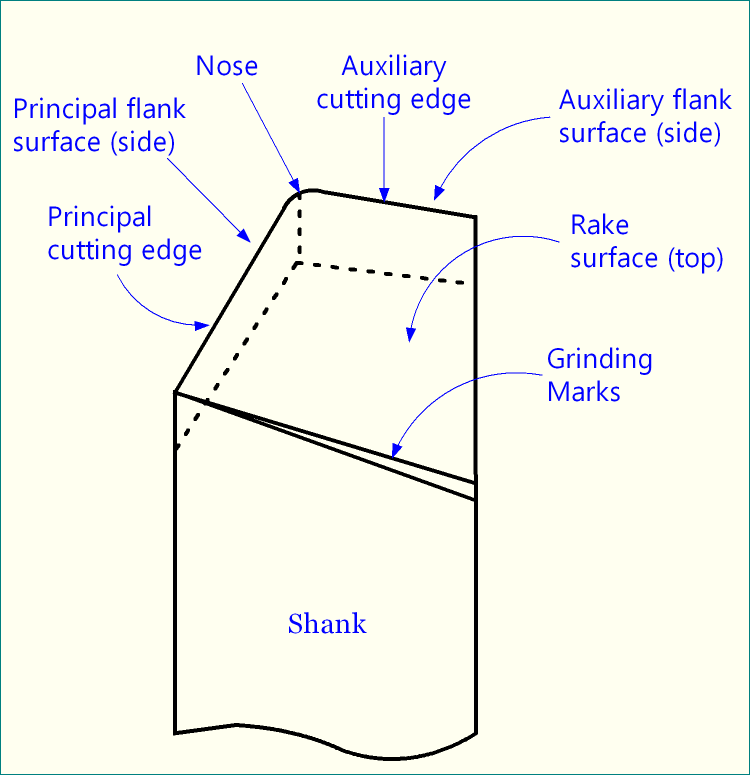

Shank In Single Point Cutting Tool . Held securely by the tool post, it provides stability and. It is the surface below and adjacent to. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. They may be left or right. The main body of the tool is known as the shank. The top surface tool on which chips passes after. Design of single point cutting tool is an important aspect of tool engineering. It is the backward part of the tool which is held by tool post. Understand the orthogonal and oblique cutting characteristics,. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. This unit deals with the design of tool shank, design of single point. It is that part of a single point cutting tool which goes into the tool holder. Or in simple language shank is used to hold the tool.

from www.minaprem.com

The top surface tool on which chips passes after. It is the surface below and adjacent to. It is that part of a single point cutting tool which goes into the tool holder. Design of single point cutting tool is an important aspect of tool engineering. It is the backward part of the tool which is held by tool post. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. They may be left or right. Understand the orthogonal and oblique cutting characteristics,. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. This unit deals with the design of tool shank, design of single point.

What is Single Point Turning Tool (SPTT)?

Shank In Single Point Cutting Tool They may be left or right. The top surface tool on which chips passes after. The main body of the tool is known as the shank. It is that part of a single point cutting tool which goes into the tool holder. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. It is the backward part of the tool which is held by tool post. Design of single point cutting tool is an important aspect of tool engineering. Understand the orthogonal and oblique cutting characteristics,. Held securely by the tool post, it provides stability and. It is the surface below and adjacent to. This unit deals with the design of tool shank, design of single point. They may be left or right. Or in simple language shank is used to hold the tool.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Shank In Single Point Cutting Tool They may be left or right. It is the surface below and adjacent to. Design of single point cutting tool is an important aspect of tool engineering. It is the backward part of the tool which is held by tool post. Or in simple language shank is used to hold the tool. Held securely by the tool post, it provides. Shank In Single Point Cutting Tool.

From dizz.com

Single Point Cutting ToolDefinition, Geometry, Nomenclature, Angle PDF Shank In Single Point Cutting Tool Design of single point cutting tool is an important aspect of tool engineering. They may be left or right. It is the surface below and adjacent to. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. This unit deals with the design of tool shank, design of single point. Held securely. Shank In Single Point Cutting Tool.

