Intake Valve Angle . a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. when cutting a valve job, you have to look at both the intake and exhaust side of things. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow.

from garage.grumpysperformance.com

As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. when cutting a valve job, you have to look at both the intake and exhaust side of things. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the.

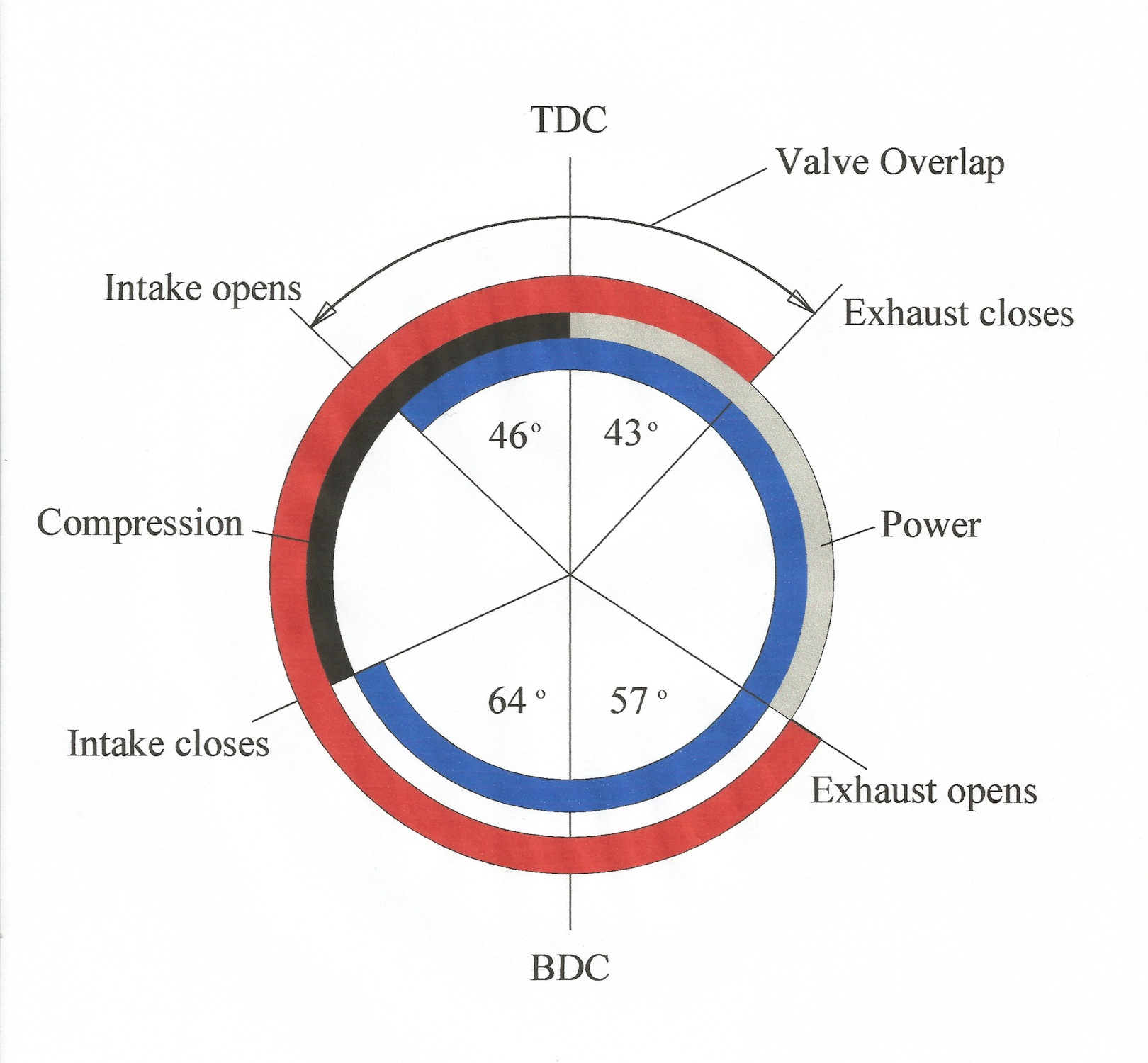

calculating overlap and lsa, or lca etc. Grumpys Performance Garage

Intake Valve Angle a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. when cutting a valve job, you have to look at both the intake and exhaust side of things. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job.

From www.youtube.com

DIY 3 Angle Valve Job. No Machinery Needed! YouTube Intake Valve Angle Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. a single. Intake Valve Angle.

From www.motortrend.com

Secrets Of Camshaft Power Car Craft Magazine Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a stock valve seat with only a single 45 degree angle cut on it. Intake Valve Angle.

From www.motortrend.com

Intake Valve Closing Point Critical for Maximizing Performance Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench. Intake Valve Angle.

From schematiclibandrea.z19.web.core.windows.net

Engine Diagram Intake Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. a stock valve seat with only a single 45 degree. Intake Valve Angle.

From garage.grumpysperformance.com

calculating overlap and lsa, or lca etc. Grumpys Performance Garage Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. Just as you shouldn’t get. Intake Valve Angle.

From www.akronbrass.com

Revolution Intake Valve (straight Inlet) Akron Brass Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow. Intake Valve Angle.

From www.cpperformance.com

Stainless Steel Intake Valves CP Performance Intake Valve Angle Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. intake valves. Intake Valve Angle.

From www.hotrod.com

Everything You Need to Know About Ford’s 351 Cleveland Powerhouse Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. intake valves should have a margin of. Intake Valve Angle.

