Liquid Silicone Molding Medical . lsr injection molding is an ideal production method for a range of medical products. Cold runner, fully automated work. injection filled mold for liquid silicone: design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. medical silicone can be either colourless or produced in a wide range of colours. This is the most common method used to form a single continuous silicone prototype using. Applications include drug delivery, such as primary drug packaging or. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. The main characteristics of lsr that benefit this type of. Medical liquid silicone has excellent resistance to. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors.

from www.better-silicone.com

injection filled mold for liquid silicone: design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. Cold runner, fully automated work. This is the most common method used to form a single continuous silicone prototype using. The main characteristics of lsr that benefit this type of. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Medical liquid silicone has excellent resistance to. Applications include drug delivery, such as primary drug packaging or. medical silicone can be either colourless or produced in a wide range of colours.

LSR Moulding for Medical Grade Liquid Silicone Tubing from China

Liquid Silicone Molding Medical Applications include drug delivery, such as primary drug packaging or. Cold runner, fully automated work. lsr injection molding is an ideal production method for a range of medical products. medical silicone can be either colourless or produced in a wide range of colours. The main characteristics of lsr that benefit this type of. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Applications include drug delivery, such as primary drug packaging or. injection filled mold for liquid silicone: design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. This is the most common method used to form a single continuous silicone prototype using. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Medical liquid silicone has excellent resistance to.

From konarksilicones.com

MedicalGrade Silicone Types of Silicone Konark Silicones Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. injection filled mold for liquid silicone: liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. This is the most common method used to form a single continuous silicone prototype using. learn about liquid silicone rubber injection molding. Liquid Silicone Molding Medical.

From www.youtube.com

Liquid Silicone Injection Molding Process for medical grade LSR Brushes Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. medical silicone can be either colourless or produced in a wide range of colours. The main characteristics of lsr that benefit this type of. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle. Liquid Silicone Molding Medical.

From www.lsrinjectionmoldingmachine.com

Silicone Medical Device Liquid Silicone Injection Molding Making Machine Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. The main characteristics of lsr that benefit this type of. lsr injection molding is an ideal production method for a range of medical products. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. This is the most common. Liquid Silicone Molding Medical.

From www.better-silicone.com

Medical Grade Liquid Silicone Injection Mold LSR Injection Mould from Liquid Silicone Molding Medical The main characteristics of lsr that benefit this type of. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Medical liquid silicone has excellent resistance to. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. lsr injection molding is an ideal. Liquid Silicone Molding Medical.