From learnmechanical.com

Single Point Cutting Tool Definition, Types, Geometry, Nomenclature Shank In Single Point Cutting Tool The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. Design of single point cutting tool is an important aspect of tool engineering. They may be left or right. This unit deals with. Shank In Single Point Cutting Tool.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Shank In Single Point Cutting Tool The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Or in simple language shank is used to hold the tool. It is the surface below and adjacent to. It is that part of a single point cutting tool which goes into the tool holder. Understand the orthogonal and oblique cutting. Shank In Single Point Cutting Tool.

From www.youtube.com

Single Point Cutting Tool, Tool Signature and Cutting tool Material Shank In Single Point Cutting Tool Or in simple language shank is used to hold the tool. Design of single point cutting tool is an important aspect of tool engineering. Held securely by the tool post, it provides stability and. It is the backward part of the tool which is held by tool post. The main body of the tool is known as the shank. The. Shank In Single Point Cutting Tool.

From www.youtube.com

Single Point Cutting Tool Geometry SolidWorks 2016 YouTube Shank In Single Point Cutting Tool It is that part of a single point cutting tool which goes into the tool holder. This unit deals with the design of tool shank, design of single point. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Design of single point cutting tool is an important aspect of tool. Shank In Single Point Cutting Tool.

From www.researchgate.net

Geometry of singlepoint cutting tool Download Scientific Diagram Shank In Single Point Cutting Tool The main body of the tool is known as the shank. Held securely by the tool post, it provides stability and. Or in simple language shank is used to hold the tool. They may be left or right. Understand the orthogonal and oblique cutting characteristics,. The top surface tool on which chips passes after. It is that part of a. Shank In Single Point Cutting Tool.

From www.youtube.com

Everything About Single Point Cutting Tool Explained Geometry Parts Shank In Single Point Cutting Tool The top surface tool on which chips passes after. It is that part of a single point cutting tool which goes into the tool holder. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. Understand the orthogonal and oblique cutting characteristics,. Or in simple language shank is used to hold the. Shank In Single Point Cutting Tool.

From www.mechanicalbooster.com

Single Point Cutting Tool Geometry, Angles, Nomenclature and Signature Shank In Single Point Cutting Tool This unit deals with the design of tool shank, design of single point. Or in simple language shank is used to hold the tool. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. It is that part of a single point cutting tool which goes into the tool holder. Understand the. Shank In Single Point Cutting Tool.

From www.riansclub.com

Single Point Cutting Tool Definition, Geometry, Nomenclature, And Shank In Single Point Cutting Tool Understand the orthogonal and oblique cutting characteristics,. The main body of the tool is known as the shank. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. It is the backward part of the tool which is held by tool post. The shank refers to the clamped section of the tool,. Shank In Single Point Cutting Tool.

From www.themachinedesign.com

Single Point Cutting Tool Nomenclature, Geometry The Machine Design Shank In Single Point Cutting Tool They may be left or right. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. It is the backward part of the tool which is held by tool post. Or in simple language shank is used to hold the tool. The top surface tool on which chips passes after. Held. Shank In Single Point Cutting Tool.

From mechanicalbasics.com

Single Point Cutting Tool With FAQ's Mechanical Basics Shank In Single Point Cutting Tool Held securely by the tool post, it provides stability and. The top surface tool on which chips passes after. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. It is the backward part of the tool which is held by tool post. The shank refers to the clamped section of the. Shank In Single Point Cutting Tool.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Shank In Single Point Cutting Tool This unit deals with the design of tool shank, design of single point. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. Or in simple language shank is used to hold the tool. Design of single point cutting tool is an important aspect of tool engineering. They may be left or. Shank In Single Point Cutting Tool.

From www.researchgate.net

1) shows elements of singlepoint tool Download Scientific Diagram Shank In Single Point Cutting Tool Design of single point cutting tool is an important aspect of tool engineering. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. It is the surface below and adjacent to. This unit deals with the design of tool shank, design of single point. The main body of the tool is known. Shank In Single Point Cutting Tool.