From dxobjcrwu.blob.core.windows.net

Engine Block Intake Valves at Carol Bell blog Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. when cutting a valve job, you have to look at both the intake and exhaust side of things. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench. Intake Valve Angle.

From dxocjdxut.blob.core.windows.net

Do Diesel Engines Have Intake Valves at Carl Vaughn blog Intake Valve Angle As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. Just as you shouldn’t get too hung up on cfm numbers, the. Intake Valve Angle.

From www.classic-motorcycle-build.com

What Is A ThreeAngle Valve Job Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. when cutting a valve job, you have to look at both the intake. Intake Valve Angle.

From www.supertechperformance.com

Supertech Performance Intake Valves HighQuality Intake Valves for Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. when cutting a valve job,. Intake Valve Angle.

From www.cbperformance.com

1588 Precision Machined Intake Valve (35.5mm) thru 1974 15001600, 53 Intake Valve Angle a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. when cutting a valve job, you have to look at both the intake and exhaust side of things. As the valve starts to open and air. Intake Valve Angle.

From f1framework.blogspot.com

F1 Framework A closer look at F1 Cylinder Head Design and Pneumatics Intake Valve Angle As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a stock valve seat with only a single. Intake Valve Angle.

From www.mdpi.com

Processes Free FullText Intake Valve Profile Optimization for a Intake Valve Angle Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. intake valves should have a margin of about 0.050 inch, and the edge should. Intake Valve Angle.

From www.victor-aviation.com

Multiple Angle Valve and Seat Machining Aircraft Engine Overhaul Intake Valve Angle a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. intake valves. Intake Valve Angle.

From jeepvillage.com

INTAKE VALVES Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. when cutting a valve job, you have to look at both the intake and exhaust side of things. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create. Intake Valve Angle.

From us.sparex.com

Intake Valve Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. Just as you shouldn’t get. Intake Valve Angle.

From www.ingenieriaymecanicaautomotriz.com

VALVE TIMING DIAGRAM OF TWO STROKE AND FOUR STROKE ENGINES THEORETICAL Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. intake valves should have a. Intake Valve Angle.

From mooregoodink.com

How Kaase created a cylinder head for modern streetstrip use Moore Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. when cutting a valve job, you have to look at both. Intake Valve Angle.

From dxozainez.blob.core.windows.net

Sbc Cylinder Heads Shootout at Glenn McNair blog Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. when cutting a valve job, you have to look at both the intake and exhaust side of things. a stock valve seat with only a single 45 degree angle cut on it will have a sharp. Intake Valve Angle.

From www.enginelabs.com

Valve Seats Will 50 or 55degree Angles Work For Your Engine? Intake Valve Angle Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. a stock valve seat with only a single. Intake Valve Angle.

From racerwalsh.com

2.3 Intake Valve 1.83″ .100″ Long RWA 1495 Racer Walsh Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a single 45 degree angle cut on the valves and seats won’t provide the same airflow,. Intake Valve Angle.

From www.engineteam.com

Intake Valve VI0183 ET 04L109601H ET Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. when cutting a valve job, you have to look at. Intake Valve Angle.

From savree.com

Engine Valve Explained saVRee saVRee Intake Valve Angle Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. As the valve starts to open and air begins to flow past the valve, the. Intake Valve Angle.

From dxojcpxzi.blob.core.windows.net

Injection Valve Port at Ed Bridgeforth blog Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. when cutting a valve job, you have to look at both the intake and exhaust side of things. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response. Intake Valve Angle.

From www.youtube.com

Valve Measurement YouTube Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. As the valve starts to open and air. Intake Valve Angle.

From www.aircraftsystemstech.com

Aircraft Reciprocating Engine Valves Types and Construction Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about. Intake Valve Angle.

From www.ingenieriaymecanicaautomotriz.com

VALVE TIMING DIAGRAM OF TWO STROKE AND FOUR STROKE ENGINES THEORETICAL Intake Valve Angle As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a single 45 degree angle cut on the. Intake Valve Angle.

From www.slideserve.com

PPT Intake and Exhaust Valves PowerPoint Presentation, free download Intake Valve Angle intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp edge just above and below the area where the valve sits on the seat. a single 45 degree. Intake Valve Angle.

From www.carid.com

IM4472 Intake Valve Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree angle cut on it will have a sharp. Intake Valve Angle.

From firesafetyusa.com

Intake Valves Intake Valve Angle a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. As the valve starts to open and air begins to flow past the valve, the. Intake Valve Angle.

From www.bimmerfest.com

2d3e throttle valve intakemanifold vacuum correlation BimmerFest BMW Intake Valve Angle when cutting a valve job, you have to look at both the intake and exhaust side of things. a single 45 degree angle cut on the valves and seats won’t provide the same airflow, throttle response and power. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench. Intake Valve Angle.

From www.researchgate.net

Schematics of a shrouded intake valve b modified shrouded intake valve Intake Valve Angle As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. Just as you shouldn’t get too hung up on cfm numbers, the same can be said about the flow bench for the valve job. a single 45 degree angle cut on the. Intake Valve Angle.

From kimray.com

The Most Common Control Valve Symbols on a P&ID Kimray Intake Valve Angle As the valve starts to open and air begins to flow past the valve, the abrupt change in angles create turbulence that reduces air velocity and flow. intake valves should have a margin of about 0.050 inch, and the edge should be sharp where it transitions to the. a stock valve seat with only a single 45 degree. Intake Valve Angle.