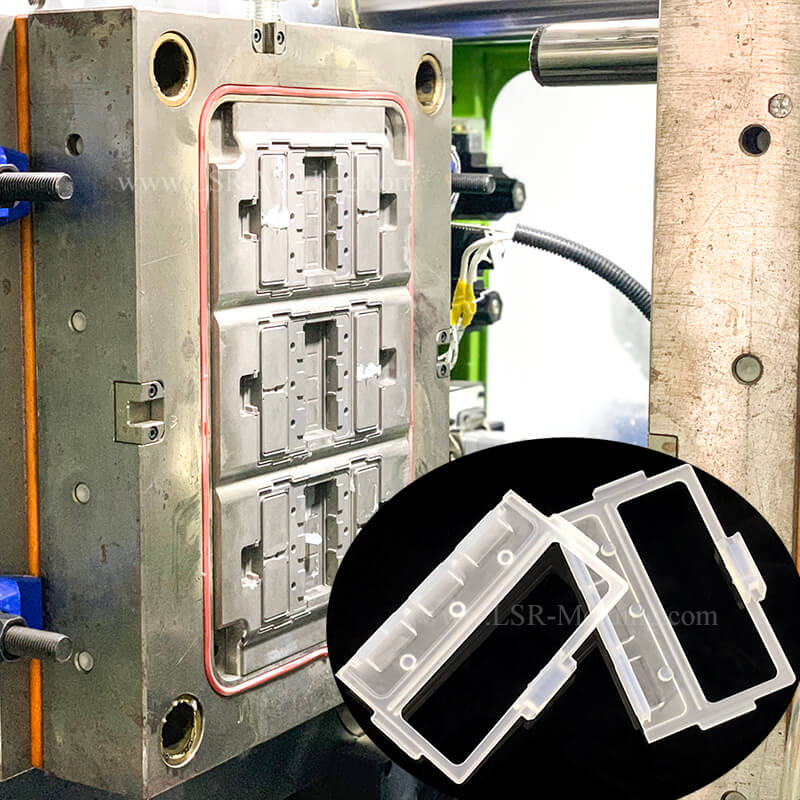

From www.lsr-molding.com

Silicone Injection Molding LSR Molding Liquid Silicone Molding Factory Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Applications include drug delivery, such as primary drug packaging or. lsr injection molding is an ideal production method for a range of medical products. medical silicone can be either colourless or produced in a wide range of colours. Cold runner, fully automated work.. Liquid Silicone Molding Medical.

From bettersilicone.en.made-in-china.com

Liquid Silicone Injection Molding for Medical Products China Liquid Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. This is the most common method used to form a single continuous silicone prototype using. Applications include drug delivery, such as primary drug packaging or. injection filled mold for liquid silicone: Medical liquid silicone has excellent resistance to. lsr injection molding is an. Liquid Silicone Molding Medical.

From www.better-silicone.com

Liquid Silicone Injection Molding LSR Mold Silicone Injection Liquid Silicone Molding Medical Medical liquid silicone has excellent resistance to. The main characteristics of lsr that benefit this type of. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Applications include drug delivery, such as primary. Liquid Silicone Molding Medical.

From biomedisca.com

Plastic Injection Molding for Medical Device Industry Biomedisca Liquid Silicone Molding Medical The main characteristics of lsr that benefit this type of. injection filled mold for liquid silicone: learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. This is the most common method used to form a single continuous silicone prototype using. Cold runner, fully automated work. lsr. Liquid Silicone Molding Medical.

From www.better-silicone.com

Liquid Silicone Injection Molding LSR Mold Silicone Injection Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Applications include drug delivery, such as primary drug packaging or. Cold runner, fully automated work. This is the most common method used to form a single continuous silicone prototype using. medical silicone can be either colourless or produced in a wide range of colours.. Liquid Silicone Molding Medical.

From www.lsrliquidsiliconerubber.com

High Transparent Medical Grade Liquid Silicone Rubber Molding For Liquid Silicone Molding Medical This is the most common method used to form a single continuous silicone prototype using. lsr injection molding is an ideal production method for a range of medical products. Cold runner, fully automated work. injection filled mold for liquid silicone: medical silicone can be either colourless or produced in a wide range of colours. learn about. Liquid Silicone Molding Medical.

From www.smcltd.com

Silicone Injection Molding Tips for Medical Industry SMC Liquid Silicone Molding Medical learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. This is the most common method used to form a single continuous silicone prototype using. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. medical silicone can be either colourless or produced. Liquid Silicone Molding Medical.

From www.melon-rubber.com

Liquid Silicone Rubber Injection Molding Medical Laryngeal Mask Airway Liquid Silicone Molding Medical The main characteristics of lsr that benefit this type of. medical silicone can be either colourless or produced in a wide range of colours. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Medical liquid silicone has excellent resistance to. lsr injection molding is an ideal. Liquid Silicone Molding Medical.

From www.better-silicone.com

LSR Moulding for Medical Grade Liquid Silicone Tubing from China Liquid Silicone Molding Medical learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Applications include drug delivery, such as primary drug packaging or. injection filled mold for liquid silicone: liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. lsr injection molding is an ideal. Liquid Silicone Molding Medical.