From www.youtube.com

Cutting tool signature Geometry of single point cutting tool YouTube Shank In Single Point Cutting Tool The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. It is the backward part of the tool which is held by tool post. The top surface tool on which chips passes after. Design of single point cutting tool is an important aspect of tool engineering. Understand the orthogonal and oblique. Shank In Single Point Cutting Tool.

From www.youtube.com

Tool Nomenclature of Single Point Cutting Tool ENGINEERING STUDY Shank In Single Point Cutting Tool This unit deals with the design of tool shank, design of single point. They may be left or right. Design of single point cutting tool is an important aspect of tool engineering. The main body of the tool is known as the shank. It is the surface below and adjacent to. Or in simple language shank is used to hold. Shank In Single Point Cutting Tool.

From www.elabengineeringequipments.com

Single Point Cutting Tool Manufacturers India, Suppliers UAE (Dubai Shank In Single Point Cutting Tool They may be left or right. The top surface tool on which chips passes after. The main body of the tool is known as the shank. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. It is that part of a single point cutting tool which goes into the tool holder.. Shank In Single Point Cutting Tool.

From www.youtube.com

02_02 Geometry of a Single Point Cutting Tool YouTube Shank In Single Point Cutting Tool The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. They may be left or right. The main body of the tool is known as the shank. It is that part of a single point cutting tool which goes into the tool holder. This unit deals with the design of tool. Shank In Single Point Cutting Tool.

From toolnotes.com

Lathe Tools and Toolholders ToolNotes Shank In Single Point Cutting Tool It is the backward part of the tool which is held by tool post. Or in simple language shank is used to hold the tool. Understand the orthogonal and oblique cutting characteristics,. This unit deals with the design of tool shank, design of single point. The shank refers to the clamped section of the tool, constituting the main body situated. Shank In Single Point Cutting Tool.

From www.theengineerspost.com

Single Point Cutting Tool Diagram, Nomenclature, Material [PDF] Shank In Single Point Cutting Tool The top surface tool on which chips passes after. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. It is that part of a single point cutting tool which goes into the tool holder. It is the backward part of the tool which is held by tool post. This unit. Shank In Single Point Cutting Tool.

From www.minaprem.com

What is Single Point Turning Tool (SPTT)? Shank In Single Point Cutting Tool The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. This unit deals with the design of tool shank, design of single point. Understand the orthogonal and oblique cutting characteristics,. Or in simple language shank is used to hold the tool. The main body of the tool is known as the. Shank In Single Point Cutting Tool.

From www.indiamart.com

Single Point Brazed Cutting Tools at best price in Pune by GTR Shank In Single Point Cutting Tool Understand the orthogonal and oblique cutting characteristics,. The main body of the tool is known as the shank. Held securely by the tool post, it provides stability and. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems. Shank In Single Point Cutting Tool.

From mechtech69.blogspot.com

SINGLE POINT CUTTING TOOL NOMENCLATURE (DRAWING , GEOMETRY , ELEMENT Shank In Single Point Cutting Tool Held securely by the tool post, it provides stability and. This unit deals with the design of tool shank, design of single point. The main body of the tool is known as the shank. It is that part of a single point cutting tool which goes into the tool holder. They may be left or right. It is the surface. Shank In Single Point Cutting Tool.

From www.youtube.com

What is shank. Why do we use shank in press tool. Shank क्या होता है Shank In Single Point Cutting Tool It is the backward part of the tool which is held by tool post. The top surface tool on which chips passes after. They may be left or right. Or in simple language shank is used to hold the tool. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Design. Shank In Single Point Cutting Tool.

From www.theengineerspost.com

Single Point Cutting Tool Diagram, Nomenclature, Material [PDF] Shank In Single Point Cutting Tool Held securely by the tool post, it provides stability and. It is the surface below and adjacent to. The top surface tool on which chips passes after. They may be left or right. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Learn about the tool geometry, tool angles, tool. Shank In Single Point Cutting Tool.

