mig Welding How Much Gas Flow But make sure to take into account the different variables while selecting the flow rate. Be aware of the unit of measurement. Typically, you need 15 to 40. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job. Gas flow. Mig Welding How Much Gas Flow.

From fractory.com

OxyAcetylene Welding Explained Gas Welding Fractory Mig Welding How Much Gas Flow Be aware of the unit of measurement. These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should. Mig Welding How Much Gas Flow.

From www.youtube.com

Mig Welding Gas Setup Made Simple YouTube Mig Welding How Much Gas Flow Typically, you need 15 to 40. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed, voltage, and shielding gas flow rate, to match the welding requirements of the specific job. Also, take into account the suggested gas flow rates for metals like aluminum or stainless steel which also have a specific gas they should. Mig Welding How Much Gas Flow.

From weldguru.com

Best Gas for MIG Welding What to Use (with Chart) Mig Welding How Much Gas Flow This chart can help figure out what flow rate you need based on the size To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. Setting up a mig welder involves adjusting several parameters, such as the wire feed speed,. Mig Welding How Much Gas Flow.

From weldguru.com

4 Main Types of Welding Processes (with diagrams) Mig Welding How Much Gas Flow Be aware of the unit of measurement. This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. This chart can help figure out what flow rate you. Mig Welding How Much Gas Flow.

From www.wcwelding.com

Shielding Gas Guide Mig Welding How Much Gas Flow Gas flow rate is typically measured in either cubic feet per hour (cfh) or liters per minute (lpm), depending on your location and equipment. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job. Setting up a mig welder involves. Mig Welding How Much Gas Flow.

From www.cwbgroup.org

How is Argon Used in MIG Welding and how do MIG and MAG Welding Differ Mig Welding How Much Gas Flow Typically, you need 15 to 40. Be aware of the unit of measurement. The correct gas flow rate in mig welding ranges between 15 to 25 cfh. But make sure to take into account the different variables while selecting the flow rate. This chart can help figure out what flow rate you need based on the size Also, take into. Mig Welding How Much Gas Flow.

From weldguru.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding How Much Gas Flow This article will show you how to set the flow rate of gas, the minimum and maximum values and the optimal gas shielding settings for the most common welding. These parameters can vary depending on the type and thickness of the metal being welded, the type of wire and shielding gas used, and the position of the weld. The correct. Mig Welding How Much Gas Flow.

From weldingzilla.com

MIG Welding Gas Pressure Settings (with Charts) Mig Welding How Much Gas Flow To figure out how much pressure and the flow rate is needed for the shield gas, you need the shroud diameter which is the tip of the mig welding handle. The gas flow rate which is measured in cubic feet per hour (cfh) gives us a rough idea about how much gas to have prior to a mig welding job.. Mig Welding How Much Gas Flow.