From www.lsr-molding.com

Silicone Injection Molding LSR Molding Liquid Silicone Molding Factory Liquid Silicone Molding Medical lsr injection molding is an ideal production method for a range of medical products. This is the most common method used to form a single continuous silicone prototype using. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. Medical liquid silicone has excellent resistance to. liquid silicone rubber is ideal for medical. Liquid Silicone Molding Medical.

From www.ahyrsilicon.com

Clear Injection Molding Non Toxic Medical Grade Liquid Silicone Rubber Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. medical silicone can be either colourless or produced in a wide range of colours. The main characteristics of lsr that benefit this type of. lsr injection molding is an ideal production method for a range of medical products. Applications include drug delivery, such. Liquid Silicone Molding Medical.

From elimold.com

Liquid Silicone Rubber Injection Molding Rubber Parts Elimold Liquid Silicone Molding Medical This is the most common method used to form a single continuous silicone prototype using. The main characteristics of lsr that benefit this type of. lsr injection molding is an ideal production method for a range of medical products. injection filled mold for liquid silicone: Applications include drug delivery, such as primary drug packaging or. liquid silicone. Liquid Silicone Molding Medical.

From www.better-silicone.com

Liquid Silicone Injection Molding for Medical Products from China Liquid Silicone Molding Medical lsr injection molding is an ideal production method for a range of medical products. Medical liquid silicone has excellent resistance to. injection filled mold for liquid silicone: The main characteristics of lsr that benefit this type of. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. liquid silicone rubber is ideal. Liquid Silicone Molding Medical.

From www.grommetseal.com

Liquid Silicone Mold LSR Mold Liquid Injection Mold Liquid Silicone Molding Medical Medical liquid silicone has excellent resistance to. This is the most common method used to form a single continuous silicone prototype using. medical silicone can be either colourless or produced in a wide range of colours. lsr injection molding is an ideal production method for a range of medical products. injection filled mold for liquid silicone: Cold. Liquid Silicone Molding Medical.

From www.lsr-molding.com

Liquid Silicone Overmolding LSR Injection Overmolding Design Guide Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. This is the most common method used to form a single continuous silicone prototype using. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. The main characteristics of lsr that benefit this type. Liquid Silicone Molding Medical.

From www.ametekemc.com

Liquid Silicone Rubber (LSR) Molding expertise supports improvements in Liquid Silicone Molding Medical learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Applications include drug delivery, such as primary drug packaging or. lsr injection molding is an ideal production method for a range of medical products. medical silicone can be either colourless or produced in a wide range of. Liquid Silicone Molding Medical.

From www.plax.it

Medical silicone molding Plax Group Liquid Silicone Molding Medical learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. lsr injection molding is an ideal production method for a range of medical products. This is the most common method used to form a single continuous silicone prototype using. medical silicone can be either colourless or produced. Liquid Silicone Molding Medical.

From www.alibaba.com

Medical Grade Liquid Silicone Molding Rtv2 Addition Cure Silicone Buy Liquid Silicone Molding Medical Cold runner, fully automated work. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Medical liquid silicone has excellent resistance to. The main characteristics of lsr that benefit this type of. medical silicone can be either colourless or produced in a wide range of colours. injection. Liquid Silicone Molding Medical.

From www.alibaba.com

Liquid Silicone Manufacture Medical Grade Liquid Silicone For Injection Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. Cold runner, fully automated work. injection filled mold for liquid silicone: medical silicone can be either colourless or produced in a wide range of colours. Medical liquid silicone has excellent resistance to. Applications include drug delivery, such as primary drug packaging or. . Liquid Silicone Molding Medical.

From www.rtv2siliconerubber.com

Medical Grade Silicone Rubber for Body Parts Casting, Life Casting Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. This is the most common method used to form a single continuous silicone prototype using. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. Cold runner, fully automated work. Applications include drug delivery, such as primary drug packaging or.. Liquid Silicone Molding Medical.