From www.green-mechanic.com

Green Mechanic Explain single point cutting tool geometry, angles and Shank In Single Point Cutting Tool It is the backward part of the tool which is held by tool post. Understand the orthogonal and oblique cutting characteristics,. The main body of the tool is known as the shank. It is that part of a single point cutting tool which goes into the tool holder. It is the surface below and adjacent to. Learn about the tool. Shank In Single Point Cutting Tool.

From grabcad.com

Free CAD Designs, Files & 3D Models The GrabCAD Community Library Shank In Single Point Cutting Tool Design of single point cutting tool is an important aspect of tool engineering. It is the surface below and adjacent to. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. Understand the orthogonal and oblique cutting characteristics,. Or in simple language shank is used to hold the tool. It is the. Shank In Single Point Cutting Tool.

From www.youtube.com

SINGLE POINT CUTTING TOOL TECHNOLOGY ALL ANGLES WITH Shank In Single Point Cutting Tool Design of single point cutting tool is an important aspect of tool engineering. Understand the orthogonal and oblique cutting characteristics,. The top surface tool on which chips passes after. Held securely by the tool post, it provides stability and. They may be left or right. Or in simple language shank is used to hold the tool. It is the backward. Shank In Single Point Cutting Tool.

From slideplayer.com

Session 2 Classification of cutting tools ppt download Shank In Single Point Cutting Tool The top surface tool on which chips passes after. Held securely by the tool post, it provides stability and. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. It is the surface below and adjacent to. It is that part of a single point cutting tool which goes into the. Shank In Single Point Cutting Tool.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Shank In Single Point Cutting Tool Held securely by the tool post, it provides stability and. Design of single point cutting tool is an important aspect of tool engineering. This unit deals with the design of tool shank, design of single point. Or in simple language shank is used to hold the tool. It is the backward part of the tool which is held by tool. Shank In Single Point Cutting Tool.

From dizz.com

Single Point Cutting Tool Vs. Multi Point Cutting Tools [PDF] Design Shank In Single Point Cutting Tool Understand the orthogonal and oblique cutting characteristics,. The main body of the tool is known as the shank. It is the backward part of the tool which is held by tool post. They may be left or right. This unit deals with the design of tool shank, design of single point. The top surface tool on which chips passes after.. Shank In Single Point Cutting Tool.

From sarkarilibrary.in

Single Point Cutting Tool and its main Parts SARKARI LIBRARY Shank In Single Point Cutting Tool It is the backward part of the tool which is held by tool post. Understand the orthogonal and oblique cutting characteristics,. It is the surface below and adjacent to. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. The top surface tool on which chips passes after. This unit deals with. Shank In Single Point Cutting Tool.

From www.mech4study.com

Single Point Cutting Tool Nomenclature, Angle,Geometry and Signature Shank In Single Point Cutting Tool It is the surface below and adjacent to. The main body of the tool is known as the shank. Held securely by the tool post, it provides stability and. The shank refers to the clamped section of the tool, constituting the main body situated beside the cutting point. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion. Shank In Single Point Cutting Tool.

From www.youtube.com

Fabrication of single point cutting tool as per given tool signature Shank In Single Point Cutting Tool It is the surface below and adjacent to. This unit deals with the design of tool shank, design of single point. Learn about the tool geometry, tool angles, tool nomenclature and tool conversion systems for single point cutting tools. The top surface tool on which chips passes after. Design of single point cutting tool is an important aspect of tool. Shank In Single Point Cutting Tool.

From www.slideshare.net

Single Point Cutting Tool Shank In Single Point Cutting Tool It is the surface below and adjacent to. Or in simple language shank is used to hold the tool. The top surface tool on which chips passes after. The main body of the tool is known as the shank. It is that part of a single point cutting tool which goes into the tool holder. It is the backward part. Shank In Single Point Cutting Tool.