From www.jglsilicone.com

China Liquid Silicone Molding For Medical Manufacturers, Suppliers Liquid Silicone Molding Medical lsr injection molding is an ideal production method for a range of medical products. injection filled mold for liquid silicone: design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Cold runner, fully automated work. Applications include drug. Liquid Silicone Molding Medical.

From www.lsrliquidsiliconerubber.com

High Transparent Medical Grade Liquid Silicone Rubber Molding For Liquid Silicone Molding Medical lsr injection molding is an ideal production method for a range of medical products. Medical liquid silicone has excellent resistance to. Applications include drug delivery, such as primary drug packaging or. Cold runner, fully automated work. injection filled mold for liquid silicone: The main characteristics of lsr that benefit this type of. This is the most common method. Liquid Silicone Molding Medical.

From www.better-silicone.com

Liquid Silicone Injection Molding LSR Mold Silicone Injection Liquid Silicone Molding Medical The main characteristics of lsr that benefit this type of. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Cold runner, fully automated work. Medical liquid silicone has excellent resistance to. injection filled mold for liquid silicone: medical silicone can be either colourless or produced in. Liquid Silicone Molding Medical.

From bettersilicone.en.made-in-china.com

Customized Medical Grade Liquid Silicone Molding for LSR Manufacturing Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Applications include drug delivery, such as primary drug packaging or. Cold runner, fully automated work. lsr injection molding is an ideal production method for a range of medical products. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and.. Liquid Silicone Molding Medical.

From www.lsrinjectionmoldingmachine.com

Silicone Medical Device Liquid Silicone Injection Molding Making Machine Liquid Silicone Molding Medical This is the most common method used to form a single continuous silicone prototype using. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Cold runner, fully automated work. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. Medical liquid silicone has. Liquid Silicone Molding Medical.

From www.stockwell.com

Liquid Silicone Injection Molding, Custom Liquid Silicone Rubber Liquid Silicone Molding Medical Cold runner, fully automated work. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. The main characteristics of lsr that benefit this type of. Applications include drug delivery, such as primary drug packaging or. learn about liquid silicone. Liquid Silicone Molding Medical.

From www.lsr-molding.com

Liquid Silicone Overmolding LSR Injection Overmolding Design Guide Liquid Silicone Molding Medical This is the most common method used to form a single continuous silicone prototype using. The main characteristics of lsr that benefit this type of. Cold runner, fully automated work. injection filled mold for liquid silicone: liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. Medical liquid silicone has excellent resistance to. . Liquid Silicone Molding Medical.

From www.better-silicone.com

Liquid Silicone Injection Molding for Medical Products from China Liquid Silicone Molding Medical Applications include drug delivery, such as primary drug packaging or. design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. injection filled mold for liquid silicone: liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. medical silicone can be either colourless or produced in a wide range. Liquid Silicone Molding Medical.

From dahuamachine.en.made-in-china.com

Liquid Silicone Rubber Injection Molding Machine for Medical Parts Liquid Silicone Molding Medical injection filled mold for liquid silicone: Cold runner, fully automated work. lsr injection molding is an ideal production method for a range of medical products. liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively. Liquid Silicone Molding Medical.

From www.lsr-molding.com

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding Liquid Silicone Molding Medical liquid silicone rubber is ideal for medical injection molded components, such as tubing connectors. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. This is the most common method used to form a single continuous silicone prototype using. The main characteristics of lsr that benefit this type. Liquid Silicone Molding Medical.

From www.lsrinjectionmoldingmachine.com

Liquid Silicone Rubber LSR Injection Molding Machine For Silicone Liquid Silicone Molding Medical design engineering, development and contract manufacture of medical molded and extruded thermoplastic, elastomer, and. learn about liquid silicone rubber injection molding and how it can produce intricate elastomeric components with relatively short cycle times. medical silicone can be either colourless or produced in a wide range of colours. This is the most common method used to form. Liquid Silicone Molding Medical.